Alloy Performance Guide - Rolled Alloys

Alloy Performance Guide - Rolled Alloys

Alloy Performance Guide - Rolled Alloys

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

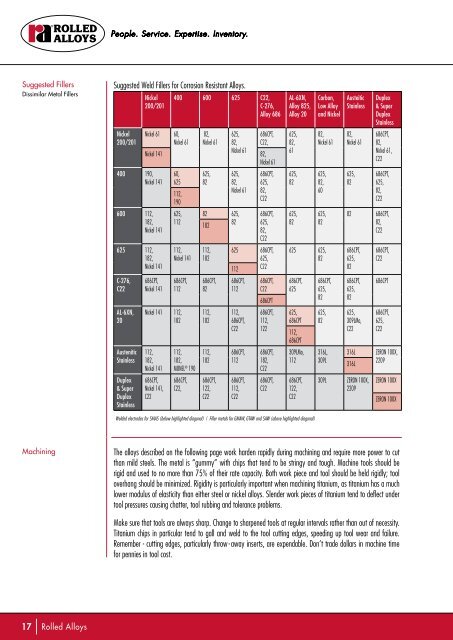

People. Service. Expertise. Inventory.Suggested FillersDissimilar Metal FillersSuggested Weld Fillers for Corrosion Resistant <strong>Alloy</strong>s.Nickel200/201Nickel200/201400 190,Nickel 141600 112,182,Nickel 141625 112,182,Nickel 141C-276,C22AL-6XN,20AusteniticStainlessDuplex& SuperDuplexStainlessNickel 61 60,Nickel 61400 600 625 C22,C-276,<strong>Alloy</strong> 68682,Nickel 61625,82,Nickel 61686CPT,C22,Nickel 141 82,Nickel 61686CPT,Nickel 14160,625112,190625,112112,Nickel 141686CPT,112Nickel 141 112,182112,182,Nickel 141686CPT,Nickel 141,C22112,182,MONEL ® 190686CPT,C22,625,82625,82,Nickel 6182 625,18282112,182686CPT,82112,182112,182686CPT,122,C22686CPT,625,82,C22686CPT,625,82,C22625 686CPT,625,112 C22686CPT,112112,686CPT,C22686CPT,112686CPT,112,C22686CPT,C22686CPT686CPT,112,122686CPT,182,C22686CPT,C22AL-6XN,<strong>Alloy</strong> 825,<strong>Alloy</strong> 20625,82,61625,82625,82Carbon,Low <strong>Alloy</strong>and Nickel82,Nickel 61625,82,60625,82625 625,82686CPT,625625,686CPT112,686CPT309LMo,112686CPT,122,C22686CPT,625,82625,82316L,309LAusteiticStainless82,Nickel 61625,82Duplex& SuperDuplexStainless686CPT,82,Nickel 61,C22686CPT,625,82,C2282 686CPT,82,C22686CPT,625,82686CPT,625,82625,309LMo,C22309L ZERON 100X,2209686CPT,C22686CPT686CPT,625,C22316L ZERON 100X,316L2209ZERON 100XZERON 100XWelded electrodes for SMAS (below highlighted diagonal) | Filler metals for GMAW, GTAW and SAW (above highlighted diagonal)MachiningThe alloys described on the following page work harden rapidly during machining and require more power to cutthan mild steels. The metal is “gummy” with chips that tend to be stringy and tough. Machine tools should berigid and used to no more than 75% of their rate capacity. Both work piece and tool should be held rigidly; tooloverhang should be minimized. Rigidity is particularly important when machining titanium, as titanium has a muchlower modulus of elasticity than either steel or nickel alloys. Slender work pieces of titanium tend to deflect undertool pressures causing chatter, tool rubbing and tolerance problems.Make sure that tools are always sharp. Change to sharpened tools at regular intervals rather than out of necessity.Titanium chips in particular tend to gall and weld to the tool cutting edges, speeding up tool wear and failure.Remember - cutting edges, particularly throw - away inserts, are expendable. Don’t trade dollars in machine timefor pennies in tool cost.17<strong>Rolled</strong> <strong>Alloy</strong>s

![RA333 Data Sheet [Heat Resistant Alloys] - Rolled Alloys](https://img.yumpu.com/50335849/1/190x245/ra333-data-sheet-heat-resistant-alloys-rolled-alloys.jpg?quality=85)