- Page 1 and 2:

Dottorato di Ricercain Ingegneria d

- Page 7:

AcknowledgementsI would like to exp

- Page 10 and 11:

Abstractinclusion of fibers and the

- Page 13:

ContentsAcknowledgementsAbstractTab

- Page 16 and 17:

Contents8.6.1 Tensile tests . . . .

- Page 18 and 19:

List of Figures2.1 Fine and coarse

- Page 20 and 21:

List of Figures4.16 Pull-out simula

- Page 22 and 23:

List of Figures6.14 Crack paths of

- Page 25:

List of Tables2.1 Mix design per cu

- Page 28 and 29:

Chapter 1. Introduction1.1.1 Fiber

- Page 30 and 31:

Chapter 1. Introductionthe fiber ad

- Page 32 and 33:

Chapter 1. Introductionand mechanic

- Page 34 and 35:

Chapter 1. Introduction[Vrech and E

- Page 36 and 37:

Chapter 1. IntroductionDespite the

- Page 38 and 39:

Chapter 1. Introduction(Figure 1.4)

- Page 40 and 41:

Chapter 1. IntroductionFigure 1.8:

- Page 42 and 43:

Chapter 1. Introductionfor structur

- Page 44 and 45:

Chapter 1. Introductioncracking beh

- Page 46 and 47:

Chapter 1. Introduction• "c" if 0

- Page 48 and 49:

Chapter 1. Introductionsumed due to

- Page 50 and 51:

Chapter 1. Introductionaleatoric na

- Page 52 and 53:

Chapter 1. IntroductionFigure 1.13:

- Page 54 and 55:

Chapter 1. IntroductionElement Meth

- Page 56 and 57:

Chapter 2. Experimental characteriz

- Page 58 and 59:

Chapter 2. Experimental characteriz

- Page 60 and 61:

Chapter 2. Experimental characteriz

- Page 62 and 63:

Chapter 2. Experimental characteriz

- Page 64 and 65: Chapter 2. Experimental characteriz

- Page 66 and 67: Chapter 2. Experimental characteriz

- Page 68 and 69: Chapter 2. Experimental characteriz

- Page 70 and 71: Chapter 3. Zero-thickness interface

- Page 72 and 73: Chapter 3. Zero-thickness interface

- Page 74 and 75: Chapter 3. Zero-thickness interface

- Page 76 and 77: Chapter 3. Zero-thickness interface

- Page 78 and 79: Chapter 3. Zero-thickness interface

- Page 80 and 81: Chapter 3. Zero-thickness interface

- Page 82 and 83: Chapter 3. Zero-thickness interface

- Page 84 and 85: Chapter 3. Zero-thickness interface

- Page 86 and 87: Chapter 3. Zero-thickness interface

- Page 88 and 89: Chapter 3. Zero-thickness interface

- Page 90 and 91: Chapter 3. Zero-thickness interface

- Page 93 and 94: 4 Bond behavior of fibers in cement

- Page 95 and 96: 4.2. Bond behavior of fibers in con

- Page 97 and 98: 4.3. Elasto-plastic joint/interface

- Page 99 and 100: 4.3. Elasto-plastic joint/interface

- Page 101 and 102: 4.3. Elasto-plastic joint/interface

- Page 103 and 104: 4.3. Elasto-plastic joint/interface

- Page 105 and 106: 4.3. Elasto-plastic joint/interface

- Page 107 and 108: 4.4. Fracture energy-based interfac

- Page 109 and 110: 4.4. Fracture energy-based interfac

- Page 111 and 112: 4.5. Numerical results and experime

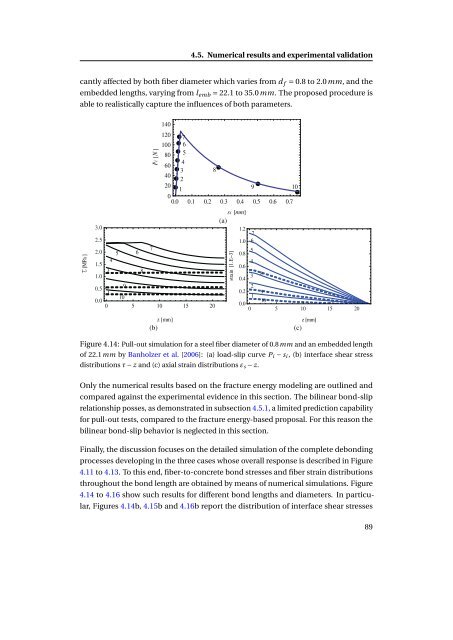

- Page 113: 4.5. Numerical results and experime

- Page 117 and 118: 4.6. Closing remarksMPa3.02.5Pi N2.

- Page 119 and 120: 5 Model performance and numericalpr

- Page 121 and 122: 5.1. Numerical analysesones mention

- Page 123 and 124: 5.1. Numerical analysesshown in Fig

- Page 125 and 126: 5.1. Numerical analysesconsidered,

- Page 127 and 128: 5.1. Numerical analysestic behavior

- Page 129 and 130: 5.1. Numerical analysesσ MPa121086

- Page 131 and 132: 5.2. Cracking analysis of the propo

- Page 133 and 134: 4 03 02 01 001 0 09 08 07 06 05 04

- Page 135 and 136: 5.2. Cracking analysis of the propo

- Page 137 and 138: 5.2. Cracking analysis of the propo

- Page 139: 5.3. Closing remarksconnecting node

- Page 142 and 143: Chapter 6. Structural scale failure

- Page 144 and 145: Chapter 6. Structural scale failure

- Page 146 and 147: Chapter 6. Structural scale failure

- Page 148 and 149: Chapter 6. Structural scale failure

- Page 150 and 151: Chapter 6. Structural scale failure

- Page 152 and 153: Chapter 6. Structural scale failure

- Page 154 and 155: Chapter 6. Structural scale failure

- Page 156 and 157: Chapter 6. Structural scale failure

- Page 158 and 159: Chapter 6. Structural scale failure

- Page 160 and 161: Chapter 6. Structural scale failure

- Page 162 and 163: Chapter 6. Structural scale failure

- Page 164 and 165:

Chapter 6. Structural scale failure

- Page 167 and 168:

7 Cracked hinge numerical modelfor

- Page 169 and 170:

7.1. Basic assumptionsSection at no

- Page 171 and 172:

7.1. Basic assumptions1997, Stankow

- Page 173 and 174:

7.2. Bond-slip bridging of fibers o

- Page 175 and 176:

7.4. Numerical predictionsvertical

- Page 177:

7.5. Closing remarksthe experimenta

- Page 180 and 181:

Chapter 8. Elasto-plastic microplan

- Page 182 and 183:

Chapter 8. Elasto-plastic microplan

- Page 184 and 185:

Chapter 8. Elasto-plastic microplan

- Page 186 and 187:

Chapter 8. Elasto-plastic microplan

- Page 188 and 189:

Chapter 8. Elasto-plastic microplan

- Page 190 and 191:

Chapter 8. Elasto-plastic microplan

- Page 192 and 193:

Chapter 8. Elasto-plastic microplan

- Page 194 and 195:

Chapter 8. Elasto-plastic microplan

- Page 196 and 197:

Chapter 8. Elasto-plastic microplan

- Page 198 and 199:

Chapter 8. Elasto-plastic microplan

- Page 200 and 201:

Chapter 9. Conclusionsof first-crac

- Page 202 and 203:

Chapter 9. Conclusionsfibers in con

- Page 204 and 205:

Chapter 9. Conclusions9.6 Future re

- Page 206 and 207:

BibliographyN. Banthia and N. Nanda

- Page 208 and 209:

BibliographyM. Butler, V. Mechtcher

- Page 210 and 211:

BibliographyCUR. Bepaling van de Bu

- Page 212 and 213:

BibliographyEN-12390-3. Testing of

- Page 214 and 215:

BibliographyT. Guttema. Ein Beitrag

- Page 216 and 217:

BibliographyE. Kuhl, P. Steinmann,

- Page 218 and 219:

BibliographyO. Manzoli, J. Oliver,

- Page 220 and 221:

BibliographyK. Park, G. Paulino, an

- Page 222 and 223:

BibliographyI. Singh, B. Mishra, an

- Page 224:

BibliographyG. Wells and L. Sluys.