Diamond Tools and Chemistry - EN / Hahn+Kolb

Diamond Tools and Chemistry - EN / Hahn+Kolb

Diamond Tools and Chemistry - EN / Hahn+Kolb

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

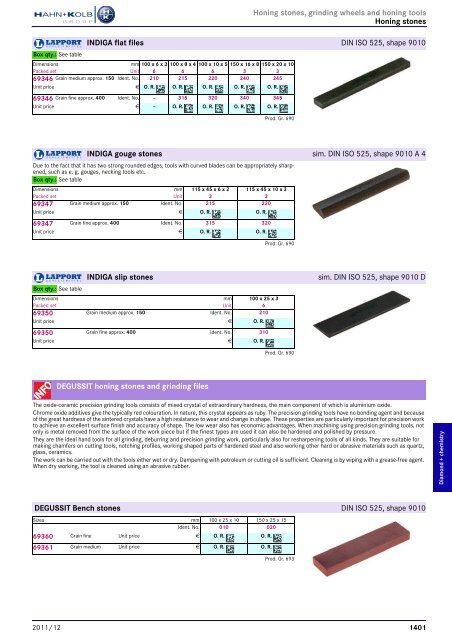

Honing stones, grinding wheels <strong>and</strong> honing toolsHoning stonesContinued next pageBox qty.: See tableINDIGA flat files DIN ISO 525, shape 9010Dimensionsmm 100x6x3 100x8x4 100x10x5 150x16x8 150x20x10Packed set Unit 6 6 6 3 369346 Grain medium approx. 150 Ident. No. 210 215 220 240 245Unit price E O. R. O. R. O. R. O. R. O. R.69346 Grain fine approx. 400 Ident. No. – 315 320 340 345Unit price E – O. R. O. R. O. R. O. R.Prod. Gr. 690Continued next pageINDIGA gouge stones sim. DIN ISO 525, shape 9010 A 4Due to the fact that it has two strong rounded edges, tools with curved blades can be appropriately sharpened,such as e. g. gouges, necking tools etc.Box qty.: See tableDimensions mm 115 x 45 x 6 x 2 115 x 45 x 10 x 3Packed set Unit 3 369347 Grain medium approx. 150 Ident. No. 215 220Unit price E O. R. O. R.69347 Grain fine approx. 400 Ident. No. 315 320Unit price E O. R. O. R.Prod. Gr. 690Continued next pageINDIGA slip stonesBox qty.: See tableDimensions mm 100 x 25 x 3Packed set Unit 669350 Grain medium approx. 150 Ident. No. 210Unit price E O. R.69350 Grain fine approx. 400 Ident. No. 310Unit price E O. R.sim. DIN ISO 525, shape 9010 DProd. Gr. 690Continued next pageDEGUSSIT honing stones <strong>and</strong> grinding filesThe oxide-ceramic precision grinding tools consists of mixed crystal of extraordinary hardness, the main component of which is aluminium oxide.Chrome oxide additives give the typically red colouration. In nature, this crystal appears as ruby. The precision grinding tools have no bonding agent <strong>and</strong> becauseof the great hardness of the sintered crystals have a high resistance to wear <strong>and</strong> change in shape. These properties are particularly important for precision workto achieve an excellent surface finish <strong>and</strong> accuracy of shape. The low wear also has economic advantages. When machining using precision grinding tools, notonly is metal removed from the surface of the work piece but if the finest types are used it can also be hardened <strong>and</strong> polished by pressure.They are the ideal h<strong>and</strong> tools for all grinding, deburring <strong>and</strong> precision grinding work, particularly also for resharpening tools of all kinds. They are suitable formaking chamfers on cutting tools, notching profiles, working shaped parts of hardened steel <strong>and</strong> also working other hard or abrasive materials such as quartz,glass, ceramics.The work can be carried out with the tools either wet or dry. Dampening with petroleum or cutting oil is sufficient. Cleaning is by wiping with a grease-free agent.When dry working, the tool is cleaned using an abrasive rubber.<strong>Diamond</strong> + chemistryContinued next pageDEGUSSIT Bench stones DIN ISO 525, shape 9010Sizes mm 100 x 25 x 10 150 x 25 x 15Ident. No. 010 02069360 Grain fine Unit price E O. R. O. R.69361 Grain medium Unit price E O. R. O. R.Prod. Gr. 6932011/121401