Solutions for IDY production - Oerlikon Barmag - Oerlikon Textile

Solutions for IDY production - Oerlikon Barmag - Oerlikon Textile

Solutions for IDY production - Oerlikon Barmag - Oerlikon Textile

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Godets<br />

<strong>Oerlikon</strong> <strong>Barmag</strong> godets are custom-developed components <strong>for</strong> manmade fiber <strong>production</strong>. Continual<br />

innovations in the areas of design, process, and safety fulfill the ever increasing demands of ever faster<br />

processes and higher denier processes. Our godet families are renowned <strong>for</strong> their countless productive<br />

details. Their technological properties make it possible to achieve outstanding results in a huge variety<br />

of processes.<br />

High productivity and competitiveness are ensured thanks to<br />

the following basic requirements:<br />

- Robust design;<br />

- Achievable high process speeds;<br />

- Low-energy consumption <strong>for</strong> HF godets;<br />

- Reduced maintenance times;<br />

This all makes the <strong>Oerlikon</strong> <strong>Barmag</strong> godet family the<br />

suitable choice <strong>for</strong> all manmade fiber processes.<br />

Cold Rolls<br />

With the increasing amount of yarn ends per position, a<br />

smooth yarn path is becoming more and more important. To<br />

ensure a proper pretension of the yarn, the <strong>Oerlikon</strong> <strong>Barmag</strong><br />

take-up <strong>for</strong> more than 6 ends uses a cold roll duo with<br />

220mm diameter.<br />

HF godets<br />

To fulfill the special demands made on godets in industrial<br />

yarn spinning processes – significant drawing and shrinkage<br />

<strong>for</strong>ces plus utmost uni<strong>for</strong>m temperature profiles – our godets<br />

have been optimized both <strong>for</strong> conventional industrial yarn<br />

32 <strong>IDY</strong> solutions – <strong>Oerlikon</strong> <strong>Barmag</strong><br />

processes and HMLS processes. The modular godet series<br />

is tailored to the latest industrial yarn processes and covers<br />

all possible product ranges up to 24 ends or a denier range<br />

up to 18,000 den per position. With these components, every<br />

take-up is tailored to the customer’s demands. High-speed<br />

bearings with long service lives, using the Barolub lubrication<br />

system, and low power consumption are further benefits.<br />

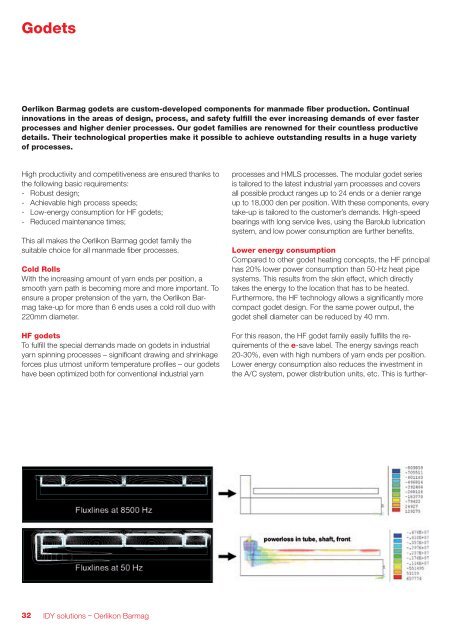

Lower energy consumption<br />

Compared to other godet heating concepts, the HF principal<br />

has 20% lower power consumption than 50-Hz heat pipe<br />

systems. This results from the skin effect, which directly<br />

takes the energy to the location that has to be heated.<br />

Furthermore, the HF technology allows a significantly more<br />

compact godet design. For the same power output, the<br />

godet shell diameter can be reduced by 40 mm.<br />

For this reason, the HF godet family easily fulfills the requirements<br />

of the e-save label. The energy savings reach<br />

20-30%, even with high numbers of yarn ends per position.<br />

Lower energy consumption also reduces the investment in<br />

the A/C system, power distribution units, etc. This is further-