Attachment 1 Statement of Work dated December 2012

Attachment 1 Statement of Work dated December 2012

Attachment 1 Statement of Work dated December 2012

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

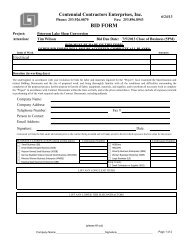

STATEMENT OF WORKFORRepair Aircraft Maintenance Hangar,Aircraft Grounding Points Building 2050FAIRCHILD AIR FORCE BASE, WASHINGTONProject No. GJKZ 09-0063Date: <strong>December</strong> <strong>2012</strong>TORFP GJKZ 09-0063ATTACHMENT 11.0 PROPOSALDuring the pre-proposal site visit MATOC contractors shall visit the site and become familiarwith the project requirements. Questions will be submitted to the Contracting Officer in writing.Answers will be provided within a reasonable time period after evaluation by the Government.This is a “Construction only” MATOC task order in compliance with the MATOC Base ContractSpecifications.2.0 Description <strong>of</strong> work2.01: This <strong>Statement</strong> <strong>of</strong> <strong>Work</strong> (SOW) defines the project scope <strong>of</strong> work to GJKZ 09-00063,Repair Aircraft Maintenance Hangar, Aircraft Grounding Points Building 2050. Drawings havebeen provided to show the nature and locations <strong>of</strong> the work scope items (see Appendices). TheMATOC Contractor shall provide as-built drawings, submittals, shop drawings, and projectschedules as outlined in the MATOC Specification, General Contract Provisions. Place <strong>of</strong>performance is at Fairchild Air Force Base (FAFB), Washington (WA). The following is adescription <strong>of</strong> the project work involved.2.02: The project shall provide four each aircraft static grounds in each <strong>of</strong> the four hangar bays<strong>of</strong> building 2050.2.03: SPECIAL WORK CONDITIONSThe project site is within a restricted area. Flight-line escorts are required. When the contractorrequires access to flight-line restricted areas the 92 Civil Engineer Squadron will provide aGovernment escort for the entire period the contractor personnel are present on the flight-line.Additional restrictions are applicable when aircraft are in the hangar. The contractor employeesshall not enter the restricted area inside the hangar during times that area is occupied by aircraft.Site access shall also require vehicle access on the flight-line. All contractor employeesoperating a contractor vehicle on the flight-line shall have a valid flight-line license with theproper endorsement indicating that the employee has completed the training for operation <strong>of</strong> avehicle on the flight-line. The contractor employee(s) shall attend a FAFB flight-line drivingcourse to receiving the flight-line license and endorsements.Page 1 <strong>of</strong> 5

TORFP GJKZ 09-0063ATTACHMENT 12.04: Submittals: Submittals shall include but not be limited to grounding rods, bonding wire,joint fill, concrete repair, epoxy system repair, paint, shop drawings and work schedule.2.05: WORK SCHEDULE: Normal contract work hours pertain to this project. Weekendwork shall not be allowed. Due to the impact <strong>of</strong> the work on the facility and the high demand forthe use <strong>of</strong> the facility during winter months, the following provisions apply to when the work canbe conducted:2.05.1 Only one hangar in Building 2050 shall be available at a time for contractor work.<strong>Work</strong> shall not take longer than 2 weeks for any particular hangar bay to allow forrequired aircraft maintenance.2.05.2 Physical work requiring the user to vacate aircraft from the hangar shall not bescheduled at a time any <strong>of</strong> the other hangers are unavailable for aircraft maintenance.2.05.3 The contractor shall coordinate the physical work period(s) with the ContractingOfficer’s representative at least two weeks in advance to request the closing <strong>of</strong> a hangarbay.3.0 SPECIFICS OF WORK3.1 Demolition3.1.1: Dispose <strong>of</strong> demolition debris IAW with FAFB BDS requirements.3.2 Construction3.2.1 General: In the concrete floor <strong>of</strong> each <strong>of</strong> the four hangars is a construction joint.The joint extends along the centerline <strong>of</strong> each hangar. The contractor shall install fourstatic grounds at the locations indicated on the Appendix drawings. The locations are in aline following along the construction joint. The Contractor shall open the constructionjoint as needed to install the static grounds. All static grounds shall be bonded to eachother and to the steel columns <strong>of</strong> the building. Provide in accordance with UFC 3-260-01and UFC 3-757-01.3.2.2. Static ground rod: Provide in accordance with UFC 3-260-01 Section B11-5 AirForce Tiedowns and Static Grounds. See appendix for example <strong>of</strong> ground rod.3.2.2. Electrical bonding conductors: Provide #4 AWG solid copper bonding wire. Runthe bonding wire in the hangar centerline construction joint. Open the joint as needed toinstall the conductor. Install the bonding cable at least two inches below finished floor.Connect the bonding conductor to each static ground rod and to the building columnusing an exothermal process similar and equal to Cadweld.Page 2 <strong>of</strong> 5

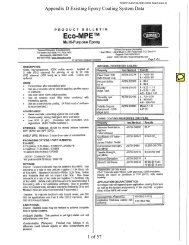

4.0 General NotesTORFP GJKZ 09-0063ATTACHMENT 1a. methods to be used to install the ground rodsb. methods used to repair the epoxy floor coatingc. methods used to extend the bonding conductor from the floor joint to the buildingsteel.d. method used to extend the bonding conductor from the building steel to thehangar bay service panel.4.1 All materials shall be non-toxic, certified free <strong>of</strong> lead and asbestos.4.2 All work sites shall be rendered safe to maximum extent possible.4.3 No hazardous materials shall be stored on site.4.4 Daily cleanup and removal <strong>of</strong> all demolished materials shall be done by end <strong>of</strong> each day.4.5 Scheduling <strong>of</strong> any utility outage <strong>of</strong> one hour or less shall be coordinated at a minimum<strong>of</strong> seven days in advance. Outages longer than one hour shall be required to have 14 daysnotice.4.6 All electrical work shall comply with the latest edition <strong>of</strong> NFPA 70: National ElectricalCode, as well as the workmanship standards outlined in ANSI/NECA 1-2000: StandardPractices for Good <strong>Work</strong>manship in Electrical Contracting.4.7 The contractor shall ensure that all demolition waste materials (concrete waste, primer,epoxy coating) are disposed in accordance with all federal, state, and local environmentalrequirements. At no time shall these materials be allowed into the sanitary or storm watersystems. MSDS's shall be required to determine hazardous characteristics <strong>of</strong> the floorcoatings. The MSDS and Contractor HAZMAT Authorization forms shall be submitted perthe basic MATOC contract.5.0 LOCATION AND CONCEPT DRAWINGS:Drawings are included with the SOW appendices. It is the contractor’s responsibility toverify existing conditions and provide work that complies with all State and Federal codesand regulations.6.0 Specifications6.1 MATOC Specification, General Contract Provisions, <strong>Attachment</strong> 7 applies to thisProject.6.2 Upon award, submittal register and submittals applicable to this Task order arerequired.Page 4 <strong>of</strong> 5

TORFP GJKZ 09-0063ATTACHMENT 1Appendices:A. As Built Epoxy Floor Drawings Showing Dimensions PDF.B. As Built Epoxy Floor Drawings Showing Dimensions ACADC. FY 2011 Previous Project Joint Sealant Asbestos SurveyD. Epoxy Coating System Used on Hangar FloorE. Aircraft Static Ground Rod To Be Used Inside HangarsF. Ground Point LocationsPage 5 <strong>of</strong> 5