People. Service. Expertise. Inventory.Suggested FillersDissimilar Metal FillersSuggested Weld Fillers for Corrosion Resistant <strong>Alloy</strong>s.Nickel200/201Nickel200/201400 190,Nickel 141600 112,182,Nickel 141625 112,182,Nickel 141C-276,C22AL-6XN,20AusteniticStainlessDuplex& SuperDuplexStainlessNickel 61 60,Nickel 61400 600 625 C22,C-276,<strong>Alloy</strong> 68682,Nickel 61625,82,Nickel 61686CPT,C22,Nickel 141 82,Nickel 61686CPT,Nickel 14160,625112,190625,112112,Nickel 141686CPT,112Nickel 141 112,182112,182,Nickel 141686CPT,Nickel 141,C22112,182,MONEL ® 190686CPT,C22,625,82625,82,Nickel 6182 625,18282112,182686CPT,82112,182112,182686CPT,122,C22686CPT,625,82,C22686CPT,625,82,C22625 686CPT,625,112 C22686CPT,112112,686CPT,C22686CPT,112686CPT,112,C22686CPT,C22686CPT686CPT,112,122686CPT,182,C22686CPT,C22AL-6XN,<strong>Alloy</strong> 825,<strong>Alloy</strong> 20625,82,61625,82625,82Carbon,Low <strong>Alloy</strong>and Nickel82,Nickel 61625,82,60625,82625 625,82686CPT,625625,686CPT112,686CPT309LMo,112686CPT,122,C22686CPT,625,82625,82316L,309LAusteiticStainless82,Nickel 61625,82Duplex& SuperDuplexStainless686CPT,82,Nickel 61,C22686CPT,625,82,C2282 686CPT,82,C22686CPT,625,82686CPT,625,82625,309LMo,C22309L ZERON 100X,2209686CPT,C22686CPT686CPT,625,C22316L ZERON 100X,316L2209ZERON 100XZERON 100XWelded electrodes for SMAS (below highlighted diagonal) | Filler metals for GMAW, GTAW and SAW (above highlighted diagonal)MachiningThe alloys described on the following page work harden rapidly during machining and require more power to cutthan mild steels. The metal is “gummy” with chips that tend to be stringy and tough. Machine tools should berigid and used to no more than 75% of their rate capacity. Both work piece and tool should be held rigidly; tooloverhang should be minimized. Rigidity is particularly important when machining titanium, as titanium has a muchlower modulus of elasticity than either steel or nickel alloys. Slender work pieces of titanium tend to deflect undertool pressures causing chatter, tool rubbing and tolerance problems.Make sure that tools are always sharp. Change to sharpened tools at regular intervals rather than out of necessity.Titanium chips in particular tend to gall and weld to the tool cutting edges, speeding up tool wear and failure.Remember - cutting edges, particularly throw - away inserts, are expendable. Don’t trade dollars in machine timefor pennies in tool cost.17<strong>Rolled</strong> <strong>Alloy</strong>s

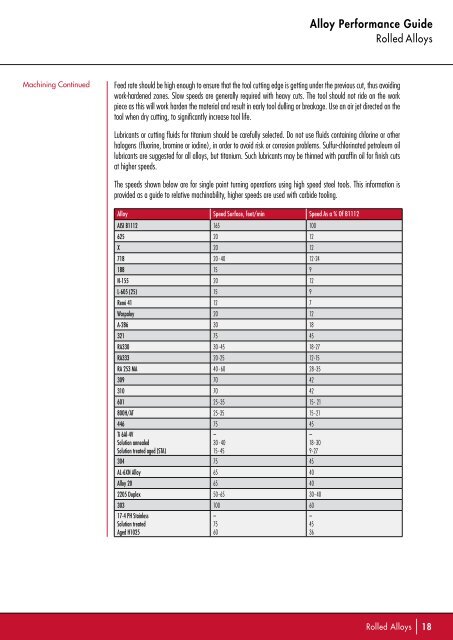

<strong>Alloy</strong> <strong>Performance</strong> <strong>Guide</strong><strong>Rolled</strong> <strong>Alloy</strong>sMachining ContinuedFeed rate should be high enough to ensure that the tool cutting edge is getting under the previous cut, thus avoidingwork-hardened zones. Slow speeds are generally required with heavy cuts. The tool should not ride on the workpiece as this will work harden the material and result in early tool dulling or breakage. Use an air jet directed on thetool when dry cutting, to significantly increase tool life.Lubricants or cutting fluids for titanium should be carefully selected. Do not use fluids containing chlorine or otherhalogens (fluorine, bromine or iodine), in order to avoid risk or corrosion problems. Sulfur-chlorinated petroleum oillubricants are suggested for all alloys, but titanium. Such lubricants may be thinned with paraffin oil for finish cutsat higher speeds.The speeds shown below are for single point turning operations using high speed steel tools. This information isprovided as a guide to relative machinability, higher speeds are used with carbide tooling.<strong>Alloy</strong> Speed Surface, feet/min Speed As a % Of B1112AISI B1112 165 100625 20 12X 20 12718 20 - 40 12 -24188 15 9N-155 20 12L-605 (25) 15 9René 41 12 7Waspaloy 20 12A-286 30 18321 75 45RA330 30 - 45 18 -27RA333 20 -25 12 -15RA 253 MA 40 - 60 28 - 35309 70 42310 70 42601 25 - 35 15 - 21800H/AT 25 - 35 15 - 21446 75 45Ti 6Al-4VSolution annealedSolution treated aged (STA)–30 - 4015 - 45–18 - 309 -27304 75 45AL-6XN <strong>Alloy</strong> 65 40<strong>Alloy</strong> 20 65 402205 Duplex 50 - 65 30 - 40303 100 6017-4 PH StainlessSolution treatedAged H1025–7560–4536<strong>Rolled</strong> <strong>Alloy</strong>s18

![RA333 Data Sheet [Heat Resistant Alloys] - Rolled Alloys](https://img.yumpu.com/50335849/1/190x245/ra333-data-sheet-heat-resistant-alloys-rolled-alloys.jpg?quality=85)