Alloy Performance Guide - Rolled Alloys

Alloy Performance Guide - Rolled Alloys

Alloy Performance Guide - Rolled Alloys

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

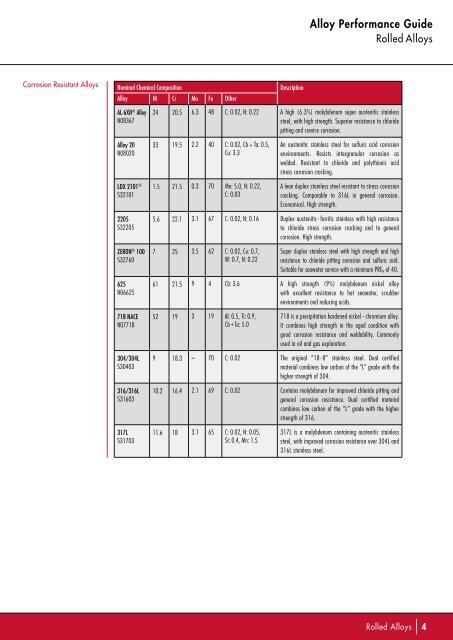

<strong>Alloy</strong> <strong>Performance</strong> <strong>Guide</strong><strong>Rolled</strong> <strong>Alloy</strong>sCorrosion Resistant <strong>Alloy</strong>s Nominal Chemical Composition Description<strong>Alloy</strong> Ni Cr Mo Fe OtherAL-6XN ® <strong>Alloy</strong>N0836724 20.5 6.3 48 C: 0.02, N: 0.22 A high (6.3%) molybdenum super austenitic stainlesssteel, with high strength. Superior resistance to chloridepitting and crevice corrosion.<strong>Alloy</strong> 20N08020LDX 2101 ®S3210133 19.5 2.2 40 C: 0.02, Cb + Ta: 0.5,Cu: 3.31.5 21.5 0.3 70 Mn: 5.0, N: 0.22,C: 0.03An austenitic stainless steel for sulfuric acid corrosionenvironments. Resists intergranular corrosion aswelded. Resistant to chloride and polythionic acidstress corrosion cracking.A lean duplex stainless steel resistant to stress corrosioncracking. Comparable to 316L in general corrosion.Economical. High strength.2205S322055.6 22.1 3.1 67 C: 0.02, N: 0.16 Duplex austenitic - ferritic stainless with high resistanceto chloride stress corrosion cracking and to generalcorrosion. High strength.ZERON ® 100S327607 25 3.5 62 C: 0.02, Cu: 0.7,W: 0.7, N: 0.22Super duplex stainless steel with high strength and highresistance to chloride pitting corrosion and sulfuric acid.Suitable for seawater service with a minimum PRE N of 40.625N0662561 21.5 9 4 Cb: 3.6 A high strength (9%) molybdenum nickel alloywith excellent resistance to hot seawater, scrubberenvironments and reducing acids.718 NACEN0771852 19 3 19 Al: 0.5, Ti: 0.9,Cb + Ta: 5.0718 is a precipitation hardened nickel - chromium alloy.It combines high strength in the aged condition withgood corrosion resistance and weldability. Commonlyused in oil and gas exploration.304/304LS30403316/316LS316039 18.3 – 70 C: 0.02 The original “18 - 8” stainless steel. Dual certifiedmaterial combines low carbon of the "L" grade with thehigher strength of 304.10.2 16.4 2.1 69 C: 0.02 Contains molybdenum for improved chloride pitting andgeneral corrosion resistance. Dual certified materialcombines low carbon of the “L” grade with the higherstrength of 316.317LS3170311.6 18 3.1 65 C: 0.02, N: 0.05,Si: 0.4, Mn: 1.5317L is a molybdenum containing austenitic stainlesssteel, with improved corrosion resistance over 304L and316L stainless steel.<strong>Rolled</strong> <strong>Alloy</strong>s4

![RA333 Data Sheet [Heat Resistant Alloys] - Rolled Alloys](https://img.yumpu.com/50335849/1/190x245/ra333-data-sheet-heat-resistant-alloys-rolled-alloys.jpg?quality=85)