Magellan 8500Xt - Koncept-L

Magellan 8500Xt - Koncept-L

Magellan 8500Xt - Koncept-L

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

TABLE OF CONTENTSSection 1. Introduction ....................................................................................... 1-1Manual Overview .......................................................................................................................1-2How to Use This Manual ................................................................................................1-3Scanner and Scanning-Scale Nomenclature ...................................................................1-4Connectors .........................................................................................................................1-5Physical Parameters ..................................................................................................................1-6Scanning .............................................................................................................................1-6EAS Tag Deactivation System .....................................................................................1-6Weighing ............................................................................................................................1-7Warm-Up Time .................................................................................................................1-8Electrical Specifications ...........................................................................................................1-9Power Supply ................................................................................................................. 1-10Laser and Product Safety ..................................................................................................... 1-11Labeling ...................................................................................................................................... 1-13Agency Compliances ............................................................................................................. 1-14Barcodes Supported .............................................................................................................. 1-15Technical Support ................................................................................................................... 1-16Datalogic Website Support ....................................................................................... 1-16Reseller Technical Support ........................................................................................ 1-16Telephone Technical Support .................................................................................. 1-16Section 2. Site Preparation and Installation ..................................................... 2-1Pre-Installation Considerations ............................................................................................2-2Checkstand Design ...................................................................................................................2-3Scanner Installation ..................................................................................................................2-4Scanner Maintenance ..............................................................................................................2-4References ....................................................................................................................................2-4Scanner Usage ............................................................................................................................2-4Site Preparation Overview ......................................................................................................2-5Ventilation and Spacing ..........................................................................................................2-7Service Access .............................................................................................................................2-8Power Installation ......................................................................................................................2-9Grounding ..........................................................................................................................2-9Checkstand Preparation ....................................................................................................... 2-10Liquid Spills and Moisture ......................................................................................... 2-11Product Reference Guide 1

Counter Cutout ........................................................................................................................2-11Checkstand Mounting .................................................................................................2-18Installation Overview .............................................................................................................2-18Unpacking ........................................................................................................................2-19Operational Verification ..............................................................................................2-20Diagnostic Modes .........................................................................................................2-23Cables & Connections ..................................................................................................2-24Remote Scale Display Placement/Installation ..............................................................2-26Lighting Considerations .............................................................................................2-26Viewing Angle ................................................................................................................2-27Remote Display Cabling .............................................................................................2-28Model 8300RD: Placing and Installing the Remote Display ...........................2-28Model 960RD: Placing and Installing the Remote Scale Display ..................2-31Changing Weighing Modes .......................................................................................2-34Set-Up & Installation ...............................................................................................................2-34Set-up ................................................................................................................................2-34Installation .......................................................................................................................2-36System Power-Up Recap .......................................................................................................2-38Section 3. Operation and Maintenance............................................................. 3-1Scanning Items ................................................................................................................. 3-1Deactivating Security Labels ....................................................................................... 3-3Proper Weighing Technique ....................................................................................... 3-5Operational Controls ................................................................................................................ 3-6Operational Modes ................................................................................................................... 3-6Power-Up/Selftest & Pre-Operation ......................................................................... 3-6Operating Mode .............................................................................................................. 3-8Additional Functions ................................................................................................................ 3-9Programming .................................................................................................................... 3-9Diagnostic Mode ............................................................................................................. 3-9Scanner and Scale Reset ............................................................................................... 3-9Scale Adjustments ........................................................................................................3-10Operational Maintenance ....................................................................................................3-12Vertical Scan Window Replacement ......................................................................3-12Horizontal Scan Window Replacement (DLC) ....................................................3-15Section 4. Problem Isolation .............................................................................. 4-12 <strong>Magellan</strong> ® <strong>8500Xt</strong> Scanner

Diagnostic Procedures ............................................................................................................ 4-2Error Codes .................................................................................................................................. 4-3Scale Error Reporting ............................................................................................................... 4-6Flowcharts ................................................................................................................................... 4-7Section 5. Calibration Procedures, Single Interval........................................... 5-1Description of Calibration Sequence ................................................................................. 5-2Motion Test ................................................................................................................................. 5-3Automatic Zero Tracking Test .............................................................................................. 5-3Preparing the Scanner/Scale for Calibration ................................................................... 5-4Calibrating the Scale (Pounds & Kilograms) .................................................................... 5-5Calibration Verification (U.S. Pounds) ................................................................................ 5-8Increasing-Load Test (Phase 1) .................................................................................. 5-8Shift Test ............................................................................................................................. 5-9Increasing- Load Test (Phase 2) ...............................................................................5-10Blanking Test ..................................................................................................................5-10Decreasing-Load Test ..................................................................................................5-11Return to Zero Test .......................................................................................................5-11Calibration Verification (Kilograms) .................................................................................5-12Increasing-Load Test (Phase 1) ................................................................................5-12Shift Test (Metric) ..........................................................................................................5-13Increasing- Load Test (Phase 2) ...............................................................................5-14Blanking Test ..................................................................................................................5-15Decreasing-Load Test ..................................................................................................5-16Return to Zero Test .......................................................................................................5-16Section 6. Calibration Procedures, Dual Interval ............................................. 6-1Description of Calibration Sequence ................................................................................. 6-2Motion Test ................................................................................................................................. 6-3Automatic Zero Setting Test ................................................................................................. 6-3Preparing the Scanner/Scale for Calibration ................................................................... 6-4Calibrating the Scale (Pounds & Kilograms) .................................................................... 6-5Calibration Verification (Pounds) ........................................................................................ 6-8Calibration Verification (Kilograms) .................................................................................6-13Section 7. Programming ..................................................................................... 7-1Introduction to Label Programming .................................................................................. 7-1Product Reference Guide 3

Understanding the Basics ....................................................................................................... 7-1Integrating the Scanner With Your Host System ........................................................... 7-1Customizing Your Scanner’s Operation .................................................................. 7-2Programming Overview .......................................................................................................... 7-3Programming via Handheld Device ......................................................................... 7-3What Is Programming Mode? ..................................................................................... 7-4Entering and Exiting Programming Mode. ............................................................ 7-4Programming Session ................................................................................................... 7-5LED and Beeper Indicators ..................................................................................................... 7-9If You Make a Mistake... ........................................................................................................... 7-9Return to Factory Settings ........................................................................................... 7-9Test Mode ........................................................................................................................7-10General Scanner and Scale Features ................................................................................7-11Double Read Timeout ..................................................................................................7-11Laser Timeout .................................................................................................................7-13Motor Timeout ...............................................................................................................7-15Green LED Idle State .....................................................................................................7-18Scanner Button Options .............................................................................................7-19Power-up Beep Control ..............................................................................................7-21Good Read Beep Control ............................................................................................7-22Good Read Beep Frequency ......................................................................................7-23Good Read Beep Length .............................................................................................7-25Good Read Beep Volume ...........................................................................................7-26Good Read When to Indicate ....................................................................................7-29Scale Enable ....................................................................................................................7-32Scale Enforced Zero Return .......................................................................................7-33Scale Interface Type .....................................................................................................7-35Remote Display — Enable/Disable .........................................................................7-37Aux Port Mode ................................................................................................................7-38Laser Failure Mode ........................................................................................................7-40Productivity Index Reporting (PIR)/Cashier Training (CT) ..............................7-41EAS Features — Sensormatic ..............................................................................................7-42EAS Mode .........................................................................................................................7-42EAS Beep Duration ........................................................................................................7-46EAS Retry Count .............................................................................................................7-47Manual EAS Deactivation Push Button .................................................................7-48EAS Deactivation Duration — Coupled ................................................................7-514 <strong>Magellan</strong> ® <strong>8500Xt</strong> Scanner

EAS Deactivation Duration — Retry .......................................................................7-52EAS Deactivation Duration — Manual ..................................................................7-53EAS Features — Checkpoint ...............................................................................................7-54EAS Active State .............................................................................................................7-54EAS Timeout ....................................................................................................................7-55Interface Related Features ...................................................................................................7-56Interface Type .................................................................................................................7-56Maximum Host-Transmitted Message Length ...................................................7-77Number of Host Transmission Buffers ...................................................................7-78Global Prefix ....................................................................................................................7-79Global Suffix ....................................................................................................................7-81IBM Features .............................................................................................................................7-83IBM Interface Options ..................................................................................................7-83IBM Scale Address .........................................................................................................7-84IBM Transmit Labels in Code 39 Format ...............................................................7-86OEM USB Interface Options .......................................................................................7-87OEM USB Scanner Device Type ................................................................................7-89RS-232 Features .......................................................................................................................7-90RS-232 Baud Rate ..........................................................................................................7-90RS-232 Number of Data Bits ......................................................................................7-94RS-232 Number of Stop Bits ......................................................................................7-95RS-232 Parity ...................................................................................................................7-96RS-232 Hardware Control ...........................................................................................7-98RS-232 Intercharacter Delay ....................................................................................7-100RS-232 Software Flow Control ................................................................................7-101RS-232 Host Echo ........................................................................................................7-102RS-232 Host Echo Quiet Interval ............................................................................7-103RS-232 Ignore Host Commands .............................................................................7-104RS-232 TTL .....................................................................................................................7-105RS-232 TTL Invert ........................................................................................................7-106RS-232 Beep on ASCII BEL ........................................................................................7-107RS-232 Beep After Weigh .........................................................................................7-108RS-232 Beep on Not on File .....................................................................................7-109RS-232 ACK NAK Enable ...........................................................................................7-110RS-232 ACK Character ...............................................................................................7-112RS-232 NAK Character ...............................................................................................7-113RS-232 Retry on ACK NAK Timeout ......................................................................7-114Product Reference Guide 5

RS-232 ACK NAK Timeout Value ........................................................................... 7-115RS-232 ACK NAK Retry Count ................................................................................ 7-116RS-232 ACK NAK Error Handling ........................................................................... 7-117RS-232 Label ID Control ........................................................................................... 7-119Single Cable RS-232 Options ............................................................................................ 7-121Single Cable RS-232 Scanner Only Protocol ..................................................... 7-122Single Cable RS-232 RTS CTS Selection .............................................................. 7-123Single Cable RS-232 Use BCC ................................................................................. 7-126Single Cable RS-232 Use ACK/NAK ...................................................................... 7-127Single Cable RS-232 Use STX .................................................................................. 7-128Set Single Cable RS-232 STX Character .............................................................. 7-129Single Cable RS-232 Use ETX .................................................................................. 7-130Set Single Cable RS-232 ETX Character .............................................................. 7-131Single Cable RS-232 Datalogic Extensions ........................................................ 7-132Symbology Programming ................................................................................................. 7-133Coupon Control .................................................................................................................... 7-133UPC-A Enable ......................................................................................................................... 7-135UPC-A Number System Character Transmission ............................................ 7-136UPC-A Check Character Transmission ................................................................ 7-137Expand UPC-A to EAN-13 ........................................................................................ 7-138UPC/EAN AIM ID ......................................................................................................... 7-139UPC-A Label ID ............................................................................................................ 7-140UPC-A 2-Digit Supplemental Label ID ................................................................ 7-141UPC-A 5-Digit Supplemental Label ID ................................................................ 7-142UPC-A 128 Supplemental Label ID ...................................................................... 7-143UPC-E Enable .......................................................................................................................... 7-144UPC-E Number System Character Transmission ............................................. 7-145UPC-E Check Character Transmission ................................................................. 7-146Expand UPC-E to UPC-A ........................................................................................... 7-147Expand UPC-E to EAN-13 ......................................................................................... 7-148UPC-E Label ID ............................................................................................................. 7-149UPC-E 2-Digit Supplemental Label ID ................................................................. 7-150UPC-E 5-Digit Supplemental Label ID ................................................................. 7-151UPC-E 128 Supplemental Label ID ....................................................................... 7-152EAN-13 Enable ....................................................................................................................... 7-153EAN-13 First Character Transmission .................................................................. 7-154EAN-13 Check Character Transmission .............................................................. 7-1556 <strong>Magellan</strong> ® <strong>8500Xt</strong> Scanner

EAN-13 ISBN Conversion Enable ...........................................................................7-156EAN 13 Label ID ...........................................................................................................7-157EAN-13 2-Digit Supplemental Label ID ...............................................................7-158EAN-13 5-Digit Supplemental Label ID ...............................................................7-159EAN-13 128 Supplemental Label ID .....................................................................7-160Bookland AIM ID ..........................................................................................................7-161Bookland Label ID .......................................................................................................7-162EAN-8 Enable ..........................................................................................................................7-163EAN-8 Check Character Transmission ..................................................................7-164Expand EAN-8 to EAN-13 .........................................................................................7-165EAN 8 Label ID ..............................................................................................................7-166EAN-8 2-Digit Supplemental Label ID .................................................................7-167EAN-8 5-Digit Supplemental Label ID .................................................................7-168EAN-8 128 Supplemental Label ID ........................................................................7-169EAN-8 Decoding Levels .............................................................................................7-170Other UPC/EAN Options .....................................................................................................7-173UPC/EAN Reconstruction .........................................................................................7-174Price Weight Check ....................................................................................................7-175Enable EAN Two Label ..............................................................................................7-178Addons ............................................................................................................................7-179UPC-A and EAN-13 Decoding Levels ...................................................................7-181GTIN Enable .............................................................................................................................7-184GTIN Label ID ................................................................................................................7-185GTIN 2-Digit Supplemental Label ID ....................................................................7-186GTIN 5-Digit Supplemental Label ID ....................................................................7-187GTIN Code 128 Supplemental Label ID ...............................................................7-188DataBar Omnidirectional Enable .....................................................................................7-189DataBar Omnidirectional Check Character Transmission ............................7-190DataBar Omnidirectional/EAN-128 Emulation .................................................7-191DataBar Omnidirectional 2D Component Enable ...........................................7-192DataBar Omnidirectional AIM ID ...........................................................................7-193DataBar Omnidirectional Label ID ........................................................................7-194DataBar Expanded Enable .................................................................................................7-195DataBar Expanded EAN-128 Emulation ..............................................................7-196DataBar Expanded 2D Component Enable .......................................................7-197DataBar Expanded AIM ID ........................................................................................7-198DataBar Expanded Label ID .....................................................................................7-199Product Reference Guide 7

DataBar Expanded Length Control ...................................................................... 7-200DataBar Expanded Length 1 .................................................................................. 7-201DataBar Expanded Length 2 .................................................................................. 7-202Code 39 Enable ..................................................................................................................... 7-203Code 39 Start Stop Character Transmission ..................................................... 7-204Code 39 Check Character Calculation ................................................................ 7-205Code 39 Check Character Transmission ............................................................. 7-206Code 39 Full ASCII ...................................................................................................... 7-207Code 39 AIM ID ........................................................................................................... 7-208Code 39 Label ID ......................................................................................................... 7-209Code 39 Length Control .......................................................................................... 7-210Code 39 Length 1 ....................................................................................................... 7-211Code 39 Length 2 ....................................................................................................... 7-212Code 39 Stitching ....................................................................................................... 7-213Code 32 Enable ..................................................................................................................... 7-214Code 32 Start Stop Character Transmission ..................................................... 7-215Code 32 Check Character Transmission ............................................................. 7-216Code 32 Label ID ......................................................................................................... 7-217Code 128 Enable ................................................................................................................... 7-218Code 128 Transmit Function Characters ........................................................... 7-219Convert Code128 to Code 39 ................................................................................ 7-220Code 128 AIM ID ......................................................................................................... 7-221Code 128 Label ID ...................................................................................................... 7-222Code 128 Length Control ........................................................................................ 7-223Code 128 Length 1 ..................................................................................................... 7-224Code 128 Length 2 ..................................................................................................... 7-225Code 128 Stitching .................................................................................................... 7-226EAN-128 Enable .................................................................................................................... 7-227EAN 128 AIM ID ........................................................................................................... 7-228EAN 128 Label ID ........................................................................................................ 7-229Interleaved 2 of 5 (I 2 OF 5) Enable ................................................................................ 7-230I 2 of 5 Check Character Calculation .................................................................... 7-231I 2 of 5 Check Character Transmission ................................................................ 7-232I 2 of 5 AIM ID ............................................................................................................... 7-233I 2 of 5 Label ID ............................................................................................................ 7-234I 2 of 5 Length Control .............................................................................................. 7-235I 2 of 5 Length 1 .......................................................................................................... 7-2368 <strong>Magellan</strong> ® <strong>8500Xt</strong> Scanner

I 2 of 5 Length 2 ...........................................................................................................7-237I 2 of 5 Stitching ...........................................................................................................7-238Codabar Enable ......................................................................................................................7-239Codabar Start Stop Character Transmission .....................................................7-240Codabar Start Stop Character Set .........................................................................7-241Codabar Start Stop Character Match ...................................................................7-243Codabar Check Character Calculation .................................................................7-244Codabar Check Character Transmission .............................................................7-245Codabar AIM ID ............................................................................................................7-246Codabar Label ID .........................................................................................................7-247Codabar Length Control ...........................................................................................7-248Codabar Length 1 .......................................................................................................7-249Codabar Length 2 .......................................................................................................7-250Codabar Stitching .......................................................................................................7-251Code 93 Enable ......................................................................................................................7-252Code 93 AIM ID ............................................................................................................7-253Code 93 Label ID .........................................................................................................7-254Code 93 Length Control ...........................................................................................7-255Code 93 Length 1 ........................................................................................................7-256Code 93 Length 2 ........................................................................................................7-257Code 93 Stitching ........................................................................................................7-258MSI/Plessey Enable ...............................................................................................................7-259MSI/Plessey Check Character Calculation ..........................................................7-260MSI/Plessey Number of Check Characters .........................................................7-261MSI/Plessey Check Character Transmission ......................................................7-262MSI/Plessey AIM ID .....................................................................................................7-263MSI/Plessey Label ID ..................................................................................................7-264MSI/Plessey Length Control ....................................................................................7-265MSI/Plessey Length 1 .................................................................................................7-266MSI/Plessey Length 2 .................................................................................................7-267MSI/Plessey Stitching ................................................................................................7-268Standard 2 of 5 Enable ........................................................................................................7-269Standard 2 of 5 Check Character Calculation ...................................................7-270Standard 2 of 5 Check Character Transmission ................................................7-271Standard 2 of 5 AIM ID ..............................................................................................7-272Standard 2 of 5 Label ID ...........................................................................................7-273Standard 2 of 5 Length Control .............................................................................7-274Product Reference Guide 9

Standard 2 of 5 Length 1 ......................................................................................... 7-275Standard 2 of 5 Length 2 ......................................................................................... 7-276Standard 2 of 5 Stitching ......................................................................................... 7-277Appendix A. LED/Beeper Indications & Controls .............................................A-1Controls and Indicators ...........................................................................................................A-2LED and Beeper Indications ........................................................................................A-2Volume/Tone Push Button ..........................................................................................A-6Manual EAS Deactivation Push Button ...................................................................A-8Scale Zero Push Button .................................................................................................A-9Calibration Switch ........................................................................................................ A-10Appendix B. Cable Information ........................................................................ B-1Introduction ................................................................................................................................ B-1General Specifications .......................................................................................................... B-1RS-232 Cable Pinout ................................................................................................................. B-2Scanner ...................................................................................................................................... B-2Scale ............................................................................................................................................ B-3IBM Cable Pinout ....................................................................................................................... B-4Scanner and Scale .................................................................................................................. B-4OEM USB Cable Pinout ............................................................................................................ B-5Scanner and Scale .................................................................................................................. B-5Auxilliary Port .............................................................................................................................. B-6External Handheld Input ...................................................................................................... B-6Power Cable ................................................................................................................................ B-7Connector Hardware ............................................................................................................. B-7Remote Display .......................................................................................................................... B-8Connector Hardware ............................................................................................................. B-8EAS Comm Port — Sensormatic .......................................................................................... B-9EAS Deactivator Control Box Connection ...................................................................... B-9EAS Interlock Connector — Checkpoint .........................................................................B-10Appendix C. Keypad ........................................................................................... C-1Appendix D. Host Commands ...........................................................................D-1Accepting Commands from an RS-232 Scanner Host ................................................. D-110 <strong>Magellan</strong> ® <strong>8500Xt</strong> Scanner

Appendix E. Factory Defaults ............................................................................ E-1Appendix F. Handheld Data Format Requirements ........................................ F-1Handheld Data Format Requirements General ....................................................F-1Datalogic Handheld Data Format Requirements .................................................F-2AIM Formats .......................................................................................................................F-9Product Reference Guide 11

NOTES12 <strong>Magellan</strong> ® <strong>8500Xt</strong> Scanner

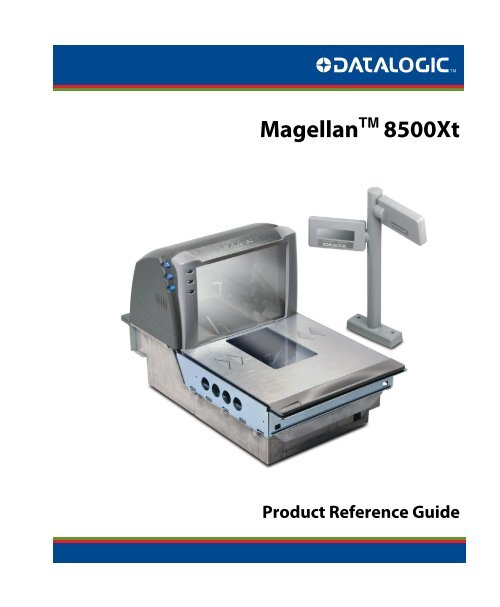

Section 1IntroductionThis Product Reference Guide contains comprehensive instructions onhow to install the scanner or scanning-scale (either model may be termed“scanner” for the purpose of simplicity in this manual), how to program itusing special programming feature barcode labels, and advanced userinformation as described in the following overview.Because of differences due to multiple model types and options, the llustrationsshown in this manual may vary from the model(s) in use at yourlocation.Product Reference Guide 1-1

Manual OverviewChapter 1, Introduction, presents the manual’s contents, describes featuresand specifications, provides regulatory and safety information, and liststhe barcode symbologies the scanner will read.Chapter 2, Site Preparation and Installation, supplies physical dimensions forthe scanner or scanning-scale and its most common accessories, anddetails counter preparation and installation. Cable routing, connectionand testing are also explained in this section.Chapter 3, Operation and Maintenance, describes use and maintenance; providingdetails about operator controls, programming and diagnosticmodes, scale “zeroing” and calibration. Scanner and scale routine maintenanceare outlined in this section as well.Chapter 4, Problem Isolation, provides an outline of three scanning-scaletest modes: Selftest, Operational Tests and Diagnostic Tests. Descriptionsof the error indications if the scanner detects a system problem and troubleshootingflowcharts to aid in problem resolution are also presented.Chapter 5, Calibration Procedures, Single Interval, explains scale calibrationand verification procedures, including procedures for calibrating the scalein pounds as well as kilograms.Chapter 7, Programming, details procedures and provides custom barcodesfor setting programmable scanner and scanning-scale features. This sectionis organized by the categories: General Features, Interface RelatedFeatures and Symbology Related Features.Appendix A, LED/Beeper Indications & Controls, lists the various functionsand indications of the scanning-scale control panel features.Appendix B, Cable Information, outlines wire requirements, connector specificationsand pinout details for associated product cabling.Appendix C, Keypad, furnishes barcodes representing the digits and charactersrequired to enter extended programming data needed during certainprogramming sessions.Appendix D, Host Commands, contains a partial listing of available hostcommands that can be used with a compatible host interface.Appendix E, Factory Defaults, provides a listing of factory default settingsbased on the most common interface.Appendix F, Handheld Data Format Requirements, provides additional references.1-2 <strong>Magellan</strong> ® <strong>8500Xt</strong> Scanner

How to Use This ManualYou’ll find it helpful to familiarize yourself with the first section of thismanual, since it provides both a general description of the product’s featuresand an overview of the manual’s contents and organization. Referencethe other sections as required for information about scanner orscanning-scale installation, operation, maintenance, calibration and barcodeprogramming.Manual Conventions‘NOTE’ blocks contain information that is helpfuland recommended. They provide information thatis critical to operations and/or proceduresdescribed in this manual.LEGAL NOTE‘LEGAL NOTE’ blocks indicate procedures oractivities which may be regulated under law bygovernmental agencies. It is your responsibility toensure compliance with the regulations that governinstallation of weighing devices.‘CAUTION’ blocks inform you that proper handling(adherence to the procedures described) isrequired to avoid damage to equipment and/orproperty.‘WARNING’ blocks alert you to potential physicalharm or injury. These statements do not includepotentially fatal hazards, which would be designatedas ‘DANGER’ blocks. Use of this productdoes not warrant the need for a DANGER block.Product Reference Guide 1-3

Scanner and Scanning-Scale NomenclatureControls, indicators and other nomenclature are shown in Figure 1-1 andFigure 1-1.EAS capabilities are optional, and may or may notbe enabled.Volume/Tone Push ButtonFigure 1-1. Scanning-Scale NomenclatureScanner LED (Green)Weighing Surface — LeanOversize Produce HereScale LED (Yellow)BonnetScale ZeroPush ButtonManual EASDeactivation PushButtonEAS LED(Tri-Color)Vertical WindowHorizontal WindowProduce RailAll Weighs Platter1-4 <strong>Magellan</strong> ® <strong>8500Xt</strong> Scanner

ConnectorsThe appearance of the connector panel (Figure 1-2) will vary dependingupon the factory options purchased with your model. Reference two typesof possible optional EAS connections in Figure 1-3a and Figure 1-3b.Figure 1-2. Connector Panel0.00POS Terminal Remote Display Aux. Port Scale Host EAS Interlock PowerPOS TERMINAL REMOTE DISPLAY AUXILIARY PORT SCALE HOST EAS INTERLOCK POWERLabel DataScale Data (forsingle cable interfaces)Application Download(where appropriate)Drives Remote DisplayTest PortOn ScreenProgramming (OSP)Application DownloadRS-232 HandheldScanner InputAuxiliary RS-232Label Data OutputScale Data (dualcable scanner/scale)Provides Good Readoutput to enable EASantenna RF outputProvides signal todrive external speakerAC Brick InputORPower off Terminal(POT) Brick InputModels with scaleonlyConnection tothis port isOptionalDual cable units only.(Scale connection maybe handled throughPOS Terminal port)Connection tothis port isOptionalFigure 1-3. Optional EAS Cable ConnectionsabTo EASSystemTo EASSystemProduct Reference Guide 1-5

Physical ParametersScanningEAS Tag Deactivation SystemThis section provides specifications for performance, environmental andelectrical parameters. Reference the second section of this manual, SitePreparation and Installation, for physical measurements of all models andsome accessories.The scanner has a scan zone between the two windows where the scannerprojects laser light in order to scan items. Two separate projections, onefrom the horizontal window and one from the vertical window, combineto form a zone where barcode labels are read. Refer to the Operation andMaintenance section of this manual for more details about the topic: ScanningItems.Scanners can be ordered from the factory to include an optional EAS(Electronic Article Surveillance) deactivation system. Two different EASsystem types are available: Checkpoint 1 and Sensormatic 2 .The AMB-9010 deactivation system requires connection as shown inFigure 1-3a. Reference Chapter 3, "Deactivating Security Labels" for moreinformation about its use.Contact Technical Support for information about installation of the Sensormatic® AMB-9010 EAS controller box. Additional details about thissystem can be referenced under the following topics:• Chapter 3, "Deactivating Security Labels"• Chapter 7, "EAS Features — Sensormatic"1. Checkpoint is a registered trademark of Checkpoint Systems, Inc2. Sensormatic is a registered trademark of Sensormatic Electronics Corporation.1-6 <strong>Magellan</strong> ® <strong>8500Xt</strong> Scanner

WeighingSpecifications for scale capacity, settling time, minimum and maximumstatic weight, zeroing, and warm-up time are given below. For more informationregarding the topic: Proper Weighing Technique, refer to the Operationand Maintenance section of this manual.Rated Weight CapacityThe scale’s operational weight capacity is:• 30.00 pounds, displayed in 0.01 incrementsOR• 15.000 kilograms 1 , displayed in 0.005 increments.Minimum IncrementThe minimum weight that can be accurately measured by the scale is 0.02lb. (0.005 kg).Maximum Static Weight (Overload)A maximum static weight of 150 pounds (68 kg) can be sustained by thescale without incurring damage or degrading performance.Automatic Zero MaintenanceThe scale’s software constantly monitors and adjusts the Zero point aslong as the deviation is within acceptable limits 2 , while compensating forany debris accumulation or removal. During power-up, the scale automaticallyre-zeros after verifying that all subsystems are functional. Additionally,the scale may be manually “zeroed” by pushing the Scale Zero PushButton located on the top of the vertical enclosure.1. The scale can also be set at the factory for 9.99 kg max.2. Acceptable limitis of deviation are set at -0.2 to +0.6 pounds (-0.078kg to 0.23kg), which is -0.67 to+2.0% of total capacity.Product Reference Guide 1-7

Warm-Up TimeThere are two pertinent warm-up times that apply to the scanning-scale:NOTEThe two warm-up periods can be performed concurrently, thereby reducingthe total required warm-up time to 60 minutes.Thermal EquilibriumWhen the unit is moved from a cooler temperature (such as a storage area)to a warmer environment (such as a checkstand location), 60 minutesmust be allowed to acclimate the unit to ambient conditions prior to calibrationor operation.Power-upOnce installed and powered up, a warm-up time of 15 minutes must beallowed before calibrating or performing weighing operations.User Configurable Warm-upThe user may configure the unit for a pre-programmed warm-up timethat is activated every time the scanner is powered up. During this time,the scale is viewed by the POS terminal as off-line.NOTEContact Technical Support to learn more about this advanced programmablefeature.1-8 <strong>Magellan</strong> ® <strong>8500Xt</strong> Scanner

POS ScannerFigure 1-4. Environmental SpecificationsOperation+40 C +104 F10 C 50 FTemperature10 to +40 C50 to +104 FDust Resistant Optics Cavity, IP5XIlluminationArtificial Light:0-450 Foot-candles(4,842 LUX)Sunlight:0-8,000 Foot-candles(86,080 LUX)Spill Proof(Datalogic MS-0006-13-0004)HumidityHot / Wet 40°C / 95% RHHot / Dry 40°C / 5% RHCold / Dry 10°C / 5% RHWarm / Wet 25%C / 50% RHStorage+70 C +158 F-40 C -40 FTemperature-40 to +70 C-40 to +158 FElectrical SpecificationsBefore installation, always verify that the site’s electrical service meets thescanning-scale’s requirements. The scanner has been engineered for compatibilitywith most international electrical systems operating in rangesfrom 100 to 240VAC at 50-60 Hz. Verify that the power source will supply“clean” electrical power to the equipment; that is, it must be free ofexcess electrical noise.Check the IEC power cord shipped with the scanning-scale. If the cordwill not plug into your AC power receptacle, the power cord shipped isnot compatible with your electrical system. Please contact your distributorimmediately to receive the necessary information and components toensure electrical compatibility.Product Reference Guide 1-9

Power SupplyThe scanner utilizes a single power supply for all models. Unique installationand international connections are accomplished through selection ofthe proper IEC power cordVOLTAGE FREQUENCY CURRENT (RMS) PART NUMBER100-240VAC ±10% 50-60 Hz 0.5 Amps @ 100V 8-0761CAUTIONSafe operation of your scanner or scanning-scale requires properly groundedelectrical outlets. Be sure to have a qualified electrician certify the earthgroundconnection on circuits which will be used to power the unit.NOTEThe scanner is powered on/off by connecting/disconnecting its AC powersupply.1-10 <strong>Magellan</strong> ® <strong>8500Xt</strong> Scanner

Laser and Product SafetyLaser safety requirements are based on IEC Standard Publication 60825-1(2001) and CDRH 21CFR, Chapter 1, Subchapter J and (CDRH) LaserProduct Performance Standard, User information [1040.10(h)1]:• User Maintenance. No user maintenance of the system other thancleaning of the scan windows is required.• Radiant Energy. The scanner is an IEC Class 1 and CDRH IIalaser product. The system uses two embedded Class 3B VisibleLaser Diodes (VLDs) operating at 650.0 or 670.0 nm, in anopto-mechanical scanner, resulting in less than 3.9µW radiatedpower as observed through a 7mm aperture and averaged over 10seconds. Maximum emitted peak output power at the lower windowis 850µW. No attempt should be made by the user to removethe protective housing of the scanning-scale.• Laser Light Viewing. The horizontal and vertical scan windowsare the only apertures through which laser light may be observedin this product.Exposure to the light emitted from the scan windows has been shown notto be harmful. The safety record of barcode scanning is perfect after millionsof hours of use worldwide. This safe and efficient use of laser technologyhas gained wide acceptance in industries throughout the world.Operators and installers of the unit should observe the following cautionsand warnings:CAUTIONUse of controls, adjustments or performance of procedures other than thosespecified herein may result in hazardous laser light exposure.The use of optical instruments with the scanner will increase eye hazard. (Opticalinstruments include binoculars, microscopes, telescopes and magnifyingglasses. This does not include eyeglasses worn by the user).To prevent exposure to laser light, do not remove the protective housing of thescanner. There are no user-serviceable parts inside your scanner or scanningscale.Product Reference Guide 1-11

Safety precautions to be taken:CAUTIONNo adjustments or alteration of the scanner or scanning-scale housing are to beattempted by the user.The failure of the facet wheel motor while the unit is continuing to emit a laserbeam causes the emission levels to exceed those for inherently safe operation.The unit has safeguards to prevent this occurrence. If, however, a stationarylaser beam is ever emitted, the failing unit should be disconnected from itspower supply until repaired by a qualified technician.WARNINGThis equipment has been tested and found to comply with the limits for a ClassA digital device, pursuant to part 15 of the FCC Rules. These limits aredesigned to provide reasonable protection against harmful interference whenthe equipment is operated in a commercial environment. This equipment generates,uses, and can radiate radio frequency energy and, if not installed andused in accordance with the instruction manual, may cause harmful interferenceto radio communications. Operation of this equipment in a residentialarea is likely to cause harmful interference in which case the user will berequired to correct the interference at his or her own expense.This Class A digital apparatus meets all requirements of the CanadianInterference-Causing Equipment Regulations.Cet appareil numerique de la classe A respecte toute les exigences duReglement sur le material broilleur du Canada.1-12 <strong>Magellan</strong> ® <strong>8500Xt</strong> Scanner

N263DYN-<strong>Magellan</strong>8401-3 (A)R35280LabelingRegulatory, reference and safety labeling is shown in Figure 1-5.Figure 1-5. LabelingIEC CLASS 1 LASER PRODUCTU.S., CANADA, MEXICO AND APAN Max 6/15 kgMin 0.04 kgInterval 1: e=2gInterval 2: e=5gT7276MTC7516+10° C/+40° C90/384/EEC090071Or... MAGELLAN <strong>8500Xt</strong> MODEL: XXXXDatalogic Scanning, Inc.959 Terry St.Eugene, OR 97402 USAPRODUCT OF USACLASS NO: XXXXXX-XXXXX-XXXXX-XXSERIAL NO: XXXXXXXXMFG DATE: Month Day YearGRAVITY(M/SEC2): 9.0123ZONE: 04 ALERT! Use of this product constitutes acceptance of the EndUser License Agreement located in the Quick Reference Guide. Datalogic Scanning, Inc.959 Terry Street• CAUTION - CLASS 3R LASER RADIATION WHEN OPEN. AVOID DIRECT EYE EXPOSURE.Eugene, OR 97402 USA• ATTENTION - RAYONNEMENT LASER DE CLASSE 3R CARTER OUVERT. EVITEZL'EXPOSITION DIRECTE DE L'OEIL.• ACHTUNG - NACH FFNUNG LASERSTRAHLUNG NACH KLASSE 3R AUGENKONTAKT MITLASERSTRAHL VERMEIDEN.Product of USA• PRECAUCI N - CUANDO ABIERTO, EMITE RAYO LASER DE LA CLASE 3R.• ADVERT NCIA - QUANDO ABERTO, EMITE RAIO DE LASER DA CLASSE 3R.• ATTENZIONE - RADIAZIONI LASER CLASSE 3R SE APERTO. EVITARE L'ESPOSIZIONEDIRETTA AGLI OCCHI.• VARNING - KLASS 3R LASERSTR LNING UTAN F RSLUTNING. UNDVIK DIREKTGONKONTAKT.U S••This device complies with Part 15 of the FCC Rules.CLASS 1 LASER PRODUCTOperation is subject to the following two conditions:LASER KLASSE 1(1) this device may not cause harmful interference, andCATAGORIA 1 PRODUCTO LASER(2) this device must accept any interference received,APPAREIL LASER DE CLASSE 1This Class A digital apparatusUse ONLY Datalogic AC/DC Power Supplyincluding interference that may cause undesired operation. based on 10 sec; IEC 60825-1+A2:2001complies with Canadian ICES-003.Input: 50 - 60 Hz (0.5 - 0.25A) Output:Cet appareil num r que de la100 - 240 VAC+5VTHIS LASER PRODUCT COMPLIES WITH 21CFR 1040 AS APPLICABLE AS A CLASS IIA PRODUCTClasse A est confirme la norme(P/N 8-0582 or 8-0761) +12VNMB-003 du Canada.Power: 18 Watts (max)COVERED BY ONE OR MORE OF THE FOLLOWING U.S. PATENTS: 4,709,369 4,749,879 4,786,798 4,792,666 4,798,943 4,799,164 4,816,660 4,861,9724,861,973 4,866,257 4,868,836 4,879,456 4,963,719 4,991,692 5,144,118 5,179,270 5,198,649 5,247,162 5,229,588 5,410,108 5,459,308 5,440,110 5,475,2075,493,108 5,705,802 5,723,852 5,834,708 5,837,983 5,929,421 6,012,639 6,059,189 6,073,849 6,454,168 6,478,224 6,568,598 6,705,527 6,783,072 6,857,5676,877,663 6,974,084 6,991,169 7,201,322 7,204,422 7,374,092 601 26 118.6 7170414 7172123 EPO1330772 RE37,166 RE40.071 OTHER PATENTS PENDINGThis illustration shows labelplacement ONLY. For actualregulatory, patent and otherapplicable information, viewthe labels on the productitself, or call your nearestsales or service office.Product Reference Guide 1-13

Agency CompliancesThe scanner and scanning-scale meets or exceeds the requirements for itsdevice type as set forth by the following agencies and regulations:COUNTRY COMPLIANCE COMMENTSElectricalUnited States UL60950-1 UL Approved and TÜV NRTLCanada CAN/CSA C22.2 No. 60950-1 TÜV NRTLWorld IEC60950 / IEC 60825-1 TÜV CBAustralia AS 3260 AS (power adapter)EmmisionsUnited States 47CFR Part 15J FCCCanada ICES-0003 Class BEurope EN 55022 Class BAustralia/N Zealand AS/NZ 3548 Class BJapan VCCI Class BTaiwan CNS 13438 Class BSafety & Emissions EMC Directive 204/108/EC CE MarkLV Directive 73/23/EECCE MarkLaser SafetyUnited States CDRH, 21CFR Part 1040 CDRH Class IIa laser deviceCanada same as CDRH SGM-1 specificationAustralia AS 2211Weights & MeasuresUnited StatesCanadaNIST Handbook 44(Dept. of Commerce)Measurement CanadaAustralia National Measurement Institute (NMI) NMI R76, Parts 1 and 2New Zealand 1987 Part 1 Reg. 4, Reg. 4AMexico NOM NOM-019-SCF1-1994New YorkNew York CertificateContact Datalogic ® Marketing at (541) 683-5700, or your Datalogic representativefor a complete listing of approvals for other countries.1-14 <strong>Magellan</strong> ® <strong>8500Xt</strong> Scanner

Barcodes SupportedThe scanner can read/decode the following barcode types (symbologies):• UPC Versions A&E• UPC Supplementals and Add-ons (2 & 5 digit supplimentals,Coupon code and Code 128)• Plural Stage Dual UPC Barcodes for Japan ( 2 label read)• DataBar Omnidirectional, DataBar Expanded, DataBar Stacked• EAN-8 & 13• JAN-8 & 13• UCC/EAN 128• Code 39• Code 39 full ASCII• Code 128 (including conversion to Code 39)• Code 93• Interleaved 2 of 5 (I 2 of 5)• Code 32 (Italian Pharmaceutical Code)• Codabar• MSI/PlesseyProduct Reference Guide 1-15

Technical SupportDatalogic Website SupportReseller Technical SupportTelephone Technical SupportThe Datalogic website (www.scanning.datalogic.com) is the completesource for technical support and information for Datalogic products. Thesite offers product support, product registration, warranty information,product manuals, product tech notes, software updates, demos, andinstructions for returning products for repair.An excellent source for technical assistance and information is an authorizedDatalogic reseller. A reseller is acquainted with specific types of businesses,application software, and computer systems and can provideindividualized assistance.If you do not have internet or email access, you may contact Datalogictechnical support at (541) 349-8283 or check the back cover of your manualfor more contact information.1-16 <strong>Magellan</strong> ® <strong>8500Xt</strong> Scanner

Section 2Site Preparation and InstallationThis section provides a reference for preparing most checkstands to receivethe scanner or scanning-scale. Included are physical parameters andinstructions for checkstand preparation, power and ventilation considerations,cable routing information and unit installation.Site Preparation lists all procedures necessary to prepare the checkstand.The instructions that follow, titled Checkstand Preparation, detail steps forthe three models that are available (shown in Figure 2-1 below) to facilitateeasy installation into almost any checkstand application around the world:• Model 8503 — Long Scanner with Sensormatic Coil• Model 8504 — Long Scanner/Scale with Sensormatic Coil• Model 8505 — Short Scanner with Sensormatic CoilSome models are designed to fit with little or no modification into openingscut for previously installed scanners such as other <strong>Magellan</strong> ® scanners,or NCR ® scanner models 7820/24 and 7870. Other models aredesigned for applications with smaller footprint requirements.Once the procedures in this section are complete, the scanner is ready foroperation; with the exception that if a scanning-scale was installed, calibrationwill be required before placing the unit into operation. You mustconsult the local weights and measures authority to ensure that all legalrequirements are met concerning calibration and certification. Section 5,Calibration Procedures, Single Interval, contains detailed procedures for calibratingthe scale in either pounds or kilograms.Product Reference Guide 2-1

Figure 2-1. The Scanner/Scale FamilyEASEASModel 8503 Model 8504EASModel 8505Pre-Installation ConsiderationsIt should be noted that the scope of this manual does not encompass allfactors related to worker safety and checkstand design. It does, however,offer a list of considerations that may be helpful in ensuring greater safetyand productivity. Careful planning using these general guidelines shouldresult in a more efficient, comfortable work environment.The U.S. Bureau of Labor Statistics reports that the incidence of repetitivemotion injuries has increased dramatically in recent years. Checkstanddesign and scanner installation and operation procedures can reduce therisk of repetitive motion injuries, but not eliminate it.Although there are currently no formal guidelines for checkstand ergonomics,the Food Marketing Institute (FMI) and the National Institute ofOccupational Safety (NIOSH) of the Department of Health and HumanServices have released the reports listed at the end of these recommendations.These reports contain useful suggestions for ergonomic improvementof checkstand designs and scanner installation, maintenance andusage. Portions of the reports are summarized below. For copies of thecomplete reports, or to inquire about any modifications to the recommendations,contact FMI and NIOSH at the addresses listed at the end ofthese recommendations.2-2 <strong>Magellan</strong> ® <strong>8500Xt</strong> Scanner

Checkstand Design1. Select a design which allows load-sharing by several musclegroups (for example designs which allow the cashier to use bothhands for scanning and bagging).2. Select checkstands which deliver products to the cashier on aninput belt and do not require the unloading of items from a cart.These designs put less stress on the cashiers’ shoulders and back.3. Minimize the distance between the input and take-away conveyors(i.e., the distance the cashier has to reach to move the products).4. Minimize the width of the input conveyor to reduce the cashier’sreach to items on the far side of the belt; use a diverter to directproducts closer to the cashier.5. Select a design which encourages the cashier to slide productsacross the scanner rather than gripping and lifting. Make sure thehorizontal surface of the scanner is flush with all surrounding surfaces.6. Choose a design which integrates the scanner and scale to eliminateextended reaches and lifts during weighing tasks.7. Provide an easily accessible bag stand at a height 13 - 17 inches(33 - 43.2 cm) lower than the top surface of the checkstand toreduce stresses to the shoulders, elbows, and risks associated withlifting products into bags.8. Do not position the bag stand between the cashier and the scanner,due to the increased reach involved.9. Position the scanner’s horizontal scanning surface 34 - 36 inches(86.4 - 91.4 cm) above the floor. Maintain a minimum of fiveinches (12.7 cm) clearance between elbows and work surfaces.10. Provide adjustable keyboard mounting (height, tilt, and horizontalreach).11. Position the printer, cash drawer, and other checkstand devicesthe cashier uses within easy reach (less than 18 inches/45.7 cm).12. Provide adequate toe space, foot rests or rails, antifatigue mats,and where feasible, an adjustable seat or stand against which thecashiers can lean.Product Reference Guide 2-3

Scanner Installation1. Mount the horizontal surface of the scanner flush with the countertopto encourage slide scanning rather than lifting.2. Position the centerline of the scanner read area 8 - 10 inches (20.3- 25.4 cm) from the edge of the checkstand (cashier side).Scanner MaintenanceReferences1. Keep scanner windows clean. This will improve productivity andreduce rescans.2. Replace scanner glass when excessive scratches are evident.Anonymous, 1992, “Ergonomic Improvement of Scanning CheckstandDesigns”,Food Marketing Institute800 Connecticut Ave. N.W.Washington, D.C. 20006Grant, Katharyn A. et al., 1992, “Ergonomic Evaluation of CheckstandDesigns in the Retail Food Industry”,National Institute of Occupational Safety and Health4676 Columbia ParkwayCincinnati, Ohio 45226Scanner Usage1. Minimize handling of heavy/bulky products. Leave these items inthe cart and use an alternative entry method such as key entry ofshort PLUs, or handheld scanning.2-4 <strong>Magellan</strong> ® <strong>8500Xt</strong> Scanner

2. Regularly train cashiers in proper scanning methods and ergonomicsprinciples, such as:Develop a smooth fluid motion during scanning, sharingwork equally between hands.Use the entire hand for grasping and lifting items.Since the scanner reads labels on all four sides plus the topand bottom, there is no need to turn a barcode toward eitherof the scanner windows.Develop efficient scanning motions, not necessarily fasterhand movements. Simply slide the item across the scanner’shorizontal window with as little orientation motion as necessary.Leave items in an upright position; do not lift and tilt.Learn how the scanner functions and where the scanning areais located.Do not favor either the vertical or horizontal window; slideitems across the scanner in their natural orientations on thecheckstand as much as possible.Site Preparation OverviewConsider the following factors before installing the scanner/scanning-scaleand its optional Remote Scale Display.Ventilation Requirements. The scanner operates without the use of aventilation fan. As long as there is adequate convective air flow and nomajor heat producing equipment in close proximity, the unit’s housingprovides adequate heat dissipation. The air temperature in the checkstandaround the scanner must not exceed 104°F (40°C).Service Access Requirements. Routine operations such as ‘zeroing’and calibration do not require removal of the scanner from the checkstandor disassembly of the product. The installer should plan service access forthe AC/DC Power Supply and cables.Product Reference Guide 2-5

Recommended Power Installation. Since the typical grocery environmentincludes conveyor belts and electric motors, care should be taken toensure that the scanner has a supply of “clean” power (power withoutexcessive electrical noise). A wiring diagram shows the recommended wiringthat will provide the scanner with a “clean” source of power. Refer toFigure 2-4.Counter Preparation. Since the majority of grocery checkout lanes aredesigned as “left-hand take away,” the counter drawings in this sectionfocus on this counter design. Simply reverse the layout for a “right-handtake away” requirement. The unit scans equally well in either of these twoconfigurations.Liquid Drainage. Should a liquid spill occur, ensure that moisture canflow through the checkstand without pooling.Leveling. Plan ahead and provide screws/bolts in the checkstand mountsand a leveling guide (board) to allow leveling of the scanner or scanningscalewithin the counter. Use a 0.375” thick board to replicate the mountingflange on the long scanner or scanning-scale, and adjust screws or boltsuntil the board is flush within the counter. Use a 4.0” wide board stood onits end to adjust leveling screws/bolts in rail support applications.Cable Routing. Placement of the scanning-scale should be planned toallow easy access to other components as well as optimize communicationbetween the scanner, the POS terminal and the optional Remote ScaleDisplay. Note that cables may drop straight down from the scanner’s connectorpanel, or may be conveniently routed along the unit’s side using thehardware provided. Do not route interface cables near any electricalmotors or other sources of electromagnetic interference.Remote Scale Display Placement. The customer, and checker in someinstances, must be able to easily view and read the Remote Scale Display.Ambient light and mounting height considerations are discussed later inthis section.Vertical Clearance. Provision must be made to allow adequate spaceabove the scanner bonnet for removal and replacement of the AllWeighs Platter (the L-shaped platter). Optimal clearance permits theplatter to be grasped at its top vertical edge and lifted for removal withoutobstruction (such as a fixed keyboard mount or any type of enclosure).2-6 <strong>Magellan</strong> ® <strong>8500Xt</strong> Scanner

Should such an enclosure be unavoidable, an alternate method of platterremoval using two coins may be employed, however a minimum verticalclearance of 1.5” (3.8 cm) MUST be provided (reference Figure 2-2).Another consideration is that the scan zone must be kept free of obstructionssuch as enclosures, keyboard mounts, etc.Figure 2-2. Vertical ClearanceDO NOTObstructL-PlatterRemovalDO NOTObstructScan Zone(Keyboard Mount)Allow a minimumclearance of1.5" (3.8cm)(Enclosure)Ventilation and SpacingThe scanning-scale’s perimeter housing has been designed to provide adequatespace for convective cooling and unrestricted movement of theweighing apparatus. Figure 2-3 shows the debris chutes and ventilationslots. The checkstand design must allow:• The ambient air temperature inside the checkstand adjacent tothe scanner must not exceed 104°F (40°C).• A source of air that provides adequate cooling by convective airflow.NOTEDO NOT place the scanner in a close-fitting, fully enclosed checkstand. Providea MINIMUM of 16 square inches (103.2 square centimeters) of air intakefrom below the installation for sufficient convective cooling.Product Reference Guide 2-7

If motors, conveyor belts, or other heat producing equipment are locatednear the scanner, forced air ventilation may be required. In most installations,a 30 cfm (.84 cmm) axial fan should provide sufficient air movement.If a ventilation fan is installed, one with a removable filter that maybe washed or replaced is recommended.Figure 2-3. Debris Chutes & Ventilation Slots(Models vary)Service AccessDebris Chutes/Ventilation SlotsThe scanner and scanning-scale have been engineered to allow performanceof all routine service and maintenance (such as “zeroing” and calibration)without removing the scanner from the checkstand. Additionallyall cable connections made at the scanner can be connected and removedwhile the unit is sitting on the countertop. The installer should provideservice access to all remaining cable connectors as well as the AC/DCPower Supply (if installed).2-8 <strong>Magellan</strong> ® <strong>8500Xt</strong> Scanner

Power InstallationGroundingReference the wiring diagram in Figure 2-4 for the recommended fusingarrangement.The AC/DC Power Supply should have an AC outlet with a clean earthground. If you are not sure how to verify the amount of electrical noise(interference) on the power line, ask a qualified electrician to measure theinput line voltage.Figure 2-4. Input Power WiringOn/OffSwitch(Modelsvary)CheckstandBreaker PanelNeutralLineGroundNeutralLineGroundPanelGroundAC/DC PowerSupplyOn/OffSwitchScanner orScanner/ScalePOS TerminalPowerMainsMainBreakerPanelNeutralLineGroundPanelGroundEarthGroundLightingInductive Loads(e.g. Conveyor Belts, Motors, etc)Product Reference Guide 2-9

Checkstand PreparationReference Figure 2-5. When performing a first time installation into a newcheckstand, verify before cutting that room will be allowed for cabling andthe AC/DC Power Supply. When making the opening, take extra care toaccurately cut to the correct dimensions. Mounting may require installationof support(s), countertop routing, or other such devices. Dependingupon checkstand design, you may wish to install an item diverter to directitems toward the scan window. See the instructions in this manual titled“Counter Cutout” for more details concerning the location and preparationof the opening.Figure 2-5. Installation Overview(Models andconnectionsvary)Counter CutoutItemDiverterCablingAC/DCPowerSupplyRoutedSupportLipSupport Rails2-10 <strong>Magellan</strong> ® <strong>8500Xt</strong> Scanner