You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

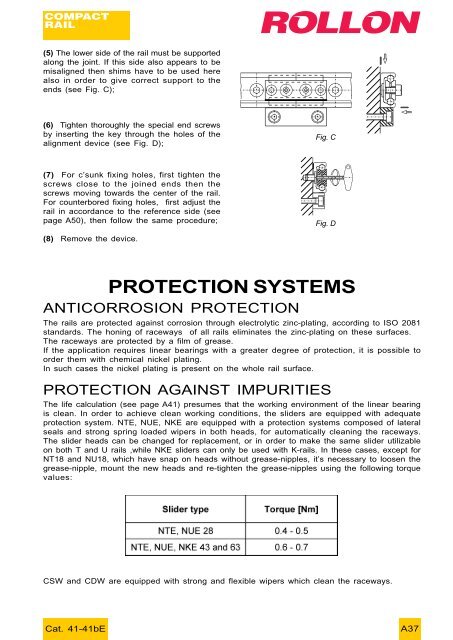

(5) The lower side of the <strong>rail</strong> must be supportedalong the joint. If this side also appears to bemisaligned then shims have to be used herealso in order to give correct support to theends (see Fig. C);(6) Tighten thoroughly the special end screwsby inserting the key through the holes of thealignment device (see Fig. D);Fig. C(7) For c’sunk fixing holes, first tighten thescrews close to the joined ends then thescrews moving towards the center of the <strong>rail</strong>.For counterbored fixing holes, first adjust the<strong>rail</strong> in accordance to the reference side (seepage A50), then follow the same procedure;Fig. D(8) Remove the device.PROTECTION SYSTEMSANTICORROSION PROTECTIONThe <strong>rail</strong>s are protected against corrosion through electrolytic zinc-plating, according to ISO 2081standards. The honing of raceways of all <strong>rail</strong>s eliminates the zinc-plating on these surfaces.The raceways are protected by a film of grease.If the application requires linear bearings with a greater degree of protection, it is possible toorder them with chemical nickel plating.In such cases the nickel plating is present on the whole <strong>rail</strong> surface.PROTECTION AGAINST IMPURITIESThe life calculation (see page A41) presumes that the working environment of the linear bearingis clean. In order to achieve clean working conditions, the sliders are equipped with adequateprotection system. NTE, NUE, NKE are equipped with a protection systems composed of lateralseals and strong spring loaded wipers in both heads, for automatically cleaning the raceways.The slider heads can be changed for replacement, or in order to make the same slider utilizableon both T and U <strong>rail</strong>s ,while NKE sliders can only be used with K-<strong>rail</strong>s. In these cases, except forNT18 and NU18, which have snap on heads without grease-nipples, it’s necessary to loosen thegrease-nipple, mount the new heads and re-tighten the grease-nipples using the following torquevalues:CSW and CDW are equipped with strong and flexible wipers which clean the raceways.Cat. 41-41bEA37