Linear Roller Way Super X

Linear Roller Way Super X

Linear Roller Way Super X

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

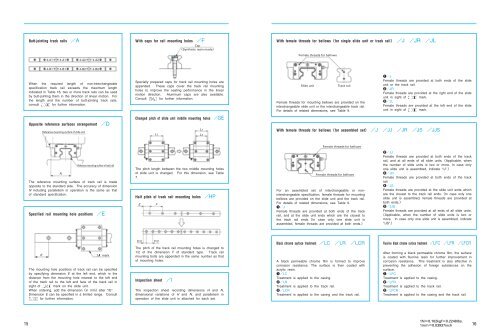

Butt-jointing track railsA4-A1 4-A1 4-A2 4-A2With caps for rail mounting holes FCapSynthetic resin madeWith female threads for bellowsfor single slide unit or track rail J JR JLFemale threads for bellows4-B1 4-B1 4-B2 4-B2When the required length of non-interchangeablespecification track rail exceeds the maximum lengthindicated in Table 16, two or more track rails can be usedby butt-jointing them in the direction of linear motion. Forthe length and the number of butt-jointing track rails,consult for further information.Opposite reference surfaces arrangementReference mounting surface of slide unitDSpecially prepared caps for track rail mounting holes areappended. These caps cover the track rail mountingholes to improve the sealing performance in the linearmotion direction. Aluminum caps are also available.Consult for further information.Changed pitch of slide unit middle mounting holesL 2L 2L 6GESlide unitTrack railFemale threads for mounting bellows are provided on theinterchangeable slide unit or the interchangeable track rail.For details of related dimensions, see Table 9.qJFemale threads are provided at both ends of the slideunit or the track rail.wJRFemale threads are provided at the right end of the slideunit in sight of mark.eJLFemale threads are provided at the left end of the slideunit in sight of mark.With female threads for bellowsfor assembled set J JJ JR JS JJSFemale threads for bellowsNReference mounting surface of track railThe reference mounting surface of track rail is madeopposite to the standard side. The accuracy of dimensionN including parallelism in operation is the same as thatof standard specification.Specified rail mounting hole positionsEThe pitch length between the two middle mounting holesof slide unit is changed. For this dimension, see Table7.Half pitch of track rail mounting holesEFHPFemale threads for bellowsFor an assembled set of interchangeable or noninterchangeablespecification, female threads for mountingbellows are provided on the slide unit and the track rail.For details of related dimensions, see Table 9.qJFemale threads are provided at both ends of the trackrail, and at the slide unit ends which are the closest tothe track rail ends.In case only one slide unit isassembled, female threads are provided at both ends.wJJFemale threads are provided at both ends of the trackrail, and at all ends of all slide units.Applicable, whenthe number of slide units is two or more. In case onlyone slide unit is assembled, indicate “/J”.eJRFemale threads are provided at both ends of the trackrail.rJSFemale threads are provided at the slide unit ends whichare the closest to the track rail ends.In case only oneslide unit is assembled, female threads are provided atboth ends.tJJSFemale threads are provided at all ends of all slide units.Applicable, when the number of slide units is two ormore. In case only one slide unit is assembled, indicate“/JS”.EmarkThe mounting hole positions of track rail can be specifiedby specifying dimension E at the left end, which is thedistance from the mounting hole nearest to the left endof the track rail to the left end face of the track rail insight of mark on the slide unit.When ordering, add the dimensionin mmafter “/E”.Dimension E can be specified in a limited range. Consultfor further information.E/2 F/2The pitch of the track rail mounting holes is changed to1/2 of the dimension F of standard type. Track railmounting bolts are appended in the same number as thatof mounting holes.Inspection sheetThe inspection sheet recording dimensions H and N,dimensional variations of H and N, and parallelism inoperation of the slide unit is attached for each set.Black chrome surface treatment LC LR LCRA black permeable chrome film is formed to improvecorrosion resistance. The surface is then coated withacrylic resin.qLCTreatment is applied to the casing.wLRTreatment is applied to the track rail.eLCRTreatment is applied to the casing and the track rail.Fluorine black chrome surface treatment LFC LFR LFCRAfter forming a black permeable chrome film, the surfaceis coated with fluorine resin for further improvement incorrosion resistance. This treatment is also effective inpreventing the adhesion of foreign substances on thesurface.qLFCTreatment is applied to the casing.wLFRTreatment is applied to the track rail.eLFCRTreatment is applied to the casing and the track rail.151N0.102kgf0.2248lbs.1mm0.03937inch 16