SOW Attachment D Epoxy Coating System Used on Hangar Floor

SOW Attachment D Epoxy Coating System Used on Hangar Floor

SOW Attachment D Epoxy Coating System Used on Hangar Floor

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

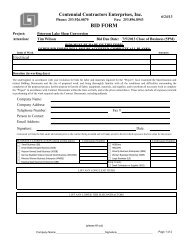

APPLICATION CHARACTERISTICS:Coverage rate will depend up<strong>on</strong> applicati<strong>on</strong> thickness as well as thetexture and porosity of the c<strong>on</strong>crete.Eco-PT 250Coverage Rate,56-70ft 2 (m 2 ) /3 bag mix)(5.2-6.5)Applicati<strong>on</strong> Thickness,inches (mm)Coverage Rate, ft 2 /gal (m 2 /L)Applicati<strong>on</strong> Thickness,wet/dry mils (micr<strong>on</strong>s)1/4-3/16(6.35-4.76)Eco-PTTopcoat200-320(4.92-7.87)5-8 per coat(127-203)Eco-HTTopcoat200-320(4.92-7.87)5-8 per coat(127-203)CHEMICAL RESISTANCE - UNPIGMENTEDTORFP GJKZ 09-0063 <str<strong>on</strong>g>SOW</str<strong>on</strong>g> <str<strong>on</strong>g>Attachment</str<strong>on</strong>g> DAppendix D Existing <str<strong>on</strong>g>Epoxy</str<strong>on</strong>g> <str<strong>on</strong>g>Coating</str<strong>on</strong>g> <str<strong>on</strong>g>System</str<strong>on</strong>g> DataBased <strong>on</strong> 1-day and 7-day spot testing <strong>on</strong> c<strong>on</strong>crete.<str<strong>on</strong>g>Coating</str<strong>on</strong>g> cured 2 weeks prior to testing.Legend:E - Excellent (No Adverse Effect) - Recommended.G - Good (Limited Adverse Effect) - Use for short-term exposure<strong>on</strong>ly.F - Fair (Moderate Adverse Effect) - Not recommended.P - Poor (Unsatisfactory) - Little or no resistance to chemical.Note: Reduced chemical resistance and increased staining ispossible in pigmented versi<strong>on</strong>s of this system.Tide ® is a registered trademark of Proctor and Gamble.Skydrol ® is a registered trademark of M<strong>on</strong>santo.IMPORTANT:READ AND FOLLOW ALL PRECAUTIONS ANDINSTRUCTIONS BEFORE PROCEEDING.Eco-PT Eco-HTTopcoat Topcoat1 / 7 Day(s) 1 / 7 Day(s)Acids, Inorganic10% Hydrochloric Acid E / E E / E30% Hydrochloric Acid (Muriatic) E / E E / E10% Nitric Acid E / G E / E50% Phosphoric Acid F / P G / G37% Sulfuric Acid (Battery Acid) G / G G / GAcids, Organic10% Acetic Acid F / P G / F10% Citric Acid E / G E / EOleic Acid G / F E / EAlkalies10% Amm<strong>on</strong>ium Hydroxide E / E E / E50% Sodium Hydroxide E / E E / ESolvents (Alcohols)Ethylene Glycol (Antifreeze) E / E E / EIsopropyl Alcohol F / F E / GMethanol F / F P / PSolvents (Aliphatic)d-Lim<strong>on</strong>ene E / E E / EJet Fuel - JP-4 E / E E / EGasoline E / E E / EMineral Spirits E / E E / ESolvents (Aromatic)Xylene F / F E / ESolvents (Chlorinated)Methylene Chloride P / P P / PSolvents (Ket<strong>on</strong>es & Esters)Methyl Ethyl Ket<strong>on</strong>e (MEK) P / P P / PPropylene Glycol Methyl EtherAcetate (PMA)F / FG / FMiscellaneous Chemicals20% Amm<strong>on</strong>ium Nitrate E / E E / EBrake Fluid F / F G / GBleach G / G E / EMotor Oil (SAE 30) E / E E / ESkydrol® 500B F / P E / ESkydrol® LD4 F / P E / E20% Sodium Chloride E / E E / E1% Tide® Laundry Soap E / E E / E10% Trisodium Phosphate E / E E / EPRELIMINARY FLOOR INSPECTIONSCHECK THE CONCRETE: C<strong>on</strong>crete must be structurallysound and free of curing membrane, paint or other sealer. Ifyou suspect that the c<strong>on</strong>crete has been previously sealed,call Tennant Company, technical support for furtherinstructi<strong>on</strong>s.CHECK FOR MOISTURE: C<strong>on</strong>crete must be dry beforeapplicati<strong>on</strong> of this floor coating material. C<strong>on</strong>crete moisturetesting must occur. Calcium chloride testing or in-situ relativehumidity testing is recommended. Readings must be below3 pounds per 1,000 square feet (1.5 kg per 150m 2 ) over a24-hour period <strong>on</strong> the calcium chloride test or below 75%relative internal c<strong>on</strong>crete humidity. Test methods can bepurchased at www.astm.org, see ASTM F1869 or F2170,respectively or follow instructi<strong>on</strong>s from the suppliers of thesetests.NOTE: Although testing is critical, it is not a guaranteeagainst future problems. This is especially true if there is novapor barrier or the vapor barrier is not functi<strong>on</strong>ing properlyand/or you suspect you may have c<strong>on</strong>crete c<strong>on</strong>taminati<strong>on</strong>from oils, chemical spills or excessive salts.CHECK THE TEMPERATURE AND HUMIDITY: <strong>Floor</strong>temperature and materials should be between 65°F (18°C)and 90°F (32°C). Humidity must be less than 80%. DO NOTcoat unless floor temperature is more than five degrees overthe dew point.APPLICATION EQUIPMENT• Protective clothing• Jiffy ® Mixer Blade[Tennant Part #: 08643-1 (small unit) or08643-5 (large unit)]• Slow speed drill (500 rpm or less)• 18-24" (457.2-609.6 mm) Flat Rubber Squeegee• Roller Assembly• Shed Resistant, 3/8" (10 mm) Nap Rollers• Mortar mixer• Screed box• Trowel (stainless steel, 3" x 12" (76.2 x 304.8 mm)• <str<strong>on</strong>g>Epoxy</str<strong>on</strong>g> power trowel with combinati<strong>on</strong> blades• Spiked shoesASSEMBLE EQUIPMENT: Due to the limited pot life of thematerial, all applicati<strong>on</strong> equipment, etc. should be ready forimmediate use.Eco-PT 250 © Tennant Company 05/21/09 Page 2 of 451 of 57