Q2 2010 - Automotive Industries

Q2 2010 - Automotive Industries

Q2 2010 - Automotive Industries

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

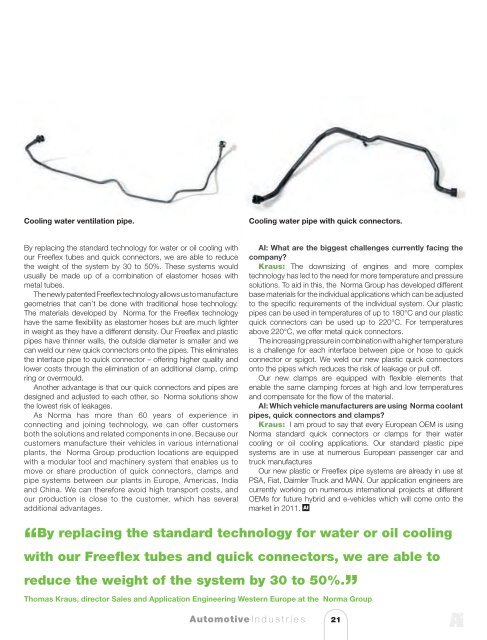

Cooling water ventilation pipe. Cooling water pipe with quick connectors.<br />

By replacing the standard technology for water or oil cooling with<br />

our Freeflex tubes and quick connectors, we are able to reduce<br />

the weight of the system by 30 to 50%. These systems would<br />

usually be made up of a combination of elastomer hoses with<br />

metal tubes.<br />

The newly patented Freeflex technology allows us to manufacture<br />

geometries that can’t be done with traditional hose technology.<br />

The materials developed by Norma for the Freeflex technology<br />

have the same flexibility as elastomer hoses but are much lighter<br />

in weight as they have a different density. Our Freeflex and plastic<br />

pipes have thinner walls, the outside diameter is smaller and we<br />

can weld our new quick connectors onto the pipes. This eliminates<br />

the interface pipe to quick connector – offering higher quality and<br />

lower costs through the elimination of an additional clamp, crimp<br />

ring or overmould.<br />

Another advantage is that our quick connectors and pipes are<br />

designed and adjusted to each other, so Norma solutions show<br />

the lowest risk of leakages.<br />

As Norma has more than 60 years of experience in<br />

connecting and joining technology, we can offer customers<br />

both the solutions and related components in one. Because our<br />

customers manufacture their vehicles in various international<br />

plants, the Norma Group production locations are equipped<br />

with a modular tool and machinery system that enables us to<br />

move or share production of quick connectors, clamps and<br />

pipe systems between our plants in Europe, Americas, India<br />

and China. We can therefore avoid high transport costs, and<br />

our production is close to the customer, which has several<br />

additional advantages.<br />

AI: What are the biggest challenges currently facing the<br />

company?<br />

Kraus: The downsizing of engines and more complex<br />

technology has led to the need for more temperature and pressure<br />

solutions. To aid in this, the Norma Group has developed different<br />

base materials for the individual applications which can be adjusted<br />

to the specific requirements of the individual system. Our plastic<br />

pipes can be used in temperatures of up to 180°C and our plastic<br />

quick connectors can be used up to 220°C. For temperatures<br />

above 220°C, we offer metal quick connectors.<br />

The increasing pressure in combination with a higher temperature<br />

is a challenge for each interface between pipe or hose to quick<br />

connector or spigot. We weld our new plastic quick connectors<br />

onto the pipes which reduces the risk of leakage or pull off.<br />

Our new clamps are equipped with flexible elements that<br />

enable the same clamping forces at high and low temperatures<br />

and compensate for the flow of the material.<br />

AI: Which vehicle manufacturers are using Norma coolant<br />

pipes, quick connectors and clamps?<br />

Kraus: I am proud to say that every European OEM is using<br />

Norma standard quick connectors or clamps for their water<br />

cooling or oil cooling applications. Our standard plastic pipe<br />

systems are in use at numerous European passenger car and<br />

truck manufactures<br />

Our new plastic or Freeflex pipe systems are already in use at<br />

PSA, Fiat, Daimler Truck and MAN. Our application engineers are<br />

currently working on numerous international projects at different<br />

OEMs for future hybrid and e-vehicles which will come onto the<br />

market in 2011. AI<br />

“ By replacing the standard technology for water or oil cooling<br />

with our Freeflex tubes and quick connectors, we are able to<br />

reduce the weight of the system by 30 to 50%. ”<br />

Thomas Kraus, director Sales and Application Engineering Western Europe at the Norma Group<br />

<strong>Automotive</strong> <strong>Industries</strong> 21