Model 162 - Cessna

Model 162 - Cessna

Model 162 - Cessna

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

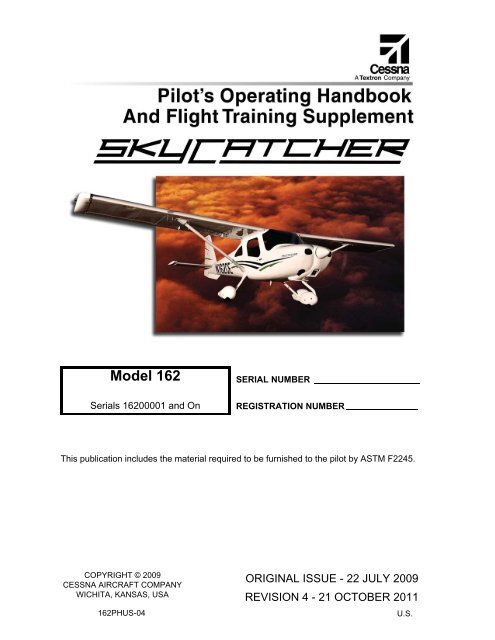

CESSNAMODEL <strong>162</strong>GARMIN G300INTRODUCTIONPILOT’S OPERATING HANDBOOKANDFLIGHT TRAINING SUPPLEMENTCESSNA MODEL <strong>162</strong>SERIALS<strong>162</strong>00001 AND ONORIGINAL ISSUE - 22 JULY 2009REVISION 4 - 21 OCTOBER 2011PART NUMBER: <strong>162</strong>PHUS-04<strong>162</strong>PHUS-04U.S.i/ii

CESSNAMODEL <strong>162</strong>GARMIN G300CONGRATULATIONSINTRODUCTIONCongratulations on your purchase and welcome to <strong>Cessna</strong> ownership!Your <strong>Cessna</strong> has been designed and constructed to give you the mostin performance, value and comfort.This Pilot’s Operating Handbook has been prepared as a guide to helpyou get the most utility from your airplane. It contains information aboutyour airplane’s equipment, operating procedures, performance andsuggested service and care. Please study it carefully and use it as areference.The worldwide <strong>Cessna</strong> Organization and <strong>Cessna</strong> Customer Serviceare prepared to serve you. The following services are offered by each<strong>Cessna</strong> Service Station:• THE CESSNA AIRPLANE WARRANTIES, which provide coveragefor parts and labor, are upheld through <strong>Cessna</strong> Service Stationsworldwide. Warranty provisions and other important information arecontained in the Customer Care Handbook supplied with yourairplane. The Customer Care Card assigned to you at delivery willestablish your eligibility under warranty and should be presented toyour local <strong>Cessna</strong> Service Station at the time of warranty service.• FACTORY TRAINED PERSONNEL to provide you with courteous,expert service.• FACTORY APPROVED SERVICE EQUIPMENT to provide youefficient and accurate workmanship.• A STOCK OF GENUINE CESSNA SERVICE PARTS are availablewhen you need them.• THE LATEST AUTHORITATIVE INFORMATION FOR SERVICINGCESSNA AIRPLANES. <strong>Cessna</strong> Service Stations have all of thecurrent Maintenance Manuals, Illustrated Parts Catalogs andvarious other support publications produced by <strong>Cessna</strong> AircraftCompany.A <strong>Cessna</strong> Service Station locator is available atwww.cessnasupport.com.We urge all <strong>Cessna</strong> owners/operators to utilize the benefits availablewithin the <strong>Cessna</strong> Organization.<strong>162</strong>PHUS-01U.S.iii

INTRODUCTIONPERFORMANCE - SPECIFICATIONSCESSNAMODEL <strong>162</strong>GARMIN G300*SPEED:Maximum at Sea Level . . . . . . . . . . . . . . 118 KNOTS (218.5 km/hr)Cruise, 69% Power at 6000 Feet. . . . . . . 109 KNOTS (201.9 km/hr)CRUISE: Recommended lean mixture with fuel allowance for enginestart, taxi, takeoff, climb and 30 minutes reserve.RANGE:69% Power at 6000 Feet . . . . . . . . . . . . . . . . . . . . . Range - 336 NM24 Gallons Usable Fuel . . . . . . . . . . . . . . . . . . . Time - 3.16 HOURSRATE OF CLIMB AT SEA LEVEL . . . . . . . . . . . 880 FPM (268.2 mpm)SERVICE CEILING . . . . . . . . . . . . . . . . . . . . 14,625 FEET (4457.7 m)TAKEOFF PERFORMANCE AT SEA LEVEL:Ground Roll . . . . . . . . . . . . . . . . . . . . . . . . . . . .640 FEET (195.1 m)Total Distance Over 50 Foot Obstacle . . . . . . . 1138 FEET (346.9 m)LANDING PERFORMANCE AT SEA LEVEL:Ground Roll . . . . . . . . . . . . . . . . . . . . . . . . . . . .671 FEET (204.6 m)Total Distance Over 50 Foot Obstacle . . . . . . .1369 FEET (417.3 m)STALL SPEED:Flaps UP, Power Idle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41 KIASFlaps FULL, Power Idle . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37 KIASNOTE* Speed performance is shown for airplanes not equippedwith the optional wheel fairings. Airplanes equipped withoptional wheel fairings will notice an increase in speeds byapproximately 2 knots. There is a corresponding differencein range, while all other performance figures areunchanged when speed fairings are installed.The above performance figures are based on airplane weights at 1320pounds (598.7 kg), standard atmospheric conditions, level, hardsurfaceddry runways and no wind. They are calculated values derivedfrom flight tests conducted by <strong>Cessna</strong> Aircraft Company under carefullydocumented conditions and will vary with individual airplanes andnumerous factors affecting flight performance.(Continued Next Page)ivU.S.<strong>162</strong>PHUS-03

CESSNAMODEL <strong>162</strong>GARMIN G300INTRODUCTIONPERFORMANCE - SPECIFICATIONS (Continued)MAXIMUM WEIGHT:Ramp. . . . . . . . . . . . . . . . . . . . . . . . . . . . 1324 POUNDS (600.5 kg)Takeoff. . . . . . . . . . . . . . . . . . . . . . . . . . . 1320 POUNDS (598.7 kg)Landing . . . . . . . . . . . . . . . . . . . . . . . . . . 1320 POUNDS (598.7 kg)Maximum Empty Weight . . . . . . . . . . . . . . 894 POUNDS (405.5 kg)STANDARD EMPTY WEIGHT. . . . . . . . . . . . 834 POUNDS (378.3 kg)MAXIMUM USEFUL LOAD . . . . . . . . . . . . . . 490 POUNDS (222.3 kg)BAGGAGE ALLOWANCE . . . . . . . . . . . . . . . . 50 POUNDS (22.68 kg)WING LOADING . . . . . . . . . . . . . . . . . . . 11.0 lbs/sq. ft. (53.7 kg/sq m)POWER LOADING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13.2 lbs/HPFUEL CAPACITY (Usable) . . . . . . . . . . . . . . . . . 24 GALLONS (90.8 l)OIL CAPACITY (Sump) . . . . . . . . . . . . . . . . . . . . . . 5 QUARTS (4.73 I)ENGINE: Teledyne Continental Motors . . . . . . . . . . . . . . . . . . . O-200D100 BHP at 2750 RPMPROPELLER:Fixed Pitch, Diameter . . . . . . . . . . . . . . . . . . . . 67 INCHES (1.70 m)<strong>162</strong>PHUS-04U.S.v

INTRODUCTIONCOVERAGECESSNAMODEL <strong>162</strong>GARMIN G300The Pilot’s Operating Handbook (POH) in the airplane at the time ofdelivery from <strong>Cessna</strong> Aircraft Company contains information applicableto the <strong>Model</strong> <strong>162</strong> airplanes by serial number and registration numbershown on the Title Page. This POH is applicable to <strong>Model</strong> <strong>162</strong>airplanes, Serials <strong>162</strong>00001 and On, equipped with Garmin G300Integrated Cockpit System. All information is based on data available atthe time of publication.This POH consists of nine sections that cover all operational aspects ofa standard equipped airplane. Section 9 contains the supplementswhich provide amended operating limitations, operating procedures,performance data and other necessary information for airplanesconducting special operations for both standard and optionalequipment installed in the airplane.Supplements are individual documents, and may be issued or revisedwithout regard to revision dates which apply to the POH itself. Thesesupplements contain a Log of Effective Pages, which should be used todetermine the status of each supplement.viU.S.<strong>162</strong>PHUS-04

CESSNAMODEL <strong>162</strong>GARMIN G300ORIGINAL ISSUE AND REVISIONSINTRODUCTIONThis Pilot’s Operating Handbook is comprised of the original issue andany subsequent revisions. To make sure that information in this manualis current, the revisions must be incorporated as they are issued. Asrevisions are issued, they will be noted in the Log of Effective Pages.The part number of this manual has also been designed to further aidthe owner/operator in determining the revision level of any POH. Referto the example below for a breakdown:<strong>162</strong> PHUS -00Revision Level (Original Issue)Manual (Pilot’s Operating Handbook, U.S.)(Serials <strong>162</strong>00001 and On)Airplane <strong>Model</strong> - (<strong>162</strong>)It is the responsibility of the owner to maintain this POH in a currentstatus when it is being used for operational purposes. Owners shouldcontact a <strong>Cessna</strong> Service Station whenever the revision status of theirPOH is in question.Revisions are distributed to owners of U.S. Registered aircraftaccording to FAA records at the time of revision issuance, and toInternationally Registered aircraft according to <strong>Cessna</strong> Owner Advisoryrecords at the time of issuance. Revisions should be read carefullyupon receipt and incorporated in this POH.<strong>162</strong>PHUS-00U.S.vii

INTRODUCTIONREVISION FILING INSTRUCTIONSCESSNAMODEL <strong>162</strong>GARMIN G300REGULAR REVISIONSPages to be removed or inserted in the Pilots’ Operating Handbook aredetermined by the Log of Effective Pages located in this section. Thislog contains the page number and revision level for each page withinthe POH. As revisions to the POH occur, the revision level on effectedpages is updated. When two pages display the same page number, thepage with the latest revision level shall be inserted into the POH. Therevision level on the Log Of Effective Pages shall also agree with therevision level of the page in question.TEMPORARY REVISIONSUnder limited circumstances, temporary revisions to the POH may beissued. These temporary revisions are to be filed in the applicablesection in accordance with filing instructions appearing on the first pageof the temporary revision.Temporary Revisions will remain current until they have either beenincorporated into the next POH revision or another temporary revisionhas been issued that supersedes that temporary revision. Eachtemporary revision is issued with a current List of Temporary Revisionsthat is to be inserted opposite the first page of the Log of EffectivePages in the front of the POH and will supersede any previously issuedList of Temporary Revisions. This list is used to track the status oftemporary revisions issued against this POH and is to be removed anddiscarded at the next revision to the POH. Removal of temporaryrevisions from the POH is accomplished per the removal instructionson each temporary revision.viiiU.S.<strong>162</strong>PHUS-00

CESSNAMODEL <strong>162</strong>GARMIN G300IDENTIFYING REVISED MATERIALINTRODUCTIONA bar will extend the full length of deleted, new, or revised text addedon new or previously existing pages. This bar will be located adjacent tothe applicable text in the margin on the left side of the page.A bar in the footer will indicate a revision to the header/footer, a newpage, format or spelling/grammar changes and/or that information hasslipped to or from that page.A bar located adjacent to the figure number in the margin on the leftside of the page will be used to indicate that the figure number only haschanged.An asterisk located at the end of a figure number will be used toindicate that an illustration has been revised or is all new material (Ex:Figure 3-4*).All revised pages will carry the revision number opposite the pagenumber on the applicable page. A list of revisions is located at thebeginning of the Log Of Effective Pages.<strong>162</strong>PHUS-00U.S.ix

INTRODUCTIONWARNINGS, CAUTIONS AND NOTESCESSNAMODEL <strong>162</strong>GARMIN G300Throughout the text, warnings, cautions and notes pertaining toairplane handling and operations are utilized. These adjuncts to the textare used to highlight or emphasize important points.WARNINGOPERATING PROCEDURES, TECHNIQUES, ETC.,WHICH CAN RESULT IN PERSONAL INJURY OR LOSSOF LIFE IF NOT CAREFULLY FOLLOWED.CAUTIONOPERATION PROCEDURES, TECHNIQUES, ETC.,WHICH CAN RESULT IN DAMAGE TO EQUIPMENT IFNOT CAREFULLY FOLLOWED.NOTEAn operating procedure, technique, etc., which isconsidered essential to emphasize.xU.S.<strong>162</strong>PHUS-00

CESSNAMODEL <strong>162</strong>GARMIN G300LOG OF EFFECTIVE PAGESINTRODUCTIONUse this page to determine the currency and applicability of your POH.Pages affected by the current revision are indicated by an asterisk (*)preceding the pages listed under the Page Number column.Revision Level Date of Issue Revision Level Date of IssueOriginal Issue 22 July 2009 Revision 3 28 September 2010Revision 1 2 November 2009 Revision 4 21 October 2011Revision 2 26 April 2010PageNumberPageStatusRevisionNumber* Title Revised 4* i/ii Revised 4iii Revised 1iv Revised 3* v thru vi Revised 4vii thru x Original 0* xi thru xv/xvi Revised 4* xvii/xviii Added 4* 1-1/1-2 Revised 41-3 thru 1-4 Revised 1* 1-5 Revised 41-6 thru 1-7 Original 0* 1-8 Revised 4* 1-9 thru 1-31/1-32 Added 4* 2-1/2-2 thru 2-20 Revised 4* 2-21/2-22 Added 4(Continued Next Page)<strong>162</strong>PHUS-04U.S.xi

INTRODUCTIONCESSNAMODEL <strong>162</strong>GARMIN G300LOG OF EFFECTIVE PAGES (Continued)PageNumberPageStatusRevisionNumber* 3-1 thru 3-40 Revised 4* 4-1 thru 4-46 Revised 4* 4-47 thru 4-49/4-50 Added 4* 5-1/5-2 Revised 45-3 thru 5-4 Revised 1* 5-5 thru 5-7 Revised 45-8 Revised 1* 5-9 thru 5-18 Revised 4* 6-1/6-2 thru 6-30 Revised 4* 7-1 thru 7-56 Revised 48-1 Original 08-2 thru 8-4 Revised 18-5 Revised 38-6 Revised 18-7 thru 8-8 Revised 38-9 Revised 18-10 Revised 3* 8-11 Revised 48-12 Original 08-13 Revised 1* 8-14 Revised 48-15 thru 8-17 Original 0* 8-18 Revised 48-19 thru 8-23 Revised 18-24 Revised 38-25/8-26 Revised 1(Continued Next Page)xiiU.S.<strong>162</strong>PHUS-04

CESSNAMODEL <strong>162</strong>GARMIN G300INTRODUCTIONLOG OF EFFECTIVE PAGES (Continued)PageNumberPageStatusRevisionNumber* 9-1/9-2 Revised 4* 10-1/10-2 Deleted 4<strong>162</strong>PHUS-04U.S.xiii/xiv

CESSNAMODEL <strong>162</strong>GARMIN G300SERVICE BULLETIN CONFIGURATION LISTINTRODUCTIONThe following is a list of Service Bulletins that are applicable to theoperation of the airplane, and have been incorporated into this manual.This list contains only those Service Bulletins that are currently active.Number Title Airplane SerialEffectivitySB10-52-01 Door Latch Modification <strong>162</strong>00002 thru<strong>162</strong>00007,<strong>162</strong>00009 thru<strong>162</strong>00020SB11-52-01 Cabin Door SecondaryLatch Installation<strong>162</strong>00002 thru<strong>162</strong>00240Revision IncorporatedIncorporated in Airplane44<strong>162</strong>PHUS-04U.S.xv/xvi

CESSNAMODEL <strong>162</strong>GARMIN G300TABLE OF CONTENTSINTRODUCTIONSECTIONGENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1LIMITATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2EMERGENCY PROCEDURES . . . . . . . . . . . . . . . . . .3NORMAL PROCEDURES . . . . . . . . . . . . . . . . . . . . . .4PERFORMANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5WEIGHT AND BALANCE/EQUIPMENT LIST . . . . . . .6AIRPLANE AND SYSTEM DESCRIPTION . . . . . . . . .7HANDLING, SERVICE AND MAINTENANCE . . . . . . .8SUPPLEMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9<strong>162</strong>PHUS-04U.S.xvii/xviii

CESSNA SECTION 1MODEL <strong>162</strong>GENERALGARMIN G300GENERALTABLE OF CONTENTSPageThree View - Normal Ground Attitude . . . . . . . . . . . . . . . . . . . . . . . .1-3Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5Descriptive Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5Propeller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5Fuel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6Fuel Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7Oil Specification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7Oil Capacity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7Maximum Certificated Weights . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8Maximum Weight In Baggage Compartment . . . . . . . . . . . . . . . .1-8Standard Airplane Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8Cabin And Entry Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8Baggage Space And Entry Dimensions . . . . . . . . . . . . . . . . . . . .1-8Specific Loadings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8Symbols, Abbreviations And Terminology . . . . . . . . . . . . . . . . . . . . .1-9General Airspeed Terminology And Symbols . . . . . . . . . . . . . . . .1-9Meteorological Terminology . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11Engine Power Terminology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11Airplane Performance And Flight Planning Terminology. . . . . . .1-13Weight And Balance Terminology . . . . . . . . . . . . . . . . . . . . . . . .1-14Electrical and Avionics Terminology . . . . . . . . . . . . . . . . . . . . . .1-16Metric/Imperial/U.S. Conversion Charts. . . . . . . . . . . . . . . . . . . . . .1-17Weight Conversions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-18Length Conversions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-20Distance Conversions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-24Volume Conversions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-25Temperature Conversions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-28Pressure Conversion. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-29Volume To Weight Conversion . . . . . . . . . . . . . . . . . . . . . . . . . .1-30Quick Conversions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-31/1-32<strong>162</strong>PHUS-04 U.S. 1-1/1-2

CESSNA SECTION 1MODEL <strong>162</strong>GENERALGARMIN G300THREE VIEW - NORMAL GROUND ATTITUDEFigure 1-1* (Sheet 1 of 2)<strong>162</strong>PHUS-01 U.S.1-3

SECTION 1CESSNAGENERAL MODEL <strong>162</strong>GARMIN G300THREE VIEW - NORMAL GROUND ATTITUDENOTE• Wing span shown with standard strobe lights installed.• Wheel base length is 62.40 inches (1.58 m).• Propeller ground clearance is 8.50 inches (215.90 mm).• Wing area is 120.0 square feet (11.15 sq. m).Figure 1-1* (Sheet 2)1-4U.S.<strong>162</strong>PHUS-01

CESSNA SECTION 1MODEL <strong>162</strong>GENERALGARMIN G300INTRODUCTIONThis POH contains 9 sections, and includes the material required to befurnished to the pilot by American Society for Testing and MaterialsInternational (ASTM) standards F2245 for Light Sport Aircraft (LSA). Italso contains supplemental data supplied by <strong>Cessna</strong> Aircraft Company.Section 1 provides basic data and information of general interest. Italso contains definitions or explanations of symbols, abbreviations, andterminology commonly used.DESCRIPTIVE DATAENGINENumber of Engines: 1Engine Manufacturer: Teledyne Continental MotorsEngine <strong>Model</strong> Number: O-200-DEngine Type: Normally aspirated, direct drive, air-cooled, horizontallyopposed, carburetor equipped, four cylinder engine with201.0 cu. in. displacement.Horsepower Rating and Engine Speed: 100 rated BHP at 2750 RPMPROPELLERPropeller Manufacturer: McCauley Propeller SystemsPropeller <strong>Model</strong> Number:Standard Composite Propeller - 1L100/LSA6754Optional Aluminum Propeller - 1A<strong>162</strong>/TCD6754Number of Blades: 2Propeller Diameter: 67 inches (1.70 m)Propeller Type: Fixed Pitch(Continued Next Page)<strong>162</strong>PHUS-04 U.S.1-5

SECTION 1CESSNAGENERAL MODEL <strong>162</strong>GARMIN G300DESCRIPTIVE DATA (Continued)FUELWARNINGUSE OF UNAPPROVED FUELS MAY RESULT INDAMAGE TO THE ENGINE AND FUEL SYSTEMCOMPONENTS, RESULTING IN POSSIBLE ENGINEFAILURE.Approved Fuel Grades (and Colors):100LL Grade Aviation Fuel (Blue)100 Grade Aviation Fuel (Green)NOTEIsopropyl alcohol or Diethylene Glycol Monomethyl Ether(DiEGME) may be added to the fuel supply in accordanceto TCM Service Information Letter (SIL99-2B). Refer toSection 8 for additional information.FUEL CAPACITYTotal Capacity . . . . . . . . . . . . . . . . . 25.46 U.S. GALLONS (96.34 l)Total Usable . . . . . . . . . . . . . . . . . . . 24.00 U.S. GALLONS (90.82 l)Total Capacity Each Tank . . . . . . . . 12.73 U.S. GALLONS (48.17 l)Total Usable Each Tank . . . . . . . . . . 12.00 U.S. GALLONS (45.41 l)NOTE• To ensure maximum fuel capacity and minimizecrossfeeding when refueling, always park the airplane ina wings level, normal ground attitude. Refer to Figure 1-1 for normal ground attitude dimensions.• The fuel filler assembly is equipped with indicator tabsfor 3/4, 1/2 and 1/4 fuel quantities.• Maximum full capacity is indicated when fuel reaches theupper hole of the indicator tab. This fuel level allows forproper thermal expansion. Filling the fuel tank above theupper hole eliminates expansion space resulting in fuelventing overboard through the fuel vent.(Continued Next Page)1-6U.S.<strong>162</strong>PHUS-00

CESSNA SECTION 1MODEL <strong>162</strong>GENERALGARMIN G300DESCRIPTIVE DATA (Continued)OILOIL SPECIFICATIONSAE J1966 Aviation Grade Non-Dispersant Mineral Oil: Used when theairplane was delivered from the factory and should be used to replenishthe supply during the first 25 hours. This oil should be drained and thefilter changed after the first 25 hours of operation. Refill the engine withSAE J1966 Aviation Grade Non-Dispersant Mineral Oil and continue touse until a total of 50 hours has accumulated or oil consumption hasstabilized.SAE J1899 Aviation Grade Ashless Dispersant Oil: Oil conforming toTeledyne Continental Motors (TCM) Service Information Letter SIL99-2B, and all revisions and supplements thereto, must be used after first50 hours or oil consumption has stabilized.RECOMMENDED VISCOSITY FOR TEMPERATURE RANGEMultiviscosity or straight grade oil may be used throughout the year forengine lubrication. Refer to the following table for temperature versusviscosity ranges.SAE J1966Non-DispersantMineral OilSAE J1899Ashless Dispersant OilSAE GradeTemperature SAE GradeAbove 4°C (40°F) 50 50 or 15W-50 or 25W-60Below 4°C (40°F) 30 30 or 15W-50 or 25W-60All Temperatures M20W-50 15W-50, 20W- 50 or 25W-60NOTEWhen operating temperatures overlap, use the lightergrade of oil.OIL CAPACITYSump. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.0 U.S. QUARTS (4.73 l)Total. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.5 U.S. QUARTS (5.20 l)Minimum Operating Quantity . . . . . . . . . .3.5 U.S. QUARTS (3.31 l)(Continued Next Page)<strong>162</strong>PHUS-00 U.S.1-7

SECTION 1CESSNAGENERAL MODEL <strong>162</strong>GARMIN G300DESCRIPTIVE DATA (Continued)MAXIMUM CERTIFICATED WEIGHTSRamp Weight:. . . . . . . . . . . . . . . . . . . . . . . . 1324 POUNDS (600.6 kg)Takeoff Weight . . . . . . . . . . . . . . . . . . . . . . . 1320 POUNDS (598.8 kg)Landing Weight . . . . . . . . . . . . . . . . . . . . . . 1320 POUNDS (598.8 kg)Maximum Empty Weight . . . . . . . . . . . . . . . . 894 POUNDS (405.5 kg)MAXIMUM WEIGHT IN BAGGAGE COMPARTMENTBaggage Area (Station 155 to 190) . . . . . . . . . 50 POUNDS (22.68 kg)STANDARD AIRPLANE WEIGHTSStandard Empty Weight . . . . . . . . . . . . . . . . . 834 POUNDS (378.3 kg)Maximum Useful Load . . . . . . . . . . . . . . . . . . 490 POUNDS (222.3 kg)CABIN AND ENTRY DIMENSIONSDetailed dimensions of the cabin interior and entry door openings areillustrated in Section 6.BAGGAGE SPACE AND ENTRY DIMENSIONSDimensions of the baggage area are illustrated in detail in Section 6.SPECIFIC LOADINGSWing Loading . . . . . . . . . . . . . . . . . . . . . 11.0 lbs/sq. ft. (53.7 kg/sq. m)Power Loading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13.2 lbs/HP1-8U.S.<strong>162</strong>PHUS-04

CESSNA SECTION 1MODEL <strong>162</strong>GENERALGARMIN G300SYMBOLS, ABBREVIATIONS AND TERMINOLOGYGENERAL AIRSPEED TERMINOLOGY AND SYMBOLSKCASKIASKTASGSV AV OV FEKnots Calibrated Airspeed is indicated airspeed correctedfor position and instrument error and expressed in knots.Knots calibrated airspeed is equal to KTAS in standardatmosphere at sea level.Knots Indicated Airspeed is the speed shown on theairspeed indicator and expressed in knots.Knots True Airspeed is the airspeed expressed in knotsrelative to undisturbed air which is KCAS corrected foraltitude and temperature.Ground Speed is the speed of an aircraft relative to theground.Design Maneuvering Speed is the maximum speed atwhich full or abrupt control movements may be used. Doesnot protect from possible overstressing the airframe.Maximum Operating Maneuvering Speed is the maximumspeed the airplane maybe stalled without exceedingstructural limitations.Maximum Flap Extended Speed is the highest speedpermissible with wing flaps in a prescribed extendedposition.(Continued Next Page)<strong>162</strong>PHUS-04 U.S.1-9

SECTION 1CESSNAGENERAL MODEL <strong>162</strong>GARMIN G300SYMBOLS, ABBREVIATIONS AND TERMINOLOGY(Continued)GENERAL AIRSPEED TERMINOLOGY AND SYMBOLS(Continued)V NOV NEV SV SOV xV YMaximum Structural Cruising Speed is the speed thatshould not be exceeded except in smooth air, then only withcaution.Never Exceed Speed is the speed limit that may not beexceeded at any time.Stalling Speed or the minimum steady flight speed is theminimum speed at which the airplane is controllable.Stalling Speed or the minimum steady flight speed is theminimum speed at which the airplane is controllable in thelanding configuration at the most forward center of gravity.Best Angle of Climb Speed is the speed which results inthe greatest gain of altitude in a given horizontal distance.Best Rate of Climb Speed is the speed which results in thegreatest gain in altitude in a given time.(Continued Next Page)1-10U.S.<strong>162</strong>PHUS-04

CESSNA SECTION 1MODEL <strong>162</strong>GENERALGARMIN G300SYMBOLS, ABBREVIATIONS AND TERMINOLOGY(Continued)METEOROLOGICAL TERMINOLOGYOATStandardTemperature(STD)PressureAltitude(PA)Outside Air Temperature is the free air statictemperature. It may be expressed in either degreesCelsius or degrees Fahrenheit.Standard Temperature is 15°C at sea level pressurealtitude and decreases by 2°C for each 1000 feet ofaltitude.Pressure Altitude is the altitude read from analtimeter when the altimeter's barometric scale hasbeen set to 29.92 inches of mercury (1013 mb).ENGINE POWER TERMINOLOGYMCPBHPRPMStatic RPMLeanMixtureMaximum Continuous Power is the maximum powerfor abnormal or emergency operations.Brake Horsepower is the power developed by theengine.Revolutions Per Minute is engine speed.Static RPM is engine speed attained during a fullthrottle engine runup when the airplane is on theground and stationary.Decreased proportion of fuel in the fuel-air mixturesupplied to the engine. As air density decreases, theamount of fuel required by the engine decreases for agiven throttle setting. Adjusting the fuel-air mixture toprovide a smaller portion of fuel is known as “leaning”the mixture.(Continued Next Page)<strong>162</strong>PHUS-04 U.S.1-11

SECTION 1CESSNAGENERAL MODEL <strong>162</strong>GARMIN G300SYMBOLS, ABBREVIATIONS AND TERMINOLOGY(Continued)ENGINE POWER TERMINOLOGY (Continued)RichMixtureFullRichIdleCutoffFullThrottleClosedThrottleCarb HeatOnCarb HeatOffFuel ShutoffOffFuel ShutoffOnIncreased proportion of fuel in the fuel-air mixturesupplied to the engine. As air density increases, theamount of fuel required by the engine increases for agiven throttle setting. Adjusting the fuel-air mixture toprovide a greater portion of fuel is known as “richening”the mixture.Mixture control full forward (pushed in, full controltravel, toward the panel).Mixture control full aft (pulled out, full control travel,away from the panel).Throttle full forward (pushed in, full control travel,toward the panel). Also known as “full open” throttle.Throttle full aft (pulled out, full control travel, away fromthe panel). Also known as the throttle “idle” position.Carburetor heat control knob full aft (pulled out, fullcontrol travel, away from the panel).Carburetor heat control knob full forward (pushed in,full control travel, toward the panel).Fuel shutoff valve knob full aft (pulled out, full controltravel, away from the panel).Fuel shutoff valve knob full forward (pushed in, fullcontrol travel, toward the panel).(Continued Next Page)1-12U.S.<strong>162</strong>PHUS-04

CESSNA SECTION 1MODEL <strong>162</strong>GENERALGARMIN G300SYMBOLS, ABBREVIATIONS AND TERMINOLOGY(Continued)AIRPLANE PERFORMANCE AND FLIGHT PLANNINGTERMINOLOGYDemonstratedCrosswindVelocityUsableFuelUnusableFuelGPHFPMgT/ODemonstrated Crosswind Velocity is the velocity ofthe crosswind component for which adequate controlof the airplane during takeoff and landing was actuallydemonstrated during certification tests. The valueshown is not considered to be limiting.Usable Fuel is the fuel available for flight planning.Unusable Fuel is the quantity of fuel that can not besafely used in flight.Gallons Per Hour is the amount of fuel consumed perhour.Feet Per Minute is the distance, in feet, traveled overthe duration of one minute.g is acceleration due to gravity.Takeoff(Continued Next Page)<strong>162</strong>PHUS-04 U.S.1-13

SECTION 1CESSNAGENERAL MODEL <strong>162</strong>GARMIN G300SYMBOLS, ABBREVIATIONS AND TERMINOLOGY(Continued)WEIGHT AND BALANCE TERMINOLOGYReferenceDatumF.S.W.L.ArmMomentCenter ofGravity(C.G.)C.G. ArmC.G. LimitsStandardEmpty WeightReference Datum is an imaginary vertical plane fromwhich all horizontal distances are measured forbalance purposes.Fuselage Station is a location along the airplanefuselage given in terms of the distance from thereference datum.Water Line is the intersection of an airplane exteriorprofile and a horizontal plane.Arm is the horizontal distance from the referencedatum to the center of gravity (C.G.) of an item.Moment is the product of the weight of an itemmultiplied by its arm. (Moment divided by the constant,1000 is used in this POH, to simplify balancecalculations by reducing the number of digits.)Center of Gravity is the point at which an airplane, orequipment, would balance if suspended. Its distancefrom the reference datum is found by dividing the totalmoment by the total weight of the airplane.Center of Gravity Arm is the arm obtained by addingthe airplane's individual moments and dividing the sumby the total weight.Center of Gravity Limits are the extreme center ofgravity locations within which the airplane must beoperated at a given weight.Standard Empty Weight is the weight of a standardairplane, including unusable fuel, full operating fluidsand full engine oil.(Continued Next Page)1-14U.S.<strong>162</strong>PHUS-04

CESSNA SECTION 1MODEL <strong>162</strong>GENERALGARMIN G300SYMBOLS, ABBREVIATIONS AND TERMINOLOGY(Continued)WEIGHT AND BALANCE TERMINOLOGY (Continued)Basic EmptyWeightMaximumEmpty WeightMaximumRamp WeightMaximumTakeoff WeightMaximumLandingWeightUseful LoadMinimumUseful LoadMACTareBasic Empty Weight is the standard empty weightplus the weight of optional equipment.Maximum Empty Weight is the difference betweenmaximum takeoff weight and minimum useful load.Maximum Ramp Weight is the maximum weightapproved for ground maneuver, and includes theweight of fuel used for start, taxi and runup.Maximum Takeoff Weight is the maximum weightapproved for the start of the takeoff roll.Maximum Landing Weight is the maximum weightapproved for the landing touchdown.Useful Load is the difference between ramp weightand the basic empty weight.Designed Minimum Useful Load is determined byASTM Regulations based on engine power.MAC (Mean Aerodynamic Chord) is a chord of animaginary rectangular airfoil having the same pitchingmoments throughout the flight range as that of theactual wing.Tare is the weight of chocks, blocks, stands, etc. usedwhen weighing an airplane, and is included in thescale readings. Tare is deducted from the scalereading to obtain the actual (net) airplane weight.<strong>162</strong>PHUS-04 U.S.1-15

SECTION 1CESSNAGENERAL MODEL <strong>162</strong>GARMIN G300SYMBOLS, ABBREVIATIONS AND TERMINOLOGY(Continued)ELECTRICAL AND AVIONICS TERMINOLOGYADAHRSAVNAUXPFDMFDELTA/PCBCAB PWREISGPSSEC PWRXPDRPTTALTBATTLDGHSIVHFNAVCOMCASBRSAirdata Attitude Heading Reference SystemAvionicsAuxiliaryPrimary Flight DisplayMulti-Functional DisplayEmergency Locator TransmitterAuto PilotCircuit BreakerCabin PowerEngine Indicating SystemGlobal Positioning SystemSecondary PowerTransponderPush-To-TalkAlternatorBatteryLandingHorizontal Situation IndicatorVery High FrequencyNavigationCommunicationCrew Alerting SystemBallistic Recovery System1-16U.S.<strong>162</strong>PHUS-04

CESSNA SECTION 1MODEL <strong>162</strong>GENERALGARMIN G300METRIC/IMPERIAL/U.S. CONVERSION CHARTSThe following charts have been provided to help international operatorsconvert U.S. measurement supplied with the Pilot’s OperatingHandbook into metric and imperial measurements.The standard followed for measurement units shown is the NationalInstitute of Standards Technology (NIST), Publication 811, “Guide forthe Use of the International System of Units (SI).”Please refer to the following pages for these charts.<strong>162</strong>PHUS-04 U.S.1-17

SECTION 1CESSNAGENERAL MODEL <strong>162</strong>GARMIN G300WEIGHT CONVERSIONSFigure 1-2* (Sheet 1 of 2)1-18U.S.<strong>162</strong>PHUS-04

CESSNA SECTION 1MODEL <strong>162</strong>GENERALGARMIN G300WEIGHT CONVERSIONSFigure 1-2* (Sheet 2)<strong>162</strong>PHUS-04 U.S.1-19

SECTION 1CESSNAGENERAL MODEL <strong>162</strong>GARMIN G300LENGTH CONVERSIONSFigure 1-3* (Sheet 1 of 4)1-20U.S.<strong>162</strong>PHUS-04

CESSNA SECTION 1MODEL <strong>162</strong>GENERALGARMIN G300LENGTH CONVERSIONSFigure 1-3* (Sheet 2)<strong>162</strong>PHUS-04 U.S.1-21

SECTION 1CESSNAGENERAL MODEL <strong>162</strong>GARMIN G300LENGTH CONVERSIONSFigure 1-3* (Sheet 3)1-22U.S.<strong>162</strong>PHUS-04

CESSNA SECTION 1MODEL <strong>162</strong>GENERALGARMIN G300LENGTH CONVERSIONSFigure 1-3* (Sheet 4)<strong>162</strong>PHUS-04 U.S.1-23

SECTION 1CESSNAGENERAL MODEL <strong>162</strong>GARMIN G300DISTANCE CONVERSIONSFigure 1-4*1-24U.S.<strong>162</strong>PHUS-04

CESSNA SECTION 1MODEL <strong>162</strong>GENERALGARMIN G300VOLUME CONVERSIONSFigure 1-5* (Sheet 1 of 3)<strong>162</strong>PHUS-04 U.S.1-25

SECTION 1CESSNAGENERAL MODEL <strong>162</strong>GARMIN G300VOLUME CONVERSIONSFigure 1-5* (Sheet 2)1-26U.S.<strong>162</strong>PHUS-04

CESSNA SECTION 1MODEL <strong>162</strong>GENERALGARMIN G300VOLUME CONVERSIONSFigure 1-5* (Sheet 3)<strong>162</strong>PHUS-04 U.S.1-27

SECTION 1CESSNAGENERAL MODEL <strong>162</strong>GARMIN G300TEMPERATURE CONVERSIONSFigure 1-6*1-28U.S.<strong>162</strong>PHUS-04

CESSNA SECTION 1MODEL <strong>162</strong>GENERALGARMIN G300PRESSURE CONVERSIONHECTOPASCALS TO INCHES OF MERCURYFigure 1-7*<strong>162</strong>PHUS-04 U.S.1-29

SECTION 1CESSNAGENERAL MODEL <strong>162</strong>GARMIN G300VOLUME TO WEIGHT CONVERSIONFigure 1-8*1-30U.S.<strong>162</strong>PHUS-04

CESSNA SECTION 1MODEL <strong>162</strong>GENERALGARMIN G300QUICK CONVERSIONSFigure 1-9*<strong>162</strong>PHUS-04 U.S. 1-31/1-32

CESSNA SECTION 2MODEL <strong>162</strong>OPERATING LIMITATIONSGARMIN G300OPERATING LIMITATIONSTABLE OF CONTENTSPageIntroduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3Airspeed Limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4Airspeed Indicator Markings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5Powerplant Limitations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6Powerplant and Electrical Instrument Markings. . . . . . . . . . . . . . . . .2-7Weight Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8Maximum Weight in Baggage Compartment. . . . . . . . . . . . . . . . .2-8Center of Gravity Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8Service Ceiling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8Maneuver Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-9Load Factors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-9Flight Load Factor Limits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9Kinds of Operations Limits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-10Kinds of Operations Equipment List . . . . . . . . . . . . . . . . . . . . . . . . 2-11Fuel Limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-14Flaps Limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-14System Limitations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1512V Power Outlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-15G300 Limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-15Placards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-16<strong>162</strong>PHUS-04 U.S. 2-1/2-2

CESSNA SECTION 2MODEL <strong>162</strong>OPERATING LIMITATIONSGARMIN G300INTRODUCTIONSection 2 includes operating limitations, instrument markings, andbasic placards necessary for the safe operation of the airplane, itsengine, standard systems and standard equipment. The limitationsincluded in this section and in Section 9 have been approved.Observance of these operating limitations is required by FederalAviation Regulations.NOTE• Refer to Section 9, Supplements, of this Pilot'sOperating Handbook for amended operating limitations,operating procedures, performance data and othernecessary information for airplanes equipped withspecific options.• The airspeeds listed in Figure 2-1, Airspeed Limitations,are based on Airspeed Calibration data shown in Section5.The <strong>Cessna</strong> <strong>Model</strong> No. <strong>162</strong> is approved under ASTM standard F2245.<strong>162</strong>PHUS-04 U.S.2-3

SECTION 2CESSNAOPERATING LIMITATIONS MODEL <strong>162</strong>GARMIN G300AIRSPEED LIMITATIONSAirspeed limitations and their operational significance are shown inFigure 2-1.AIRSPEED LIMITATIONSSYMBOL SPEED KCAS KIAS REMARKSV S Stall Speed - Clean 44 41 Stall speed flap up.V SOV FEV OV AStall Speed - LandingConfigurationMaximum FlapExtended Speed:FLAPS 10°FLAPS 25°FLAPS FULLMaximum OperatingManeuvering Speed1320 Pounds1200 Pounds1100 Pounds40 37 Stall speed flaps full9884718884811008570898580Design ManeuveringSpeed: 100 102Do not exceed this speedwith flaps down.Maximum speed at whichthe airplane may bestalled without exceedingstructural limitations.Do not make full or abruptcontrol movements abovethis speed.Does not provideprotection from possibleoverstressing the airplane.V NE Never Exceed Speed 143 148 Do not exceed this speedin any operation.V NOMaximum StructuralCruising Speed120 124 Do not exceed this speedexcept in smooth air, andthen only with caution.Figure 2-12-4U.S.<strong>162</strong>PHUS-04

CESSNA SECTION 2MODEL <strong>162</strong>OPERATING LIMITATIONSGARMIN G300AIRSPEED INDICATOR MARKINGSAirspeed indicator markings and their color code significance areshown in Figure 2-2.MARKINGAIRSPEED INDICATOR MARKINGSKIAS VALUE ORRANGERed Band 149 Maximum speed for all operations.Flaps 25°Tick MarkFlaps 10°Tick MarkVx TickMarkVy TickMark85 Maximum Flaps 25° Operation100 Maximum Flaps 10° Operation57 Best Angle of Climb Air Speed62 Best Rate of Climb Air SpeedFigure 2-2<strong>162</strong>PHUS-04 U.S.2-5

SECTION 2CESSNAOPERATING LIMITATIONS MODEL <strong>162</strong>GARMIN G300POWERPLANT LIMITATIONSEngine Manufacturer: Teledyne Continental MotorsEngine <strong>Model</strong> Number: O-200-DMaximum Power: 100 BHP RatingEngine Operating Limits for Takeoff and Continuous Operations:Maximum Engine Speed:. . . . . . . . . . . . . . . . . . . . . . . . . .2750 RPMNOTEThe static RPM range at full throttle with carburetor heat offand mixture leaned to maximum RPM is 2375 - 2475 RPM.For allowable variations in static RPM at non-standardtemperatures, refer to the <strong>162</strong> Maintenance Manual.Maximum Oil Temperature: . . . . . . . . . . . . . . . . . . . . .240°F (116°C)Oil Pressure, Minimum: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10 PSIOil Pressure, Maximum: . . . . . . . . . . . . . . . . . . . . . . . . . . . .100 PSICAUTIONENGINE OPERATION WITH INDICATED OIL PRESSUREBELOW THE GREEN BAND RANGE WHILE IN CRUISEOR CLIMB CONFIGURATION IS CONSIDEREDABNORMAL. REFER TO SECTION 3, AMPLIFIEDEMERGENCY PROCEDURES, "LOW OIL PRESSURE".Fuel Grade: Refer to Fuel LimitationsOil Grade (Specification):SAE J1966 Aviation Grade Non-Dispersant Mineral Oil or SAEJ1899 Aviation Grade Ashless Dispersant Oil. Oil must comply withthe latest revision and/or supplement for Teledyne ContinentalMotors (TCM) Service Information Letter SIL99-2B or later revision,must be used.Propeller Manufacturer: McCauley Propeller SystemsStandard Composite Propeller <strong>Model</strong> Number. . . . . . . 1L100/LSA6754Maximum Propeller Diameter . . . . . . . . . . . . 67.0 INCHES (1.70 m)Minimum Propeller Diameter . . . . . . . . . . . . . 66.5 INCHES (1.69 m)Optional Aluminum Propeller <strong>Model</strong> Number . . . . . . . .1A<strong>162</strong>/TCD6754Maximum Propeller Diameter . . . . . . . . . . . . 67.0 INCHES (1.70 m)Minimum Propeller Diameter . . . . . . . . . . . . . 66.0 INCHES (1.68 m)2-6U.S.<strong>162</strong>PHUS-04

CESSNA SECTION 2MODEL <strong>162</strong>OPERATING LIMITATIONSGARMIN G300POWERPLANT AND ELECTRICAL INSTRUMENTMARKINGSPowerplant and electrical instrument markings and their color codesignificance are shown in Figure 2-3. Operation with indications in thered range is prohibited. Avoid operating with indicators in the yellowrange.POWERPLANT AND ELECTRICAL INSTRUMENT MARKINGSINSTRUMENTTachometer(RPM)OilTemperature(OIL °F)Oil Pressure(OIL PSI)Exhaust GasTemperature(if installed)(EGT °F)CarburetorTemperature(CARB °F)BatteryCurrent(AMPS)Bus Voltage(VOLTS)RED(LOWERWARNING)YELLOW(LOWERCAUTION)GREEN(NORMALOPERATINGRANGE)---- ---- 2000 to 2750RPMYELLOW(UPPERCAUTION)RED(UPPERWARNING)2750* to 3500RPM---- 0 to 75°F 75 to 220°F 220 to 240°F 240* to 265°F0 to 10 PSI 10 to 30 PSI 30 to 60 PSI 60 to 100 PSI 100* to 140 PSI---- ---- 1000 to 1600°FWhite Advisory5 to 40°F-35 to 35White Advisory-30 to 12.5 12.5 to 15 15 to 16 16 to 30*Maximum operating limit is lower end of red.Figure 2-3<strong>162</strong>PHUS-04 U.S.2-7

SECTION 2CESSNAOPERATING LIMITATIONS MODEL <strong>162</strong>GARMIN G300WEIGHT LIMITSMaximum Ramp Weight: . . . . . . . . . . . . . . . 1324 POUNDS (600.6 kg)Maximum Takeoff Weight . . . . . . . . . . . . . . . 1320 POUNDS (598.8 kg)Maximum Landing Weight . . . . . . . . . . . . . . 1320 POUNDS (598.8 kg)Maximum Empty Weight . . . . . . . . . . . . . . . . 894 POUNDS (405.5 kg)MAXIMUM WEIGHT IN BAGGAGE COMPARTMENTBaggage Area (Station 155 to 190) . . . . . . . . . 50 POUNDS (22.68 kg)WARNINGAFT BULKHEAD CLOSEOUT NET REQUIRED FORFLIGHT.NOTEMaximum baggage compartment loading must not exceed8 pounds per square foot.CENTER OF GRAVITY LIMITSCenter Of Gravity Range:Forward: 134.46 inches (3415.28 mm) aft of datum at 1320pounds (598.74 kg) or less, with straight line variationto 132.06 inches (3354.32 mm) aft of datum at 1050pounds (476.27 kg).Aft:136.86 inches (3476.24 mm) aft of datum at allweights.Reference Datum: Lower portion of front face of firewall.SERVICE CEILING: . . . . . . . . . . . . . . . . 14,625 Feet (4457.7 m)2-8U.S.<strong>162</strong>PHUS-04

CESSNA SECTION 2MODEL <strong>162</strong>OPERATING LIMITATIONSGARMIN G300MANEUVER LIMITSThis airplane is approved under ASTM standard F2245 and is intendedfor recreational and instructional flight operations. In the acquisition ofvarious pilot certificates certain maneuvers are required and thesemaneuvers are permitted in this airplane.MANEUVERS AND RECOMMENDED ENTRY SPEED*Chandelles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .102 KIASLazy Eights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .102 KIASSteep Turns. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .102 KIASStalls (Except Whip Stalls) . . . . . . . . . . . . . . . . . . Slow DecelerationPower On Stalls. . . . . . . . . . . . . . . . . . . . . . . . . . . Slow Deceleration(limit pitch to 30° nose up attitude)* Abrupt use of the controls is prohibited above 102 KIAS.WARNING• AEROBATIC MANEUVERS, INCLUDING SPINS, AREPROHIBITED.• INTENTIONAL FLIGHT WITH CABIN DOOR(S) OPENIS PROHIBITED.LOAD FACTORSFLIGHT LOAD FACTOR LIMITSFlight Load Factors (Maximum Takeoff Weight - 1320 POUNDS):Flaps UP: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .+4.0g, -2.0gFlaps FULL:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +2.0g<strong>162</strong>PHUS-04 U.S.2-9

SECTION 2CESSNAOPERATING LIMITATIONS MODEL <strong>162</strong>GARMIN G300KINDS OF OPERATIONS LIMITSThe <strong>Cessna</strong> <strong>162</strong> airplane is approved for DAY - NIGHT - VFRoperations only. Flight into known icing conditions is prohibited.The minimum equipment for approved operations required under theOperating Rules are defined by 14 CFR 91 and ASTM standard F2245,as applicable.The following Kinds of Operations Equipment List (KOEL) identifies theequipment required to be operational for airplane airworthiness in thelisted kind of operations.2-10U.S.<strong>162</strong>PHUS-04

VFRCESSNA SECTION 2MODEL <strong>162</strong>OPERATING LIMITATIONSGARMIN G300KINDS OF OPERATIONS EQUIPMENT LISTKIND OFOPERATIONVFRNIGHTSystem, Instrument, Equipmentand/or FunctionPLACARDS AND MARKINGSDAYCOMMENTS1 - <strong>162</strong> POH/FTS - Garmin G300 0 0 Recommended to beaccessible to pilot inflight.2 - <strong>162</strong> Pilot’s Checklist 1 1 Required to beaccessible to pilot inflight.3 - Garmin G300 Pilot’s Guide 0 0 Recommended to beaccessible to pilot inflight.AIR CONDITIONING1 - Avionics Fan 1 1COMMUNICATIONS1 - VHF COM 0 0ELECTRICAL POWER1 - 12V Main Battery 1 12 - 14V Alternator 1 13 - Secondary Battery 0 14 - Ammeter 0 1EQUIPMENT AND FURNISHINGS1 - Seat Belt Assembly 1 1 Each Seat Occupant2 - Shoulder Harness 1 1 Each Seat Occupant3 - Aft Bulkhead Closeout Net 1 1FLIGHT CONTROLS1 - Elevator Trim System 1 12 - Elevator Trim Indicator 1 1(Continued Next Page)<strong>162</strong>PHUS-04 U.S.2-11

SECTION 2CESSNAOPERATING LIMITATIONS MODEL <strong>162</strong>GARMIN G300KINDS OF OPERATIONS EQUIPMENT LIST (Continued)System, Instrument, Equipment and/or FunctionFUEL SYSTEMKIND OFOPERATIONVFRDAYVFRNIGHT(Continued Next Page)COMMENTS1 - Fuel Shutoff Control Valve 1 12 - Cockpit Fuel Quantity Indicator - 1 1L Tank3 - Cockpit Fuel Quantity Indicator - 1 1R TankINDICATING/RECORDINGSYSTEM1 - Low Airspeed Alert and Stall 1 1Warning System2 - G300 System Annunciator and 1 1Warning DisplaysLANDING GEAR1 - Wheel Fairings 0 0 RemovableLIGHTING1 - PFD Bezel Lighting 0 02 - PFD Display Backlighting 1 13 - MFD Bezel Lighting (if installed) 0 04 - MFD Display Backlighting1 1(if installed)5 - Cockpit Overhead Panel Lighting 0 16 - Aircraft Position (NAV) Lights 0 17 - STROBE Light System 1 18 - LAND (Landing) Light 0 19 - Non-stabilized Magnetic0 0Compass Internal Lighting(if installed)2-12U.S.<strong>162</strong>PHUS-04

CESSNA SECTION 2MODEL <strong>162</strong>OPERATING LIMITATIONSGARMIN G300KINDS OF OPERATIONS EQUIPMENT LIST (Continued)System, Instrument, Equipment and/or FunctionKIND OFOPERATIONVFRDAYVFRNIGHTCOMMENTSNAVIGATION AND PITOT-STATIC SYSTEM1 - G300 Airspeed Indicator 1 12 - G300 Altimeter 1 13 - G300 Vertical Speed Indicator 0 04 - G300 Attitude Indicator 0 05 - G300 Directional Indicator (HSI) 0 06 - G300 Turn Coordinator 0 07 - G300 Magnetic Heading1 1Indicator8 - GPS Receiver/Navigator A/R A/R As RequiredProcedure.Per9 - GTX 327 Mode C Transponder A/R A/R As RequiredProcedure.Per10 - Blind Altitude Encoder A/R A/R As RequiredProcedure.Per11 - G300 Clock 0 012 - Magnetic Compass (if installed) 0 013 - Autopilot System 0 0ENGINE INDICATING1 - Tachometer (RPM) 1 12 - Carburetor Temperature Indicator 0 0(CARB °F)3 - Oil Pressure Indicator 1 14 - Oil Temperature Indicator 1 15 - Exhaust Gas Temperature (EGT)Indicator (if installed)0 0ENGINE OIL1 - Engine Crankcase Dipstick 1 1<strong>162</strong>PHUS-04 U.S.2-13

SECTION 2CESSNAOPERATING LIMITATIONS MODEL <strong>162</strong>GARMIN G300FUEL LIMITATIONSTotal Fuel: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25.46 U.S. GALLONS(12.73 GALLONS per tank)Usable Fuel (all flight conditions): . . . . . . . . . . . . .24.0 U.S. GALLONS(12 GALLONS per tank)Unusable Fuel: . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.46 U.S. GALLONS(0.73 GALLONS per tank)WARNINGTAKEOFF IS PROHIBITED IF EITHER SIGHT GAGEINDICATES LESS THAN ¼ TANK OF FUEL OR FUELLEVEL IS BELOW THE BOTTOM OF THE FUELINDICATOR TAB.GRNDMINT.O.MARKING ON FUEL INDICATORNOTETo ensure maximum fuel capacity and minimizecrossfeeding when refueling, always park the airplane in awings level, normal ground attitude. Refer to Figure 1-1 fornormal ground attitude definition.Fuel remaining in the tank after the fuel quantity indicator reads “E”cannot be safely used in flight.Approved Fuel Grades (And Colors):100LL Grade Aviation Fuel (Blue)100 Grade Aviation Fuel (Green)FLAP LIMITATIONSApproved Takeoff Range:. . . . . . . . . . . . . . . . . . . . . . . . . . . . UP to 10°Approved Landing Range: . . . . . . . . . . . . . . . . . . . . . . . . . .UP to FULL2-14U.S.<strong>162</strong>PHUS-04

CESSNA SECTION 2MODEL <strong>162</strong>OPERATING LIMITATIONSGARMIN G300SYSTEM LIMITATIONS12V POWER OUTLETThe 12 Volt Power Outlet (POWER OUTLET 12V - 7.5A) is not certifiedfor supplying power to flight-critical communications or navigationdevices.Use of the 12 Volt Power Outlet is prohibited during takeoff and landing.G300 LIMITATIONSNOTEIt is recommended that a current Garmin G300 Pilot’sGuide be available to the pilot during flight.Use of the MAP page for pilotage navigation is prohibited. Thenavigation map is intended only to enhance situational awareness.Navigation is to be conducted using only current charts, data andauthorized navigation facilities.Use of the TERRAIN information for primary terrain and obstacleavoidance is prohibited. The terrain map is intended only to enhancesituational awareness. It is the pilot’s responsibility to provide terrainclearance at all times.Navigation using the G300 is not authorized north of 70° North latitudeor south of 70° South latitude due to unsuitability of the magnetic fieldsnear the Earth's poles. In addition, operations are not authorized in thefollowing two regions:1. North of 65° North latitude between longitude 75° W and 120° W(Northern Canada).2. South of 55° South latitude between longitude 120° E and 165° E(region south of Australia and New Zealand).<strong>162</strong>PHUS-04 U.S.2-15

SECTION 2CESSNAOPERATING LIMITATIONS MODEL <strong>162</strong>GARMIN G300PLACARDSThe following information must be displayed in the form of composite orindividual placards.1. In full view of the pilot: (The DAY-NIGHT-VFR entry, shown onthe example below, will vary with installed equipment):The markings and placards installed in this airplane contain operatinglimitations which must be complied with when operating this airplane.Other operating limitations which must be complied with whenoperating this airplane in this category are contained in the Pilot’sOperating Handbook.No acrobatic maneuvers, including spins, are approved.Flight into known icing conditions prohibited.This airplane is approved for the following flight operations as of thedate of original airworthiness certificate:DAY - NIGHT - VFR2. On control lock:3. On left instrument panel above magnetos switch:TAKEOFF PROHIBITED WITH LESS THAN 1/4 FUELMINTO(Continued Next Page)2-16U.S.<strong>162</strong>PHUS-04

CESSNA SECTION 2MODEL <strong>162</strong>OPERATING LIMITATIONSGARMIN G300PLACARDS (Continued)4. On the lower left instrument panel:WARNINGAssure that all contaminants,including water, are removedfrom fuel and fuel systemsbefore flight. Failure to assurecontaminant free fuel and heedall safety instructions andowner advisories prior to flightcan result in bodily injury or death.5. On the upper left instrument panel:NO INTENTIONAL SPINS6. On the instrument panel directly above the PFD:MAXIMUM OPERATING MANEUVERING SPEED: 89 KIASDESIGN MANEUVERING SPEED: 102 KIAS7. On the upper right instrument panel:8. On the right instrument panel:This aircraft wasmanufactured inaccordance with LightSport Aircraft airworthinessstandards and does not conformto standard category airworthinessrequirements.(Continued Next Page)<strong>162</strong>PHUS-04 U.S.2-17

SECTION 2CESSNAOPERATING LIMITATIONS MODEL <strong>162</strong>GARMIN G300PLACARDS (Continued)9. On the right side of the baggage compartment below thewindow:10. Near both fuel tank filler caps:11. On the engine oil access door:(Continued Next Page)2-18U.S.<strong>162</strong>PHUS-04

CESSNA SECTION 2MODEL <strong>162</strong>OPERATING LIMITATIONSGARMIN G300PLACARDS (Continued)12. On firewall adjacent to battery box and second placard onexternal power receptacle door if external power receptacleoption is installed:13. Located on both left and right fuel sight tubes.(Continued Next Page)<strong>162</strong>PHUS-04 U.S.2-19

SECTION 2CESSNAOPERATING LIMITATIONS MODEL <strong>162</strong>GARMIN G300PLACARDS (Continued)14. Located adjacent to both exterior cabin door latch assemblies.15. Located adjacent to both primary interior cabin door latchassemblies.(Continued Next Page)2-20U.S.<strong>162</strong>PHUS-04

CESSNA SECTION 2MODEL <strong>162</strong>OPERATING LIMITATIONSGARMIN G300PLACARDS (Continued)On Airplanes <strong>162</strong>00241 and on, and Airplanes <strong>162</strong>00002 thru<strong>162</strong>00240 incorporating SB11-52-01.16. Located adjacent to both secondary interior cabin door latchassemblies.<strong>162</strong>PHUS-04 U.S. 2-21/2-22

CESSNA SECTION 3MODEL <strong>162</strong>EMERGENCY PROCEDURESGARMIN G300EMERGENCY PROCEDURESTABLE OF CONTENTSPageIntroduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-5Airspeeds For Emergency Operations. . . . . . . . . . . . . . . . . . . . . . . .3-5EMERGENCY PROCEDURES . . . . . . . . . . . . . . . . . . . . . . . . .3-6ENGINE FAILURES AND MALFUNCTIONS . . . . . . . . . . . . . . . . . .3-6Engine Failure During Takeoff Roll . . . . . . . . . . . . . . . . . . . . . . . .3-6Engine Failure Immediately After Takeoff . . . . . . . . . . . . . . . . . . .3-6Engine Failure During Flight (Restart Procedures) . . . . . . . . . . . .3-7Oil PSI Indicator In Red Band Range (Red Digits) . . . . . . . . . . . .3-7Carb °F Indicator In Yellow Band Range (Yellow Digits) . . . . . . . .3-8FORCED LANDINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-9Emergency Landing Without Engine Power . . . . . . . . . . . . . . . . .3-9Precautionary Landing With Engine Power. . . . . . . . . . . . . . . . .3-10Ditching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11FIRES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-12During Start On Ground . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-12Engine Fire In Flight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-12Electrical Fire or Cabin Fire In Flight. . . . . . . . . . . . . . . . . . . . . .3-13Wing Fire. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-14ICING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-15Inadvertent Icing Encounter During Flight. . . . . . . . . . . . . . . . . .3-15ABNORMAL LANDINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-17Landing With Partial or No Flight Instrument Information . . . . . .3-17Landing With A Flat Main Tire . . . . . . . . . . . . . . . . . . . . . . . . . . .3-17Landing With A Flat Nose Tire . . . . . . . . . . . . . . . . . . . . . . . . . .3-18Door Open in Flight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-18Landing With Door Open. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-18(Continued Next Page)<strong>162</strong>PHUS-04 U.S.3-1

SECTION 3CESSNAEMERGENCY PROCEDURES MODEL <strong>162</strong>GARMIN G300TABLE OF CONTENTS (Continued)PageELECTRICAL POWER SUPPLY SYSTEM MALFUNCTIONS . . . 3-19Loss Of All Electrical Power (Except PFD) . . . . . . . . . . . . . . . . 3-19LOW VOLTS Annunciator Comes On or Volts Indication BelowGreen Band Range or Volts Less Than 12.5. . . . . . . . . . . . . . 3-20Volts Indication Above Green Band Range orVolts More Than 15 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-22AIR DATA, ATTITUDE AND HEADING REFERENCE SYSTEM(ADAHRS) FAILURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-23Red X - PFD or MFD Indicators (Airspeed, Altitude, Attitude,Horizontal Situation Indicator (HSI), or Engine IndicatingSystem (EIS)) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-23PFD/MFD DISPLAY MALFUNCTION OR FAILURE . . . . . . . . . . . 3-24PFD or MFD Display Black (No Information) . . . . . . . . . . . . . . . 3-24PFD or MFD Display Information Not Updating. . . . . . . . . . . . . 3-25Electric Pitch Trim Failure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-26(Continued Next Page)3-2U.S.<strong>162</strong>PHUS-04

CESSNA SECTION 3MODEL <strong>162</strong>EMERGENCY PROCEDURESGARMIN G300TABLE OF CONTENTS (Continued)PageAMPLIFIED EMERGENCY PROCEDURES. . . . . . . . . . . . . . . . . .3-27Engine Failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-27Maximum Glide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-28Forced Landings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-29Landing Without Elevator Control . . . . . . . . . . . . . . . . . . . . . . . . . .3-30Fires. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-30Emergency Operation In Clouds . . . . . . . . . . . . . . . . . . . . . . . . . . .3-31Executing A 180° Turn In Clouds (ADAHRS FAILED) . . . . . . . .3-31Emergency Descent Through Clouds (ADAHRS FAILED) . . . . .3-32Recovery From Spiral Dive In The Clouds (ADAHRS FAILED) .3-33Inadvertent Flight Into Icing Conditions . . . . . . . . . . . . . . . . . . . . . .3-34Spins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-35Rough Engine Operation Or Loss Of Power . . . . . . . . . . . . . . . . . .3-36Carburetor Icing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-36Spark Plug Fouling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-36Magneto Malfunction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-36Idle Power Engine Roughness . . . . . . . . . . . . . . . . . . . . . . . . . .3-37Low Oil Pressure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-37Electrical Power Supply System Malfunctions. . . . . . . . . . . . . . . . .3-38Excessive Rate Of Charge . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-38Insufficient Rate Of Charge. . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-39Other Emergencies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-40Windshield Damage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-40G300 Failures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-40<strong>162</strong>PHUS-04 U.S. 3-3/3-4

CESSNA SECTION 3MODEL <strong>162</strong>EMERGENCY PROCEDURESGARMIN G300INTRODUCTIONSection 3 provides checklist and amplified procedures for coping withemergencies that may occur. Emergencies caused by airplane orengine malfunctions are extremely rare if proper preflight inspectionsand maintenance are practiced. Enroute weather emergencies can beminimized or eliminated by careful flight planning and good judgmentwhen unexpected weather is encountered. However, should anemergency arise, the basic guidelines described in this section shouldbe considered and applied as necessary to correct the problem. In anyemergency situation, the most important task is continued control of theairplane and maneuver to execute a successful landing.Emergency procedures associated with optional or supplementalequipment are found in Section 9, Supplements.AIRSPEEDS FOR EMERGENCY OPERATIONSENGINE FAILURE AFTER TAKEOFFWing Flaps UP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70 KIASWing Flaps 10° - FULL . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65 KIASMAXIMUM OPERATING MANEUVERING SPEED1320 POUNDS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .89 KIAS1200 POUNDS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85 KIAS1100 POUNDS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80 KIASDESIGN MANEUVERING SPEED . . . . . . . . . . . . . . . . . . . . .102 KIASMAXIMUM GLIDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70 KIASPRECAUTIONARY LANDING WITH ENGINE POWER. . . . . .60 KIASLANDING WITHOUT ENGINE POWERWing Flaps UP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70 KIASWing Flaps 10° - FULL . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65 KIAS<strong>162</strong>PHUS-04 U.S.3-5

SECTION 3CESSNAEMERGENCY PROCEDURES MODEL <strong>162</strong>GARMIN G300EMERGENCY PROCEDURESProcedures in the Emergency Procedures Checklist portion of thissection shown in bold faced type are immediate action items whichshould be committed to memory.ENGINE FAILURES AND MALFUNCTIONSENGINE FAILURE DURING TAKEOFF ROLL1. THROTTLE Control - IDLE (pull full out)2. Brakes - APPLY3. Wing Flaps - RETRACT4. MIXTURE Control - IDLE CUTOFF (pull full out)5. MAGNETOS Switch - OFF6. MASTER Switch (ALT and BAT) - OFFENGINE FAILURE IMMEDIATELY AFTER TAKEOFF1. Airspeed - 70 KIAS - Flaps UP65 KIAS - Flaps 10° - FULL2. MIXTURE Control - IDLE CUTOFF (pull full out)3. FUEL SHUTOFF Valve - OFF (pull full out)4. MAGNETOS Switch - OFF5. Wing Flaps - AS REQUIRED (FULL recommended)6. MASTER Switch (ALT and BAT) - OFF (when landing isassured)7. Land - STRAIGHT AHEAD8. Secondary Interior Door Latch (if installed) - OPEN9. Primary Interior Door Latch - OPEN (just prior to touchdown)CAUTIONNON-EMERGENCY FLIGHT WITH DOOR(S) OPEN ISPROHIBITED.NOTEBoth cabin doors are equipped with gas struts and shouldopen automatically when unlatched. Delaying opening untiljust prior to touchdown will reduce cabin buffeting and windnoise.(Continued Next Page)3-6U.S.<strong>162</strong>PHUS-04

CESSNA SECTION 3MODEL <strong>162</strong>EMERGENCY PROCEDURESGARMIN G300ENGINE FAILURES AND MALFUNCTIONS (Continued)ENGINE FAILURE DURING FLIGHT (Restart Procedures)1. Airspeed - 70 KIAS (best glide speed)2. THROTTLE Control - IDLE (pull full out)3. CARB HEAT Control Knob - ON (pull full out)4. FUEL SHUTOFF Valve - ON (push full in)5. MIXTURE Control - RICH (if restart has not occurred)6. PRIMER (if installed) - IN and LOCKED7. MAGNETOS Switch - BOTH (or START if propeller is stopped)NOTEIf the propeller is windmilling, engine will restartautomatically within a few seconds. If propeller has stopped(possible at low speeds), turn MAGNETOS switch toSTART, advance throttle slowly from idle and lean themixture from full rich as required to obtain smoothoperation.OIL PSI INDICATOR IN RED BAND RANGE (RED DIGITS)1. OIL °F - CHECKIF OIL °F ABOVE GREEN BAND RANGE OR OIL °F RISING(engine failure imminent)2. Throttle Control - REDUCE POWER IMMEDIATELY3. Airspeed - 70 KIAS (best glide speed)4. Land as soon as possible (refer to EMERGENCY LANDINGWITHOUT ENGINE POWER)IF OIL °F WITHIN GREEN BAND RANGE2. OIL °F - MONITOR3. OIL PSI - MONITOR4. Land as soon as practical. (nearest suitable airportrecommended)(Continued Next Page)<strong>162</strong>PHUS-04 U.S.3-7

SECTION 3CESSNAEMERGENCY PROCEDURES MODEL <strong>162</strong>GARMIN G300ENGINE FAILURES AND MALFUNCTIONS (Continued)CARB °F INDICATOR IN YELLOW BAND RANGE(YELLOW DIGITS)1. ENGINE - MONITOR FOR ROUGHNESS AND/OR RPM LOSSNOTECarb °F indicator in yellow band range indicatestemperatures may support carb icing formation.IF ENGINE ROUGHNESS AND/OR RPM LOSS IS DETECTED(CARB °F IN YELLOW BAND RANGE)2. CARB HEAT Control Knob - ON (pull full out)3. THROTTLE Control - FULL (push full in)4. MIXTURE Control - LEAN (as required)5. CARB °F Indicator - CHECKIF ENGINE ROUGHNESS CONTINUES6. CARB °F Indicator - MONITOR7. ALTITUDE - CONSIDER CHANGE (to warmer or drier air massif terrain permits)8. Land as soon as practical.IF ENGINE ROUGHNESS AND/OR RPM LOSS IS NOTDETECTED2. CARB °F Indicator - MONITOR3. CARB HEAT Control Knob - AS REQUIRED4. Continue flight as normal.3-8U.S.<strong>162</strong>PHUS-04

CESSNA SECTION 3MODEL <strong>162</strong>EMERGENCY PROCEDURESGARMIN G300FORCED LANDINGSEMERGENCY LANDING WITHOUT ENGINE POWER1. Seats and Seat Belts - SECURE2. Airspeed -70 KIAS - Flaps UP65 KIAS - Flaps 10° - FULL3. MIXTURE Control - IDLE CUTOFF (pull full out)4. FUEL SHUTOFF Valve - OFF (pull full out)5. Radio - ALERT ATC or TRANSMIT MAYDAY ON 121.5 MHZ,(give location, intentions and SQUAWK 7700)6. MAGNETOS Switch - OFF7. Wing Flaps - AS REQUIRED (FULL recommended)8. MASTER Switch (ALT and BAT) - OFF (when landing isassured)9. ELT - ACTIVATE10. Secondary Interior Door Latch (if installed) - OPEN11. Primary Interior Door Latch - OPEN (just prior to touchdown)CAUTIONNON-EMERGENCY FLIGHT WITH DOOR(S) OPEN ISPROHIBITED.NOTEBoth cabin doors are equipped with gas struts and shouldopen automatically when unlatched. Delaying opening untiljust prior to touchdown will reduce cabin buffeting and windnoise.12. Touchdown - SLIGHTLY TAIL LOW13. Brakes - APPLY HEAVILY(Continued Next Page)<strong>162</strong>PHUS-04 U.S.3-9

SECTION 3CESSNAEMERGENCY PROCEDURES MODEL <strong>162</strong>GARMIN G300FORCED LANDINGS (Continued)PRECAUTIONARY LANDING WITH ENGINE POWER1. Seats and Seat Belts - SECURE2. Airspeed - 70 KIAS3. Wing Flaps - 10° or 25°4. Radio - ALERT ATC or TRANSMIT MAYDAY ON 121.5 MHZ,(give location, intentions and SQUAWK 7700)5. Selected Field - FLY OVER (noting terrain and obstructions)6. Wing Flaps - FULL (on final approach)7. Airspeed - 60 KIAS8. MASTER Switch (ALT and BAT) - OFF (when landing assured)9. ELT - ACTIVATE10. Secondary Interior Door Latch (if installed) - OPEN11. Primary Interior Door Latch - OPEN (just prior to touchdown)CAUTIONNON-EMERGENCY FLIGHT WITH DOOR(S) OPEN ISPROHIBITED.NOTEBoth cabin doors are equipped with gas struts and shouldopen automatically when unlatched. Delaying opening untiljust prior to touchdown will reduce cabin buffeting and windnoise.12. Touchdown - SLIGHTLY TAIL LOW13. MIXTURE Control - IDLE CUTOFF (pull full out)14. MAGNETOS Switch - OFF15. Brakes - APPLY HEAVILY3-10U.S.<strong>162</strong>PHUS-04

CESSNA SECTION 3MODEL <strong>162</strong>EMERGENCY PROCEDURESGARMIN G300FORCED LANDINGS (Continued)DITCHING1. Radio - TRANSMIT MAYDAY on 121.5 MHz, (give location,intentions and SQUAWK 7700)2. Heavy Objects (in baggage area) - SECURE (if possible)3. Seats and Seat Belts - SECURE4. Wing Flaps - 25° or FULL5. Power - ESTABLISH 300 FT/MIN DESCENT AT 60 KIASNOTEIf no power is available, approach at 70 KIAS with Flaps UPor at 65 KIAS with Flaps 10°.6. Approach - High Winds, Heavy Seas - INTO THE WINDLight Winds, Heavy Swells - PARALLEL TOSWELLS7. ELT - ACTIVATE8. Secondary Interior Door Latch (if installed) - OPEN9. Primary Interior Door Latch - OPEN (just prior to touchdown)CAUTIONNON-EMERGENCY FLIGHT WITH DOOR(S) OPEN ISPROHIBITED.NOTEBoth cabin doors are equipped with gas struts and shouldopen automatically when unlatched. Delaying opening untiljust prior to touchdown will reduce cabin buffeting and windnoise.10. Touchdown - LEVEL ATTITUDE AT ESTABLISHED 300 FT/MINDESCENT11. Face - CUSHION AT TOUCHDOWN (with folded coat)12. Airplane - EVACUATE THROUGH CABIN DOORS<strong>162</strong>PHUS-04 U.S.3-11

SECTION 3CESSNAEMERGENCY PROCEDURES MODEL <strong>162</strong>GARMIN G300FIRESDURING START ON GROUND1. MAGNETOS Switch - START (continue cranking to start theengine)IF ENGINE STARTS2. Power - 1800 RPM (for a few minutes)3. Engine - SHUTDOWN (inspect for damage)IF ENGINE FAILS TO START2. THROTTLE Control - FULL (push full in)3. MIXTURE Control - IDLE CUTOFF (pull full out)4. MAGNETOS Switch - START (continue cranking)5. FUEL SHUTOFF Valve - OFF (pull full out)6. MAGNETOS Switch - OFF7. MASTER Switch (ALT and BAT) - OFF8. Engine - SECURE9. Parking Brake - RELEASE10. Fire Extinguisher - OBTAIN (have ground attendants obtain if notinstalled)11. Airplane - EVACUATE12. Fire - EXTINGUISH (using fire extinguisher, wool blanket, or dirt)13. Fire Damage - INSPECT (repair or replace damagedcomponents and/or wiring before conducting another flight)ENGINE FIRE IN FLIGHT1. MIXTURE Control - IDLE CUTOFF (pull full out)2. FUEL SHUTOFF Valve - OFF (pull full out)3. MASTER Switch (ALT Only) - OFF4. Cabin Vents - OPEN (as needed)5. CABIN HEAT Control Knob - OFF (push full in) (to avoid drafts)6. Airspeed - 85 KIAS (If fire is not extinguished, increase glidespeed to find an airspeed, within airspeed limitations, which willprovide an incombustible mixture)7. Forced Landing - EXECUTE (refer to EMERGENCY LANDINGWITHOUT ENGINE POWER)(Continued Next Page)3-12U.S.<strong>162</strong>PHUS-04

CESSNA SECTION 3MODEL <strong>162</strong>EMERGENCY PROCEDURESGARMIN G300FIRES (Continued)ELECTRICAL FIRE OR CABIN FIRE IN FLIGHT1. MASTER Switch (ALT and BAT) - OFFWARNINGOUTSIDE VISUAL REFERENCE MUST BE USED TOMAINTAIN SITUATIONAL AWARENESS. ALL FLIGHTINSTRUMENTS, RADIOS, AND PITCH TRIM WILL BEINOPERATIVE WHEN MASTER SWITCH IS TURNEDOFF.2. Cabin Vents - CLOSED (to avoid drafts)3. CABIN HEAT Control Knob - OFF (push full in) (to avoiddrafts)4. Fire Extinguisher - ACTIVATE (if available)5. AVN MASTER Switch - OFF6. All Other Switches (except MAGNETOS switch) - OFFIF FIRE HAS NOT BEEN EXTINGUISHED7. MASTER Switch (ALT and BAT) - ON8. Rapid Descent - EXECUTE (Perform sideslip to rapidly losealtitude and shorten exposure time).9. AVN MASTER Switch - ON10. Radio - ALERT ATC or TRANSMIT MAYDAY ON 121.5 MHZ,(give location, intentions and SQUAWK 7700)11. Forced Landing - EXECUTE (refer to PRECAUTIONARYLANDING WITH ENGINE POWER)NOTEThe G300 self-test and ADAHRS alignment may takeseveral minutes to establish thus delaying display of flightinstrument data. It may be necessary to execute landingwithout airspeed or altitude information.(Continued Next Page)<strong>162</strong>PHUS-04 U.S.3-13

SECTION 3CESSNAEMERGENCY PROCEDURES MODEL <strong>162</strong>GARMIN G300FIRES (Continued)ELECTRICAL FIRE OR CABIN FIRE IN FLIGHT (Continued)IF FIRE HAS BEEN EXTINGUISHED AND ELECTRICAL POWERIS NECESSARY FOR CONTINUED FLIGHT TO NEARESTSUITABLE AIRPORT OR LANDING AREAWARNINGAFTER THE FIRE EXTINGUISHER HAS BEEN USED,MAKE SURE THAT THE FIRE IS EXTINGUISHEDBEFORE EXTERIOR AIR IS USED TO REMOVE SMOKEFROM THE CABIN.7. Cabin Vents - OPEN (when sure that fire is completelyextinguished)8. CABIN HEAT Control Knob - ON (pull full out) (when sure that fireis completely extinguished)9. Circuit Breakers - CHECK (for OPEN circuit(s), do not reset)10.MASTER Switch (ALT and BAT) - ON11.AVN MASTER Switch - ON12.Land the airplane as soon as possible to inspect for damage.WING FIRE1. LDG Light Switch - OFF2. NAV Light Switch - OFF3. STROBE Light Switch - OFFNOTEPerform a sideslip to keep the flames away from the fueltank and cabin.4. Land as soon as possible.3-14U.S.<strong>162</strong>PHUS-04

CESSNA SECTION 3MODEL <strong>162</strong>EMERGENCY PROCEDURESGARMIN G300ICINGINADVERTENT ICING ENCOUNTER DURING FLIGHT1. Turn back or change altitude to exit icing conditions.Consider lateral or vertical flight path reversal to return to last"known good" flight conditions (to obtain an outside airtemperature that is less conducive to icing). Maintain VFR flight.WARNINGFAILURE TO ACT QUICKLY MAY RESULT IN ANUNRECOVERABLE ICING ENCOUNTER.2. CABIN HEAT Control Knob - ON (pull full out)3. A/P DISC/CWS (if installed) - PRESS (verify autopilotdisengages and aural alert is heard)WARNINGDO NOT ENGAGE AUTOPILOT WITH VISIBLE ICE ONAIRFRAME OR AFTER ENCOUNTERING ICINGCONDITIONS.4. Watch for signs of induction air filter icing and apply carburetorheat as required. Monitoring the G300 Carb °F Indicator mayassist early detection. A loss of engine RPM could be caused bycarburetor ice or ice blocking the air intake filter. Adjust thethrottle as necessary to hold engine RPM. Adjust mixture asnecessary for any change in power settings or if carburetor heatis used continuously.5. Watch for ice accretion on pitot tube and signs of pitot-staticicing. Airspeed and altimeter indications may becomeunreliable.a. Attitude and Heading information will remain reliable inevent of airspeed and altimeter failure. Use attitude indicatorto monitor pitch and bank.b. Reference GS (ground speed) in conjunction with GPSderived wind information to determine an approximateairspeed.(Continued Next Page)<strong>162</strong>PHUS-04 U.S.3-15

SECTION 3CESSNAEMERGENCY PROCEDURES MODEL <strong>162</strong>GARMIN G300ICING (Continued)INADVERTENT ICING ENCOUNTER DURING FLIGHT(Continued)c. Reference GPS ALTITUDE on MFD INFO page (if installed)or select G300 TERRAIN Profile page. GPS Altitude isprovided by the white arrowhead on the left side of theTERRAIN Profile display.d. Navigate using Heading Strip, Lateral Deviation, and GPSmoving map (GPS moving map and TERRAIN Profile cannot be displayed at the same time).NOTEGPS information is not as accurate as barometric data butwill provide an approximate value for comparison to pitotstaticinstruments or a back-up if barometric instrumentsbecome unreliable.6. Plan a landing at the nearest airport. With an extremely rapid icebuild-up, select a suitable off airport landing site.7. With an ice accumulation of 0.25 inch (6.35 mm) or more on thewing leading edges, be prepared for significantly higher powerrequirements, higher approach and stall speeds, and a longerlanding roll. Gently pitch and yaw the airplane periodically tokeep ice bridging on the controls to a minimum.8. Leave wing flaps retracted. With a severe ice build-up on thehorizontal tail, the change in wing wake airflow direction causedby wing flap extension could result in a loss of elevatoreffectiveness.9. Perform a landing approach using a forward slip, if necessary,for improved visibility.10. Approach at 65 to 70 KIAS (estimated 70 KTS if using GPS forairspeed indication) depending upon the amount of iceaccumulation.11. Perform landing in level attitude.12. Go arounds should be avoided whenever possible because ofseverely reduced climb capability.3-16U.S.<strong>162</strong>PHUS-04

CESSNA SECTION 3MODEL <strong>162</strong>EMERGENCY PROCEDURESGARMIN G300ABNORMAL LANDINGSLANDING WITH PARTIAL OR NO FLIGHT INSTRUMENTINFORMATION1. Transponder - Select Pressure Alt display using FUNC button(ADAHRS may be providing altitude information to transponder).2. Selected Field - FLY OVER (noting terrain, obstructions, andany visual cues that may be used for speed references (i.e.traffic on nearby highway, etc))3. Approach - NORMAL4. Wing Flaps - AS REQUIRED (FULL recommended)5. Speed - Use best pilot judgment and experience to referencespeed cues such as flap extension forces, slipstream sounds,etc. Stall warning horn will function and provide approximately 5knot stall warning.6. Touchdown - NORMAL7. Directional Control - MAINTAINNOTEWithout accurate speed information, landing may be madeat faster than normal speeds. Gently apply brakes whilecontinuing to “fly” the airplane during roll-out. Loss ofdirectional control may result from locked brakes andskidding tires due to over braking.LANDING WITH A FLAT MAIN TIRE1. Approach - NORMAL2. Wing Flaps - FULL3. Touchdown - GOOD MAIN TIRE FIRST (hold airplane off flat tireas long as possible with aileron control)4. Directional Control - MAINTAIN (using rudder and brake ongood wheel as required)<strong>162</strong>PHUS-04 U.S.3-17

SECTION 3CESSNAEMERGENCY PROCEDURES MODEL <strong>162</strong>GARMIN G300ABNORMAL LANDINGS (Continued)LANDING WITH A FLAT NOSE TIRE1. Approach - NORMAL (choose longest runway if possible)2. Wing Flaps - AS REQUIREDa. 65 to 70 KIAS - Flaps UP - 10°b. Below 65 KIAS - Flaps 10° - FULL3. Touchdown - ON MAINS (tail slightly low)4. Elevator - continue stick to full aft as airplane slows (holdnosewheel off the ground as long as possible)5. When nosewheel touches down, maintain full up elevator asairplane slows to stop.6. Directional Control - MAINTAIN (using full rudder control)Attempt to limit differential braking.7. Braking - Use brakes only as needed to lessen chance of propstrike. Rolling drag of the flat nose tire will increase brakingeffect.DOOR OPEN IN FLIGHTWARNINGINTENTIONAL FLIGHT WITH DOOR(S) OPEN ISPROHIBITED.1. CABIN DOOR - LEAVE OPEN (do not attempt to close)2. THROTTLE Control - REDUCE (as necessary)3. Airspeed - 80 KIAS (or less)4. Seat Belts - CHECK (verify secure and tight)5. Cabin - CHECK (stow loose materials)6. Land as soon as practical.LANDING WITH DOOR OPEN1. Wing Flaps - AS REQUIREDa. 65 to 70 KIAS - Flaps UP - 10°b. Below 65 KIAS - Flaps 10° - FULL2. Landing Approach - NORMAL (limit sideslip angle if possible)3. Touchdown - NORMAL3-18U.S.<strong>162</strong>PHUS-04

CESSNA SECTION 3MODEL <strong>162</strong>EMERGENCY PROCEDURESGARMIN G300ELECTRICAL POWER SUPPLY SYSTEMMALFUNCTIONSLOSS OF ALL ELECTRICAL POWER (EXCEPT PFD)1. MAIN CB RESET Switch - PRESS MOMENTARILYIF ELECTRICAL POWER RESUMES NORMAL OPERATION2. Continue flight and land as soon as practical.IF ELECTRICAL POWER REMAINS INOPERATIVE (EXCEPTPFD)2. Land as soon as possible.NOTEThe PFD will be operating on the secondary battery only.The secondary battery is not a back-up battery. It isincluded in the electrical system to limit display presentationissues that might arise during the voltage drop whichoccurs during engine start. In good condition, thesecondary battery may provide 5 to 10 minutes of PFDoperation.3. Prepare for total loss of electrical power and PFD. Refer toABNORMAL LANDINGS, LANDING WITH PARTIAL OR NOFLIGHT INSTRUMENT INFORMATION.(Continued Next Page)<strong>162</strong>PHUS-04 U.S.3-19