Epoxy Application Guide - Loctite.ph

Epoxy Application Guide - Loctite.ph

Epoxy Application Guide - Loctite.ph

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

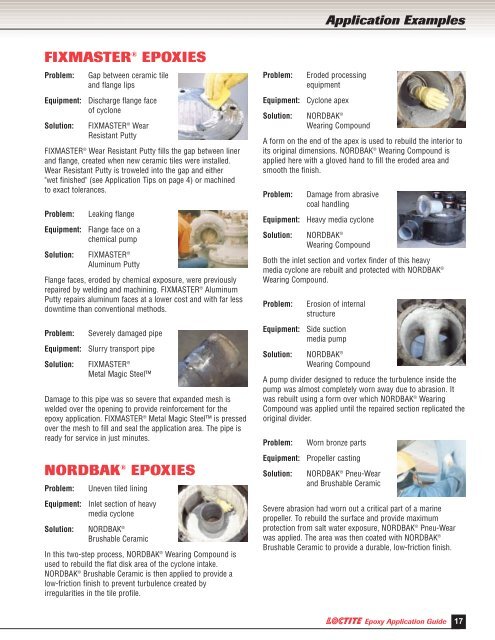

<strong>Application</strong> ExamplesFIXMASTER ® EPOXIESProblem:Equipment:Solution:Gap between ceramic tileand flange lipsDischarge flange faceof cycloneFIXMASTER ® WearResistant PuttyFIXMASTER ® Wear Resistant Putty fills the gap between linerand flange, created when new ceramic tiles were installed.Wear Resistant Putty is troweled into the gap and either"wet finished" (see <strong>Application</strong> Tips on page 4) or machinedto exact tolerances.Problem:Equipment:Leaking flangeFlange face on achemical pumpSolution: FIXMASTER ®Aluminum PuttyFlange faces, eroded by chemical exposure, were previouslyrepaired by welding and machining. FIXMASTER ® AluminumPutty repairs aluminum faces at a lower cost and with far lessdowntime than conventional methods.Problem:Equipment:Severely damaged pipeSlurry transport pipeSolution: FIXMASTER ®Metal Magic SteelDamage to this pipe was so severe that expanded mesh iswelded over the opening to provide reinforcement for theepoxy application. FIXMASTER ® Metal Magic Steel is pressedover the mesh to fill and seal the application area. The pipe isready for service in just minutes.NORDBAK ® EPOXIESProblem:Equipment:Uneven tiled liningInlet section of heavymedia cycloneSolution: NORDBAK ®Brushable CeramicIn this two-step process, NORDBAK ® Wearing Compound isused to rebuild the flat disk area of the cyclone intake.NORDBAK ® Brushable Ceramic is then applied to provide alow-friction finish to prevent turbulence created byirregularities in the tile profile.Problem:Equipment:Eroded processingequipmentCyclone apexSolution: NORDBAK ®Wearing CompoundA form on the end of the apex is used to rebuild the interior toits original dimensions. NORDBAK ® Wearing Compound isapplied here with a gloved hand to fill the eroded area andsmooth the finish.Problem:Equipment:Damage from abrasivecoal handlingHeavy media cycloneSolution: NORDBAK ®Wearing CompoundBoth the inlet section and vortex finder of this heavymedia cyclone are rebuilt and protected with NORDBAK ®Wearing Compound.Problem:Equipment:Erosion of internalstructureSide suctionmedia pumpSolution: NORDBAK ®Wearing CompoundA pump divider designed to reduce the turbulence inside thepump was almost completely worn away due to abrasion. Itwas rebuilt using a form over which NORDBAK ® WearingCompound was applied until the repaired section replicated theoriginal divider.Problem:Equipment:Solution:Worn bronze partsPropeller castingNORDBAK ® Pneu-Wearand Brushable CeramicSevere abrasion had worn out a critical part of a marinepropeller. To rebuild the surface and provide maximumprotection from salt water exposure, NORDBAK ® Pneu-Wearwas applied. The area was then coated with NORDBAK ®Brushable Ceramic to provide a durable, low-friction finish.<strong>Epoxy</strong> <strong>Application</strong> <strong>Guide</strong>17