MALTING QUALITY TRAITS - Canadian Malting Barley Technical ...

MALTING QUALITY TRAITS - Canadian Malting Barley Technical ...

MALTING QUALITY TRAITS - Canadian Malting Barley Technical ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

5 Brewing<br />

Whirl<br />

Pool<br />

Hot<br />

Wort<br />

Tank<br />

Wort<br />

Cooler<br />

Shipping<br />

Weigh<br />

Hopper<br />

Brew<br />

Kettle<br />

Ware<br />

House<br />

Malt Storage<br />

Cereal Storage<br />

Malt<br />

Mill<br />

Lauter<br />

Tun<br />

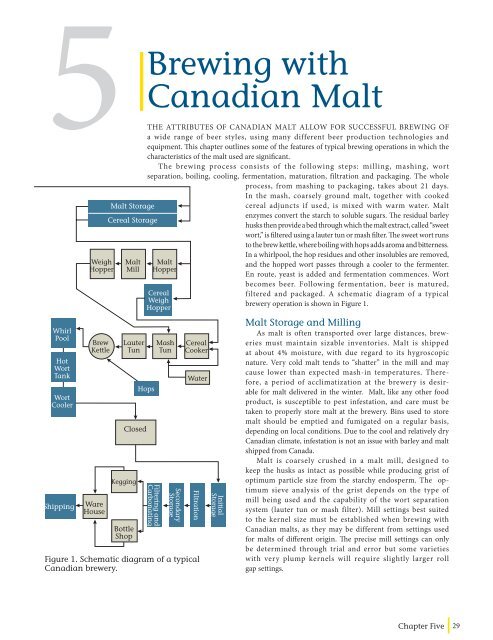

Figure 1. Schematic diagram of a typical<br />

<strong>Canadian</strong> brewery.<br />

with<br />

<strong>Canadian</strong> Malt<br />

THE ATTRIBUTES OF CANADIAN MALT ALLOW FOR SUCCESSFUL BREWING OF<br />

a wide range of beer styles, using many different beer production technologies and<br />

equipment. This chapter outlines some of the features of typical brewing operations in which the<br />

characteristics of the malt used are significant.<br />

The brewing process consists of the following steps: milling, mashing, wort<br />

separation, boiling, cooling, fermentation, maturation, filtration and packaging. The whole<br />

process, from mashing to packaging, takes about 21 days.<br />

Malt<br />

Hopper<br />

Cereal<br />

Weigh<br />

Hopper<br />

Hops<br />

Closed<br />

Kegging<br />

Bottle<br />

Shop<br />

Filtering and<br />

Carbonating<br />

Mash<br />

Tun<br />

Secondary<br />

Storage<br />

Cereal<br />

Cooker<br />

Water<br />

Filtration<br />

Initial<br />

Storage<br />

In the mash, coarsely ground malt, together with cooked<br />

cereal adjuncts if used, is mixed with warm water. Malt<br />

enzymes convert the starch to soluble sugars. The residual barley<br />

husks then provide a bed through which the malt extract, called “sweet<br />

wort,” is filtered using a lauter tun or mash filter. The sweet wort runs<br />

to the brew kettle, where boiling with hops adds aroma and bitterness.<br />

In a whirlpool, the hop residues and other insolubles are removed,<br />

and the hopped wort passes through a cooler to the fermenter.<br />

En route, yeast is added and fermentation commences. Wort<br />

becomes beer. Following fermentation, beer is matured,<br />

filtered and packaged. A schematic diagram of a typical<br />

brewery operation is shown in Figure 1.<br />

Malt Storage and Milling<br />

As malt is often transported over large distances, breweries<br />

must maintain sizable inventories. Malt is shipped<br />

at about 4% moisture, with due regard to its hygroscopic<br />

nature. Very cold malt tends to “shatter” in the mill and may<br />

cause lower than expected mash-in temperatures. Therefore,<br />

a period of acclimatization at the brewery is desirable<br />

for malt delivered in the winter. Malt, like any other food<br />

product, is susceptible to pest infestation, and care must be<br />

taken to properly store malt at the brewery. Bins used to store<br />

malt should be emptied and fumigated on a regular basis,<br />

depending on local conditions. Due to the cool and relatively dry<br />

<strong>Canadian</strong> climate, infestation is not an issue with barley and malt<br />

shipped from Canada.<br />

Malt is coarsely crushed in a malt mill, designed to<br />

keep the husks as intact as possible while producing grist of<br />

optimum particle size from the starchy endosperm. The optimum<br />

sieve analysis of the grist depends on the type of<br />

mill being used and the capability of the wort separation<br />

system (lauter tun or mash filter). Mill settings best suited<br />

to the kernel size must be established when brewing with<br />

<strong>Canadian</strong> malts, as they may be different from settings used<br />

for malts of different origin. The precise mill settings can only<br />

be determined through trial and error but some varieties<br />

with very plump kernels will require slightly larger roll<br />

gap settings.<br />

Chapter Five<br />

29