Q2 - Cessna

Q2 - Cessna

Q2 - Cessna

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

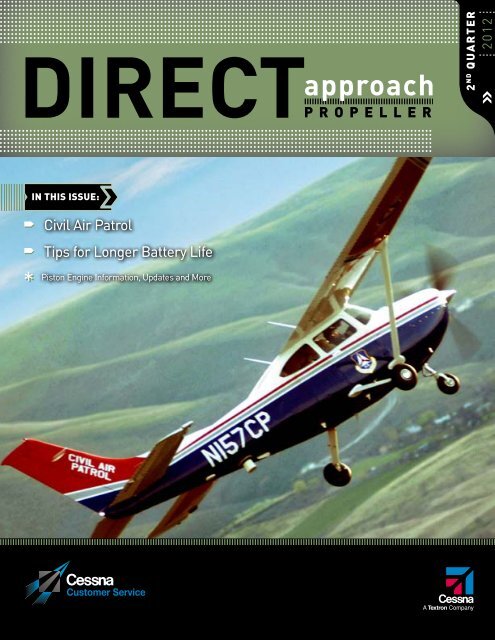

CAP Con’t“The ugly memories were when Ihad to call a family and say, ‘I’msorry we couldn’t find them,’ ”he says. A search last summerended much better, with thespotting of two hikers lost for 48hours on the Upper Peninsula.“These people would not be here,their daughter would be anorphan, if not for what ourvolunteers did that weekend.”Disasters bring the CAP out innumbers. In recent years,volunteers from near and farworked floods in the Midwest,hurricanes, and the oil spill inthe Gulf.Over three months in 2010,50-plus CAP aircraft flew over1,000 missions totaling nearly2,400 flight hours during theDeepwater Horizon spill. Crewsfrom across the country rotatedin to perform reconnaissance,taking aerial photos that helpedtrack the oil spill and progresscontaining it.When Hurricane Ike hit Texas in2008, CAP crews took 40,000photos and made maps ofdamage for the state of Texasand FEMA.“If we are not doing it, it’sgoing to be the Coast Guard, orthe Army with helicopters, orthe Air Force with their jets,”Vazquez says. “It’s going to cost10 times as much for them todo it. We are freeing the militaryto do other things, and we savethe taxpayers millions.”Providing Needed Toolsand TrainingWhen CAP picks up a <strong>Cessna</strong>from the factory, the aircraftis ready to take its place on theline. A customized radio suiteand other special equipmenthave been installed. Specialsearch and rescue software hasbeen added to the G1000avionics. And the plane hasbeen outfitted in CAP red,white and blue.“One of the best parts is thefactory training at Independence,”Smith says. “Everyonewho comes out says it’s the besttraining they’ve ever received,including Air Force pilots.”training for educators, includingorientation flights. Schools haveadopted their textbooks, and CAPdeveloped Science, Technology,Engineering and Math (STEM)national curricula forkindergarten through college.The cadet programs are intertwinedwith aerospace education.Serving more than 26,500 cadetsages 12 to 20, the programteaches leadership, aerospace,fitness and character development.“We are a youth programthat is more heavily accentedtoward leadership,” Vazquez says.Cadets progress as they learnabout aviation, space andtechnology. They take orientationflights in powered aircraft andgliders, study model rocketryand attend summer camps.“I learned a lot about leadershipand those skills translated intoevery job that I’ve held,” Burkesays. “The cadet review boardswere more difficult than any jobinterview I had. The goal is forthem to be leaders wherever theyend up, whether in the military,in government or in business.”The success of the nationalcadet program is measurable,providing about 10 percent ofeach U.S. Air Force Academyclass. In addition, cadets who’veattained a certain level can entermost service branches at ahigher pay grade. Success comesin more basic ways, too.Each summer at <strong>Cessna</strong>’sIndependence factory,cadets learn the nuts, boltsand rivets of aircraftproduction through aprogram in which hundredsapply and about 20 areselected. “They come outand we assign themmentors,” says Terry Clark,general manager at theplant. “They get to work onthe production line with thementors and help buildairplanes.”“We keep kids off the street andteach them to stay in school,be a good person and be a goodcitizen,” says Smith, sharing hiscolleague Virginia Keller’sconviction that, “with our searchand rescue mission, we saveabout 100 lives on a yearlybasis, and we probably savethat many lives in our cadetprogram on a daily basis.”Aerospace Training andYouth LeadershipTeaching the public about aviationwas a goal starting in the1940s, and has been updated forthe space age and beyond.CAP supplies lesson plans,classroom materials, andPLEASE SEE NEXT PAGEpage 4page 5

Ours is RebuiltImproved Ignition Exciterfor the CaravanAt Overhaul PricesTempest Tornado PumpsRebuilt to “new” tolerancesImproved warranty: 2 years - 1200hours (overhauled is 1000 hours)Patented “Wear Indicator Port”Improved bandless design to reducepremature failuresA revolutionary patent-pending LRT oildiverter system is designed to drain oilfrom leaking garlock seals away fromthe pumpClosed front ends prevent the residualoils and solvents which result frompressure washing from entering thedrive mechanism of the pumpTAKING OVERHAULTO THE NEXT LEVELChampion’s CH92015-1 PT6A ExciterHave you ever needed a back-up exciter?Did your maintenance technician travel to where theno-start occurred?If you answered “yes” to either of these questions,consider Champion’s CH92015-1 exciter solution.Operators of the PT6A engines have relied on theChampion CH92015-1 exciter for over 10 years. ManyCaravan operators fly with two exciters installed, one adormant back-up unit.The Caravan’s exciter (10-381550-4) was introduced inthe early 1980s. This exciter utilizes a “spark gap” that isa break-over devise that transfers energy from the exciterto the igniters. The unit has only one “spark gap” thatprovides energy to both output channels. Subsequently,if the spark gap fails, the exciter is not functional andrequires replacement to start the engine. Spark gapshave a limited life and do wear out with continued use.The Champion exciter, with two separate ignitionchannels, is able to offer a lighter weight exciter withbackup redundancy not offered with the competitor’sexciter. The solid state switches that provide the sparkfor the CH92015-1 are designed with the latesttechnology; and the solid state components also donot have a limited life. The unit has FAA-PMA approvalbased on Identicality and it carries an OEM partnumber on the label (3043937-04).Champion CH92015-1 exciter benefits include:Rebuilt Tempest Tornado Pumps are only availablethrough <strong>Cessna</strong> Authorized Service Facilities.Click here for a quote.• Quicker starts (a 3-spark per second solid state ignition system compared with the current 1-spark persecond for 10-381550-4)• 1.2 joules of energy per second to light the engine (compared with .07 joule per second for 10-381550-4)• Tested in 2009 to the current OEM temperature and vibration requirements• Non-HAZMAT exciter, solid state components provide the energy (no spark gap)• Painted with high temperature paint for corrosion protection• 3-year new parts warranty• Competitively priced with a repair/exchange units• Currently offering rebates for competitor’s coresFor more information or to order, please call your <strong>Cessna</strong> Authorized Service Facility. To locate the onenearest you, call 866-777-6150 or 316-261-8063 (international).page6page7www.cessna.com

TIPS FORLONGER BATTERY LIFEMcCauleySelling DirectIn aircraft that sitfor more than oneweek at a time, thebattery will tend toself-discharge dueto inactivity.Just like the muscles in yourbody – if you do not use them,you lose them. Concorde highlyrecommends that the battery bemaintained with a charger thatis voltage regulated with temperaturecompensation, like theBatteryMINDER. Or, if the aircraftis parked outside, with a solarcharger. For maximum life andperformance, these maintainersshould be on 24/7, keeping thebattery in a ready state of charge.Sometimes, but not every time,modern avionics are hot wireddirectly to the battery, bypassingthe Battery Master Switch. Thismay cause a very small parasiticload. In time, though, this conditiontakes a toll on small aircraftbatteries causing them todischarge faster than they wouldby simply self-discharging due totemperature. Lead Acid Batteriesself-discharge at a much higherrate at warm temperatures thanin freezing temperatures.Terminal CorrosionBattery cables and their ringterminals are copper, and allConcorde Batteries havecopper terminals that do notcorrode. Copper alloy terminalsand hardware come with thebattery and provide lowresistance connections.FAA Approved InstallationFAA Aircraft Circular AC 23-27allows you, as the aircraft owner/RG24-15Moperator, to install a ConcordeBattery into your unpressurized<strong>Cessna</strong> aircraft with just alogbook entry. Concorde BatteryCorporation has obtained FAAParts Manufacturing Approvalfor every <strong>Cessna</strong> battery partnumber.RG® VRLA-AGM BatteriesRecombinant Gas (RG ® ) ValveRegulated Lead Acid (VRLA)Batteries or Absorbed Glass Mat(AGM) Batteries have almost replacedthe flooded, or vented, drycharged batteries that need tobe activated, charged and testedbefore being placed in service.RG ® Batteries have plateswrapped in electrolyte-absorbedAGM and packed closely together,with less space between theplates. The reduced electrolyteweight has been replaced withmore lead plates per cell, whichmeans more active material andlower internal resistance forgreater cranking power, alongwith more power for essential oremergency requirements.RG24-16RG-380E/44Erroneously, some pilots believethat higher capacity batteries maybe detrimental to the aircraftsystems. The opposite is true.With a higher capacity battery thestarter, starter contacts, and allassociated electrical equipmentand avionics are taxed lessbecause the systems voltageremains higher and the amperagedraw is lower. Therefore, thehighest capacity battery availablefor your aircraft is the safest andprovides the longest life.Platinum® Series versusStandard BatteriesThere is a difference. Platinum ®Series has more positive andnegative plates per cell than thestandard battery series. Thereby,it has lower internal resistance,for greater cranking power andmore capacity for emergency oressential power.Concorde Battery has been manufacturingmilitary and commercial TSO, FAA-PMAand OEM certified aircraft batteries forover 30 years.McCauley Propeller Systems,(McCauley) under new leadership,announced at Sun ‘n Fun THEY willenter into retail sales.This means customers now have the option ofpurchasing propellers and products directly fromMcCauley, the original equipment manufacturer,or through a McCauley Authorized ServiceFacility.Brad White, McCauley’s Business Leader, stated,“After analyzing the general aviation market andeconomic trends, McCauley has decided toexpand our current distribution strategy intoretail sales.” Domestic or internationalcustomers may call 1-800-621-7767 to placeorders directly with McCauley. White went on tocomment that, “In today’s world with improvedfreight and logistical services, there is no reasonthat a customer should not be able to pick up thephone and order what they need directly fromMcCauley and have it the next day.”Historically, McCauley has operated under adistribution model in which product has onlybeen available through the company’sAuthorized Service Facility network. Movingforward, McCauley will continue to partner withtheir 54 worldwide service center affiliates, butnow will also satisfy customer demand directly.McCauley‘s intention is to ensure that customerscan obtain product as conveniently and quicklyas possible.McCauley has grown its internal sales andcustomer service team to accommodate thischange. “We are reengineering the way we dobusiness to ensure we continue to serve ourcustomers by delivering reliable and high qualityproducts. Selling direct is only one of manychanges contemplated to provide customerswith more reasons to fly McCauley propellers,”said White.All retail sales are covered by the McCauleywarranty. T&C’s are available on the McCauleyweb site at www.mccauley.textron.com. Orders willbe accepted with an approved credit card or moneywire transfer. Warranty will be honored based onthe T&C’s and installation in accordance to FederalAviation Administration requirements.For more information:sales@mccauley.textron.com1-800-621-7767McCauley has been designing and manufacturing high-qualitypropellers for more than 75 years, supporting commercial, generalaviation and defense products with propellers and supportingsystems. McCauley is a division of <strong>Cessna</strong> Aircraft Company, aTextron (NYSE: TXT) Company.page 10page11www.cessna.com

product spotlightCorvalis TTX ®is fast,sleek,gracefuland fullof upgradesWhat do you do with thefastest single-pilot pistonaircraft in production, onewith great ramp appeal,the latest in avionics anda long aviation legacybacking it?<strong>Cessna</strong> Purchases ColumbiaAircraftDerived from a Lancair kit design,the all-composite Columbia 300was certified in 1998 and the400 – basis of the TTX ® – in 2003.Just four years later, wrestlingwith bankruptcy, Columbia Aircraftwas sold to <strong>Cessna</strong>.“We had an opening in our productline that the airplane fit intobelow the small jet category,” saysRichard Ake, Corvalis businessunit team member.In 2009 production moved toChihuahua, Mexico, where Textronhas a facility, and to <strong>Cessna</strong>’sfactory in Independence, Kansas.“Mexico lays-up or puts togetherevery composite part, the fuselageshell, the wing, everything,”says Jesse Martinez, Corvalisoperations process leader. “It’s allshipped to Independence and theairplane is assembled. They addthe engine and the avionics.”After taking over production,<strong>Cessna</strong> began making upgrades:redesigning and controlling thewing production so vortexgenerators weren’t required,relocating and consolidating theoxygen system components,improving the floor structure, andusing more durable paint. “Wedidn’t have to make revolutionarychanges. We got a high-qualityproduct to start with,” Ake says.PLEASE SEE NEXT PAGEPhotos from Chihuahua, Mexico facility.Top left: wing assymbly area. Top right:prime/paint room. Bottom: fuselageassymbly.For <strong>Cessna</strong>, the answer wasclear: Make the Corvalis evenbetter. As production resumes,a host of upgrades and newfeatures will roll out with thenewest model, the TTX ® .Onboard are Garmin G2000touchscreen avionics, acommunications system withvoice and text, lightningdetection, the option of theTKS Flight Into Known Icingsystem plus a more extensivewarranty package. Four plushnew interior schemes areavailable, plus flashy new paintfor an airplane already so sleek“it looks like it’s going fastwhen sitting on the ramp.”With production gearing upthrough summer and intofall in Independence, Kansas,and Chihuahua, Mexico,deliveries are expected toresume in December, and theairplane is sold into the thirdquarter of next year. Startingat Oshkosh, a flashy blackand gold TTX ® will make therounds to announce theairplane’s return.“We are a firm believer in thisproduct. The money we’reinvesting in production facilitiesis a commitment by <strong>Cessna</strong>, notto mention all the improvementswe’ve made,” says Scott Howell,product marketing manager forpiston products.“<strong>Cessna</strong> and Textron stronglysupport the program, and we seethat through our senior leadershipand their commitment tocapital investments to makethe program what it needs tobe,” says Terry Shriner, <strong>Cessna</strong>’sbusiness unit leader for theCorvalis.“It’s the most advancedsingle engine in the airtoday. And we have thesupport and servicenetwork to do right by it.”Terry ShrinerPLEASE SEE NEXT PAGEpage12page 13

Corvalis, con’t.ANTI-ICE SYSTEM -TKS ON CARAVANSThe power plant didn’t escapeupgrades, either. It now comeswith a five-year parts and laborwarranty and a new starter thatimproves turnover.Clark knows the characteristicsof Corvalis owners and the TTX ®target market: “They are pilotswho want to be at 25,000 feetflying 300 knots. They are loyaland love their airplane.”Owner’s Experience:The Cat’s MeowJerry Shapiro, a dentist inSouthhampton, Pa., nearPhiladelphia, purchased a new<strong>Cessna</strong> Skylane in 2005, butthen,” I wanted to go faster,so I bought a Corvalis.”“I tested every aircraft therewas. I wanted to have thefinest,” says Shapiro, who is6’ 2”. “Somebody told me to trythe Corvalis, and it was roomy.It was incredible.”Since 1999, he’s flown hundredsof patients on sightseeing tripsas a way to market his practice.New York City and the JerseyShore are popular jaunts. Twoyears ago, he and a pilot-patienttook three weeks and put theCorvalis’ speed and range towork on a dream trip around theUnited States. “I landed everyplacecool,” he says. Along theway, the Corvalis carried aJerry Shapiroflying in hisCorvalis.beacon allowing patients andothers to track his progress.“I just love the Corvalis. It’sperformed for me. At thehighest airports it was like sealevel. It’s quiet and smooth.Even when it’s turbulent forother aircraft, I don’t feel it inmine,” he says. “My plane isthe cat’s meow.”<strong>Cessna</strong> has refined the preflightoperational test for the TKS anti-ice systeminstalled as an option on some CaravansThe initial revision to the POHsupplement requires thesystem to be operated fourminutes in backup mode topurge the panels. This assuresonly TKS fluid is present in thepanels at departure. The revisionalso requires all panels areobserved for even flow orwetting of the panel activesurface during the purge. Thisfour minute purge is to beperformed after any grounddeicing operations.Experience has shown thatatmospheric moisture, such asrain and ground deice fluid, canpenetrate the active surface ofthe TKS panels and raise thefreezing point of the fluid within.This elevated freezing point canreduce initial system functionin-flight when icing conditionsare encountered.When surface conditions makeit necessary to apply Type II, III,or IV deice fluid to increase holdover time, after the initial deiceand preflight activities arecomplete, the TKS system shouldbe operated in the Backup Modeduring the application. Thisreduces the possibility of grounddeice fluid contamination ofthe panels.The initial revision’s requirementfor even flow may not be metwhen surface temperatures areabove 50 degrees Fahrenheit. Thissystem characteristic is due to thereduction in viscosity of the TKSanti-ice fluid at elevated temperatures.The second revision tothe POH supplement requires thesystem to be operated in BackupMode initially to check operationof the Warn Light and then MaxMode to provide the increase influid volume to more fully wet outthe active area of the panels. Atsurface temperatures above 80degrees Fahrenheit, flow may notbe present on the upper portionof the vertical stabilizer panel andthe outboard upper areas of thewing panels during operation inMax Mode. This is a systemcharacteristic and is not causefor a maintenance action.Corvalis TTX ® by the NumbersMaximum Cruise Speed235 ktasMaximum Range 11,250 nmTakeoff Distance (S.L., ISA, MTOW) 2 1,900 ft.Landing Distance (S.L., ISA, MLW) 2,640 ft.Maximum Operating Altitude 25,000 ft.Maximum Climb Rate (Sea Level) 1,400 fpmAvionics Intrinzic (Garmin G2000)Engine330 hp Continental TSIO-550-CFuel capacity102 gallons145 minute fuel reserves, 45% power @ 25,000 ft.2Distance to 50 feet above the runwayThe flow during high temperatures. Note that only thelower portion of the panel active area has wetted.Once again, this is a system characteristic and does notrepresent a cause for a maintenance action.page page1617www.cessna.com

NEW G1000SOFTWARE RELEASENew G1000 con’t.FOR <strong>Cessna</strong> Nav III AircraftTwo new Service Bulletins upgrading G1000 softwarereleased in April, SEB-34-03 for non-WAASequipped and SEB-34-02 for WAAS equipped<strong>Cessna</strong> G1000 single engine high wing airplanes.The upgrade evens the playing field for both WAASand non-WAAS models. The same system softwareversion, 563.26 is applicable to both G1000 systems.There are several new and exciting features offeredby these upgrades.New for Non-WAAS Equipped Aircraft:Another new feature:You can now load a“future” Jepp Nav Datadatabase while the“current” database is stillbeing used by the G1000.When the effective datefor the “future” databasearrives, the database willbe automatically used byG1000 as the activedatabase.The much-anticipated enablement of “pathways”for operators who have installed Synthetic Vision.Pathways provides a three-dimensional perspectiveview of a selected route of flight, shown as coloredrectangular boxes representing the horizontal andvertical flight path of the active flight plan.Fixed Content Data Logging. This feature providesthe capability of logging flight data to a commaseparated-value(CSV) file on an SD card in the upperMFD slot. Data Logging will automatically storecritical flight and engine data on an SD card (up to16GB). The system will write one data point everysecond as long as power is applied to the G1000system, whether the airplane is flying, or sitting inthe hangar. Another feature of the Garmin DataLogging is the ability to track flights using aprogram that can be downloaded for free from thewww.flygarmin.com website. The program convertsthe flights logged to a csv file on the SD card to KMLfile for viewing in the Google Earth environment.PATHWAYSMFD screen shot showingdatabase synchronizingAlso please note that ifyou are getting the AHRSMV DB (IGRF) out of datemessage, this database isbundled into the Jepp NavData database. You need tofollow the prompts listedin the CRG to load thisdatabase into the G1000.These new features are highlights of what theSEB-34-03 for non-WAAS equipped or SEB-34-02 forWAAS G1000 software upgrade has to offer.MFD screen shot showingthe effective date of afuture Jepp Nav DatabaseNew for WAAS and Non-WAASEquipped Aircraft:A new feature of the 563.26 software is the ability totransfer databases from one -43 database card tothe other one. This will ensure that the data is thesame on the PFD and MFD database card and shouldeliminate issues with database mismatch alerts onthe G1000.PLEASE SEE NEXT PAGEFor more information or to schedule your G1000software upgrade, please contact your <strong>Cessna</strong>Authorized Service Facility. To locate the onenearest you, call 866-777-6150 or 316-261-8063(international).page 18page19www.cessna.com

100 series supplementalinspection documents (sid)published<strong>Cessna</strong> published themaintenance manual temporaryrevisions containing the 100series supplemental inspectionprogram requirements formodels delivered withmaintenance manuals.These inspections were developed fromcondition reports, service difficulty reports anddata gathered from maintenance professionals.When properly performed, these inspectionswill identify issues that will contribute to thereduction in structural load carrying capabilitiesof the airframe.Satellite-Based FlightTracking System That ShowsYour Location at all Times.Around the world, pilots and fleet operatorsare recognizing the safety and benefits offollowing an aircraft’s location and progresson every flight.Spidertracks can send the location, altitude,speed and direction of the aircraft every one ortwo minutes, via the Iridium satellite network tosecure websites. The track is displayed overtopographical and satellite maps.Friends and family can follow the flight in realtime from any PC, anywhere, or by using the freeiSpiderViewer iPhone app.PDF copies of the maintenance manual revisionsare available at <strong>Cessna</strong>.com. Choose Service andthen Customer Access. Sign up for an account -it is a free service that provides access to servicebulletins and letters, as well.The compliance statement as follows allows atwo year grace period for performance of theinitial inspection:The SID inspection times are based on total airframehours or calendar time in service. If aspecific airframe component has been replaced,the component is to be inspected, based on totalcomponent hours or calendar time requirements.However, any attachment structure that was notreplaced when the component was replaced mustbe inspected, based on the total airframe hours orcalendar time requirements. Inspections are dueat the lesser of specified flight hours or calendartime. The inspections must be completed byJune 30, 2014.<strong>Cessna</strong> in partnership with the NationalCenter for Aviation Training in Wichita, Kansas,has developed task-specific, non-destructivetesting training. This training will allowmaintenance technicians to perform the NDTtasks required by the inspection on high timeairframes. General information and contactdetails to take advantage of this training are alsoavailable at the web address above.<strong>Cessna</strong> encourages all owners and operators totake advantage of these inspection programs toassure their airplane is maintained properly andany issues are identified early to minimizerepair expense.Questions, please contact:<strong>Cessna</strong> Customer Care316-517-5800 or 1-800-423-7762Customercare@cessna.textron.comPilots are operating in more than 25 countriesSimple to usePortable – can be moved easilybetween aircraftAutomatic SOS alerting with Spiderwatchactive tracking serviceWeight: less than one poundPosition accuracy within 8’“…The reliability of this system has been proven to be second to none.”Barry Diamand,No installation costsSydney Flight Training CentreClick here for a quote.page 20page21www.cessna.com

Customer ProfileSINCE HESTARTEDFLYING,HE JUSTHASN’TSTOPPEDBob Kean isn’t one of those pilots who lookedskyward at age six and couldn’t imagine goinganywhere but up.But after entering the Army during World War IIhe developed a passion for flying that hasn’tlet up over nearly seven decades. At age 89, heplans to remain in the pilot’s seat as long ashe can fly regularly in the <strong>Cessna</strong> 182H hebought new in 1965.Kean, who will turn 90 in August, is a retired waterutility executive who lives in Oldwick, N.J.Married with five grown boys, each summer hespends a month on Cape Cod in Mass., and eachwinter travels to Florida. Both trips come aboardthe Skylane, which is based at Solberg Airport, a<strong>Cessna</strong> Service Center, when he’s home in NewJersey. All together, he’s accumulated more than4,800 hours at the controls.“He’s a fine gentleman, delightful, intelligent andenthusiastic about flying. He handles the planebeautifully. He’s not afraid of the wind,” says SuzySolberg Nagle, whose family operates SolbergAirport in Readington.Photos courtesy of Nico Kean. Bob Kean shows his granddaughter Schuyler “Sky” Kean his 1965Skylane several years ago when she was six.Off to Flight School and WarKean joined the Army ROTC during college andreported for active duty after graduation in 1943.While at training camp, “I saw these little planescoming in. It intrigued me and I signed up.”“The romance and freedom offlying soon enthralled me,and have stayed with meundiminished ever since.”-Bob KeanFlight school was with the infantry-supportingartillery. He learned to fly in Pittsburg, Kan., from acivilian crop duster, and trained as a field artilleryspotter at Fort Sill, Okla. “Once I got started and feltI could handle it, I was sold,” he says. “You didn’thave any ammunition or means of defense, but youcould call in three battalions of artillery.”PLEASE SEE NEXT PAGEKean shipped out to Europe in late 1944 andserved with an infantry division in Belgium andGermany, with action including the Battle of theBulge and the Bridge at Remagen. “We didn’tthink it terribly dangerous; they didn’t go afterus,” he says of the Messerschmidts and Stukasthat zoomed by in attempts to destroy that keybridge over the Rhine.The Battle of the Bulge had alarming moments.“Our position was overrun at dawn on December16, and we took off one by one, avoiding tracersfrom Tiger tanks rumbling over the side of a hillto our east. It was close to the ground flying. Wedid not operate out of airports. We picked fieldsand sometimes roads, whatever you neededto land a bunch of planes on. Fields with cowsmeant no land mines,” he says, recalling that foryears afterward he could not look at roads andfields without wondering if they could serve as alanding strip.Generally, “we led a pretty good life,” he says ofhis service, which earned him a DistinguishedFlying Cross.Never Stopped FlyingBack in the States, Kean couldn’t stay away fromaviation.“It was hard to give it up. I’d go to little airportsand rent something. I found out if you signed upto the reserves, they let you fly a certain numberof hours on the government – they wanted to keepthese pilots’ skills up,” Kean says.He bought his first plane and then a secondbefore settling on the Skylane he owns to this day.“I think it’s a very safe and stable plane, I like thevisibility and it’s fast enough to get you there.”Paint and regular maintenance aside, Kean hasn’tdone much to his 182 in four-plus decades. “Ifancied up the cabin with good leather about fiveyears ago,” he says. “Otherwise, it is still theperfect plane for me.”Most of his time aloft is for fun. “Flying is one of thefavorite things I do on vacation. I rarely fly straight andlevel. I enjoy practicing various maneuvers andlandings. I go out over islands or watch the whalesnear Provincetown, then I go back and shoot somelandings there.”Trips to Florida, with a son along, are more involved.He’ll stop for the night in Charleston or Hilton Head,S.C., or Savannah, Ga. Then it’s on to North PalmBeach County Airport, where he keeps the plane. Onreturn trips, the nighttime stop is usually atDare County Airport on North Carolina’s OuterBanks – “I stop by there for seafood.”The Skylane winters in Florida. After the season off,when Kean returns to the cockpit, “I act like a newpilot and teach myself how to fly again. If I was onlyflying every couple of months, I think that would bedangerous. It’s a year-to-year thing at this age.I have a belief that you shouldn’t fly unless youfly a lot.”Bob Kean and “Sky” Kean in the cockpit of his 182H.page page2223www.cessna.com

ask THE EXPERTSEXPERTS FROM THE CESSNA SUPPORT TEAMSHARE ADVICE AND SHED LIGHTANSWERSQuestion:Is it permissible to use “you name it” for cleaning or polishing the airplane?Answer<strong>Cessna</strong> publishes tested and approved cleaning and polishing information in the Service orMaintenance Manual, Section 2 (GAMA Manuals) or Chapter 12 and 20 of (ATA Manuals) respectively.Some of the early manuals do not contain a great deal of information; the latest is contained in theSingle Engine Restart manuals. In most of the manuals, section or chapter, there is a Note that states:“Equivalent substitutes may be used.” The only way to determine if a particular substitute may be usedis to learn whether or not the cleaning compound meets the “sandwich corrosion,” “total immersion,”“effects on plastic” and “pH” requirements established in either MIL-PRF 85570 or Mil-C-43616.What is a “Sandwich Corrosion Test?” This is used to evaluate how corrosive the aircraft maintenancechemical is when present between faying surfaces (the sandwich) of aluminum alloys commonly usedfor aircraft structures. The goal is to determine whether aircraft structural aluminum alloy is susceptibleto damage by application of the chemical being tested during routine maintenance operations.You can obtain information from the product manufacturer to see if a specific product meets eitherMIL-PRF 85570 or Mil-C-43616 specifications. If so, they could be consider equivalent substitutes.Otherwise, <strong>Cessna</strong> does not approve the use of other cleaning products.How Tosubmit comments andask THE EXPERTSTHE DIRECT APPROACH IS EMAILED QUARTERLY BY THE CESSNA CUSTOMER SERVICE ORGANIZATION.ASK THE EXPERTS AT:Customercare@cessna.textron.comAnd put Ask An Expert in the subject line<strong>Cessna</strong> hopes to make this a regular feature of this newsletter, but needs help to make it worthy. So if a question hasbeen nagging or you just thought of something that others might be interested in, please Ask An Expert. <strong>Cessna</strong> expertswill do their best to answer all submissions. If the responses do not appear here, an answer will be sent by email.THANKS for taking time to read our publication!We appreciate your readership and will do our best to continue to present you with thelatest piston related news, products & happenings throughout the year.page24www.cessna.com