Alloy Performance Guide - Rolled Alloys

Alloy Performance Guide - Rolled Alloys

Alloy Performance Guide - Rolled Alloys

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

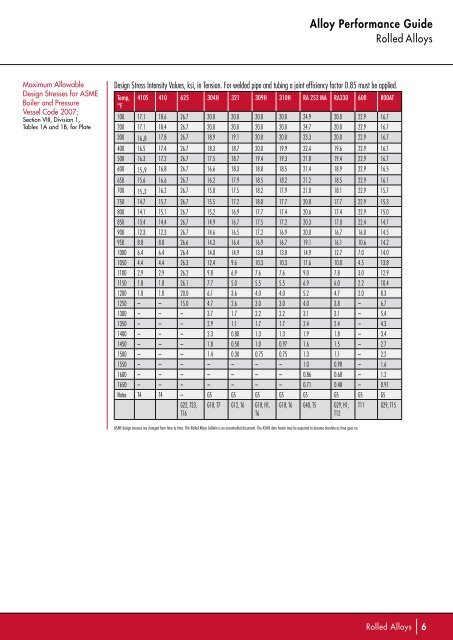

<strong>Alloy</strong> <strong>Performance</strong> <strong>Guide</strong><strong>Rolled</strong> <strong>Alloy</strong>sMaximum AllowableDesign Stresses for ASMEBoiler and PressureVessel Code 2007;Section VIII, Division 1,Tables 1A and 1B, for PlateDesign Stress Intensity Values, ksi, in Tension. For welded pipe and tubing a joint efficiency factor 0.85 must be applied.Temp, 410S 410 625 304H 321 309H 310H RA 253 MA RA330 600 800AT°F100 17.1 18.6 26.7 20.0 20.0 20.0 20.0 24.9 20.0 22.9 16.7200 17.1 18.4 26.7 20.0 20.0 20.0 20.0 24.7 20.0 22.9 16.7300 16.8 17.8 26.7 18.9 19.1 20.0 20.0 23.3 20.0 22.9 16.7400 16.5 17.4 26.7 18.3 18.7 20.0 19.9 22.4 19.6 22.9 16.7500 16.3 17.2 26.7 17.5 18.7 19.4 19.3 21.8 19.4 22.9 16.7600 15.9 16.8 26.7 16.6 18.3 18.8 18.5 21.4 18.9 22.9 16.5650 15.6 16.6 26.7 16.2 17.9 18.5 18.2 21.2 18.5 22.9 16.1700 15.2 16.2 26.7 15.8 17.5 18.2 17.9 21.0 18.1 22.9 15.7750 14.7 15.7 26.7 15.5 17.2 18.0 17.7 20.8 17.7 22.9 15.3800 14.1 15.1 26.7 15.2 16.9 17.7 17.4 20.6 17.4 22.9 15.0850 13.4 14.4 26.7 14.9 16.7 17.5 17.2 20.3 17.0 22.4 14.7900 12.3 12.3 26.7 14.6 16.5 17.2 16.9 20.0 16.7 16.0 14.5950 8.8 8.8 26.6 14.3 16.4 16.9 16.7 19.1 16.1 10.6 14.21000 6.4 6.4 26.4 14.0 14.9 13.8 13.8 14.9 12.7 7.0 14.01050 4.4 4.4 26.3 12.4 9.6 10.3 10.3 11.6 10.0 4.5 13.81100 2.9 2.9 26.2 9.8 6.9 7.6 7.6 9.0 7.8 3.0 12.91150 1.8 1.8 26.1 7.7 5.0 5.5 5.5 6.9 6.0 2.2 10.41200 1.0 1.0 20.0 6.1 3.6 4.0 4.0 5.2 4.7 2.0 8.31250 – – 15.0 4.7 2.6 3.0 3.0 4.0 3.8 – 6.71300 – – – 3.7 1.7 2.2 2.2 3.1 3.1 – 5.41350 – – – 2.9 1.1 1.7 1.7 2.4 2.4 – 4.31400 – – – 2.3 0.80 1.3 1.3 1.9 1.8 – 3.41450 – – – 1.8 0.50 1.0 0.97 1.6 1.5 – 2.71500 – – – 1.4 0.30 0.75 0.75 1.3 1.1 – 2.21550 – – – – – – – 1.0 0.90 – 1.61600 – – – – – – – 0.86 0.68 – 1.21650 – – – – – – – 0.71 0.48 – 0.91Notes T4 T4 – G5 G5 G5 G5 G5 G5 G5 G5G22, T23,T16G18, T7 G12, T6 G18, H1,T6G18, T6 G40, T5 G29, H1,T12T11G29, T15ASME design stresses are changed from time to time. This <strong>Rolled</strong> <strong>Alloy</strong>s bulletin is an uncontrolled document. The ASME data herein may be expected to become obsolete as time goes on.<strong>Rolled</strong> <strong>Alloy</strong>s6

![RA333 Data Sheet [Heat Resistant Alloys] - Rolled Alloys](https://img.yumpu.com/50335849/1/190x245/ra333-data-sheet-heat-resistant-alloys-rolled-alloys.jpg?quality=85)