Pigments

Pigments

Pigments

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

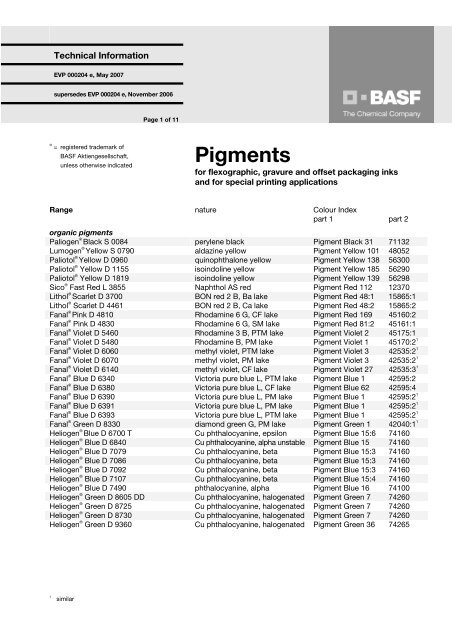

Technical InformationEVP 000204 e, May 2007supersedes EVP 000204 e, November 2006Page 1 of 11®= registered trademark ofBASF Aktiengesellschaft,unless otherwise indicated<strong>Pigments</strong>for flexographic, gravure and offset packaging inksand for special printing applicationsRangenatureColour Indexpart 1 part 2organic pigmentsPaliogen ® Black S 0084 perylene black Pigment Black 31 71132Lumogen ® Yellow S 0790 aldazine yellow Pigment Yellow 101 48052Paliotol ® Yellow D 0960 quinophthalone yellow Pigment Yellow 138 56300Paliotol ® Yellow D 1155 isoindoline yellow Pigment Yellow 185 56290Paliotol ® Yellow D 1819 isoindoline yellow Pigment Yellow 139 56298Sico ® Fast Red L 3855 Naphthol AS red Pigment Red 112 12370Lithol ® Scarlet D 3700 BON red 2 B, Ba lake Pigment Red 48:1 15865:1Lithol ® Scarlet D 4461 BON red 2 B, Ca lake Pigment Red 48:2 15865:2Fanal ® Pink D 4810 Rhodamine 6 G, CF lake Pigment Red 169 45160:2Fanal ® Pink D 4830 Rhodamine 6 G, SM lake Pigment Red 81:2 45161:1Fanal ® Violet D 5460 Rhodamine 3 B, PTM lake Pigment Violet 2 45175:1Fanal ® Violet D 5480 Rhodamine B, PM lake Pigment Violet 1 45170:2 1Fanal ® Violet D 6060 methyl violet, PTM lake Pigment Violet 3 42535:2 1Fanal ® Violet D 6070 methyl violet, PM lake Pigment Violet 3 42535:2 1Fanal ® Violet D 6140 methyl violet, CF lake Pigment Violet 27 42535:3 1Fanal ® Blue D 6340 Victoria pure blue L, PTM lake Pigment Blue 1 42595:2Fanal ® Blue D 6380 Victoria pure blue L, CF lake Pigment Blue 62 42595:4Fanal ® Blue D 6390 Victoria pure blue L, PM lake Pigment Blue 1 42595:2 1Fanal ® Blue D 6391 Victoria pure blue L, PM lake Pigment Blue 1 42595:2 1Fanal ® Blue D 6393 Victoria pure blue L, PTM lake Pigment Blue 1 42595:2 1Fanal ® Green D 8330 diamond green G, PM lake Pigment Green 1 42040:1 1Heliogen ® Blue D 6700 T Cu phthalocyanine, epsilon Pigment Blue 15:6 74160Heliogen ® Blue D 6840 Cu phthalocyanine, alpha unstable Pigment Blue 15 74160Heliogen ® Blue D 7079 Cu phthalocyanine, beta Pigment Blue 15:3 74160Heliogen ® Blue D 7086 Cu phthalocyanine, beta Pigment Blue 15:3 74160Heliogen ® Blue D 7092 Cu phthalocyanine, beta Pigment Blue 15:3 74160Heliogen ® Blue D 7107 Cu phthalocyanine, beta Pigment Blue 15:4 74160Heliogen ® Blue D 7490 phthalocyanine, alpha Pigment Blue 16 74100Heliogen ® Green D 8605 DD Cu phthalocyanine, halogenated Pigment Green 7 74260Heliogen ® Green D 8725 Cu phthalocyanine, halogenated Pigment Green 7 74260Heliogen ® Green D 8730 Cu phthalocyanine, halogenated Pigment Green 7 74260Heliogen ® Green D 9360 Cu phthalocyanine, halogenated Pigment Green 36 742651similar

EVP 000204 e, May 2007 Page 2 of 11 <strong>Pigments</strong>for flexographic, gravure and offset packaginginks and for special printing applicationsnatureColour Indexpart 1 part 2inorganic pigmentsMagnetic Pigment 025 BASF iron powder – –Magnetic Pigment 340 BASF iron[II]/iron[III] oxide Pigment Black 11 77499Magnetic Pigment 345 BASF iron[II]/iron[III] oxide Pigment Black 11 77499Magnetic Pigment 346 BASF iron[II]/iron[III] oxide Pigment Black 11 77499Physical formStoragepowderAccording to experience gained so far, pigments can be stored forat least 10 years from the time of delivery if stored properly andunder dry conditions.PropertiesTables 1 and 2 list important data on the physical properties of thepigments and their behavior towards solvents. The fastness to solventsis rated on a 5-point scale (5 = very good, no coloration ofthe solvent). The tests on the pigment powders are severe and canonly give a rough idea of the solvent fastness of the prints.Table 3 lists the main data on fastness properties of the pigments,determined on proofs carried out by gravure printing with inksbased on cellulose nitrate (NC).Table 4 lists similar data, this time determined on proofs preparedwith offset inks.Please refer to our Technical Information bulletin “Test methods forcolorants for printing inks” for details of the test methods and testmedia.Table 5 describes the main application fields for the individualpigments.

EVP 000204 e, May 2007 Page 3 of 11 <strong>Pigments</strong>for flexographic, gravure and offset packaginginks and for special printing applicationsTable 1Physical propertiesspecific density bulk volumesurface BET[m²/g] [g/cm³] [l/kg]organic pigmentsPaliogen ® Black S 0084 31 1.42 4.2 8.4Lumogen ® Yellow S 0790 5 1.34 5.0 6.5Paliotol ® Yellow D 0960 24 1.82 2.5 5.5Paliotol ® Yellow D 1155 36 1.49 4.0 5.5Paliotol ® Yellow D 1819 55 1.60 4.0 7.5Sico ® Fast Red L 3855 23 1.47 4.1 6.3Lithol ® Scarlet D 3700 38 1.90 4.5 5.5Lithol ® Scarlet D 4461 58 1.69 3.2 8.0Fanal ® Pink D 4810 87 1.47 4.5 7.5Fanal ® Pink D 4830 52 1.82 4.0 8.0Fanal ® Violet D 5460 26 2.23 3.0 10.0Fanal ® Violet D 5480 65 1.82 2.9 5.5Fanal ® Violet D 6060 37 1.93 3.3 8.0Fanal ® Violet D 6070 47 1.87 3.2 9.0Fanal ® Violet D 6140 66 1.53 6.0 8.0Fanal ® Blue D 6340 43 1.74 2.5 7.5Fanal ® Blue D 6380 57 1.40 3.0 5.0Fanal ® Blue D 6390 54 1.59 2.6 8.0Fanal ® Blue D 6391 48 1.62 3.8 5.3Fanal ® Blue D 6393 53 1.68 3.1 7.2Fanal ® Green D 8330 38 1.91 3.5 7.0Heliogen ® Blue D 6700 T 58 1.57 4.0 6.0Heliogen ® Blue D 6840 66 1.61 3.0 5.5Heliogen ® Blue D 7079 62 1.59 3.6 7.0Heliogen ® Blue D 7086 68 1.62 3.1 6.9Heliogen ® Blue D 7092 70 1.63 3.0 7.0Heliogen ® Blue D 7107 48 1.50 3.1 5.8Heliogen ® Blue D 7490 72 1.45 2.1 7.0Heliogen ® Green D 8605 DD 62 2.10 2.8 9.0Heliogen ® Green D 8725 61 2.10 2.6 6.2Heliogen ® Green D 8730 60 2.20 2.5 9.0Heliogen ® Green D 9360 61 2.84 2.5 7.0inorganic pigmentsMagnetic Pigment 025 BASF 0.4 7.70 0.4 7.3Magnetic Pigment 340 BASF 3.6 5.20 0.6 8.0Magnetic Pigment 345 BASF 4.4 5.20 0.6 7.9Magnetic Pigment 346 BASF 7.0 5.00 0.8 5.4pH value

EVP 000204 e, May 2007 Page 4 of 11 <strong>Pigments</strong>for flexographic, gravure and offset packaginginks and for special printing applicationsTable 2Solvent fastness of the pigmentswaterethanolethylacetatemethyl ethylketonetoluenewhite spiritNC solvent 2linseed oilorganic pigmentsPaliogen ® Black S 0084 4 2–3 3 2–3 3 5 3 5Lumogen ® Yellow S 0790 5 4 3 3 3 4 3 –Paliotol ® Yellow D 0960 4–5 4–5 4–5 4 4 5 4 5Paliotol ® Yellow D 1155 4–5 4–5 4–5 5 5 3–4 5Paliotol ® Yellow D 1819 4–5 3 2–3 2–3 2–3 3 2–3 5Sico ® Fast Red L 3855 4 3 2–3 2–3 2 3 3 3–4Lithol ® Scarlet D 3700 5 3 5 4 5 5 4 5Lithol ® Scarlet D 4461 4 3 4–5 4–5 5 5 4 5Fanal ® Pink D 4810 3 2 3 2 3–4 4 2 1Fanal ® Pink D 4830 4 2 4 2 4–5 5 2 5Fanal ® Violet D 5460 3 2 4 1 3–4 4 2 2Fanal ® Violet D 5480 3 2 4 1 4–5 5 2 3Fanal ® Violet D 6060 4–5 2 4–5 1 4–5 5 2 2–3Fanal ® Violet D 6070 4 1 4 1 4 5 1 3Fanal ® Violet D 6140 4–5 1 4–5 1 5 5 1 3Fanal ® Blue D 6340 4–5 1 1 1 2 4 1 2Fanal ® Blue D 6380 4–5 1 1 1 2 4 1 2Fanal ® Blue D 6390 5 1 2–3 1 2–3 4 1 2Fanal ® Blue D 6391 3 1–2 2 1 3 4–5 1–2 2Fanal ® Blue D 6393 5 1 2 1 4 4–5 1 3Fanal ® Green D 8330 5 2 4 1 4 5 2 3–4Heliogen ® Blue D 6700 T 5 5 5 5 5 5 5 5Heliogen ® Blue D 6840 5 5 5 5 5 5 4–5 5Heliogen ® Blue D 7079 5 5 5 5 5 5 5 5Heliogen ® Blue D 7086 5 4–5 5 4–5 5 5 4–5 5Heliogen ® Blue D 7092 5 4–5 5 4–5 5 5 4–5 5Heliogen ® Blue D 7107 4 2 5 3 5 5 2 5Heliogen ® Blue D 7490 4 4 4–5 4 5 4–5 3 5Heliogen ® Green D 8605 DD 5 5 4 4 4 5 4 5Heliogen ® Green D 8725 5 2 3 3 4 5 3–4 5Heliogen ® Green D 8730 5 5 4 4 4 5 4 5Heliogen ® Green D 9360 5 5 5 5 5 5 4 5inorganic pigmentsMagnetic Pigment 025 BASF 5 5 5 5 5 5 5 5Magnetic Pigment 340 BASF 5 5 5 5 5 5 5 5Magnetic Pigment 345 BASF 5 5 5 5 5 5 5 5Magnetic Pigment 346 BASF 5 5 5 5 5 5 5 3–42composition of the NC solvent:60 % ethanol30 % ethyl acetate10 % 2-methoxy propanol-1

EVP 000204 e, May 2007 Page 5 of 11 <strong>Pigments</strong>for flexographic, gravure and offset packaginginks and for special printing applicationsTable 3Fastness properties ofNC gravure printspaperlightaluwaterbuttercurdcheesealkalisacidssoapparaffinmigration3organic pigmentsPaliogen ® Black S 0084 7 7 5 5 5 5 5 5 5 4Lumogen ® Yellow S 0790 3 3 5 3 5 2 5 4 5 2Paliotol ® Yellow D 0960 7 7 5 5 5 5 5 5 5 4Paliotol ® Yellow D 1155 7 d 4 6-7 5 5 5 1 5 5 5 4-5Paliotol ® Yellow D 1819 7 7-8 5 5 5 3-4 5 5 5 4-5Sico ® Fast Red L 3855 6 6 5 3 5 5 5 5 5 1Lithol ® Scarlet D 3700 4 3 5 5 5 5 2-3 5 5 4-5Lithol ® Scarlet D 4461 5-6 5 5 5 5 5 2-3 3-4 5 5Fanal ® Pink D 4810 3 3 3 4 2-3 2 3 2 5 1Fanal ® Pink D 4830 4-5 d 4 4-5 d 4 4-5 4-5 5 5 5 4 5 1Fanal ® Violet D 5460 4 4 5 5 5 5 5 5 5 1Fanal ® Violet D 5480 4 d 4 4 d 4 4-5 5 3 2 5 2 5 1Fanal ® Violet D 6060 3-4 d 4 3 d 4 5 5 5 5 5 3-4 5 1Fanal ® Violet D 6070 3-4 d 4 3 d 4 5 5 5 5 5 5 5 1Fanal ® Violet D 6140 2-3 2 2-3 5 3-4 4 2-3 2-3 5 1Fanal ® Blue D 6340 3 2-3 5 5 5 5 4-5 5 5 1Fanal ® Blue D 6380 2 2 2-3 5 5 5 2-3 3 5 1Fanal ® Blue D 6390 4-5 4 5 5 5 5 4-5 5 5 1Fanal ® Green D 8330 4 d 4 4 d 4 5 5 5 5 5 5 5 1Heliogen ® Blue D 6700 T 7-8 7-8 5 5 5 5 5 5 5 5Heliogen ® Blue D 6840 7-8 7-8 5 5 5 5 5 5 5 5Heliogen ® Blue D 7079 8 8 5 5 5 5 5 5 5 5Heliogen ® Blue D 7086 8 8 5 5 5 5 5 5 5 5Heliogen ® Blue D 7107 8 8 5 5 5 5 5 5 5 5Heliogen ® Blue D 7490 7-8 7-8 5 5 5 5 5 5 5 4-5Heliogen ® Green D 8605 DD 8 7-8 5 5 5 5 5 5 5 5Heliogen ® Green D 8725 8 8 5 5 5 5 5 5 5 5Heliogen ® Green D 8730 8 7-8 5 5 5 5 5 5 5 5Heliogen ® Green D 9360 7 7-8 5 5 5 5 5 5 5 5inorganic pigmentsMagnetic Pigment 025 BASF 6 6 5 5 5 5 5 5 5 5Magnetic Pigment 340 BASF 6 6 5 5 5 5 5 5 5 5Magnetic Pigment 345 BASF 6 6 5 5 5 5 5 5 5 5Magnetic Pigment 346 BASF 6 6 5 5 5 5 5 5 5 534migration test:Keep the printed film made from plasticized PVC in a drying oven for 2 hours at 150 °C (302 °F). Then wash with methylethyl ketone andevaluate the coloration of the washed-off film on the gray scale according to ISO 105-A02.nachdunkeln

EVP 000204 e, May 2007 Page 6 of 11 <strong>Pigments</strong>for flexographic, gravure and offset packaginginks and for special printing applicationsTable 4Fastness properties of offset printslightwateracidsalkalissoapbutterNC solventsterilizingwater open steam1 h 1 h 1 h120 °C 120 °C 133 °C(248 °F) (248 °F) (271°F)organic pigmentsPaliogen ® Black S 0084 8 5 5 5 5 5 5 4–5 5/5 4 3Lumogen ® Yellow S 0790 3 5 5 2 5 3 3 4–5/5 4–5 3–4Paliotol ® Yellow D 0960 7 5 5 5 5 5 5 5/5 5 5Paliotol ® Yellow D 1155 7 5 5 2 5 5 5 5/5 5 4–5Paliotol ® Yellow D 1819 7 5 5 2–3 5 5 5 5/5 5 5Sico ® Fast Red L 3855 5–6 5 4 5 4–5 4–5 5 5/5 4 3Lithol ® Scarlet D 3700 3–4 5 4 5 5 5 5 5/5 5 5Lithol ® Scarlet D 4461 5 5 4–5 4–5 2–3 5 5 5/5 5 5Fanal ® Pink D 4810 3–4 d 4 3 4–5 2 1 4–5 4 3/4 3 3Fanal ® Pink D 4830 4 d 4 4–5 4–5 4 2 2 4 4/5 5 4Fanal ® Violet D 5460 4–5 d 4 5 5 4–5 3 4–5 3–4 3/4 3 3Fanal ® Violet D 5480 4–5 d 4 2 3 2 1 1 3 4/4 5 4Fanal ® Violet D 6060 3–4 d 4 4 4–5 4 2 1 3 5/5 5 5Fanal ® Violet D 6070 3–4 d 4 5 5 4 3 1 4 5/5 5 5Fanal ® Blue D 6340 4 d 4 4 4–5 4–5 3 3 3 5/5 5 5Fanal ® Blue D 6390 4 d 4 5 4–5 5 3 1 5 5/5 5 5Fanal ® Blue D 6391 4 d 4 5 3 5 4 4–5 3 2/5 2–3 2Fanal ® Blue D 6393 4 d 4 5 4 4–5 5 5 3 – – –Fanal ® Green D 8330 3 d 4 5 5 4–5 4 1 3 5/5 4 3Heliogen ® Blue D 6700 T 8 5 5 5 5 5 5 5/5 5 5Heliogen ® Blue D 6840 8 5 5 5 5 5 5 5/5 5 5Heliogen ® Blue D 7079 8 5 5 5 5 5 5 5/5 5 5Heliogen ® Blue D 7086 8 5 5 5 5 5 5 5/5 5 5Heliogen ® Blue D 7092 8 5 5 5 5 5 5 5/5 5 5Heliogen ® Blue D 7490 8 5 5 5 5 5 5 5/5 5 5Heliogen ® Green D 8605 DD 8 5 5 5 5 5 5 5/5 5 5Heliogen ® Green D 8725 8 5 5 5 5 5 5 5/5 5 5Heliogen ® Green D 8730 8 5 5 5 5 5 5 5/5 5 5Heliogen ® Green D 9360 8 5 5 5 5 5 5 5/5 5 5inorganic pigmentsMagnetic Pigment 025 BASF 6 5 5 5 5 5 5 5/5 5 5Magnetic Pigment 340 BASF 6 5 5 5 5 5 5 5/5 5 5Magnetic Pigment 345 BASF 6 5 5 5 5 5 5 5/5 5 5Magnetic Pigment 346 BASF 6 4–5 3 4 5 5 5 5/5 5 55Druck wird angegriffen

EVP 000204 e, May 2007 Page 7 of 11 <strong>Pigments</strong>for flexographic, gravure and offset packaginginks and for special printing applicationsTable 5flexographic and gravure inks based onSuitability of the pigments water cellulosenitratepolyamideresinPVCcopolymerorganic pigmentsPaliogen ® Black S 0084 •Lumogen ® Yellow S 0790 • • •Paliotol ® Yellow D 0960 • • • • •Paliotol ® Yellow D 1155 • • •Paliotol ® Yellow D 1819 • • • •Sico ® Fast Red L 3855 • • • •Lithol ® Scarlet D 3700 • • • • •Lithol ® Scarlet D 4461 • • • •Fanal ® Pink D 4810 • Fanal ® Pink D 4830 • •Fanal ® Violet D 5460 • •Fanal ® Violet D 5480 • •Fanal ® Violet D 6060 • •Fanal ® Violet D 6070 • •Fanal ® Violet D 6140 • Fanal ® Blue D 6340 • •Fanal ® Blue D 6380 • Fanal ® Blue D 6390 • •Fanal ® Blue D 6391 •Fanal ® Blue D 6393 •Fanal ® Green D 8330 • •Heliogen ® Blue D 6700 T • • • • •Heliogen ® Blue D 6840 • •Heliogen ® Blue D 7079 • • •Heliogen ® Blue D 7086 • • •Heliogen ® Blue D 7092 • •Heliogen ® Blue D 7107 • • • Heliogen ® Blue D 7490 • •Heliogen ® Green D 8605 DD • •Heliogen ® Green D 8725 • • • Heliogen ® Green D 8730 • • • • •Heliogen ® Green D 9360 • • • • •inorganic pigmentsMagnetic Pigment 025 BASF •Magnetic Pigment 340 BASF •Magnetic Pigment 345 BASF •Magnetic Pigment 346 BASF •• suitable limited suitability not suitableoffset inks

EVP 000204 e, May 2007 Page 8 of 11 <strong>Pigments</strong>for flexographic, gravure and offset packaginginks and for special printing applicationsApplicationFlexographic and gravure inks forpackaging and special applicationsFlexographic and gravure inks for printing packaging materialssuch as paper, cardboard, aluminum, cellophane and plastic filmsare highly fluid and dry by rapid evaporation and absorption of thesolvents. Solvents commonly used are alcohols, water, esters andketones.Cellulose nitrate is the most common binder. Other binders usedalone or in combination are polyamide resins, acrylic resins, polyurethaneresins, polyvinyl butyric (PVB) and VC/VA copolymers.Binders such as Laroflex ® MP, cellulose acetopropionate (CAP),cyclized rubber, chlorinated rubber and chlorinated polypropyleneare of significance in some markets.Cyclized rubber, chlorinated polypropylene and polyurethaneresins are used for printing on plastic films, e. g., pre-treated polyethyleneterephthalate and OPP films.PVB is used for printing films that are subsequently converted intocomposite films or laminates by co-extrusion or lamination. <strong>Pigments</strong>suitable for NC are in principle also suitable for PVB. PVBsystems often include a primer to improve ink adhesion on compositefilm. In selecting suitable pigments, it should be noted thatsome of the primers used are strongly alkaline.Polyamide resinsTo formulate flexographic and gravure inks with good adhesion toa wide variety of materials, it is often an advantage to use specialpolyamide resins. In selecting the pigments, it should be noted thatin printing inks containing polyamide resinsmany pigments tend to flocculation and thixotropy,all Fanal ® pigments tend to migrate through polyethylene andpolypropylene,pigments containing manganese or other heavy metals (e. g.,Fanal ® Pink D 4810, Fanal ® Violet D 6140 and Fanal ® Blue D 6380),catalyze oxidative degradation of the polyamide resin and cancause unpleasant odor. The same applies to pigment blends containinglead chromate or lead molybdate.Some suppliers of polyamide resins recommend to add antioxidantsor offer stabilized resin grades so these lead pigments couldbe used.By combining polyamide resins with cellulose nitrate it is possibleto counter the tendency to flocculation, prevent migration throughpolyethylene, and raise the blocking point.Table 5 gives an indication of the suitability of pigments for waterbasedsystems and for inks based on NC, polyamide and PVC.

EVP 000204 e, May 2007 Page 9 of 11 <strong>Pigments</strong>for flexographic, gravure and offset packaginginks and for special printing applicationsSuitability for PVC was tested in UCAR 6 VAGH, a PVC copolymerbased on VC/VA/vinyl alcohol.Decorative offset inksThe main field of application for decorative paste inks is the offsetprinting of packaging materials, including paper, cardboard and –in small market segments – film. The inks contain mineral andvegetable oil as solvents. Colorants used are mostly organic pigments.In selecting the colorants, the fastness requirements for thefinal printed article must be observed.Information on individual pigmentsPaliogen ® Black S 0084Lumogen ® Yellow S 0790Paliotol ® Yellow D 0960Paliotol ® Yellow D 1155Paliotol ® Yellow D 1819Sico ® Fast Red L 3855Lithol ® Scarlet D 3700Lithol ® Scarlet D 4461Fanal ® pigmentsFanal ® Pink D 4810Fanal ® Violet D 6140Fanal ® Blue D 6380Fanal ® Pink D 4830perylene pigment that reflects infra-red light, outstanding fastnesspropertiesbrilliant daylight fluorescent pigment for special applicationsgreenish yellow pigment with very good fastness propertiespure greenish yellow with high color strength, high gloss, very goodlight fastness, high transparency and good compatibility with estersFor outdoor application (for which good weathering resistance isrequired), it is essential to carry out trials in the chosen binder system,especially in the case of reductions with titanium dioxide.The main applications for Paliotol ® Yellow D 1155 are flexographicand special gravure printing, particularly in NC inks.Alcoholic NC inks, on prolonged storage, are likely to develop alovage-like odor. Odor development is accelerated if the NC inkscontain titanium acetyl acetonate (TAA). Material printed with suchinks will also not be free from odor.reddish complement to Paliotol ® Yellow D 1155, high in colorstrength, lightfast and stable to heatred pigment with very good fastness to light; combining Sico ® FastRed L 3855 with Lupasol ® WF in PVB inks can cause an odor (mothpowder)yellowish scarlet grade with very good flow propertiesreadily dispersible calcium lake with high transparency and favorableflow propertiesFanal ® pigments show extremely pure and brilliant shades. Due totheir chemical structure they are not resistant to chemicals and, inparticularly with polar solvents present, not very stable. As a result,during storage of the ink the shade may shift, flocculation andsettling may occur. Pre-trials in the binder system intended to beused are therefore indispensable.copper hexacyanoferrate lakes, particularly suitable for waterbasedinks and publication gravure inks; for other liquid printinginks we recommend our two- and three-salt Fanal ® gradessilicon-molybdenum lake6trademark of Dow Chemical Company

EVP 000204 e, May 2007 Page 10 of 11 <strong>Pigments</strong>for flexographic, gravure and offset packaginginks and for special printing applicationsFanal ® Violet D 5480Fanal ® Violet D 6070Fanal ® Blue D 6390Fanal ® Blue D 6391Fanal ® Green D 8330Fanal ® Violet D 5460Fanal ® Violet D 6060Fanal ® Blue D 6340Fanal ® Blue D 6393Heliogen ® Blue D 6700 THeliogen ® Blue D 6840Heliogen ® Blue D 7079Heliogen ® Blue D 7086Heliogen ® Blue D 7092Heliogen ® Blue D 7107Heliogen ® Blue D 7490Heliogen ® Green D 8605 DDHeliogen ® Green D 8725Heliogen ® Green D 8730Heliogen ® Green D 9360Magnetic Pigment 025 BASFMagnetic Pigment 340 BASFMagnetic Pigment 345 BASFMagnetic Pigment 346 BASFphosphorous-molybdenum lakesphosphorous-tungsten-molybdenum lakesparticularly reddish, high-chroma, abrasion-free phthalocyanineblue pigment, epsilon modificationreddish alpha copper phthalocyanine blue pigment, unstable inaromatics, particularly suitable for water-based inksfor decorative offset inks, readily dispersible, high color strengthmore reddish than Heliogen ® Blue D 7079, universal applicationfor offset inks, good flow propertiesspecial grade for solvent-based inkscopper-free phthalocyanine blue, particularly suitable for waterbasedsystemsreadily dispersible green pigment for decorative offset inks andwater-based inksspecial grade for solvent-based inksuniversal grade for all ink typeshalogenated phthalocyanine green for all ink typesmagnetizable printing inks for the manufacture of magnetic coatings;details are given in the Technical Information bulletin Magnetic<strong>Pigments</strong>SafetyWhen handling these products, advice and information given in thesafety data sheet must be complied with. Further, protective andworkplace hygiene measures adequate for handling chemicalsmust be observed.

EVP 000204 e, May 2007 Page 11 of 11 <strong>Pigments</strong>for flexographic, gravure and offset packaginginks and for special printing applicationsNoteThe data contained in this publication are based on our currentknowledge and experience. In view of the many factors that mayaffect processing and application of our product, these data do notrelieve processors from carrying out their own investigations andtests; neither do these data imply any guarantee of certain properties,nor the suitability of the product for a specific purpose. Anydescriptions, drawings, photographs, data, proportions, weights,etc. given herein may change without prior information and do notconstitute the agreed contractual quality of the product. It is theresponsibility of the recipient of our products to ensure that anyproprietary rights and existing laws and legislation are observed.20070503_evp000204_e_s_ti_pigmente_verpackungsdruck.doc /EVP 000204-0705 EBASF AktiengesellschaftPerformance Chemicals forCoatings, Plastics and Specialties67056 Ludwigshafen, Germanywww.basf.com/pigmentswww.basf.com/resinswww.basf.com/lightstabilizers