Solutions for IDY production - Oerlikon Barmag - Oerlikon Textile

Solutions for IDY production - Oerlikon Barmag - Oerlikon Textile

Solutions for IDY production - Oerlikon Barmag - Oerlikon Textile

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Efficient operating<br />

The extended parking time diameter up to 210 mm allows<br />

more relaxed doffing, as the time window in which doffing<br />

has to be carried out has been considerably expanded. In<br />

the development of the new ACW: the designers have also<br />

taken the operator into consideration; the noise level has<br />

been significantly reduced with the BIROTOR / multi stroke<br />

traverse motion unit (MST).<br />

The semi-automatic string-up device simplifies the stringup<br />

process <strong>for</strong> the operator, hence improving efficiency by<br />

ensuring a fast and reliable string-up.<br />

Cost advantages<br />

The ACW winder series designed <strong>for</strong> <strong>IDY</strong> offer cost competitive<br />

<strong>production</strong> by supplying en<strong>for</strong>ced components <strong>for</strong> <strong>IDY</strong><br />

products up to 6,000 den per end or up to 16,000 den per<br />

winder. The robust design leads to:<br />

- High reliability;<br />

- Low maintenance requirements;<br />

- Long lifetime;<br />

- High utilization rate.<br />

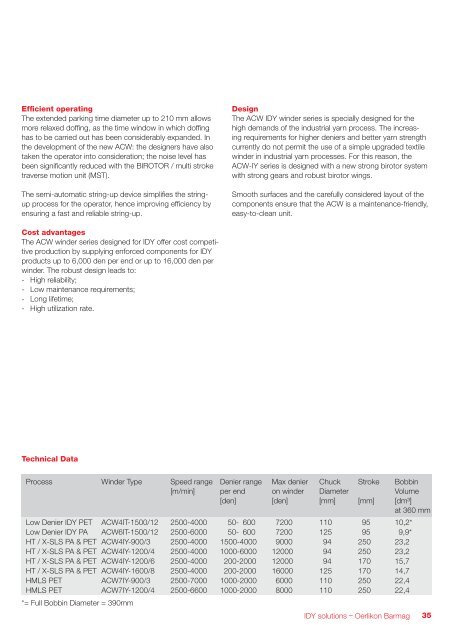

Technical Data<br />

Process Winder Type Speed range<br />

[m/min]<br />

Design<br />

The ACW <strong>IDY</strong> winder series is specially designed <strong>for</strong> the<br />

high demands of the industrial yarn process. The increasing<br />

requirements <strong>for</strong> higher deniers and better yarn strength<br />

currently do not permit the use of a simple upgraded textile<br />

winder in industrial yarn processes. For this reason, the<br />

ACW-IY series is designed with a new strong birotor system<br />

with strong gears and robust birotor wings.<br />

Smooth surfaces and the carefully considered layout of the<br />

components ensure that the ACW is a maintenance-friendly,<br />

easy-to-clean unit.<br />

Denier range<br />

per end<br />

[den]<br />

Max denier<br />

on winder<br />

[den]<br />

Chuck<br />

Diameter<br />

[mm]<br />

Stroke<br />

[mm]<br />

<strong>IDY</strong> solutions – <strong>Oerlikon</strong> <strong>Barmag</strong><br />

Bobbin<br />

Volume<br />

[dm³]<br />

at 360 mm<br />

Low Denier <strong>IDY</strong> PET ACW4IT-1500/12 2500-4000 50- 600 7200 110 95 10,2*<br />

Low Denier <strong>IDY</strong> PA ACW6IT-1500/12 2500-6000 50- 600 7200 125 95 9,9*<br />

HT / X-SLS PA & PET ACW4IY-900/3 2500-4000 1500-4000 9000 94 250 23,2<br />

HT / X-SLS PA & PET ACW4IY-1200/4 2500-4000 1000-6000 12000 94 250 23,2<br />

HT / X-SLS PA & PET ACW4IY-1200/6 2500-4000 200-2000 12000 94 170 15,7<br />

HT / X-SLS PA & PET ACW4IY-1600/8 2500-4000 200-2000 16000 125 170 14,7<br />

HMLS PET ACW7IY-900/3 2500-7000 1000-2000 6000 110 250 22,4<br />

HMLS PET ACW7IY-1200/4 2500-6600 1000-2000 8000 110 250 22,4<br />

*= Full Bobbin Diameter = 390mm<br />

35