Goodman AEPT Variable Speed Air Handler - Desco Energy

Goodman AEPT Variable Speed Air Handler - Desco Energy

Goodman AEPT Variable Speed Air Handler - Desco Energy

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

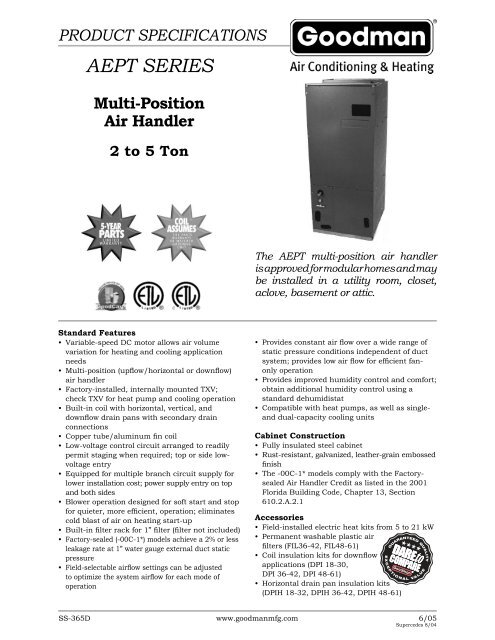

PRODUCT SPECIFICATIONS<strong>AEPT</strong> SERIESMulti-Position<strong>Air</strong> <strong>Handler</strong>2 to 5 TonThe <strong>AEPT</strong> multi-position air handleris approved for modular homes and maybe installed in a utility room, closet,aclove, basement or attic.Standard Features• <strong>Variable</strong>-speed DC motor allows air volumevariation for heating and cooling applicationneeds• Multi-position (upflow/horizontal or downflow)air handler• Factory-installed, internally mounted TXV;check TXV for heat pump and cooling operation• Built-in coil with horizontal, vertical, anddownflow drain pans with secondary drainconnections• Copper tube/aluminum fin coil• Low-voltage control circuit arranged to readilypermit staging when required; top or side lowvoltageentry• Equipped for multiple branch circuit supply forlower installation cost; power supply entry on topand both sides• Blower operation designed for soft start and stopfor quieter, more efficient, operation; eliminatescold blast of air on heating start-up• Built-in filter rack for 1” filter (filter not included)• Factory-sealed (-00C-1*) models achieve a 2% or lessleakage rate at 1” water gauge external duct staticpressure• Field-selectable airflow settings can be adjustedto optimize the system airflow for each mode ofoperation• Provides constant air flow over a wide range ofstatic pressure conditions independent of ductsystem; provides low air flow for efficient fanonlyoperation• Provides improved humidity control and comfort;obtain additional humidity control using astandard dehumidistat• Compatible with heat pumps, as well as singleanddual-capacity cooling unitsCabinet Construction• Fully insulated steel cabinet• Rust-resistant, galvanized, leather-grain embossedfinish• The -00C-1* models comply with the Factorysealed<strong>Air</strong> <strong>Handler</strong> Credit as listed in the 2001Florida Building Code, Chapter 13, Section610.2.A.2.1Accessories• Field-installed electric heat kits from 5 to 21 kW• Permanent washable plastic airfilters (FIL36-42, FIL48-61)• Coil insulation kits for downflowapplications (DPI 18-30,DPI 36-42, DPI 48-61)• Horizontal drain pan insulation kits(DPIH 18-32, DPIH 36-42, DPIH 48-61)SS-365Dwww.goodmanmfg.com 6/05Supercedes 8/04

PRODUCT SPECIFICATIONSDimensionsJ2.572’’2.875’’IModel A B C D E F G H I J<strong>AEPT</strong>030-00C-1/00C-1A 46¾” 22” 17½” 19½” 10” 14½” 11.935” 17⅛” 17.938” 2.024”<strong>AEPT</strong>036-00C-1/00C-1A<strong>AEPT</strong>060-00C-1/00C-1A53¼” 24” 20” 22” 12” 14½” 11.935” 19⅝” 17.938 1.837”3

PRODUCT SPECIFICATIONS<strong>AEPT</strong> OverviewThe <strong>AEPT</strong> air handler represents thenext generation of indoor air moving andconditioning equipment. Combining all ofthe advantages of our standard air handlerswith the features and benefits of a variablespeedDC programmable motor, the <strong>AEPT</strong>air handler has been designed to provide thehighest level of indoor comfort at the increasedefficiency levels demanded today.The <strong>AEPT</strong> air handlers do not require anyspecial external electronic controls and canbe operated with the same controls as ourstandard air handlers without any extensiveor complicated connections.EfficiencyThe variable-speed DC motors utilized in the <strong>AEPT</strong> air handler are, at full load, over 20% moreefficient than the motors utilized in the typical air handler. They also maintain their efficiencythroughout the entire load range in variable-speed applications.Constant CFM vs. Static PressureThe air flow delivered to a system by a typicalair handler is dependent upon the staticpressure requiring careful attention to thedesign of the air distribution network. Often,the system’s air flow requirements in thecooling mode are different from the heatingmode, making it necessary to design the airdistribution network for the cooling or heatingmode, or a compromise of the two. In suchcases, the system’s capacity may be reduced,resulting in higher operating costs and a lowerlevel of comfort.The <strong>AEPT</strong> air handler delivers the optimumair flow for the system size, whether inheating or cooling mode, regardless ofthe static pressure imposed by the airdistribution.Constant FanThe air flow delivered to the system in constant fan operation by the typical air handler is the fullsystem requirement. In most applications, the constant fan operation is intended to provide aircirculation throughout the conditioned space to prevent air stratification. In such applications,the full system air flow is not required and results in a high background noise level and highoperating cost.The <strong>AEPT</strong> air handler delivers to the system approximately 30% of the full system air flowin constant fan operation (60% or Y1 air flow can be field -selected). This results in lowerbackground noise levels and lower operating cost.4

PRODUCT SPECIFICATIONSHumidity ControlWhen matched with today’s high-efficiency outdoor sections, the typical air handler operatingunder high-humidity conditions may not remove sufficient moisture from the conditioned air toprovide the desired comfort level.The <strong>AEPT</strong> air handler provides further humidity control when operated with a standard24V de-humidistat. When the de-humidistat detects a high-humidity condition, the airflow delivered to the system is reduced, allowing the indoor coil to remove more moisturefrom the conditioned air. When the de-humidistat detects normal humidity conditions,the air flow delivered to the system is increased to the normal level.Soft Start/Stop vs. Instant On/OffUpon a call for system operation, the blowermotor of a typical air handler is energized atfull speed. Because of the time lag betweena call for system operation and the systemoperating at full capacity, this often results incomplaints of blasts of warm air at start-up inthe cooling mode, and of blasts of cold air atstart-up in the heating mode. There are alsopotential complaints of noise and distractioncaused by the blower motor starting at fullspeed.<strong>Air</strong> flow delivered to the system by the <strong>AEPT</strong> air handlerSoft Startfor a typical cooling/heating cycle.Upon a call for system operation, the <strong>AEPT</strong>’s blower motor provides a soft start. This means theair flow gradually increases from zero to the system’s full air flow requirements. Ramping theair flow during the system start-up matches the air flow more closely to the immediate systemcapacity, eliminating blasts of warm or cold air. Ramping the air flow from zero to full systemrequirements also eliminates the perceived noise and distraction, which occurs on start-up withthe typical air handler.Soft StopUpon a call to shut down system operation, the <strong>AEPT</strong>’s blower motor provides a soft stop. Thismeans the air flow delivered to the system ramps down to approximately 50% of the full systemrequirements and remains there for a period of time and then ramps down to a full stop. Theshut-down air profile is intended to take the maximum advantage of the residual cooling orheating capacity of the indoor coil without blasts of warm or cold air. Ramping the air flow fromfull system requirements to zero also eliminates the perceived noise and distraction, whichoccurs on shut-down with a typical air handler.Two-<strong>Speed</strong> ApplicationThe typical air handler blower motor, when matched with a 2-speed outdoor section, normallydoes not deliver the optimum air flow to the system for both high- and low-speed operation. Thisis due to design limitations inherent in the design of the standard induction motor. Because ofthis, the typical 2-speed application is designed to operate based upon the air flow delivered ateither high or low speed. As a result, the overall system efficiency and comfort level provided bythe system are compromised.The <strong>AEPT</strong> air handler delivers the optimum air flow to the system for both high- and lowspeedoperations. As a result, the overall system efficiency and comfort level provided bythe system are not compromised.5

PRODUCT SPECIFICATIONS<strong>AEPT</strong> DipswitchesThe <strong>AEPT</strong> air handler blower motors have been pre-programmed for operation at four distinct air flow levelswhen operating in the Cooling, Heat Pump Heating, Backup Heating (Electric Heating) and Backup + HeatPump Heating. Each mode has four levels to deliver different CFM. Simply flip the dipswitch, and you canget a different CFM combination.Setting Up Your MotorDipswitchFunctionInstructionsNumber1 Electric Heat ModeSelect the taps allowed in the tables (Dipswitch 1/2) below.2 Electric Heat Mode3 N/A N/AON = The system operates with single-stage units using a single-stagecooling or heat pump thermostat. (factory default)OFF = The system operates with two-stage units with either aconventional two-stage cooling/heat pump thermostat or with an4 Thermostat Modeencoded two-stage thermostat for cooling operation. The encodedthermostats can be used with two-stage condensing units in retrofitapplications where there aren’t enough existing wires available forconnections to the indoor thermostat and outdoor units.5 Cooling/Heat Pump Mode Find the air flow for your application in the tables (Dipswitch 5/6) below.6 Cooling/Heat Pump Mode Set up the motor based on the outdoor unit capacity tons.7 Trim CFM Adjust Mode Increase or decrease your selected air flow to fit your requirement.ON-OFF = Increases selected Cool/Heat Pump air flow by 10%.8 Trim CFM Adjust Mode OFF-ON = Decreases selected Cool/Heat Pump air flow by 15%NOTE: Other settings have no effect on the set air flow.Dipswitch 1/2<strong>AEPT</strong>30HeatingElement (kW)SwitchPositionEmergencyBackupUp to 10 OFF-OFF 1,100 1,210Up to 10 ON-OFF 850 9355 OFF-ON 700 770<strong>AEPT</strong>36/60Heat Pumpwith BackupHeatingElement (kW)SwitchPositionEmergencyBackupHeat Pumpwith BackupUp to 20 OFF-OFF 2,050 2,150Up to 20 ON-OFF 1,750 1,835Up to 15 OFF-ON 1,600 1,680Up to 10 ON-ON 1,200 1,260Dipswitch 5/6<strong>AEPT</strong>30Outdoor Unit Switch Indoor <strong>Air</strong> Flow(Tons) Position Cool Heat Pump2.5 OFF-OFF 1,100 1,1002 ON-OFF 800 8001.5 OFF-ON 600 600<strong>AEPT</strong>36/60Outdoor Unit Switch Indoor <strong>Air</strong> Flow(Tons) Position Cool Heat Pump5 OFF-OFF 1,800 1,8004 ON-OFF 1,580 1,5803.5 OFF-ON 1,480 1,4803 ON-ON 1,200 1,200NOTE: When applying a humidistat (normally closed), refer to the installation and operating instructions. Thehumidistat can adjust the cooling air flow to 85%.6

PRODUCT SPECIFICATIONSHeat Kit SelectionModel <strong>AEPT</strong>030-00C-1/00C-1A <strong>AEPT</strong>036-00C-1/00C-1A <strong>AEPT</strong>060-00C-1/00C-1AHKR-05CXHKR-08C X XHKR-10C X X XHKR-15C X XHKR-20CXHKR-21CXNOTE: The C indicates circuit breakers are optional*Heat Kit requires 3-phase power supply7

PRODUCT SPECIFICATIONS<strong>Goodman</strong> Manufacturing Company, L.P., reserves the right to discontinue, or change at any time, specifications or designs without notice or without incurring obligations.Copyright © 2005 <strong>Goodman</strong> Manufacturing Company, L.P. • Houston, Texas • Printed in the USA. • <strong>Goodman</strong> products are made proudly in the USA.8