SOW Attachment D Epoxy Coating System Used on Hangar Floor

SOW Attachment D Epoxy Coating System Used on Hangar Floor

SOW Attachment D Epoxy Coating System Used on Hangar Floor

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

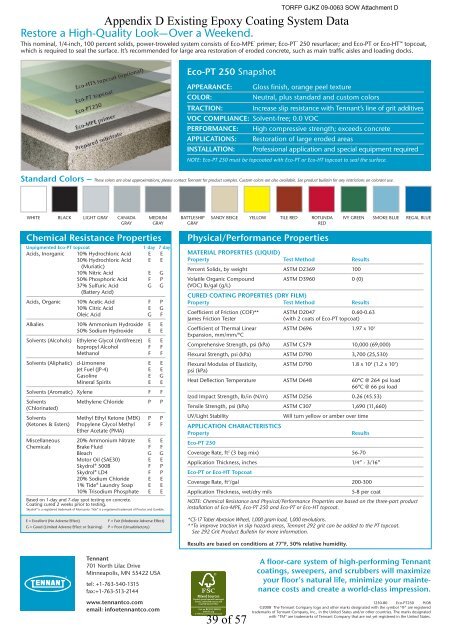

Eco-PT 250 SnapshotAPPEARANCE:COLOR:TRACTION:Gloss finish, orange peel textureNeutral, plus standard and custom colorsIncrease slip resistance with Tennant’s line of grit additivesVOC COMPLIANCE: Solvent-free; 0.0 VOCPERFORMANCE:APPLICATIONS:INSTALLATION:TORFP GJKZ 09-0063 <str<strong>on</strong>g>SOW</str<strong>on</strong>g> <str<strong>on</strong>g>Attachment</str<strong>on</strong>g> DAppendix D Existing <str<strong>on</strong>g>Epoxy</str<strong>on</strong>g> <str<strong>on</strong>g>Coating</str<strong>on</strong>g> <str<strong>on</strong>g>System</str<strong>on</strong>g> DataRestore a High-Quality Look—Over a Weekend.This nominal, 1/4-inch, 100 percent solids, power-troweled system c<strong>on</strong>sists of Eco-MPE primer; Eco-PT 250 resurfacer; and Eco-PT or Eco-HT topcoat,which is required to seal the surface. It’s recommended for large area restorati<strong>on</strong> of eroded c<strong>on</strong>crete, such as main traffic aisles and loading docks.High compressive strength; exceeds c<strong>on</strong>creteRestorati<strong>on</strong> of large eroded areasProfessi<strong>on</strong>al applicati<strong>on</strong> and special equipment requiredNOTE: Eco-PT 250 must be topcoated with Eco-PT or Eco-HT topcoat to seal the surface.Standard Colors – These colors are close approximati<strong>on</strong>s; please c<strong>on</strong>tact Tennant for product samples. Custom colors are also available. See product bulletin for any restricti<strong>on</strong>s <strong>on</strong> colorant use.WHITE BLACK LIGHT GRAY CANADAGRAYMEDIUM BATTLESHIP SANDY BEIGE YELLOWGRAYGRAYTILE RED ROTUNDA IVY GREEN SMOKE BLUE REGAL BLUEREDChemical Resistance PropertiesUnpigmented Eco-PT topcoat1 day 7 dayAcids, Inorganic 10% Hydrochloric Acid E E30% Hydrochloric Acid E E(Muriatic)10% Nitric Acid E G50% Phosphoric Acid F P37% Sulfuric Acid G G(Battery Acid)Acids, Organic 10% Acetic Acid F P10% Citric Acid E GOleic Acid G FAlkalies 10% Amm<strong>on</strong>ium Hydroxide E E50% Sodium Hydroxide E ESolvents (Alcohols) Ethylene Glycol (Antifreeze) E EIsopropyl Alcohol F FMethanol F FSolvents (Aliphatic) d-Lim<strong>on</strong>ene E EJet Fuel (JP-4) E EGasoline E GMineral Spirits E ESolvents (Aromatic) Xylene F FSolvents Methylene Chloride P P(Chlorinated)Solvents Methyl Ethyl Ket<strong>on</strong>e (MEK) P P(Ket<strong>on</strong>es & Esters) Propylene Glycol Methyl F FEther Acetate (PMA)Miscellaneous 20% Amm<strong>on</strong>ium Nitrate E EChemicals Brake Fluid F FBleach G GMotor Oil (SAE30) E ESkydrol® 500B F PSkydrol® LD4 F P20% Sodium Chloride E E1% Tide® Laundry Soap E E10% Trisodium Phosphate E EBased <strong>on</strong> 1-day and 7-day spot testing <strong>on</strong> c<strong>on</strong>crete.<str<strong>on</strong>g>Coating</str<strong>on</strong>g> cured 2 weeks prior to testing.Skydrol® is a registered trademark of M<strong>on</strong>santo. Tide® is a registered trademark of Proctor and Gamble.Physical/Performance PropertiesMATERIAL PROPERTIES (LIQUID)Property Test Method ResultsPercent Solids, by weight ASTM D2369 100Volatile Organic Compound ASTM D3960 0 (0)(VOC) lb/gal (g/L)CURED COATING PROPERTIES (DRY FILM)Property Test Method ResultsCoefficient of Fricti<strong>on</strong> (COF)** ASTM D2047 0.60-0.63James Fricti<strong>on</strong> Tester(with 2 coats of Eco-PT topcoat)Coefficient of Thermal Linear ASTM D696 1.97 x 10 5Expansi<strong>on</strong>, mm/mm/ºCComprehensive Strength, psi (kPa) ASTM C579 10,000 (69,000)Flexural Strength, psi (kPa) ASTM D790 3,700 (25,530)Flexural Modulas of Elasticity, ASTM D790 1.8 x 10 6 (1.2 x 10 7 )psi (kPa)Heat Deflecti<strong>on</strong> Temperature ASTM D648 60ºC @ 264 psi load66ºC @ 66 psi loadIzod Impact Strength, lb/in (N/m) ASTM D256 0.26 (45.53)Tensile Strength, psi (kPa) ASTM C307 1,690 (11,660)UV/Light StabilityAPPLICATION CHARACTERISTICSPropertyEco-PT 250Will turn yellow or amber over timeResultsCoverage Rate, ft 2 (3 bag mix) 56-70Applicati<strong>on</strong> Thickness, inches 1/4” - 3/16”Eco-PT or Eco-HT TopcoatCoverage Rate, ft 2 /gal 200-300Applicati<strong>on</strong> Thickness, wet/dry mils5-8 per coatNOTE: Chemical Resistance and Physical/Performance Properties are based <strong>on</strong> the three-part productinstallati<strong>on</strong> of Eco-MPE, Eco-PT 250 and Eco-PT or Eco-HT topcoat.E = Excellent (No Adverse Effect)G = Good (Limited Adverse Effect or Staining)F = Fair (Moderate Adverse Effect)P = Poor (Unsatisfactory)*CS-17 Taber Abrasi<strong>on</strong> Wheel, 1,000 gram load, 1,000 revoluti<strong>on</strong>s.**To improve tracti<strong>on</strong> in slip hazard areas, Tennant 292 grit can be added to the PT topcoat.See 292 Grit Product Bulletin for more informati<strong>on</strong>.Results are based <strong>on</strong> c<strong>on</strong>diti<strong>on</strong>s at 77°F, 50% relative humidity.Tennant701 North Lilac DriveMinneapolis, MN 55422 USAtel: +1-763-540-1315fax:+1-763-513-2144www.tennantco.comemail: info@tennantco.comBV-COC-94065539 of 57A floor-care system of high-performing Tennantcoatings, sweepers, and scrubbers will maximizeyour floor's natural life, minimize your maintenancecosts and create a world-class impressi<strong>on</strong>.1250-80 Eco-PT250 9/08©2008 The Tennant Company logo and other marks designated with the symbol "®" are registeredtrademarks of Tennant Company, Inc., in the United States and/or other countries. The marks designatedwith "TM" are trademarks of Tennant Company that are not yet registered in the United States.