- Page 6 and 7: INDEXRAIL MOUNTING DIMENSIONS......

- Page 10 and 11: MAIN COMPONENTSSLIDERS- N... SERIES

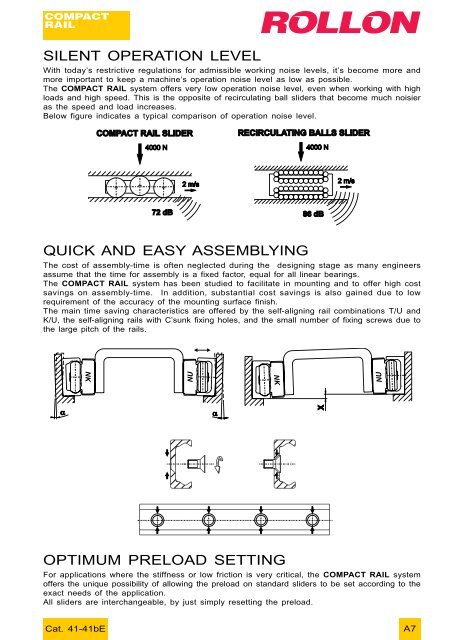

- Page 12 and 13: GENERAL PERFORMANCELOAD CAPACITIES

- Page 14 and 15: RAILS18 SERIES Rail weight:550 g/mW

- Page 16 and 17: - CSW.. SERIES28 SERIESSlider typeC

- Page 18 and 19: LOAD CAPACITYThe load capacities in

- Page 20 and 21: - CSW.. SERIES43 SERIESSlider typeC

- Page 22 and 23: TL.../NTE43TL.../NTE43LUL.../NUE43U

- Page 24 and 25: SLIDERS- N... SERIES63 SERIESSlider

- Page 26 and 27: TL.../NTE63UL.../NUE6363 SERIESMOUN

- Page 28 and 29: RAIL MOUNTING-HOLE CRITERIAROLLON o

- Page 30 and 31: GENERAL INSTRUCTIONS FOR THEUSE OF

- Page 32: GENERAL TOLERANCESRAIL TOLERANCESL

- Page 38 and 39: JOINED RAILSGENERAL INFORMATIONSThe

- Page 40 and 41: PRELOADCLASSES OF PRELOADThe slider

- Page 42 and 43: VERIFICATION UNDER STATIC LOADCALCU

- Page 44 and 45: STIFFNESSTOTAL DEFORMATIONThe total

- Page 46 and 47: 63 SERIESThe deformations given in

- Page 48 and 49: LUBRICATIONROLLER LUBRICATIONThe ro

- Page 50 and 51: THRUST FORCEFRICTIONAL RESISTANCETh

- Page 52 and 53: MOUNTING INSTRUCTIONSSINGLE RAIL MO

- Page 54 and 55: MOUNTING OF TWO “T” PARALLEL RA

- Page 56 and 57: MOUNTING OF “K+U” SYSTEMConside

- Page 58 and 59:

FORMULAE FOR DETERMINING THELOAD ON

- Page 60 and 61:

SELECTION CRITERIA FOR THECORRECT C

- Page 62 and 63:

FIELDS OF APPLICATIONThe applicatio

- Page 64 and 65:

TRAIN DOORSApplications for the tra

- Page 66 and 67:

X-RAY TABLEThe COMPACT RAIL system

- Page 68 and 69:

ORDER CODESSliders can be ordered s

- Page 70 and 71:

U70INSERTOUNILINE

- Page 72 and 73:

INDEXLINEAR UNIT A100C.............

- Page 74 and 75:

FAMILIESBelow and in the following

- Page 76 and 77:

“E” FAMILY:Set-screwsMoving tro

- Page 78 and 79:

LOAD CAPACITIESAs indicated below,

- Page 80 and 81:

A55108 200 Stroke108Trolley length

- Page 82 and 83:

E55Housing for shaft Ø12 h7with 4x

- Page 84 and 85:

C75116 285 Stroke116Trolley length(

- Page 86 and 87:

ED75116 330 Stroke116* Position of

- Page 88 and 89:

VERSION “D”(Double trolley)“D

- Page 90 and 91:

VERIFICATION UNDER STATIC LOADCALCU

- Page 92 and 93:

CALCULATION METHODSM Zand M YFOR LO

- Page 94 and 95:

2 AXIS GANTRY (2X-Y)This example sh

- Page 96 and 97:

X-Y GANTRYAnother typical applicati

- Page 98 and 99:

MOTOR / GEARBOX CONNECTIONProper in

- Page 100 and 101:

LUBRICATIONUNILINE units are suppli

- Page 102 and 103:

- “NEMA” plates for “40” an

- Page 104 and 105:

“X” PLATEThis plate allows two

- Page 106 and 107:

LINEAR ACTUATOR A100CThe ROLLON lin

- Page 108 and 109:

Motor connections: version AM 619*3

- Page 110 and 111:

Technical characteristics of the st

- Page 112 and 113:

Order codesStandard linear actuator

- Page 114 and 115:

U114INSERTOTELESCOPIC RAIL

- Page 116 and 117:

TELESCOPIC RAIL: BEARINGSTHAT MOVE

- Page 118 and 119:

LOAD CAPACITIESThe load capacities

- Page 120 and 121:

APPLICATION EXAMPLESThe slides in t

- Page 122 and 123:

Order code:DS S 28 -DS SERIESThe ne

- Page 124 and 125:

“DSS” LOCKING SYSTEM(only for c

- Page 126 and 127:

DE SERIESThis slide is formed by id

- Page 128 and 129:

DBN SERIESThis slide is formed by i

- Page 130 and 131:

LTF44 SERIESThis slide is formed by

- Page 132 and 133:

end-stop screwM zC 0axFixed memberW

- Page 134 and 135:

DMS63 SERIESTELESCOPIC RAILS WITH H

- Page 136 and 137:

PRODUCT SELECTIONThe choice of a te

- Page 138 and 139:

TECHNICAL APPLICATIONSUGGESTIONAll

- Page 140 and 141:

U140INSERTOEASY RAIL

- Page 142 and 143:

EASY RAIL:THE SOLUTION IS EASYSimpl

- Page 144 and 145:

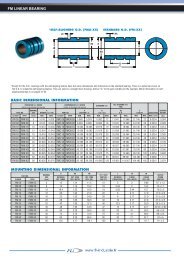

ORDER CODESThe SN series linear bea

- Page 146 and 147:

TECHNICAL DATABy combining the thre

- Page 148 and 149:

STANDARD CONFIGURATIONSSN35 SERIESS

- Page 150 and 151:

VERIFICATION UNDER STATIC LOADThe l

- Page 152 and 153:

APPLICATION NOTESThe SN series line

- Page 154 and 155:

U154INSERTOECOLINE

- Page 156 and 157:

ECOLINE:AFFORDABLE AND INNOVATIVELI

- Page 158 and 159:

• MOUNTED SLIDER/RAIL SETWhen des

- Page 160 and 161:

“XM” VERSION (LINEAR UNIT)ECOLI

- Page 162 and 163:

- MOTOR INTERFACE PLATE:3.5Ø9Ø7.5

- Page 164 and 165:

U164INSERTOX RAIL

- Page 166 and 167:

TEX - CEX SERIES...perfect for wash

- Page 168 and 169:

SLIDER (CEX - CES)ACBEDNo. 4 holes

- Page 170 and 171:

LOAD CAPACITIESC 0radC 0axTECHNICAL

- Page 172 and 173:

U172INSERTOCURVILINE

- Page 174 and 175:

CURVILINE:...the rail that goes str

- Page 176 and 177:

MOUNTED RAIL / SLIDER(Variable Radi

- Page 178 and 179:

CONVERSION FACTORSNOTES:U178

- Page 180:

RETROCOPERTINA41-41bE