Epoxy Application Guide - Loctite.ph

Epoxy Application Guide - Loctite.ph

Epoxy Application Guide - Loctite.ph

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

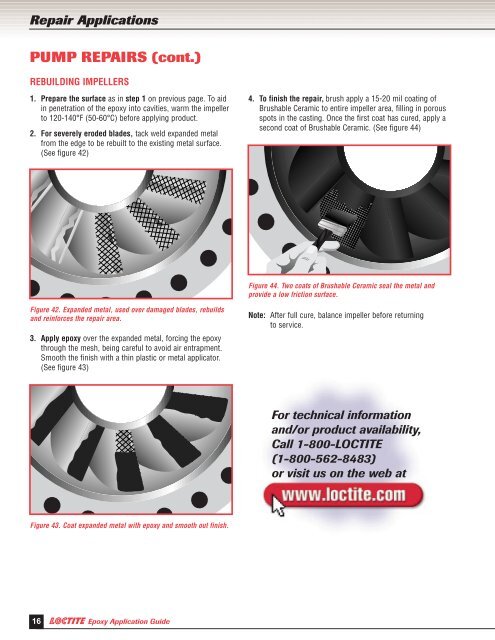

Repair <strong>Application</strong>sPUMP REPAIRS (cont.)REBUILDING IMPELLERS1. Prepare the surface as in step 1 on previous page. To aidin penetration of the epoxy into cavities, warm the impellerto 120-140°F (50-60°C) before applying product.2. For severely eroded blades, tack weld expanded metalfrom the edge to be rebuilt to the existing metal surface.(See figure 42)4. To finish the repair, brush apply a 15-20 mil coating ofBrushable Ceramic to entire impeller area, filling in porousspots in the casting. Once the first coat has cured, apply asecond coat of Brushable Ceramic. (See figure 44)Figure 44. Two coats of Brushable Ceramic seal the metal andprovide a low friction surface.Figure 42. Expanded metal, used over damaged blades, rebuildsand reinforces the repair area.3. Apply epoxy over the expanded metal, forcing the epoxythrough the mesh, being careful to avoid air entrapment.Smooth the finish with a thin plastic or metal applicator.(See figure 43)Note: After full cure, balance impeller before returningto service.For technical informationand/or product availability,Call 1-800-LOCTITE(1-800-562-8483)or visit us on the web atFigure 43. Coat expanded metal with epoxy and smooth out finish.16 <strong>Epoxy</strong> <strong>Application</strong> <strong>Guide</strong>