Educational solutions - Schneider Electric

Educational solutions - Schneider Electric

Educational solutions - Schneider Electric

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

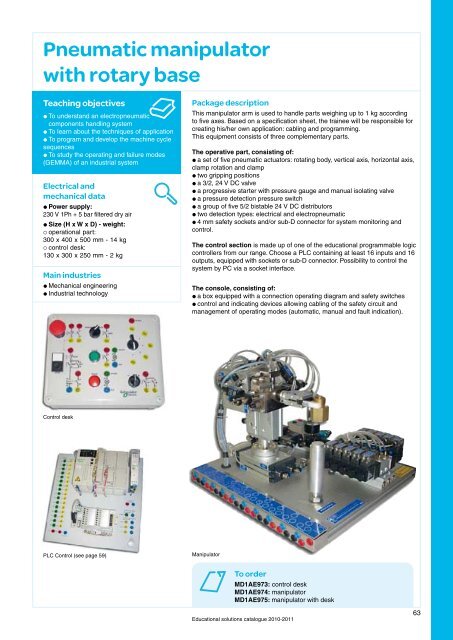

Pneumatic manipulatorwith rotary baseTeaching objectives@ To understand an electropneumaticcomponents handling system@ To learn about the techniques of application@ To program and develop the machine cyclesequences@ To study the operating and failure modes(GEMMA) of an industrial system<strong>Electric</strong>al andmechanical data@ Power supply:230 V 1Ph + 5 bar filtered dry air@ Size (H x W x D) - weight:_ operational part:300 x 400 x 500 mm - 14 kg_ control desk:130 x 300 x 250 mm - 2 kgMain industries@ Mechanical engineering@ Industrial technologyPackage descriptionThis manipulator arm is used to handle parts weighing up to 1 kg accordingto fi ve axes. Based on a specifi cation sheet, the trainee will be responsible forcreating his/her own application: cabling and programming.This equipment consists of three complementary parts.The operative part, consisting of:@ a set of fi ve pneumatic actuators: rotating body, vertical axis, horizontal axis,clamp rotation and clamp@ two gripping positions@ a 3/2, 24 V DC valve@ a progressive starter with pressure gauge and manual isolating valve@ a pressure detection pressure switch@ a group of fi ve 5/2 bistable 24 V DC distributors@ two detection types: electrical and electropneumatic@ 4 mm safety sockets and/or sub-D connector for system monitoring andcontrol.The control section is made up of one of the educational programmable logiccontrollers from our range. Choose a PLC containing at least 16 inputs and 16outputs, equipped with sockets or sub-D connector. Possibility to control thesystem by PC via a socket interface.The console, consisting of:@ a box equipped with a connection operating diagram and safety switches@ control and indicating devices allowing cabling of the safety circuit andmanagement of operating modes (automatic, manual and fault indication).Control deskPLC Control (see page 59)ManipulatorTo orderMD1AE973: control deskMD1AE974: manipulatorMD1AE975: manipulator with desk<strong>Educational</strong> <strong>solutions</strong> catalogue 2010-201163