R-MOSAIC

R-MOSAIC

R-MOSAIC

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

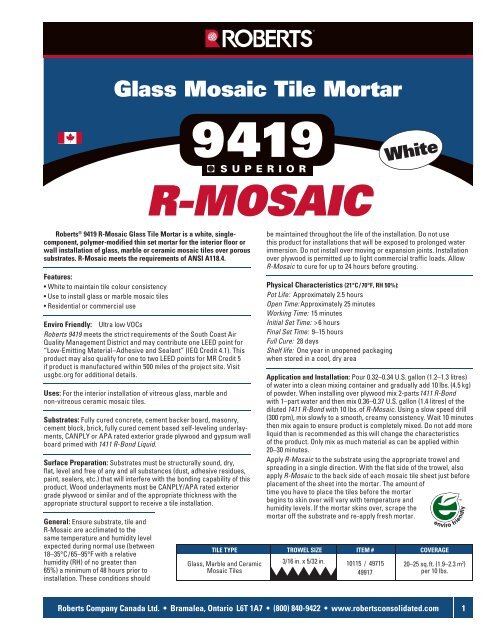

Glass Mosaic Tile Mortar9419SUPERIORWhiteR-<strong>MOSAIC</strong>Roberts ® 9419 R-Mosaic Glass Tile Mortar is a white, singlecomponent,polymer-modified thin set mortar for the interior floor orwall installation of glass, marble or ceramic mosaic tiles over poroussubstrates. R-Mosaic meets the requirements of ANSI A118.4.Features:• White to maintain tile colour consistency• Use to install glass or marble mosaic tiles• Residential or commercial useEnviro Friendly: Ultra low VOCsRoberts 9419 meets the strict requirements of the South Coast AirQuality Management District and may contribute one LEED point for“Low-Emitting Material–Adhesive and Sealant” (IEQ Credit 4.1). Thisproduct may also qualify for one to two LEED points for MR Credit 5if product is manufactured within 500 miles of the project site. Visitusgbc.org for additional details.Uses: For the interior installation of vitreous glass, marble andnon-vitreous ceramic mosaic tiles.Substrates: Fully cured concrete, cement backer board, masonry,cement block, brick, fully cured cement based self-leveling underlayments,CANPLY or APA rated exterior grade plywood and gypsum wallboard primed with 1411 R-Bond Liquid.Surface Preparation: Substrates must be structurally sound, dry,flat, level and free of any and all substances (dust, adhesive residues,paint, sealers, etc.) that will interfere with the bonding capability of thisproduct. Wood underlayments must be CANPLY/APA rated exteriorgrade plywood or similar and of the appropriate thickness with theappropriate structural support to receive a tile installation.General: Ensure substrate, tile andR-Mosaic are acclimated to thesame temperature and humidity levelexpected during normal use (between18–35°C / 65–95°F with a relativehumidity (RH) of no greater than65%) a minimum of 48 hours prior toinstallation. These conditions shouldGlass, Marble and CeramicMosaic Tilesbe maintained throughout the life of the installation. Do not usethis product for installations that will be exposed to prolonged waterimmersion. Do not install over moving or expansion joints. Installationover plywood is permitted up to light commercial traffic loads. AllowR-Mosaic to cure for up to 24 hours before grouting.Physical Characteristics (21°C / 70°F, RH 50%):Pot Life: Approximately 2.5 hoursOpen Time: Approximately 25 minutesWorking Time: 15 minutesInitial Set Time: >6 hoursFinal Set Time: 9–15 hoursFull Cure: 28 daysShelf life: One year in unopened packagingwhen stored in a cool, dry areaApplication and Installation: Pour 0.32–0.34 U.S. gallon (1.2–1.3 litres)of water into a clean mixing container and gradually add 10 lbs. (4.5 kg)of powder. When installing over plywood mix 2-parts 1411 R-Bondwith 1–part water and then mix 0.36–0.37 U.S. gallon (1.4 litres) of thediluted 1411 R-Bond with 10 lbs. of R-Mosaic. Using a slow speed drill(300 rpm), mix slowly to a smooth, creamy consistency. Wait 10 minutesthen mix again to ensure product is completely mixed. Do not add moreliquid than is recommended as this will change the characteristicsof the product. Only mix as much material as can be applied within20–30 minutes.Apply R-Mosaic to the substrate using the appropriate trowel andspreading in a single direction. With the flat side of the trowel, alsoapply R-Mosaic to the back side of each mosaic tile sheet just beforeplacement of the sheet into the mortar. The amount oftime you have to place the tiles before the mortarbegins to skin over will vary with temperature andhumidity levels. If the mortar skins over, scrape themortar off the substrate and re-apply fresh mortar.TILE TYPE TROWEL SIZE ITEM # COVERAGE3/16 in. x 5/32 in. 10115 / 4971549917enviro friendly20–25 sq. ft. (1.9–2.3 m 2 )per 10 lbs.Roberts Company Canada Ltd. • Bramalea, Ontario L6T 1A7 • (800) 840-9422 • www.robertsconsolidated.com 1

Application and Installation (continued):Use a grout float to gently beat the tiles to ensuretiles are seated into the mortar properly and thesurface of the mosaic sheet has a flat surface.Ensure grout joints are aligned then allow the mortarto harden for 20–60 minutes. Remove any excessmortar from joint areas and face of the tiles while themortar is still fresh.Once the mortar has hardened enough dampen theface sheets and remove the paper. Allow to cure24 hours before grouting.Clean Up: With water while fresh.Refer to www.robertsconsolidated.com, materialsafety data sheet, product data sheet and industry standards prior toinstallation for additional information.Limited Warranty: Buyer assumes all risk of use, handling and storageof product not in strict accordance with the label, printed literature andindustry standards. This limited warranty excludes all other expressor implied warranties including the warranties of merchantability orfitness for a particular use or purpose. Any implied warranties arisingby operation of law are limited to one year. Roberts will not be liablefor any incidental or consequential damages. Some provinces do notallow these limitations or exclusions, therefore they may not apply. Thiswarranty gives you specific legal rights and you may also have otherrights which vary from province to province.Available Sizes:SIZE PRODUCT # UPC25 lb. (11.3 kg) Bag 9419RB25 07537894192710 lb. (4.5 kg) Pail 9419RB10 075378941910WARNING: EXISTING FLOORING AND ADHESIVES MAY CONTAIN ASBESTOS. Unless you have confirmation that the existing flooringsystem is not asbestos containing, do not sand, dry sweep, dry scrape, abrade, drill, saw, bead blast, mechanically chip or pulverizeexisting flooring or adhesive without taking all appropriate precautions. Refer to local, state and federal guidelines for treatment andremoval of these products. You may also refer to the Resilient Floor Covering Institute’s “Recommended Work Practices for Removalof Resilient Floor Coverings.”EXISTING PAINT MAY CONTAIN LEAD. Unless you have confirmation that the existing paint is not lead containing, do not sand,dry sweep, dry scrape, abrade, drill, saw, bead blast, mechanically chip or pulverize existing paint without taking all appropriateprecautions. Refer to local, state and federal guidelines for treatment and removal of lead containing paint. You may also refer towww.epa.gov/lead.Roberts Company Canada Ltd. • Bramalea, Ontario L6T 1A7 • (800) 840-9422 • www.robertsconsolidated.com 2S0711_6564