Solutions for IDY production - Oerlikon Barmag - Oerlikon Textile

Solutions for IDY production - Oerlikon Barmag - Oerlikon Textile

Solutions for IDY production - Oerlikon Barmag - Oerlikon Textile

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

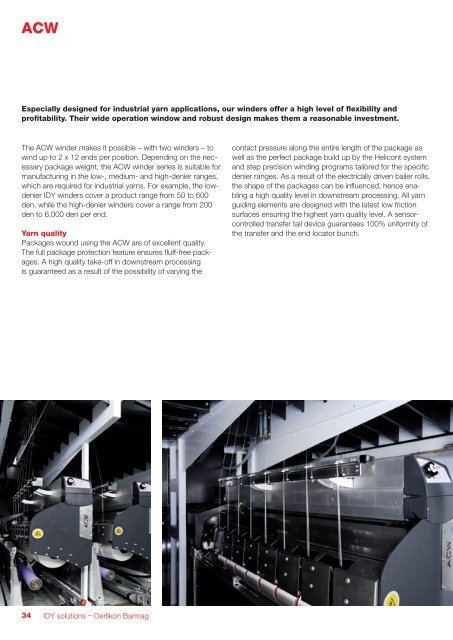

ACW<br />

Especially designed <strong>for</strong> industrial yarn applications, our winders offer a high level of flexibility and<br />

profitability. Their wide operation window and robust design makes them a reasonable investment.<br />

The ACW winder makes it possible – with two winders – to<br />

wind up to 2 x 12 ends per position. Depending on the necessary<br />

package weight, the ACW winder series is suitable <strong>for</strong><br />

manufacturing in the low-, medium- and high-denier ranges,<br />

which are required <strong>for</strong> industrial yarns. For example, the lowdenier<br />

<strong>IDY</strong> winders cover a product range from 50 to 600<br />

den, while the high-denier winders cover a range from 200<br />

den to 6,000 den per end.<br />

Yarn quality<br />

Packages wound using the ACW are of excellent quality.<br />

The full package protection feature ensures fluff-free packages.<br />

A high quality take-off in downstream processing<br />

is guaranteed as a result of the possibility of varying the<br />

34 <strong>IDY</strong> solutions – <strong>Oerlikon</strong> <strong>Barmag</strong><br />

contact pressure along the entire length of the package as<br />

well as the perfect package build up by the Helicont system<br />

and step precision winding programs tailored <strong>for</strong> the specific<br />

denier ranges. As a result of the electrically driven bailer rolls,<br />

the shape of the packages can be influenced, hence enabling<br />

a high quality level in downstream processing. All yarn<br />

guiding elements are designed with the latest low friction<br />

surfaces ensuring the highest yarn quality level. A sensorcontrolled<br />

transfer tail device guarantees 100% uni<strong>for</strong>mity of<br />

the transfer and the end locator bunch.