SOW Attachment D Epoxy Coating System Used on Hangar Floor

SOW Attachment D Epoxy Coating System Used on Hangar Floor

SOW Attachment D Epoxy Coating System Used on Hangar Floor

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

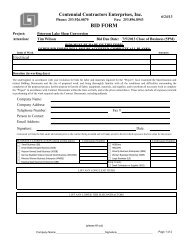

TORFP GJKZ 09-0063 <str<strong>on</strong>g>SOW</str<strong>on</strong>g> <str<strong>on</strong>g>Attachment</str<strong>on</strong>g> DAppendix D Existing <str<strong>on</strong>g>Epoxy</str<strong>on</strong>g> <str<strong>on</strong>g>Coating</str<strong>on</strong>g> <str<strong>on</strong>g>System</str<strong>on</strong>g> DataWear Life of <str<strong>on</strong>g>Coating</str<strong>on</strong>g> ProductsCURING MEMBRANESFLOOR PAINTSEPOXIESOIL-MODIFIED URETHANESMOISTURE-CURED URETHANESECO-HTS 100ABRASION RESISTANCEBased <strong>on</strong> relative mil loss, Eco-HTS 100 has a l<strong>on</strong>ger wear life.Eco-HTS 100 SnapshotAPPEARANCE:Satin finish with slight textureCOLOR:Clear, plus standard and custom colorsTRACTION:Increase slip resistance with Tennant’s grit additivesVOC COMPLIANCE: Very low VOC, 86 g/LABRASION RESISTANCE: SuperiorCHEMICAL RESISTANCE: SuperiorUV STABILITY: 100% aliphatic formula; n<strong>on</strong>-yellowing*APPLICATIONS: Aisles, loading docks, repair shops, hangars andother high-traffic areasINSTALLATION: Customer or c<strong>on</strong>tractor applied*Over the normal life of the coating.100 g/L Colors – 100 g/L areas require 100 g/L colorants; please c<strong>on</strong>tact Tennant for current available selecti<strong>on</strong>. All n<strong>on</strong> 100 g/L areas see standard colorants.Standard Colors – These colors are close approximati<strong>on</strong>s; please c<strong>on</strong>tact Tennant for product samples. Custom colors are also available.WHITE BLACK LIGHT GRAY CANADAGRAYChemical Resistance Properties1 day 7 dayAcids, Inorganic 10% Hydrochloric Acid E E30% Hydrochloric Acid(Muriatic) E E10% Nitric Acid E E50% Phosphoric Acid E G37% Sulfuric Acid(Battery Acid) E EAcids, Organic 10% Acetic Acid E E10% Citric Acid E EOleic Acid E EAlkalies 10% Amm<strong>on</strong>ium Hydroxide E E50% Sodium Hydroxide E ESolvents (Alcohols) Ethylene Glycol (Antifreeze) E EIsopropyl Alcohol E EMethanol E ESolvents (Aliphatic) d-Lim<strong>on</strong>ene E EJet Fuel (JP-4) E EGasoline E EMineral Spirits E ESolvents (Aromatic) Xylene E ESolvents Methylene Chloride P P(Chlorinated)Solvents Methyl Ethyl Ket<strong>on</strong>e (MEK) E E(Ket<strong>on</strong>es & Esters) Propylene Glycol MethylEther Acetate (PMA) E EMiscellaneous 20% Amm<strong>on</strong>ium Nitrate E EChemicals Brake Fluid E EBleach E EMotor Oil (SAE30) E ESkydrol® 500B E ESkydrol® LD4 E E20% Sodium Chloride E E1% Tide® Laundry Soap E E10% Trisodium Phosphate E EBased <strong>on</strong> 1-day and 7-day spot testing <strong>on</strong> c<strong>on</strong>crete.<str<strong>on</strong>g>Coating</str<strong>on</strong>g> cured 2 weeks prior to testing.Skydrol® is a registered trademark of Solutia, Inc. Tide® is a registered trademark of Proctor and Gamble.E = Excellent (No Adverse Effect)G = Good (Limited Adverse Effect or Staining)F = Fair (Moderate Adverse Effect)P = Poor (Unsatisfactory)MEDIUM BATTLESHIP SANDY BEIGE YELLOWGRAYGRAYPhysical/Performance PropertiesMATERIAL PROPERTIES (LIQUID)Property Test Method ResultsFlash Point, °F (°C) ASTM D3278 Part A: >200 (93)Seta Closed Cup Part B: >200 (93)Percent Solids, by weight ASTM D2369 Part A: 99.35Part B: 59.23Part C: 100A+B+C = 94.00Density, lb/gal (kg/L) ASTM D1475 Part A: 9.56 (1.15)(A/B) Part B: 9.54 (1.15)Part C: 33.00 (3.96)A+B+C = 11.93 (1.43)Shelf Life2 years from date of manufactureViscosity, cps ASTM D2196 A+B+C = 700-800BrookfieldVolatile Organic Compound ASTM D3960 Mixed: A+B+C(VOC) lb/gal (g/L) 0.71 (86)CURED COATING PROPERTIES (DRY FILM)Property Test Method ResultsAbrasi<strong>on</strong> Resistance, mg loss ASTM D4060* 18.0Taber AbraserCoefficient of Fricti<strong>on</strong> (COF)** ASTM D2047 0.63James Fricti<strong>on</strong> TesterDry Film Thickness, mils3.0 (1 coat)Tensile Strength, psi (kPa) (resin <strong>on</strong>ly) ASTM C2370 6,250 (43,088)Percent El<strong>on</strong>gati<strong>on</strong> (resin <strong>on</strong>ly) ASTM D2370 6König Hardness (3 mil film) (resin <strong>on</strong>ly) 171.3APPLICATION CHARACTERISTICS (1 GALLON)PropertyResultsCoverage Rate, ft 2 /gal 500Applicati<strong>on</strong> Thickness, wet mils3.2 (1 coat)*CS-17 Taber Abrasi<strong>on</strong> Wheel, 1,000 gram load, 1,000 revoluti<strong>on</strong>s.**To improve tracti<strong>on</strong> in slip hazard areas, use Tennant 291 Grit.See 291 Grit Product Bulletin for more informati<strong>on</strong>.Results are based <strong>on</strong> c<strong>on</strong>diti<strong>on</strong>s at 77°F, 50% relative humidity.TILE RED ROTUNDA IVY GREEN SMOKE BLUE REGAL BLUEREDTennant701 North Lilac DriveMinneapolis, MN 55422 USAtel: +1-763-540-1315fax:+1-763-513-2144www.tennantco.comemail: info@tennantco.comA floor-care system of high-performing Tennant coatings, sweepers,and scrubbers will maximize your floor's natural life, minimize yourmaintenance costs and create a world-class impressi<strong>on</strong>.35 of 571250-74 Eco-HTS 100 9/08©2008 The Tennant Company logo and other marks designated with the symbol "♦" are registeredtrademarks of Tennant Company, Inc., in the United States and/or other countries. The marks designatedwith "TM" are trademarks of Tennant Company that are not yet registered in the United States.