Lumogen Yellow S 0790

Lumogen Yellow S 0790

Lumogen Yellow S 0790

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

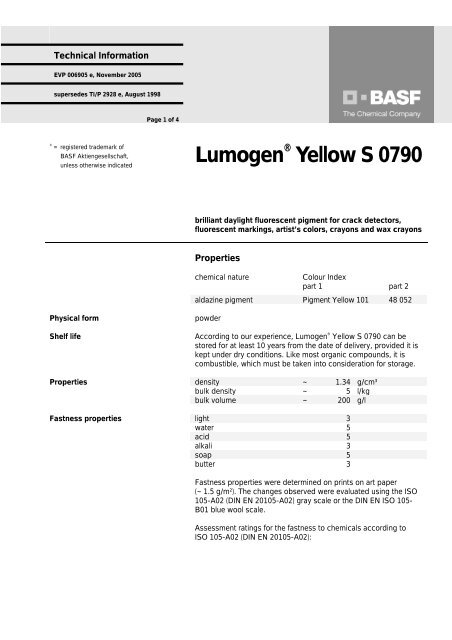

Technical InformationEVP 006905 e, November 2005supersedes TI/P 2928 e, August 1998Page 1 of 4®= registered trademark ofBASF Aktiengesellschaft,unless otherwise indicated<strong>Lumogen</strong> ® <strong>Yellow</strong> S <strong>0790</strong>brilliant daylight fluorescent pigment for crack detectors,fluorescent markings, artist’s colors, crayons and wax crayonsPropertieschemical natureColour Indexpart 1 part 2aldazine pigment Pigment <strong>Yellow</strong> 101 48 052Physical formShelf lifePropertiesFastness propertiespowderAccording to our experience, <strong>Lumogen</strong> ® <strong>Yellow</strong> S <strong>0790</strong> can bestored for at least 10 years from the date of delivery, provided it iskept under dry conditions. Like most organic compounds, it iscombustible, which must be taken into consideration for storage.density ~ 1.34 g/cm³bulk density ~ 5 l/kgbulk volume ~ 200 g/llight 3water 5acid 5alkali 3soap 5butter 3Fastness properties were determined on prints on art paper(~ 1.5 g/m²). The changes observed were evaluated using the ISO105-A02 (DIN EN 20105-A02) gray scale or the DIN EN ISO 105-B01 blue wool scale.Assessment ratings for the fastness to chemicals according toISO 105-A02 (DIN EN 20105-A02):

EVP 006905 e, November 2005 Page 2 of 4 <strong>Lumogen</strong> ® <strong>Yellow</strong> S <strong>0790</strong>rating fastness discoloration1 poor strong2 moderate considerable3 fairly good somewhat4 good trace5 very good noneAssessment ratings for the fastness to light according toDIN EN ISO 105-B01:ratingfastness1 very poor2 poor3 moderate4 fairly good5 good6 very good7 excellent8 outstandingFluorescence spectraThe emission and excitation spectra were measured on drawdownson 50 µm acetate film. The cellulose nitrate combinationcoating used was pigmented with 1.25 % <strong>Lumogen</strong> ® <strong>Yellow</strong>S <strong>0790</strong>.relative emission120010008006004002000400 450 500 550 600 650 700 750 800wavelength [nm]excitationemissionApplicationNon-destructive material testingcrack detectionFinished parts made of ferromagnetic metals, e. g., steel, cast ironor welding seams in these parts are often subjected to a magneticpowder test. This method is used to determine whether a finishedpart is free from faults and therefore suitable for its intendedapplication because the magnetic lines of force are deviated bystray fields or cracks in the metal, which can be made visible in thelight of a UV lamp.

EVP 006905 e, November 2005 Page 3 of 4 <strong>Lumogen</strong> ® <strong>Yellow</strong> S <strong>0790</strong>The fluorescent magnetic powder can also be applied to the part tobe tested in the form of a suspension in a suitable solvent.<strong>Lumogen</strong> ® <strong>Yellow</strong> S <strong>0790</strong> has established itself for the use incombination with magnetizable iron oxide.Fluorescent markingsWhen crop protection agents are applied, it is often necessary tocontrol the agricultural field. In such cases, the spray solution canbe pigmented with <strong>Lumogen</strong> ® <strong>Yellow</strong> S <strong>0790</strong> and the applicationcan then be controled at night with a portable UV lamp.In order to develop the full color strength, the pigment should firstbe ground on the edge mill with chalk or a similar inert diluent andthen added to the spray solution. Another method is to prepare afinely divided pigment paste and add that to the solution.The requisite concentration for application is approximately 0.1–0.5 g/l.Fluorescent markings can also be applied by stamping with acoding machine. A typical formulation for a rapidly drying stampingink is:10–20 parts <strong>Lumogen</strong> ® <strong>Yellow</strong> S <strong>0790</strong>90–80 parts Resin solution, consisting of20 % maleic resin and80 % ethanolThis mixture is ground in suitable equipment such as ball mill,attritor, dissolver etc.Poster colorsLuminous yellow poster colors can be formulated following thisrecipe:15 parts <strong>Lumogen</strong> ® <strong>Yellow</strong> S <strong>0790</strong>80 parts casein solution 12.5 %20 parts polymer dispersion based on vinylpropionate, e. g., Propiofan ® grades10 parts watergrind in funnel mill or with dissolverColored crayonsColored leads with an intense yellow fluorescence in UV light canbe obtained with:12 parts <strong>Lumogen</strong> ® <strong>Yellow</strong> S <strong>0790</strong>65 parts Kaolin23 parts Methylhydroxyethylcellulose,10 %ig in WasserMix intensively in kneader, then press to leads.The leads are dried and then prepared as usual with a wax mix.

EVP 006905 e, November 2005 Page 4 of 4 <strong>Lumogen</strong> ® <strong>Yellow</strong> S <strong>0790</strong>Wax crayons<strong>Yellow</strong> wax crayons that show up brightly in UV light can beprepared with:5 parts <strong>Lumogen</strong> ® <strong>Yellow</strong> S <strong>0790</strong>37 parts stearin38 parts paraffin wax 52/54 °C (126/130 °F)20 parts china clay<strong>Lumogen</strong> ® <strong>Yellow</strong> S <strong>0790</strong> and china clay are stirred into the meltconsisting of stearin and paraffin wax at approximately 90 °C(190 °F). Grinding of the pigments on the edge roller is normally notnecessary.The melt is then poured into molds as usual.SafetyWhen handling these products, advice and information given in thesafety data sheet must be complied with. Further, protective andworkplace hygiene measures adequate for handling chemicalsmust be observed.NoteThe data contained in this publication are based on our currentknowledge and experience. In view of the many factors that mayaffect processing and application of our product, these data do notrelieve processors from carrying out their own investigations andtests; neither do these data imply any guarantee of certain properties,nor the suitability of the product for a specific purpose. Anydescriptions, drawings, photographs, data, proportions, weights,etc. given herein may change without prior information and do notconstitute the agreed contractual quality of the product. It is theresponsibility of the recipient of our products to ensure that anyproprietary rights and existing laws and legislation are observed.BASF AktiengesellschaftPerformance Chemicals forCoatings, Plastics and Specialties67056 Ludwigshafen, Germanywww.basf.com/pigmentswww.basf.com/resinswww.basf.com/lightstabilizers