SOW Attachment D Epoxy Coating System Used on Hangar Floor

SOW Attachment D Epoxy Coating System Used on Hangar Floor

SOW Attachment D Epoxy Coating System Used on Hangar Floor

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

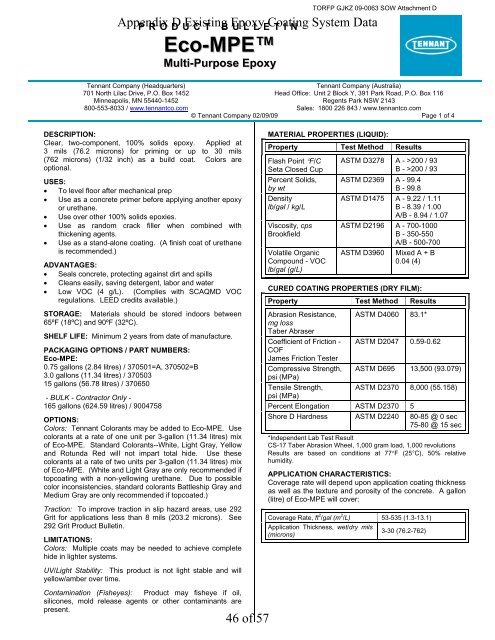

PRODUCT BULLETINEco-MPEMulti-Purpose <str<strong>on</strong>g>Epoxy</str<strong>on</strong>g>TORFP GJKZ 09-0063 <str<strong>on</strong>g>SOW</str<strong>on</strong>g> <str<strong>on</strong>g>Attachment</str<strong>on</strong>g> DAppendix D Existing <str<strong>on</strong>g>Epoxy</str<strong>on</strong>g> <str<strong>on</strong>g>Coating</str<strong>on</strong>g> <str<strong>on</strong>g>System</str<strong>on</strong>g> DataTennant Company (Headquarters)Tennant Company (Australia)701 North Lilac Drive, P.O. Box 1452Head Office: Unit 2 Block Y, 391 Park Road, P.O. Box 116Minneapolis, MN 55440-1452Regents Park NSW 2143800-553-8033 / www.tennantco.comSales: 1800 226 843 / www.tennantco.com© Tennant Company 02/09/09 Page 1 of 4DESCRIPTION:Clear, two-comp<strong>on</strong>ent, 100% solids epoxy. Applied at3 mils (76.2 micr<strong>on</strong>s) for priming or up to 30 mils(762 micr<strong>on</strong>s) (1/32 inch) as a build coat. Colors areopti<strong>on</strong>al.USES:• To level floor after mechanical prep• Use as a c<strong>on</strong>crete primer before applying another epoxyor urethane.• Use over other 100% solids epoxies.• Use as random crack filler when combined withthickening agents.• Use as a stand-al<strong>on</strong>e coating. (A finish coat of urethaneis recommended.)ADVANTAGES:• Seals c<strong>on</strong>crete, protecting against dirt and spills• Cleans easily, saving detergent, labor and water• Low VOC (4 g/L). (Complies with SCAQMD VOCregulati<strong>on</strong>s. LEED credits available.)STORAGE: Materials should be stored indoors between65ºF (18ºC) and 90ºF (32ºC).SHELF LIFE: Minimum 2 years from date of manufacture.PACKAGING OPTIONS / PART NUMBERS:Eco-MPE:0.75 gall<strong>on</strong>s (2.84 litres) / 370501=A, 370502=B3.0 gall<strong>on</strong>s (11.34 litres) / 37050315 gall<strong>on</strong>s (56.78 litres) / 370650- BULK - C<strong>on</strong>tractor Only -165 gall<strong>on</strong>s (624.59 litres) / 9004758OPTIONS:Colors: Tennant Colorants may be added to Eco-MPE. Usecolorants at a rate of <strong>on</strong>e unit per 3-gall<strong>on</strong> (11.34 litres) mixof Eco-MPE. Standard Colorants--White, Light Gray, Yellowand Rotunda Red will not impart total hide. Use thesecolorants at a rate of two units per 3-gall<strong>on</strong> (11.34 litres) mixof Eco-MPE. (White and Light Gray are <strong>on</strong>ly recommended iftopcoating with a n<strong>on</strong>-yellowing urethane. Due to possiblecolor inc<strong>on</strong>sistencies, standard colorants Battleship Gray andMedium Gray are <strong>on</strong>ly recommended if topcoated.)Tracti<strong>on</strong>: To improve tracti<strong>on</strong> in slip hazard areas, use 292Grit for applicati<strong>on</strong>s less than 8 mils (203.2 micr<strong>on</strong>s). See292 Grit Product Bulletin.LIMITATIONS:Colors: Multiple coats may be needed to achieve completehide in lighter systems.UV/Light Stability: This product is not light stable and willyellow/amber over time.C<strong>on</strong>taminati<strong>on</strong> (Fisheyes): Product may fisheye if oil,silic<strong>on</strong>es, mold release agents or other c<strong>on</strong>taminants arepresent.46 of 57MATERIAL PROPERTIES (LIQUID):Property Test Method ResultsFlash Point °F/CSeta Closed CupPercent Solids,by wtDensitylb/gal / kg/LViscosity, cpsBrookfieldVolatile OrganicCompound - VOClb/gal (g/L)ASTM D3278 A - >200 / 93B - >200 / 93ASTM D2369 A - 99.4B - 99.8ASTM D1475 A - 9.22 / 1.11B - 8.39 / 1.00A/B - 8.94 / 1.07ASTM D2196 A - 700-1000B - 350-550A/B - 500-700ASTM D3960 Mixed A + B0.04 (4)CURED COATING PROPERTIES (DRY FILM):Property Test Method ResultsAbrasi<strong>on</strong> Resistance, ASTM D4060 83.1*mg lossTaber AbraserCoefficient of Fricti<strong>on</strong> - ASTM D2047 0.59-0.62COFJames Fricti<strong>on</strong> TesterCompressive Strength, ASTM D695 13,500 (93.079)psi (MPa)Tensile Strength, ASTM D2370 8,000 (55.158)psi (MPa)Percent El<strong>on</strong>gati<strong>on</strong> ASTM D2370 5Shore D Hardness ASTM D2240 80-85 @ 0 sec75-80 @ 15 sec*Independent Lab Test ResultCS-17 Taber Abrasi<strong>on</strong> Wheel, 1,000 gram load, 1,000 revoluti<strong>on</strong>sResults are based <strong>on</strong> c<strong>on</strong>diti<strong>on</strong>s at 77°F (25°C), 50% relativehumidity.APPLICATION CHARACTERISTICS:Coverage rate will depend up<strong>on</strong> applicati<strong>on</strong> coating thicknessas well as the texture and porosity of the c<strong>on</strong>crete. A gall<strong>on</strong>(litre) of Eco-MPE will cover:Coverage Rate, ft 2 /gal (m 2 /L) 53-535 (1.3-13.1)Applicati<strong>on</strong> Thickness, wet/dry mils(micr<strong>on</strong>s)3-30 (76.2-762)