Linear Roller Way Super X

Linear Roller Way Super X

Linear Roller Way Super X

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

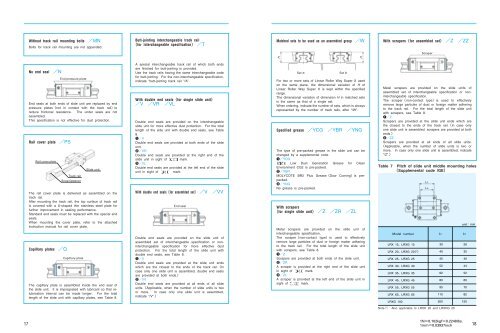

Without track rail mounting boltsMNBolts for track rail mounting are not appended.Butt-jointing interchangeable track railfor interchangeable specification TMatched sets to be used as an assembled groupWWith scrapersfor assembled set ZZZScraperHHNo end sealNEnd pressure plateEnd seals at both ends of slide unit are replaced by endpressure platesnot in contact with the track railtoreduce frictional resistance. The under seals are notassembled.This specification is not effective for dust protection.Rail cover plateRail cover plateCapillary platesPSSnap fastenerQTrack railCapillary plateSlide unitThe rail cover plate is delivered as assembled on thetrack rail.After mounting the track rail, the top surface of track railis covered with a U-shaped thin stainless steel plate forfurther improvement in sealing performance.Standard end seals must be replaced with the special endseals.When mounting the cover plate, refer to the attachedinstruction manual for rail cover plate.The capillary plate is assembled inside the end seal ofthe slide unit. It is impregnated with lubricant so that relubricationinterval can be made longer. For the totallength of the slide unit with capillary plates, see Table 8.A special interchangeable track rail of which both endsare finished for butt-jointing is provided.Use the track rails having the same interchangeable codefor butt-jointing. For the non-interchangeable specification,indicate “butt-jointing track rail “/A”.With double end sealsfor single slide unitV VR VLDouble end seals are provided on the interchangeableslide unit for more effective dust protection. For the totallength of the side unit with double end seals, see Table8.qVDouble end seals are provided at both ends of the slideunit.wVRDouble end seals are provided at the right end of theslide unit in sight of mark.eVLDouble end seals are provided at the left end of the slideunit in sight of mark.With double end sealsfor assembled set VEnd sealVVDouble end seals are provided on the slide unit ofassembled set of interchangeable specification or noninterchangeablespecification for more effective dustprotection. For the total length of the slide unit withdouble end seals, see Table 8.qVDouble end seals are provided at the slide unit endswhich are the closest to the ends of the track rail.Incase only one slide unit is assembled, double end sealsare provided at both ends.wVVDouble end seals are provided at all ends of all slideunits.Applicable, when the number of slide units is twoor more. In case only one slide unit is assembled,indicate “/V”.SetSetFor two or more sets of <strong>Linear</strong> <strong>Roller</strong> <strong>Way</strong> <strong>Super</strong> X usedon the same plane, the dimensional variation of H of<strong>Linear</strong> <strong>Roller</strong> <strong>Way</strong> <strong>Super</strong> X is kept within the specifiedrange.The dimensional variation of dimension H in matched setsis the same as that of a single set.When ordering, indicate the number of sets, which is alwaysrepresented by the number of track rails, after “/W”.Specified grease YCG YBR YNGThe type of pre-packed grease in the slide unit can bechanged by a supplemental code.qYCGLow Dust Generation Grease for CleanEnvironment CG2 is pre-packed.wYBRMOLYCOTE BR2 Plus GreaseDow Corningis prepacked.eYNGNo grease is pre-packed.With scrapersfor single slide unit Z ZR ZLMetal scrapers are provided on the slide unit ofinterchangeable specification.The scrapernon-contact typeis used to effectivelyremove large particles of dust or foreign matter adheringto the track rail. For the total length of the slide unitwith scrapers, see Table 8.qZScrapers are provided at both ends of the slide unit.wZRA scraper is provided at the right end of the slide unitin sight of mark.eZLA scraper is provided at the left end of the slide unit insight of mark.Metal scrapers are provided on the slide units ofassembled set of interchangeable specification or noninterchangeablespecification.The scrapernon-contact typeis used to effectivelyremove large particles of dust or foreign matter adheringto the track rail. For the total length of the slide unitwith scrapers, see Table 8.qZScrapers are provided at the slide unit ends which arethe closest to the ends of the track rail.In case onlyone slide unit is assembled, scrapers are provided at bothends.wZZScrapers are provided at all ends of all slide units.Applicable, when the number of slide units is two ormore. In case only one slide unit is assembled, indicate“/Z”.Table 7 Pitch of slide unit middle mounting holesSupplemental code /GEModel number L2 L6LRX 15LRXG 15LRX 20LRXG 20 1 LRX 25LRXG 25LRX 30LRXG 30LRX 35LRXG 35LRX 45LRXG 45LRX 55LRXG 55LRX 65LRXG 65LRXG 100L 2L 630 2640 3545 4052 4462 5280 6095 70110 82200 150mm unitmmNote 1 Also applicable to LRXH 20 and LRXHG 20.171N0.102kgf0.2248lbs.1mm0.03937inch 18