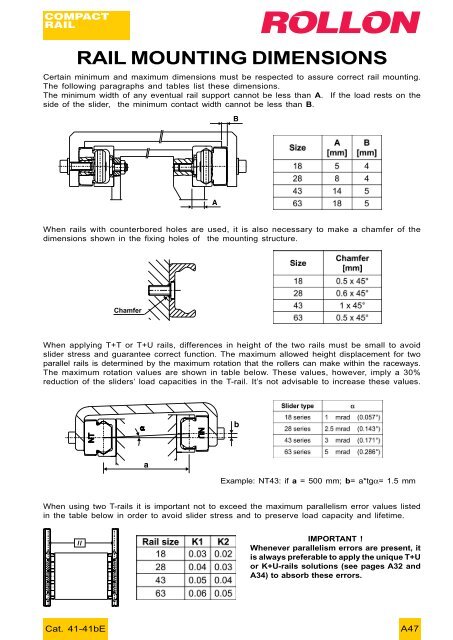

- Page 6 and 7: INDEXRAIL MOUNTING DIMENSIONS......

- Page 9 and 10: SILENT OPERATION LEVELWith today’

- Page 11 and 12: RAILSThree different type rails - e

- Page 13 and 14: SLIDERS- N... SERIES18 SERIESSlider

- Page 15 and 16: SLIDERS- N... SERIES28 SERIESSlider

- Page 17 and 18: RAILS28 SERIESRail weight:1000 g/mH

- Page 19 and 20: SLIDERS- N... SERIES43 SERIESSlider

- Page 21 and 22: RAILS43 SERIESRail weight:2600 g/mW

- Page 23 and 24: 43 SERIESThe sliders of N.43L serie

- Page 25 and 26: RAILS63 SERIESRail weight:6000 g/mW

- Page 27 and 28: CPA / CPN ROLLERSROLLERSThe CPA is

- Page 29 and 30: TORX ® HEAD SCREWSCHARACTERISTICSF

- Page 31 and 32: POSSIBILITIES IN SLIDER MOUNTINGCOM

- Page 37 and 38: In order to obtain the best results

- Page 39 and 40: (5) The lower side of the rail must

- Page 41 and 42: LINEAR PRECISIONRUNNING PARALLELISM

- Page 43 and 44: LIFETIMELIFE CALCULATIONThe dynamic

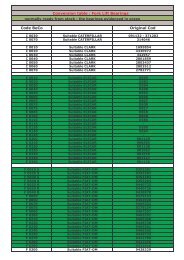

- Page 45 and 46: - Axial loadNT/CSW18NTE/CSW28NTE/CS

- Page 47: - Axial loadNTE63CSW63- Mx momentNT

- Page 51 and 52: 18 SIZE SLIDERSCoefficient of frict

- Page 53 and 54: - Rail mounting without any support

- Page 55 and 56: MOUNTING OF “T+U” SYSTEMThe mou

- Page 57 and 58: (4) Fix the U.. rail, following the

- Page 59 and 60: VERTICAL MOVEMENTSTATIC VERIFICATIO

- Page 61 and 62: SELECTION FLOW-CHARTThe following f

- Page 63 and 64: EXAMPLES OF APPLICATION3 AXES PALLE

- Page 65 and 66: PLASMA CUTTING MACHINEThis machine

- Page 67 and 68: EXPOSURE UNITIn the photographic ap

- Page 69 and 70: INSERTOUNILINE

- Page 71 and 72: INDEXUNILINE - THE ONLY CHOICE.....

- Page 73 and 74: UNILINE - THE ONLY CHOICEUNILINE is

- Page 75 and 76: “A” FAMILY:Set-screwsMoving tro

- Page 77 and 78: WHICH ACTUATOR TO CHOOSE(PERFORMANC

- Page 79 and 80: A407.5 1542.5 8091.5 165 Stroke91.5

- Page 81 and 82: C55108 200 Stroke108Trolley length(

- Page 83 and 84: A75116 285 Stroke116Trolley length(

- Page 85 and 86: E75116 285 Stroke116* Position of t

- Page 87 and 88: VERSION “L” (Long trolley)“L

- Page 89 and 90: VERSION “H”The H units are “s

- Page 91 and 92: LIFETIMELIFE CALCULATIONThe dynamic

- Page 93 and 94: MOUNTING CONFIGURATIONSAND INSTRUCT

- Page 95 and 96: 2 AXIS GANTRY (Y-2Z and 2Y-Z)In the

- Page 97 and 98: 3 AXIS GANTRY (2X-Y-Z)This example

- Page 99 and 100:

BELT TENSIONINGThe UNILINE linear u

- Page 101 and 102:

MOUNTING ACCESSORIESMETRIC INTERFAC

- Page 103 and 104:

“T” PLATEThis plate allows two

- Page 105 and 106:

OTHER USEFUL INFORMATIONRUNNING PAR

- Page 107 and 108:

The linear slide inside the actuato

- Page 109 and 110:

NotesThe linear actuator is supplie

- Page 111 and 112:

4545Special versionsSpecial version

- Page 113 and 114:

INSERTOTELESCOPIC RAIL

- Page 115 and 116:

INDEXTELESCOPIC RAIL: BEARINGS THAT

- Page 117 and 118:

PRODUCT OVERVIEWAll of the rails in

- Page 119 and 120:

WHAT MAKES ROLLON’S TELESCOPICRAI

- Page 121 and 122:

ELECTROMEDICAL BEDASNLTF44MACHINE T

- Page 123 and 124:

- Single direction stroke (version

- Page 125 and 126:

TECHNICAL DATA:DLCALtotBStrokeTypeL

- Page 127 and 128:

end-stop screwWeight DE22: 2.5 kg/m

- Page 129 and 130:

end-stop screwWeight DBN22: 2.5 kg/

- Page 131 and 132:

ASN SERIESThis slide is formed by a

- Page 133 and 134:

Order code:ASN 63 - 770 - 433Series

- Page 135 and 136:

TECHNICAL DATA:length Lstroke Hleft

- Page 137 and 138:

VERIFICATION OF STATIC LOADAs you c

- Page 139 and 140:

INSERTOEASY RAIL

- Page 141 and 142:

INDEXEASY RAIL: THE SOLUTION IS EAS

- Page 143 and 144:

EXAMPLES OF LOAD CAPACITIES63432211

- Page 145 and 146:

MOUNTING EXAMPLESWith regard to the

- Page 147 and 148:

• “SN35” SERIES15.8M610R2Coun

- Page 149 and 150:

SN63 SERIESSN43 SERIESCat. 41-41bED

- Page 151 and 152:

LIFETIME CALCULATIONThe life of a l

- Page 153 and 154:

INSERTOECOLINE

- Page 155 and 156:

INDEXECOLINE: AFFORDABLE AND INNOVA

- Page 157 and 158:

TECHNICAL DATA AND ORDER CODESRails

- Page 159 and 160:

SETTING SLIDER PRELOAD ANDROLLER OR

- Page 161 and 162:

- “XM37” WITH SINGLE SLIDER “

- Page 163 and 164:

INSERTOX RAIL

- Page 165 and 166:

INDEXTEX - CEX SERIES..............

- Page 167 and 168:

MOUNTED RAIL / SLIDERBeccentric rol

- Page 169 and 170:

ROLLERSCRPACRPNBFG (eccentricity)BD

- Page 171 and 172:

INSERTOCURVILINE

- Page 173 and 174:

INDEXCURVILINE: THE RAIL THAT GOES

- Page 175 and 176:

APPLICATION EXAMPLES:VARIABLE RADIU

- Page 177 and 178:

MOUNTED RAIL / SLIDER(Constant Radi

- Page 179 and 180:

Branches:Via Trieste 26, 20059 Vime