SOW Attachment D Epoxy Coating System Used on Hangar Floor

SOW Attachment D Epoxy Coating System Used on Hangar Floor

SOW Attachment D Epoxy Coating System Used on Hangar Floor

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

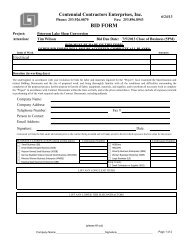

Light Blast: Use magnetic broom to remove excess shot,sweep to remove large debris and vacuum to remove finedust.THICK FILM APPLICATIONS 11-30 mils / 279.4-762micr<strong>on</strong>s):Steel Shot Blast, use magnetic broom to remove excessshot, sweep to remove large debris and vacuum to removefine dust.Scarify, sweep to remove large debris and vacuum to removefine dust.JOINTS: Depending <strong>on</strong> the preference of the facility owner,joints may or may not be filled. If the joints are filled, n<strong>on</strong>movingjoints, i.e. c<strong>on</strong>tracti<strong>on</strong> or c<strong>on</strong>trol joints, can be hardfilled with thickened, 100% solids epoxy or with a semi-rigidjoint filler such as Eco-PJS or Eco-EJF. C<strong>on</strong>structi<strong>on</strong>joints less than <strong>on</strong>e inch wide may also be filled withEco-PJS. Isolati<strong>on</strong> or expansi<strong>on</strong> joints must be filled with aflexible material designed for this purpose. <str<strong>on</strong>g>Coating</str<strong>on</strong>g> appliedover filled joints will crack if there is c<strong>on</strong>crete movement.APPLICATION - PRIMER COATA thin coat of primer will wet out c<strong>on</strong>crete, help seal offc<strong>on</strong>crete pores and minimize outgassing bubbles. Apply atight coat of primer with a clean, flexible squeegee.Backrolling is not recommended. There should be no milbuild over the high spots of the c<strong>on</strong>crete.COVERAGE RATE will depend up<strong>on</strong> coating thickness.Much of this will soak into porous c<strong>on</strong>crete. A gall<strong>on</strong> ofEco-RCE/M will cover:535 ft 2 (13.1 m 2 ) @ 3 mils (76.2 micr<strong>on</strong>s) wet/dry film400 ft 2 (9.8 m 2 ) @ 4 mils (101.6 micr<strong>on</strong>s) wet/dry film321 ft 2 (7.9 m 2 ) @ 5 mils (127 micr<strong>on</strong>s) wet/dry filmPREMIX PART A using a Jiffy® mixer blade and slow speeddrill. For full-fill 5’s (18.9 litres), pour out 2 gal (7.56 litres)into a measuring c<strong>on</strong>tainer. Then, pour the measured Part Ainto a mixing pail.COLORS: Premix Tennant 100 Series Colorants to ensureuniform color. Colorant is added to the Part A and mixedusing a Jiffy® mixer blade and slow speed drill. NOTE:When using colorant in the bulk units, add the colorant to thePart A that has been measured into the "mixing pail".ADD ECO-MPE PART B TO ECO-RCE PART A(3 GALLONS / 11.34 LITRES MAX). For full-fill 5’s(18.9 litres), pour out 1 gal (3.78 litres) Part B into ameasuring c<strong>on</strong>tainer that is separate from the <strong>on</strong>e used withthe Part A. Then, add the measured Part B to the Part Aalready in the mixing pail. POTLIFE: Mix <strong>on</strong>ly enoughmaterial which can be applied within the work time (timebetween the additi<strong>on</strong> of Part B to Part A and the completi<strong>on</strong>of all applicati<strong>on</strong> acti<strong>on</strong>s). Check the following chart for worktimes at various temperatures. For smaller quantities, use 2parts PART A to 1 part PART B by volume.APPROXIMATE WORK TIME (minutes)°F / 65 / 70 / 75 / 80 / 90 /(°C 18.3 21.1 23.9 26.7 32.2)Eco-RCE/M 35 25 20 15 NRMIX FOR 2 MINUTES using a Jiffy® mixer blade and slowspeed drill. (Failure to do so could result in lower/diminishedcoating properties.)IMMEDIATELY POUR ALL OF THE MIXED MATERIAL<strong>on</strong>to the floor in a single bead.TORFP GJKZ 09-0063 <str<strong>on</strong>g>SOW</str<strong>on</strong>g> <str<strong>on</strong>g>Attachment</str<strong>on</strong>g> DAppendix D Existing <str<strong>on</strong>g>Epoxy</str<strong>on</strong>g> <str<strong>on</strong>g>Coating</str<strong>on</strong>g> <str<strong>on</strong>g>System</str<strong>on</strong>g> DataPUSH THE FLAT SQUEEGEE at an even speed withsufficient down pressure to apply the thinnest coat.START THE SECOND AND REMAINING PASSES bypushing material parallel to the first stroke. Hold the bead ofmaterial near the center of the bar. NOTE: <str<strong>on</strong>g>Epoxy</str<strong>on</strong>g> appliedthin may "bridge" holes and cracks momentarily beforesoaking in--make sure the previously squeegeed area isoverlapped (halfway). NOTE: The use of spiked shoes willallow freedom of movement <strong>on</strong> the wet floor.TO REDUCE OUTGASSING BUBBLES, it is best to waituntil the primer has set up enough to walk <strong>on</strong> before applyinga build coat of Eco-RCE/M. The primer does not need to besanded if coated within 24 hours.If primer is not coated within 24 hours, it must be sanded with60 grit paper. We recommend thorough sanding with aswing-type buffer so that multiple scratch marks cause anobvious gloss loss <strong>on</strong> all areas (depressi<strong>on</strong>s will remainshiny), and the floor is uniformly dulled. The ability to seeindividual scratch marks is an indicati<strong>on</strong> that sanding is notadequate. Scrub with detergent and rinse with clean waterbefore coating.APPLICATION - BUILD COAT - (IF REQUIRED)COVERAGE RATE will depend up<strong>on</strong> required thickness. Agall<strong>on</strong> (litre) of Eco-RCE/M will cover:160 ft 2 (3.9 m 2 ) @ 10 mils (254 micr<strong>on</strong>s) wet/dry film107 ft 2 (2.6 m 2 ) @ 15 mils (381 micr<strong>on</strong>s) wet/dry film80 ft 2 (1.9 m 2 ) @ 20 mils (508 micr<strong>on</strong>s) wet/dry filmNOTE: Total Eco-RCE/M (prime and build coat) should notexceed 35 mils (889 micr<strong>on</strong>s).REPEAT STEPS used for mixing and spreading of the primercoat. A notched squeegee can be used to increase thethickness applied.*1/16" (1.59 mm) notched squeegee to apply 10-15 mils(254-381 micr<strong>on</strong>s)*1/8" (3.18 mm) notched squeegee to apply 15-20 mils(254-508 micr<strong>on</strong>s)*1/4" (6.35 mm) notched squeegee to apply more than20 mils (508 micr<strong>on</strong>s)*These guidelines were arrived at by using new squeegees<strong>on</strong> smooth c<strong>on</strong>crete with little applied pressure. Theapplicati<strong>on</strong> rate is affected by worn squeegees, appliedpressure and texture of the c<strong>on</strong>crete.Immediately after the Eco-RCE/M is applied and there isroom to roll, a sec<strong>on</strong>d pers<strong>on</strong> will BACKROLL THEMATERIAL with a 3/8” (10 mm) roller to a smooth anduniform appearance. NOTE: Get off the Eco-RCE/M asso<strong>on</strong> as possible.ALLOW COATING TO CURE 24 hours at 75°F (24°C)before opening to light traffic. Allow more time at lowtemperatures or for heavier traffic. Full coating propertiestake 14 days to develop.APPLICATION OF ADDITIONAL COATINGSIf Eco-RCE/M is being topcoated with a Tennant urethaneexcept Eco-HPS and Eco-HPS 100 at floor temperaturesof 65-90°F (18-32°C), it does not need to be sanded ifapplied within 24 hours. NOTE: This is a Tennant soluti<strong>on</strong><strong>on</strong>ly, DO NOT try this with competitive epoxies.Eco-RCE/M © Tennant Company 02/09/09 Page 3 of 456 of 57