- Page 2 and 3: ISBN:0-8247-0491-6 This book is pri

- Page 4 and 5: iv Preface biodegrade rapidly and h

- Page 7 and 8: Contents Preface iii Contributors i

- Page 9 and 10: Contributors Shoaib Arif Home Care,

- Page 11 and 12: 1 Alkyl Polyglycosides KARL SCHMID

- Page 13 and 14: FIG. 2 Summary of methods for the s

- Page 15 and 16: Alkyl Polyglycosides 5 kernel oil f

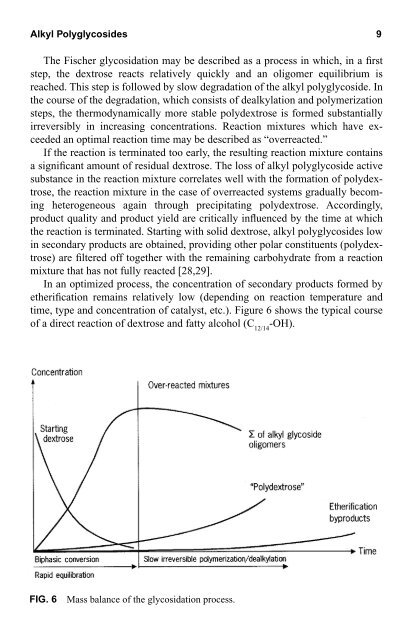

- Page 17: Alkyl Polyglycosides 7 synthesis an

- Page 21 and 22: Alkyl Polyglycosides 11 In case of

- Page 23 and 24: Alkyl Polyglycosides 13 TABLE 1 Com

- Page 25 and 26: Alkyl Polyglycosides 15 dencies, nu

- Page 27 and 28: Alkyl Polyglycosides 17 FIG. 13 Pha

- Page 29 and 30: Alkyl Polyglycosides 19 is at its l

- Page 31 and 32: Alkyl Polyglycosides 21 The lamella

- Page 33 and 34: FIG. 17 Dishwashing performance of

- Page 35 and 36: FIG. 19 Dishwashing performance of

- Page 37 and 38: Alkyl Polyglycosides 27 FIG. 22 Muc

- Page 39 and 40: Alkyl Polyglycosides 29 FIG. 23 Dis

- Page 41 and 42: Alkyl Polyglycosides 31 polyglycosi

- Page 43 and 44: Alkyl Polyglycosides 33 ing deterge

- Page 45 and 46: Alkyl Polyglycosides 35 TABLE 6 C 1

- Page 47 and 48: Alkyl Polyglycosides 37 FIG. 28 Per

- Page 49 and 50: Alkyl Polyglycosides 39 1. All-Purp

- Page 51 and 52: Alkyl Polyglycosides 41 FIG. 29 Cle

- Page 53 and 54: Alkyl Polyglycosides 43 TABLE 13 Ge

- Page 55 and 56: Alkyl Polyglycosides 45 alkyl chain

- Page 57 and 58: Alkyl Polyglycosides 47 FIG. 35 Inc

- Page 59 and 60: Alkyl Polyglycosides 49 sides in a

- Page 61 and 62: Alkyl Polyglycosides 51 alkyl polyg

- Page 63 and 64: Alkyl Polyglycosides 53 Of greater

- Page 65 and 66: Alkyl Polyglycosides 55 FIG. 43 Inc

- Page 67 and 68: Alkyl Polyglycosides 57 parting imp

- Page 69 and 70:

Alkyl Polyglycosides 59 move scales

- Page 71 and 72:

Alkyl Polyglycosides 61 the skin is

- Page 73 and 74:

Alkyl Polyglycosides 63 TABLE 20 Al

- Page 75 and 76:

Alkyl Polyglycosides 65 FIG. 45 Bio

- Page 77 and 78:

Alkyl Polyglycosides 67 34. N Busch

- Page 79:

Alkyl Polyglycosides 69 100. Henkel

- Page 82 and 83:

72 Arif and Friedli esters as worka

- Page 84 and 85:

74 Arif and Friedli FIG. 3 CMC of C

- Page 86 and 87:

76 Arif and Friedli TABLE 1 Deterge

- Page 88 and 89:

78 Arif and Friedli TABLE 3 Effect

- Page 90 and 91:

80 Arif and Friedli TABLE 6 Correla

- Page 92 and 93:

82 Arif and Friedli TABLE 9 Dye Tra

- Page 94 and 95:

84 Arif and Friedli TABLE 15 Fine-F

- Page 96 and 97:

86 Arif and Friedli The monoethanol

- Page 98 and 99:

88 Arif and Friedli TABLE 20 Averag

- Page 100 and 101:

90 Arif and Friedli TABLE 26 Heavy-

- Page 102 and 103:

92 Arif and Friedli FIG. 8 Synthesi

- Page 104 and 105:

94 Arif and Friedli Amphoterics/bet

- Page 106 and 107:

96 Arif and Friedli TABLE 32 Laundr

- Page 108 and 109:

98 Arif and Friedli TABLE 38 Base B

- Page 110 and 111:

100 Arif and Friedli alkaline produ

- Page 112 and 113:

102 Arif and Friedli TABLE 50 Tub a

- Page 114 and 115:

104 Arif and Friedli TABLE 55 Glass

- Page 116 and 117:

106 Arif and Friedli well for thick

- Page 118 and 119:

108 Arif and Friedli FIG. 12 Amine

- Page 120 and 121:

110 Arif and Friedli TABLE 65 Dye T

- Page 122 and 123:

112 Arif and Friedli FIG. 13 Specia

- Page 124 and 125:

114 Arif and Friedli complete biode

- Page 127 and 128:

3 Sulfonated Methyl Esters TERRI GE

- Page 129 and 130:

Sulfonated Methyl Esters 119 SMEs m

- Page 131 and 132:

Sulfonated Methyl Esters 121 Kamesh

- Page 133 and 134:

Sulfonated Methyl Esters 123 FIG. 5

- Page 135 and 136:

Sulfonated Methyl Esters 125 FIG. 8

- Page 137 and 138:

Sulfonated Methyl Esters 127 FIG. 1

- Page 139 and 140:

Sulfonated Methyl Esters 129 TABLE

- Page 141 and 142:

Sulfonated Methyl Esters 131 soft w

- Page 143 and 144:

Sulfonated Methyl Esters 133 cotton

- Page 145 and 146:

Sulfonated Methyl Esters 135 factan

- Page 147 and 148:

Sulfonated Methyl Esters 137 FIG. 1

- Page 149 and 150:

Sulfonated Methyl Esters 139 ethoxy

- Page 151 and 152:

Sulfonated Methyl Esters 141 FIG. 1

- Page 153:

Sulfonated Methyl Esters 143 35. Pr

- Page 156 and 157:

146 Quencer and Loughney Traditiona

- Page 158 and 159:

148 Quencer and Loughney FIG. 2 Pro

- Page 160 and 161:

150 Quencer and Loughney FIG. 3 Com

- Page 162 and 163:

152 Quencer and Loughney A phase in

- Page 164 and 165:

154 Quencer and Loughney from hydro

- Page 166 and 167:

156 Quencer and Loughney FIG. 8 Mod

- Page 168 and 169:

158 Quencer and Loughney Subsequent

- Page 170 and 171:

160 Quencer and Loughney IV. ENVIRO

- Page 172 and 173:

162 Quencer and Loughney FIG. 12 Pr

- Page 174 and 175:

164 Quencer and Loughney ACKNOWLEDG

- Page 177 and 178:

5 Methyl Ester Ethoxylates MICHAEL

- Page 179 and 180:

Methyl Ester Ethoxylates 169 duces

- Page 181 and 182:

Methyl Ester Ethoxylates 171 B C

- Page 183 and 184:

Methyl Ester Ethoxylates 173 FIG. 4

- Page 185 and 186:

Methyl Ester Ethoxylates 175 FIG. 5

- Page 187 and 188:

Methyl Ester Ethoxylates 177 cohol

- Page 189 and 190:

Methyl Ester Ethoxylates 179 FIG. 8

- Page 191 and 192:

Methyl Ester Ethoxylates 181 FIG. 1

- Page 193 and 194:

Methyl Ester Ethoxylates 183 ably d

- Page 195 and 196:

Methyl Ester Ethoxylates 185 TABLE

- Page 197 and 198:

Methyl Ester Ethoxylates 187 B. C 1

- Page 199 and 200:

Methyl Ester Ethoxylates 189 FIG. 1

- Page 201 and 202:

Methyl Ester Ethoxylates 191 FIG. 2

- Page 203:

Methyl Ester Ethoxylates 193 19. Y

- Page 206 and 207:

196 Crudden and complexing agent. T

- Page 208 and 209:

198 Crudden FIG. 2 Titration of LED

- Page 210 and 211:

200 Crudden FIG. 3 Surface tension

- Page 212 and 213:

202 Crudden FIG. 5 Lather drainage

- Page 214 and 215:

204 Crudden FIG. 7 Calcium chelatio

- Page 216 and 217:

206 Crudden FIG. 10 Influence of co

- Page 218 and 219:

208 Crudden FIG. 12 Draves Wetting

- Page 220 and 221:

210 Crudden Percent Hydrotrope (to

- Page 222 and 223:

212 Crudden TABLE 4 Brightness Gain

- Page 224 and 225:

214 Crudden weight loss % 90 80 70

- Page 226 and 227:

216 Crudden 1. Dermal Irritation Na

- Page 228 and 229:

218 Crudden The results indicate th

- Page 231 and 232:

7 Surfactants for the Prewash Marke

- Page 233 and 234:

Surfactants for the Prewash Market

- Page 235 and 236:

Surfactants for the Prewash Market

- Page 237 and 238:

Surfactants for the Prewash Market

- Page 239 and 240:

Surfactants for the Prewash Market

- Page 241 and 242:

Surfactants for the Prewash Market

- Page 243 and 244:

Surfactants for the Prewash Market

- Page 245 and 246:

Surfactants for the Prewash Market

- Page 247 and 248:

Surfactants for the Prewash Market

- Page 249 and 250:

8 Dry Cleaning Surfactants AL DABES

- Page 251 and 252:

Dry Cleaning Surfactants 241 blend

- Page 253 and 254:

Dry Cleaning Surfactants 243 Progre

- Page 255 and 256:

Dry Cleaning Surfactants 245 3. Pet

- Page 257 and 258:

Dry Cleaning Surfactants 247 with l

- Page 259 and 260:

Dry Cleaning Surfactants 249 Format

- Page 261 and 262:

Dry Cleaning Surfactants 251 equili

- Page 263 and 264:

Dry Cleaning Surfactants 253 black

- Page 265 and 266:

9 Concentrated and Efficient Fabric

- Page 267 and 268:

Concentrated and Efficient Fabric S

- Page 269 and 270:

Concentrated and Efficient Fabric S

- Page 271 and 272:

Concentrated and Efficient Fabric S

- Page 273 and 274:

Concentrated and Efficient Fabric S

- Page 275 and 276:

Concentrated and Efficient Fabric S

- Page 277 and 278:

Concentrated and Efficient Fabric S

- Page 279 and 280:

Concentrated and Efficient Fabric S

- Page 281 and 282:

Concentrated and Efficient Fabric S

- Page 283 and 284:

Concentrated and Efficient Fabric S

- Page 285 and 286:

(a) (b) Concentrated and Efficient

- Page 287 and 288:

Concentrated and Efficient Fabric S

- Page 289 and 290:

Concentrated and Efficient Fabric S

- Page 291 and 292:

Index Acid cleaners, 104-107, 136 A

- Page 293 and 294:

Index 283 Hair conditioner, 255 Har