ALUCOBOND Verarbeitung - Ravago

ALUCOBOND Verarbeitung - Ravago

ALUCOBOND Verarbeitung - Ravago

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

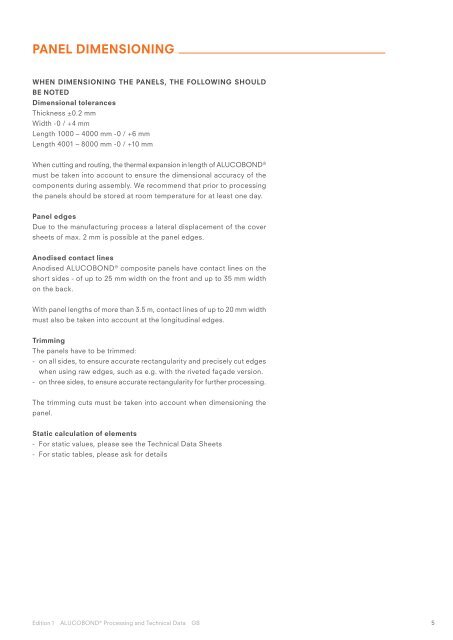

PANEL DIMENSIONINGWHEN DIMENSIONING THE PANELS, THE FOLLOWING SHOULDBE NOTEDDimensional tolerancesThickness ±0.2 mmWidth -0 / +4 mmLength 1000 – 4000 mm -0 / +6 mmLength 4001 – 8000 mm -0 / +10 mmWhen cutting and routing, the thermal expansion in length of <strong>ALUCOBOND</strong> ®must be taken into account to ensure the dimensional accuracy of thecomponents during assembly. We recommend that prior to processingthe panels should be stored at room temperature for at least one day.Panel edgesDue to the manufacturing process a lateral displacement of the coversheets of max. 2 mm is possible at the panel edges.Anodised contact linesAnodised <strong>ALUCOBOND</strong> ® composite panels have contact lines on theshort sides - of up to 25 mm width on the front and up to 35 mm widthon the back.With panel lengths of more than 3.5 m, contact lines of up to 20 mm widthmust also be taken into account at the longitudinal edges.TrimmingThe panels have to be trimmed:--on all sides, to ensure accurate rectangularity and precisely cut edgeswhen using raw edges, such as e.g. with the riveted façade version.--on three sides, to ensure accurate rectangularity for further processing.The trimming cuts must be taken into account when dimensioning thepanel.Static calculation of elements--For static values, please see the Technical Data Sheets--For static tables, please ask for detailsEdition 1<strong>ALUCOBOND</strong> ® Processing and Technical Data GB5