4.1.1 MOVPE growth and HRXRD characterisation of GaAsSb/InP ...

4.1.1 MOVPE growth and HRXRD characterisation of GaAsSb/InP ...

4.1.1 MOVPE growth and HRXRD characterisation of GaAsSb/InP ...

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

14 Annual Report 2004 - Solid-State Electronics Department<strong>4.1.1</strong> <strong>MOVPE</strong> <strong>growth</strong> <strong>and</strong> <strong>HRXRD</strong> <strong>characterisation</strong> <strong>of</strong> <strong>GaAsSb</strong>/<strong>InP</strong>superlatticeScientist:S. NeumannBackroundThe low b<strong>and</strong>gap material GaAs x Sb 1-x (x < 0.73) forms a type-II staggered heterojunction with <strong>InP</strong>[1]. This characteristic <strong>and</strong> its ultra-high p-type doping capability make this material ideal as thebase layer in <strong>InP</strong>-based heterostructure bipolar transistor (HBT) structures. The ternary III/Vsemiconductor GaAs x Sb 1-x has a solid phase miscibility gap ranging from x = 0.2 to 0.8 [2]. UsingMBE <strong>and</strong> <strong>MOVPE</strong> the metastable <strong>growth</strong> <strong>of</strong> <strong>GaAsSb</strong> lattice matched on <strong>InP</strong> has been demonstrated[2]. The use as base material in <strong>InP</strong> based HBT was first demonstrated in 1996 [3]. A staggeredheterojunction line up enables the use <strong>of</strong> <strong>InP</strong> as emitter <strong>and</strong> collector. Basic double heterostructurebipolar transistor (DHBT) structures can be realized with the advantages <strong>of</strong> low turn-on <strong>and</strong> highbreak down voltages [4]The most challenging step in the <strong>MOVPE</strong> <strong>growth</strong> <strong>of</strong> <strong>InP</strong>/<strong>GaAsSb</strong>/<strong>InP</strong> heterostructures for DHBTapplication is the optimisation <strong>of</strong> the most critical GaAs x Sb 1-x /<strong>InP</strong> heterojunction forming the base<strong>and</strong> emitter layer in a HBT structure. Posibel Sb <strong>and</strong> As segregation <strong>and</strong> desorption results information <strong>of</strong> interlayers which may degrade the performance <strong>of</strong> devices. A <strong>growth</strong> interruptionbetween the GaAs x Sb 1-x base layer <strong>and</strong> the following <strong>InP</strong> emitter layer with group V stabilization <strong>of</strong>the surface leads to Sb contamination <strong>of</strong> the surface <strong>and</strong> to strong segregation <strong>of</strong> the Sb into the <strong>InP</strong>emitter layer [5]. To prevent this effect, a surface stabilization with Sb is impossible. Thestabilization with As as group V element, only, leads also to a possible GaAs interlayer with the outdiffusion <strong>of</strong> Sb at the surface region. Results from molecular beam epitaxie (MBE) indicate the Asto Sb exchange resulting in highly strained <strong>and</strong> degraded interfacial layers [6]. In this work weinvestigated the formation <strong>of</strong> the <strong>GaAsSb</strong>/<strong>InP</strong> interface grown by <strong>MOVPE</strong> using nitrogen as carriergas. Superlattice structures with different <strong>growth</strong> interruptions were realized <strong>and</strong> characterized withhigh resolution x-ray diffraction.Experimental SetupThe experiments were done on semi insulating, exactly oriented (001) <strong>InP</strong> substrate in a AIX 200reactor with RF heating at a substrate temperature <strong>of</strong> T g = 550 °C. Purified nitrogen (N 2 ) as carriergas was used to adjust the reactor pressure <strong>of</strong> p tot = 50 mbar at a total flow <strong>of</strong> Q tot = 3.4 slm.Hydrogen was connected to the source gas line, only. We used a complete non gaseous sourceconfiguration with tertiarybutylphosphine (TBP) / tertiarybutylarsine (TBAs) / trimethylantimony(TMSb) as group V sources, carbon tetrabromide (CBr 4 ) as group IV doping sources <strong>and</strong> the metalorganicsources trimethylindium (TMIn) / triethylgallium (TEGa). The group V to group III ratios(V/III) <strong>and</strong> also the group IV to group III ratios (IV/III) were calculated from the ratio <strong>of</strong> the partialpressures <strong>of</strong> the precursors involved. For the determination <strong>of</strong> the antimony (Sb) concentration inthe partial highly strained <strong>GaAsSb</strong> interlayers high resolution x-ray diffractometry (<strong>HRXRD</strong>) wasused. The integrity <strong>of</strong> the layer structures is proven by <strong>HRXRD</strong> measurements in the vicinity <strong>of</strong> the

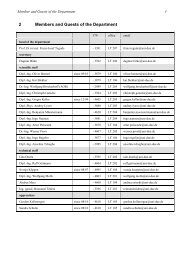

Annual Report 2004 - Solid-State Electronics Department 15004 <strong>and</strong> 002-reflection in a coupled Θ-2Θ-mode using a double monochromator set-up. Therecorded reflection curves were compared to simulations using commercial s<strong>of</strong>tware.Results <strong>and</strong> DiscussionThe <strong>growth</strong> <strong>of</strong> GaAs x Sb 1-x /<strong>InP</strong> superlattice with nitrogen as carrier gas at a <strong>growth</strong> temperature <strong>of</strong>T g = 550°C was investigated. At this <strong>growth</strong> temperature the cracking <strong>of</strong> TBP is incomplete. Weused a V/III ratio <strong>of</strong> V/III=80 <strong>and</strong> a <strong>growth</strong> rate <strong>of</strong> r=5 nm/min to obtain <strong>InP</strong> layers with a mirrorlike surface. The <strong>GaAsSb</strong> layers were grown with a V/III ratio <strong>of</strong> V/III=0.8. A IV/V ratio <strong>of</strong>IV/V=8.4% resulted in a doping level <strong>of</strong> p=4x10 19 cm –3 . Figure 1 shows the high resolution x-raydiffraction curves in the vicinity <strong>of</strong> the(004) - <strong>and</strong> the (002) - reflection <strong>of</strong> aselected <strong>GaAsSb</strong>/<strong>InP</strong> superlattice. Wesimulate both reflections with one set <strong>of</strong>parameters. Equal layers, which weregrown under the same <strong>growth</strong> conditions,are coupled to minimize the number <strong>of</strong>free parameters. This enables us todetermine the composition <strong>and</strong> the layerthickness <strong>of</strong> each layer. The period <strong>of</strong> thefringes can be associated to single layers<strong>of</strong> the superlattice structure. Thedetermined values <strong>of</strong> composition <strong>and</strong>thickness (layer parameter) are in goodagreement with the intended data. Thesimulation <strong>of</strong> the x-ray data <strong>of</strong> this layerstack shows an excellent agreement to themeasured curves. To optimize the emitterbase junction, a TBAs purge between the<strong>GaAsSb</strong>:C base layer <strong>and</strong> the following<strong>InP</strong> layer was included. To force a change<strong>of</strong> the possible interlayer we varied thepurge time from t p = 1 s to t p = 60 s. Weobserved, that after a short purge a stableAs rich GaAs x Sb 1-x interlayer with aaverage composition <strong>of</strong> x ≈ 90 occurs. Asummary <strong>of</strong> the experimental results isgiven in Table 1. The composition isoutside the solid phase miscibility gap forthe used <strong>growth</strong> temperature <strong>of</strong>Fig. 6 X-ray recorded <strong>and</strong> simulated reflected T g =550°C. Independent <strong>of</strong> the purgeintensity in the vicinity <strong>of</strong> <strong>InP</strong> (004) <strong>and</strong> (002)time, we can not observe a trend <strong>of</strong> thereflextion <strong>of</strong> a superlattice structure (10 x 6 nm <strong>InP</strong> /composition or thickness <strong>of</strong> this31 nm GaAs 0.46 Sb 0.54 grown with 1 s As purge at the<strong>growth</strong> interruption. An optimum agreement is interlayer which has an average thicknessobtained for a 0.9 nm thick GaAs interlayer.<strong>of</strong> t interlayer = 7 Å.

16 Annual Report 2004 - Solid-State Electronics DepartmentTable 1:Probe Growth interruption Composition Interlayer thicknessM3148 1s GaAs 0.95 Sb 0.05 0.9 nmM2990 5 s GaAs 1.0 Sb 0.0 0.3 nmM3076 10 s GaAs 0.86 Sb 0.14 0.4 nmM3077 30 s GaAs 0.89 Sb 0.11 0.8 nmM3078 60 s GaAs 0.91 Sb 0.09 0.6 nmSimulation results <strong>of</strong> the interface composition <strong>and</strong> thickness between <strong>GaAsSb</strong> <strong>and</strong><strong>InP</strong> heterostructuresThese results were confirmed independent by reflectance anisotropy (RA) spectroscopy <strong>and</strong> lowenergyelectron diffraction (LEED) [7]. The As terminated surface lead to a typical GaAsreconstructed surface. Growth <strong>of</strong> <strong>GaAsSb</strong> with a t p =10 s, TBAs stabilized <strong>growth</strong> interruption leadto similar results [8]. A fast change in the RA spectrum could be observed resulting in a 0.76 nmthick GaAs interlayer. All grown superlattic shown a mirror like surface <strong>and</strong> the <strong>HRXRD</strong>measurement prove the high crystal quality. To prevent the critical GaAs x Sb 1-x /<strong>InP</strong> heterojunctionfor possible contamination a short <strong>growth</strong> interruptions is preferable.ConclusionA novel <strong>growth</strong> method for the fabrication <strong>of</strong> <strong>GaAsSb</strong>/<strong>InP</strong> heterostructures using nitrogen as carriergas has been elaborated. It has been demonstrated that the segregations <strong>of</strong> Sb is controllable. Toprevent a segration <strong>of</strong> Sb in following layers an As purge after the <strong>growth</strong> <strong>of</strong> GaAs x Sb 1-x isnecessary. This forms a thin GaAs like interlayer between GaAs x Sb 1-x <strong>and</strong> the following layer.References:[1] M. Peter, N. Herres, F. Fuchs, K. Winkler, K.-H. Bachem, J. Wagner;“ “ , Appl. Phys. Lett, Vol. 74(3), 1999[2] M. J. Cherng, R. M. Cohen, G. B. Stringfellow;” ”, J. <strong>of</strong> Electronic Materials, Vol. 13, No. 5, 1984[3] R. Bhat, W-P. Hong, C. Caneau, M. A. Koza, C-K. Nguyen, S. Goswami;” “, Appl. Phys. Lett, Vol.68 (7), 1996[4] C. R. Bolognesi, N. Matine, X.G. Xu, G. Soerensen, S. Watkins;” “, Microelectronics Reliability, 39(1999) 1833-1838[5] C.X. Wang, O.J. Pitts, S.P. Watkins;” “, J. Crystal Growth,Vol. 248, 2003[6] R. Kaspi;”Compositional abruptness at the InAs-GaSb interface: optimizing <strong>growth</strong> by using the Sbdesorbtion signatur“,J. Crystal Growth, Vol. 201/202, 1999[7] Z. Kollonitsch_, K. Möller, F. Willig, T. Hannappel ;”Reconstructions <strong>of</strong> <strong>MOVPE</strong>-prepared group-Vrich<strong>GaAsSb</strong>(1 0 0) surfaces“,Journal <strong>of</strong> Crystal Growth, Vol. 272, 2004[8] O.J. Pitts, S.P. Watkins, C.X. Wang;”RDS characterization <strong>of</strong> <strong>GaAsSb</strong> <strong>and</strong> GaSb grown by <strong>MOVPE</strong>“,J. Crystal Growth,Vol 248, 2003