Conveyor system closures Universal · RGT - Stöbich Brandschutz

Conveyor system closures Universal · RGT - Stöbich Brandschutz

Conveyor system closures Universal · RGT - Stöbich Brandschutz

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Conveyor</strong> <strong>system</strong> <strong>closures</strong><br />

<strong>Universal</strong> <strong>·</strong> <strong>RGT</strong> <strong>·</strong> Omnischott <strong>·</strong> ECC<br />

Smoke barriers<br />

Smoke protection <strong>closures</strong><br />

Textile fire protection <strong>closures</strong><br />

<strong>Conveyor</strong> <strong>system</strong> <strong>closures</strong><br />

Tube <strong>closures</strong><br />

Fire protection stacking doors<br />

Fire protection high-speed doors<br />

Control units<br />

Fire protection hoods<br />

Fire protection-insulation doors for ships and buildings<br />

Fire protection doors - panel walls/hygiene<br />

Fluid barriers

<strong>Stöbich</strong> Customer Cosmos<br />

Safety<br />

by solidity<br />

of the company<br />

and<br />

range of benefits<br />

within the group of<br />

companies<br />

S t a t e - o f-t h e - a r t<br />

Safety<br />

by competence<br />

in planning<br />

and<br />

innovative product<br />

design<br />

S t a t e - o f -t h e - a r t<br />

Safety<br />

in planning,<br />

implementation<br />

and<br />

during the use<br />

S t a te - o f -t h e - a r t<br />

Safety<br />

due to quality<br />

of the processes<br />

and<br />

of the products<br />

S t a t e - o f- t h e - a r t<br />

securing<br />

s t a t e - o f -t h e - a r t<br />

Safety<br />

many years<br />

of experience<br />

and<br />

ambition for new<br />

challenges<br />

S ta te - o f -t h e - a r t<br />

Safety<br />

best solution<br />

and<br />

reliable partner<br />

St a t e- o f-t h e - a r t

Summary<br />

Page Type of closure Design Type of conveyor<br />

1<br />

2<br />

4<br />

5<br />

<strong>Universal</strong> B<br />

<strong>RGT</strong><br />

OS<br />

ECC-S<br />

closed<br />

construction<br />

open<br />

construction<br />

foamed steel<br />

elements<br />

steel plate<br />

elements<br />

belt, roller, carrying chain<br />

belt, roller, carrying chain<br />

belt, roller, carrying chain<br />

belt, roller, carrying chain<br />

9 OC stacking door belt, roller, carrying chain<br />

6<br />

7<br />

8<br />

3<br />

11<br />

10<br />

12<br />

ECC-RS<br />

ECC-FLEX<br />

Q<br />

<strong>RGT</strong>/K<br />

<strong>Universal</strong> EH<br />

<strong>Universal</strong> BZ<br />

Isogate<br />

15 <strong>Universal</strong> S/T/K<br />

13<br />

14<br />

Special<br />

constructions<br />

retaining and<br />

clearing <strong>system</strong>s<br />

steel Roller<br />

Shutter<br />

flexible,<br />

coilable<br />

closure<br />

clap design,<br />

horizontal axle<br />

open<br />

construction<br />

revolving<br />

doors<br />

closed<br />

construction<br />

cold and fire insulation,<br />

foamed<br />

construction<br />

slider,<br />

clap,<br />

drum<br />

belt, roller, carrying chain<br />

belt, roller, carrying chain,<br />

circular conveyors,<br />

mono rails<br />

belt, hinge chain, carrying<br />

chain<br />

overhead, Power + Free,<br />

chain conveyors<br />

mono rails<br />

newspaper conveyors<br />

various conveyors<br />

for cold storage<br />

and freezing rooms<br />

container conveyors<br />

various designs various conveyors<br />

for stopped<br />

and continuing<br />

conveyors

<strong>Conveyor</strong> <strong>system</strong> <strong>closures</strong> made by <strong>Stöbich</strong> …<br />

… not a standard door, but the innovative solution<br />

gas-tight<br />

despite of<br />

high<br />

operation cycles<br />

Trouble free<br />

conveying process<br />

despite of<br />

secure sealing<br />

Approval from the<br />

building supervision for<br />

the control unit<br />

despite of<br />

connection to the<br />

conveyor technique,<br />

emergency power,<br />

sealing<br />

applicable for<br />

clean rooms<br />

despite of<br />

mineralic building materials<br />

for numerous situations of the closing technique<br />

Secure closing<br />

despite of<br />

complicated<br />

conveyor<br />

technique<br />

Secure fixing regarding<br />

the fire protection<br />

despite of<br />

different wall qualities<br />

Approval from<br />

building supervision<br />

despite of<br />

large dimensions<br />

Clearing of the<br />

closing area<br />

despite of<br />

power failure<br />

Various closing directions<br />

and installation positions<br />

because of<br />

limitations in space<br />

Secure clearing<br />

despite of<br />

different conveyed<br />

materials<br />

These specific requirements are defined in the corresponding norms.<br />

In Germany until now the DIN 4102 was used together with guidelines for fire protection<br />

<strong>closures</strong> for track bound conveyor <strong>system</strong>s.<br />

This will be regulated in the future by the European Norm EN 1366-7.<br />

In Germany the certification by an accredited expert is required.

R0 type - interrupted<br />

conveyor <strong>system</strong>s<br />

<strong>Universal</strong> B type<br />

System advantages<br />

<strong>·</strong> Very large construction, clear openings up to 8 x 5 m are possible<br />

<strong>·</strong> Construction in elements as high as the wall or installation into hoods<br />

<strong>·</strong> Displaced closing level in front of the wall level, or frame enlargement<br />

<strong>·</strong> Limited closing power and controlled closing velocity (ex-version is possible)<br />

<strong>·</strong> As an option: Acceptability for clean rooms<br />

Design<br />

<strong>·</strong> Corrosion-less dimension-adapted steel construction<br />

<strong>·</strong> Shutter and frame plated with 20 mm Promatect H on both sides, many special<br />

constructions respectively adaptations are possible, e.g. telescope construction<br />

<strong>·</strong> Planking of the Promatect plate alternatively with galvanized steel or stainless steel<br />

respectively colour coated<br />

<strong>·</strong> Re-opening is done manually, electric motor driven or pneumatically<br />

<strong>·</strong> Duplex-sealing <strong>system</strong> (integrable cable fittings)<br />

<strong>·</strong> Design for clean rooms with even, easy to clean surfaces and encapsulated building materials<br />

Closure types for the conveyor technique<br />

R1 type - swivel roller with<br />

different closing directions<br />

and vice versa<br />

G5 type - brought together<br />

belts, continuous supporting<br />

construction underneath the<br />

closing level<br />

R2 type - continuous bearing<br />

bars, embraced roll<br />

Application<br />

parameters<br />

≥LB + 310 LB = 200 - 2500 ≥145<br />

8000<br />

≥100 LH = 200 - 2700 ≥250<br />

5000<br />

K3 type - continuous slide<br />

steel sheets and cross beams,<br />

recirculation through sleeve<br />

R3 type - continuous bearing<br />

bars and driving elements,<br />

external roll<br />

and vice versa<br />

for and the vice RO versa type<br />

for the RO type<br />

≥200 LB = 200 - 2500 ≥455<br />

6000<br />

K5 type - continuous slide steel<br />

sheets/guiding plates - lower<br />

belt through sleeve<br />

R4 type - interrupted conveyors<br />

with bridging roll<br />

≥100 LH = 200 -2700 ≥LH + 310<br />

5000<br />

Page 1<br />

Clean room<br />

design as an<br />

option<br />

Brickwork<br />

according to DIN 1053-1,<br />

wall thickness d ≥ 115 mm<br />

Concrete according to DIN 1045,<br />

wall thickness d ≥ 100 mm<br />

Metal single-planked walls<br />

G11 type - tray belt,<br />

continuous carrying bars,<br />

recirculation through sleeve<br />

K2 type - continuous chain<br />

conveyors or travelling<br />

carriage<br />

<strong>Universal</strong> B type<br />

in combination with high speed door<br />

Dimensions: Red = technical feasibility,<br />

White = according to the approval Wall qualities<br />

You will find the approval at www.stoebich.de

<strong>RGT</strong> type<br />

System advantages<br />

R 0 type - interrupted<br />

conveying <strong>system</strong>s<br />

• Open construction, thus good access for maintenance<br />

• Limited closing power and controlled closing velocity<br />

• In case of horizontal closing direction the shutter lowering in the closing area is<br />

possible in the closing position, thus minimum split for smoke penetration<br />

• Suitable for all conveyor <strong>system</strong>s, e.g. chain conveyors<br />

Design<br />

• Special galvanized particular-steel profiles for frames and closure envelopings<br />

• Shutter elements as sandwich-construction with full-cored mineral<br />

and calcium silicate plates Promatect H<br />

• Shutters alternatively planked with galvanized steel or stainless<br />

steel, respectively colour-coated<br />

• Re-opening is done manually, by electric motor or pneumatically<br />

Closure types for the conveyor technique<br />

R 2 type - continuous<br />

bearing bars, embraced<br />

roll<br />

G 5 type - brought<br />

together belts, continuous<br />

supporting construction<br />

underneath the closing level<br />

R 3 type - continuous<br />

bearing bars and driving<br />

elements, external roll<br />

Application<br />

parameters<br />

and vice versa<br />

≥ 100 LH = ≥<br />

200 - 2700 340<br />

5000<br />

≥ LB + 400 LB =<br />

200 - 2500<br />

6000<br />

≥ 220<br />

K 3 type - continuous slide<br />

steel sheets and cross<br />

beams, recirculation<br />

through sleeve<br />

K 2 type - continuous<br />

chain conveyors or<br />

travelling carriage<br />

and vice versa<br />

for the RO type<br />

K 5 type - continuous slide<br />

steel sheets/guiding<br />

plates - lower belt through<br />

sleeve<br />

KS type - hinge chain for<br />

steel and synthetic plates<br />

≥ LH =<br />

200 - 2700<br />

5000<br />

≥ 100<br />

≥ 400 LB = 200 - 2500 ≥ 240<br />

6000<br />

≥ LH + 400<br />

Page 2<br />

Brickwork<br />

according to DIN 1053-1,<br />

wall thickness<br />

d ≥ 175 mm<br />

Concrete<br />

according to DIN 1045,<br />

wall thickness<br />

d ≥ 140 mm<br />

G 11 type- tray belt,<br />

continuous carrying bars,<br />

recirculation through sleeve<br />

S type - container<br />

conveyor <strong>system</strong>, fixed rails<br />

Dimensions: Red = technical feasibility,<br />

White = according to the approval You will find the approval at www.stoebich.de<br />

Wall qualities

<strong>RGT</strong>/K type<br />

System advantages<br />

<strong>·</strong> For continuous circular conveyors, as cardan joint chains, overhead chains,<br />

power & free <strong>system</strong>s<br />

<strong>·</strong> Horizontal closing directions as well as closing direction from below<br />

<strong>·</strong> Open construction, thus good access for maintenance<br />

<strong>·</strong> Limited closing power and controlled closing velocity<br />

<strong>·</strong> Running gear on top of the shutter <strong>system</strong>, thus no obstructions in the<br />

floor area<br />

Design<br />

<strong>·</strong> Fixed closure for continuous conveyor <strong>system</strong> with integrated intumescent<br />

construction components, such as heat consuming building material components<br />

<strong>·</strong> The side guide is integrated in the closure blade and is guided on track rollers at the<br />

wall as well as in the fixed closing<br />

<strong>·</strong> Particular galvanized special steel profiles for frames and closure envelopings<br />

<strong>·</strong> Shutter elements as sandwich-construction from mineral wool and calcium silicate<br />

plates Promatect H<br />

<strong>·</strong> Shutter alternatively coated with galvanized steel or stainless steel respectively<br />

colour-coated<br />

<strong>·</strong> Re-opening is done manually, by electric motor or pneumatically<br />

Closure types for the conveyor technique<br />

mk type - continuous<br />

cardan joint conveyor<br />

Application<br />

parameters<br />

≥LB+700 LB 200-2500 ≥200<br />

6000<br />

mo type - continuous<br />

overhead chain conveyor<br />

LH 200-2700 ≥<br />

300<br />

mp type - continuous<br />

power & free conveyor<br />

and vice versa ≥ LH+250 LH 200-2700 ≥300<br />

≥470 LB 200-2500 ≥240<br />

4000<br />

Page 3<br />

Brickwork<br />

according to DIN 1053-1,<br />

wall thickness<br />

d ≥ 175 mm<br />

Concrete<br />

according to DIN 1045,<br />

wall thickness<br />

d ≥ 140 mm<br />

Dimensions: Red = technical feasibility,<br />

White = according to the approval You will find the approval at www.stoebich.de<br />

Wall qualities

OS type<br />

System advantages<br />

<strong>·</strong> Economical standard design<br />

<strong>·</strong> Minimum space requirement for overlapping<br />

<strong>·</strong> Easier transports due to 600 mm wide elements, sheet steel construction<br />

<strong>·</strong> Different fire resistance classes EI30 – EI90<br />

<strong>·</strong> Controlled closing velocity<br />

<strong>·</strong> As an option: Smoke-/gas tight design to reduce the loss of invert gases<br />

Design<br />

<strong>·</strong> Steel sheet case bays foamed with mineral foam<br />

<strong>·</strong> Element construction, standard heights 600 resp. 900 mm<br />

<strong>·</strong> Galvanized steel plate construction, alternatively in stainless steel, alternatively colour coating<br />

<strong>·</strong> Horizontal joints of the individual elements<br />

<strong>·</strong> Motorized re-opening is the standard (manual on request)<br />

<strong>·</strong> For the gas tight design: Cone shaped sealing <strong>system</strong> which guarantees the sealing in its end<br />

position<br />

Closure types for the conveyor technique<br />

R0 type - interrupted<br />

conveyor <strong>system</strong>s<br />

R1 type - swivel roller<br />

with different closing<br />

directions<br />

G5 supporting underneath belts, type continuous<br />

- brought construction<br />

the closing together level K3 steel beams, through type sheets recirculation<br />

- sleeve continuous and cross slide K5 type - continuous slide<br />

steel sheets/guiding plates<br />

– lower belt through sleeve<br />

R2 type - continuous<br />

bearing bars, embraced<br />

roll<br />

Application<br />

parameters<br />

≥ 120 LH = ≥ 240<br />

500 - 2500<br />

4000<br />

R3 type - continuous<br />

bearing bars and driving<br />

elements, external roll<br />

and vice versa<br />

for the RO type<br />

R4 type - interrupted<br />

conveyor with bridge roll<br />

≥ 120<br />

LH =<br />

≥ LH + 140<br />

500 - 2500<br />

4000<br />

Page 4<br />

Smoke-/<br />

inert gas tight<br />

G11 type - tray belt,<br />

continuous carrying bars,<br />

recirculation through sleeve<br />

K2 type – continuous<br />

chain conveyors or<br />

travelling carriage<br />

Omnischott in Kombination<br />

mit Schnelllauftor<br />

and vice versa<br />

Masonry<br />

according to DIN 1053-1,<br />

wall thickness d ≥ 240 mm<br />

Wall from concrete<br />

according to DIN 1045,<br />

wall thickness d ≥ 140 mm<br />

≥ LB + 200<br />

LB =<br />

500 - 2500<br />

3750<br />

≥ 175<br />

≥175 LB = 500 - 2500<br />

3750<br />

≥ 175<br />

Gas concrete<br />

according to DIN 4165,<br />

wall thickness d ≥ 200 mm<br />

Dimensions: Red = technical feasibility,<br />

White = according to the approval Wall qualities<br />

You will find the approval at www.stoebich.de

ECC-S type<br />

System advantages<br />

<strong>·</strong> Economical standard design<br />

<strong>·</strong> Robust sheet steel design<br />

<strong>·</strong> Open construction, therefore easy access for maintenance<br />

<strong>·</strong> Little demand for space on the wall for the overlapping<br />

<strong>·</strong> Various fire resistance classifications EI30 – EI90 (EI120)<br />

Design<br />

<strong>·</strong> Modular design for the closure elements, standard widths of the elements is 750<br />

respectively 1.000mm<br />

<strong>·</strong> Vertical joints of the elements<br />

<strong>·</strong> Sheet steel elements are filled with mineral wool<br />

<strong>·</strong> Galvanized sheet steel design<br />

<strong>·</strong> Fixed panel (underneath of the conveyor <strong>system</strong>) made of adjustable components<br />

<strong>·</strong> Motorized re-opening<br />

Closure types for the conveyor technique<br />

RO type - interrupted conveyor<br />

<strong>system</strong><br />

R1 type - swivel roller with different<br />

closing directions<br />

G1 type - brought together<br />

belts, continuous supporting<br />

construction underneath the<br />

sealing level<br />

R2 type - continuing carrying<br />

bars, embraced roller<br />

Application<br />

parameters<br />

K3 type - continuing slide steel<br />

sheets/guiding plates – recirculation<br />

through sleeve<br />

R3 type - continuing carrying<br />

bars and drive elements,<br />

external roller<br />

Dimensions: Red = technical feasibility,<br />

White = area where the approval is applied for<br />

* depending on the wall quality<br />

Page 5<br />

K5 type - continuing slide steel<br />

sheets/guiding plates – lower<br />

belt runs through the sleeve<br />

R4 type - interrupted conveyor<br />

with bridge roller<br />

G11 type – tray belt, continuous<br />

carrying bars, recirculation<br />

through sleeve<br />

K2 type - continuing carrying<br />

chain conveyors or travelling<br />

carriages<br />

Wall qualities<br />

Masonry according to DIN 1053-1<br />

Wall thickness ≥ 115mm<br />

Wall thickness ≥ 240mm<br />

Concrete according to DIN 1045<br />

Wall thickness ≥ 100mm<br />

Wall thickness ≥ 140mm<br />

Armoured gas concrete<br />

Wall thickness ≥ 200mm<br />

Gas concrete according to DIN 4165<br />

Wall thickness ≥ 175mm<br />

Wall thickness ≥ 200mm<br />

Covered steel building<br />

components F90 according to DIN 4102-4<br />

Installation walls<br />

Wall thickness ≥ 100mm

ECC-RS type<br />

System advantages<br />

<strong>·</strong> Economical, robust solution due to the easy construction<br />

<strong>·</strong> Little demand for space above the clear opening<br />

<strong>·</strong> Large openings can be sealed<br />

<strong>·</strong> Little demand for lateral space<br />

<strong>·</strong> Small interruptions for interrupted conveyors, only 35mm<br />

<strong>·</strong> Safe sealing for continuing carrying bars and drive units<br />

<strong>·</strong> Safe sealing of rollers which may be positioned in the closing area<br />

<strong>·</strong> Cycle ability: C3 according to DIN EN 14600<br />

Design<br />

<strong>·</strong> The door elements are stored on a coil above the opening<br />

<strong>·</strong> Single (E) or double-walled (EW) profiles<br />

<strong>·</strong> Roller Shutter profiles made of sheet steel<br />

<strong>·</strong> Electro motorized opening and controlled closing velocity by an external drive unit<br />

<strong>·</strong> Motorized opening and closing by an internal tubular motor<br />

<strong>·</strong> Lateral construction and door elements can be galvanized, powder coated or made of<br />

stainless steel as options<br />

Closure types<br />

R0 type - interrupted conveyor<br />

<strong>system</strong>s<br />

K2 type - continuing carrying<br />

chain conveyor or travelling<br />

carriage<br />

R2 type - continuing carrying<br />

bars, embraced roller<br />

K3 type - continuing slide steel<br />

sheets and bars, recirculation<br />

through sleeve<br />

Wall qualities<br />

Masonry<br />

250mm thickness and a volume of 600kg/m²<br />

Masonry<br />

210mm thickness and a volume of 1.651kg/m²<br />

Gas concrete<br />

150mm thickness and a volume of 600kg/m²<br />

Further wall qualities<br />

Provided that the volume is > 600kg/m²<br />

R3 type - continuing carrying<br />

bars and drive elements,<br />

external roller<br />

Application<br />

parameters<br />

90<br />

Page 6<br />

≥ LH = 3100<br />

6500<br />

145 LB = 3500 145<br />

Dimensions: Red = technical feasibility <strong>·</strong><br />

White = area where the approval is applied for * depending on the wall quality<br />

6000<br />

380<br />

<strong>Stöbich</strong> – engineer like solution acco<br />

�����������<br />

���<br />

���<br />

���<br />

���<br />

!<br />

�����������<br />

���<br />

���<br />

���<br />

���<br />

����� ����� ���������� � ��������� � ��������� � ������� � �������<br />

���������������� �� ��� �������� �� ��� ��������<br />

����� ������ ����� ������<br />

�� ��<br />

�<br />

�<br />

�<br />

� �� �� �� �� �� �� ���<br />

����� �����<br />

����� �����<br />

����� �����<br />

���<br />

���� ���� ���������������� ���� ������� ������� �������� ������� �����<br />

No Integrity as there is no<br />

closure <strong>system</strong> underneath the<br />

conveyor technique<br />

Plastic = 30 min<br />

Wood = 35 min<br />

Paper = 35 min<br />

0 100mm 200mm<br />

� �<br />

� � ��<br />

No Integrity as there is no<br />

sealing of the gaps which are<br />

necessary due to the function<br />

�����������<br />

���<br />

���<br />

���<br />

���<br />

��<br />

�����������<br />

���<br />

���<br />

���<br />

���<br />

��<br />

Plast<br />

Woo<br />

Pape<br />

No engineer like solution to achi<br />

no “E” classification according to

Typ ECC-FLEX<br />

rding to EN 1366-7<br />

Plastic = melted without ignition<br />

Wood = 53 min<br />

Paper = 53 min<br />

ic = 58 min<br />

d = 45 min<br />

r = 45 min<br />

300mm<br />

���� �������<br />

�� �� �� ���<br />

�����<br />

�����<br />

�����<br />

���� �������� ���� ��� ������� �����<br />

eve Integrity/<br />

EN 13501-2<br />

!<br />

Radiation – therefore ignition<br />

of combustible components<br />

of the conveyor technique<br />

respectively of the conveyed<br />

material<br />

System advantages<br />

<strong>·</strong> Applicable for large openings<br />

<strong>·</strong> Various fire protection classifications for engineer like fire protection E90 – EW90<br />

<strong>·</strong> Safe sealing of continuing carrying bars and drive units<br />

<strong>·</strong> Safe sealing of rollers which may be positioned in the closing area<br />

<strong>·</strong> Extreme little demand for space in the lintel area and in the area of the side guides<br />

<strong>·</strong> Little expansion under fire load, therefore applicable for all fire wall constructions<br />

<strong>·</strong> Controlled closing velocity<br />

<strong>·</strong> Cycle ability: C3 according to DIN EN 14600<br />

<strong>·</strong> Economical solution<br />

Closure types<br />

Closure of the cross section of the conveyor<br />

<strong>system</strong>:<br />

<strong>·</strong> Non combustible sealing element made of a fabric<br />

<strong>·</strong> Coiled up into the casing<br />

<strong>·</strong> Electro motorized re-opening by a tubular motor<br />

<strong>·</strong> Galvanized sheet steel design, as an option stainless<br />

steel or powder coating<br />

0 100m<br />

0 100m<br />

R0 type - interrupted conveyor<br />

<strong>system</strong>s<br />

K3 type - continuing slide steel<br />

sheets and bars, recirculation<br />

through sleeve<br />

Application parameters<br />

≥ LH = 3100<br />

6500<br />

145 LB = 3500 145<br />

6000<br />

380<br />

Page 7<br />

R2 type - continuing carrying<br />

bars, embraced roller<br />

mp type - continuing Power +<br />

Free conveyors<br />

>105<br />

145 LB = 3500 145<br />

6000<br />

≥ LH = 3100<br />

6500<br />

380<br />

depending<br />

FT<br />

R3 type - continuing carrying<br />

bars and drive elements,<br />

external roller<br />

mo type - continuing<br />

Overhead conveyors<br />

6000<br />

≥ LH = 3500<br />

380 6500<br />

380<br />

145 LB = 3500 145<br />

Closure of the conveyor <strong>system</strong>:<br />

<strong>·</strong> Robust Durasteel plate (sandwich sheet steel with<br />

Calcium Silicate intermediate layer)<br />

<strong>·</strong> Sealing of the continuing carrying construction, drive<br />

units and further rollers which may be in the closing area<br />

by intumescend, heat consuming parts<br />

<strong>·</strong> Design which is adjusted to the individual protection<br />

target<br />

K2 type - continuing carrying<br />

chain conveyor or travelling<br />

carriage<br />

A1 type - continuing monorail<br />

conveyors made of Aluminium<br />

Wall qualities<br />

Masonry<br />

According to DIN 1053-1 - wall thickness ≥ 115mm<br />

Concrete<br />

According to DIN 1045 - wall thickness ≥ 100mm<br />

Gas concrete<br />

Wall thickness ≥ 100mm<br />

Gypsum fibre board wall according to DIN 4102<br />

Gas concrete<br />

According to DIN 4165 – wall thickness ≥ 200mm<br />

Aspired certificate: MIWO-wall construction (MIneral WOol)<br />

Dimensions: Red = technical feasibility <strong>·</strong> White = area where the approval is applied for<br />

* depending on the wall quality

Q type<br />

System advantages<br />

<strong>·</strong> Shutter closing edge is tongue shaped, ideal for belt conveyors with high lateral guiding steel sheets<br />

<strong>·</strong> Limited closing and opening force due to gas pressure spring <strong>system</strong><br />

<strong>·</strong> Extremely minimal space demand, as the flap blade can stand in the conveying direction<br />

<strong>·</strong> Mechanical locking device in the closed position, usable for access control<br />

Design<br />

<strong>·</strong> Bearing corrosion-protected steel construction of the closure<br />

<strong>·</strong> Planking on both sides with 20 mm Promatect H<br />

<strong>·</strong> Closing edge of the flap is adapted to the conveyor cross section<br />

<strong>·</strong> Fold-like tong frame for the sealing of the flap blade<br />

<strong>·</strong> Gas pressure springs on both sides, bedded by 2 hinge <strong>system</strong>s<br />

<strong>·</strong> Re-opening is done manually or by an electric motor<br />

Closure types for the conveyor technique<br />

K3 type - continuous slide<br />

steel sheets and cross<br />

beams, recirculation<br />

through sleeve<br />

K2 type - continuous chain<br />

conveyors or travelling<br />

carriage<br />

G5 type - brought together<br />

belts, continuous supporting<br />

construction underneath<br />

the closing level<br />

KS type - hinge chain for<br />

steel and synthetic plates<br />

Application<br />

parameters<br />

Dimensions:<br />

Red =<br />

technical feasibility,<br />

White =<br />

according to the approval<br />

K5 type - continuous slide<br />

steel sheets/guiding plates<br />

– under belt through sleeve<br />

KC type - container<br />

conveyor <strong>system</strong><br />

≥190 LB = 800 - 1400 ≥190<br />

4500<br />

G11 type - tray belt,<br />

continuous bearing bars,<br />

recirculation through sleeve<br />

≥100 LH = ≥250<br />

1000 - 1350<br />

2500<br />

Page 8<br />

Brickwork<br />

according to DIN<br />

1053-1,<br />

wall thickness<br />

d ≥ 115 mm<br />

Concrete / reinforced<br />

concrete<br />

according to DIN 1045,<br />

wall thickness<br />

d ≥ 100 mm<br />

Wall qualities<br />

You will find the approval at www.stoebich.de

OC type<br />

System advantages<br />

<strong>·</strong> Minimal space requirement above the clear opening<br />

<strong>·</strong> Very large openings up to 9 x 6 m can be shut off<br />

<strong>·</strong> Simple installation due to a segmented construction<br />

<strong>·</strong> Blade height 500 mm / 360 mm in the screen<br />

<strong>·</strong> Limited closing power and controlled closing velocity<br />

Design<br />

<strong>·</strong> Segmented construction of the closing element<br />

<strong>·</strong> Steel plate case bays filled with mineral foam constitute the sealing elements<br />

<strong>·</strong> Segments are stackable above the opening<br />

<strong>·</strong> Electric motor driven opening process, velocity controlled closing process<br />

<strong>·</strong> At the closing edge of the lowest elements is the corresponding sealing element of the<br />

continuous conveyor <strong>system</strong><br />

<strong>·</strong> Blades and side guides galvanized, alternatively in stainless steel version or powder coated<br />

Closure types for the conveyor technique<br />

K3 type - continuous slide<br />

steel sheets and cross<br />

beams, recirculation<br />

through sleeve<br />

R3 type - continuous<br />

bearing bars and driving<br />

elements, external roll<br />

K5 type - continuous slide<br />

steel sheets/guiding plates<br />

– lower belt through sleeve<br />

R3 type - continuous<br />

bearing bars and driving<br />

elements, external roll<br />

Application<br />

parameters<br />

Dimensions:<br />

Red = technical feasibility<br />

R0 type - interrupted<br />

conveying <strong>system</strong>s<br />

R4 type - interrupted<br />

conveyor with bridge roll<br />

≥ 100 LH = 2000 - 6000 ≥ 740<br />

≥ 230 LB = 1000 - 9000 ≥ 230<br />

Page 9<br />

G11 type - tray belt,<br />

continuous carrying<br />

bars, recirculation<br />

through sleeve<br />

K2 type - continuous<br />

chain conveyors or<br />

travelling carriage<br />

Brickwork<br />

according to DIN 1053-1,<br />

wall thickness d ≥ 240 mm<br />

Concrete / reinforced<br />

concrete according to DIN 1045,<br />

wall thickness d ≥ 140 mm<br />

Foam mortar, blocks or concrete precision blocks<br />

according to DIN 4165,<br />

wall thickness d ≥ 240 mm<br />

Walls from armoured,<br />

lying or standing<br />

Gas concrete plates<br />

wall thickness d ≥ 200 mm<br />

Wall qualities<br />

You will find the approval at www.stoebich.de

BZ type<br />

System advantages<br />

• Complicated plastic parts of the newspaper conveyor are sealed-off reliably<br />

• Installation to the wall and to the ceiling<br />

• Several conveyor tracks (up to 4 <strong>system</strong>s) through one closure<br />

• Continuous guide rails for the guidance of the newspapers (support)<br />

• Integrated ejection device for the newspaper, in case of standing conveyor <strong>system</strong><br />

combinations with unlocking <strong>system</strong> of the conveyor technique<br />

Design<br />

• Bearing corrosion protected steel construction, on all sides planked with<br />

Promatect H-plates<br />

• Shutter and fixed curtain with patented, temperature-controlled activation of<br />

the foaming process<br />

• Construction of 280 mm depth for shutter and fixed sealing<br />

• Reverse motion through fixed closure, which is coated with foaming building<br />

material<br />

• Re-opening is manual, electric motor driven or pneumatical<br />

Closure types for the conveyor technique<br />

BZ type - continuous<br />

newspaper conveyor<br />

Application<br />

parameters<br />

Dimensions:<br />

Red = technical feasibility<br />

White = according to the<br />

approval<br />

≥830 LH= ≥620<br />

100-350<br />

420<br />

≥200 LB=400-700 ≥430<br />

5000<br />

Page 10<br />

Brickwork<br />

according to DIN 1053-1,<br />

wall thickness<br />

d ≥ 115 mm<br />

Walls from concrete<br />

according to DIN 1045,<br />

wall thickness<br />

d ≥ 100 mm<br />

Ceilings from reinforcedconcrete<br />

according to DIN 1045,<br />

ceiling thickness<br />

d ≥ 140 mm<br />

Wall qualities<br />

You will find the approval at www.stoebich.de

EH type<br />

System advantages<br />

<strong>·</strong> Continuous aluminium or steel rail, including conductor rails<br />

<strong>·</strong> No movable guiding components, as for example necessary when swinging out<br />

(wearing/noises)<br />

<strong>·</strong> No restrictions in the carrying capacity of the conveyor <strong>system</strong><br />

<strong>·</strong> Minimal space requirement for folding doors with opening angle of 90°<br />

<strong>·</strong> In case of restriction by the conveyor <strong>system</strong> (e.g. bow, rotary wing in the swinging range)<br />

use of sliding dors<br />

<strong>·</strong> Can be combined with one-piece sliding elements<br />

Design<br />

<strong>·</strong> 2 half-shell sleeves embrace, in the closed position, the continuous rail<br />

<strong>·</strong> Double-winged revolving or sliding door with integrated sleeves<br />

<strong>·</strong> Sleeves are protected by double sided covers<br />

<strong>·</strong> Sliding gates with thermomechanical lock<br />

<strong>·</strong> Controlled closing sequence with revolving doors<br />

Closure types for the conveyor technique<br />

A1 type - continuous aluminium<br />

electric mono-rail<br />

≥ 200<br />

LB =<br />

1500 - 2500<br />

3.250<br />

≥ 200<br />

S1 type - continuous steel electric<br />

mono-rail<br />

Application parameters<br />

LH = 1700 - 3000<br />

4000<br />

Dimensions: Red = technical feasibility,<br />

White = according to the approval<br />

≥ LB +600<br />

LB =<br />

2 2500 - 8500 ≥ LB +600<br />

2<br />

Page 11<br />

2000 - 6000 ≥295<br />

Brickwork according<br />

to DIN 1053-1,<br />

wall thickness<br />

d ≥ 240 mm<br />

Concrete/reinforced<br />

concrete according<br />

to DIN 1045,<br />

wall thickness<br />

d ≥ 140 mm<br />

Wall qualities<br />

You will find the approval at www.stoebich.de

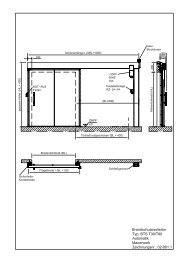

Isogate type<br />

System advantages<br />

<strong>·</strong> Tested according to DIN/EN<br />

<strong>·</strong> Outstanding characteristics for the insulation (K = 0,0184) due to state-of-the-art insulation materials<br />

<strong>·</strong> Low weight of the door, starting from 35 kg/m²<br />

<strong>·</strong> Easy to operate<br />

<strong>·</strong> Design being conform to veterinary demands<br />

<strong>·</strong> Re-opening can be done manual or motorized<br />

<strong>·</strong> Access control by a locking <strong>system</strong>, card reader<br />

<strong>·</strong> Average opening velocity of up to 0,6m/sec. for sliding doors<br />

Design<br />

Revolving door:<br />

<strong>·</strong> Surface made of stainless steel / RAL<br />

<strong>·</strong> Increasing hinges<br />

<strong>·</strong> Lock with panic function<br />

<strong>·</strong> Pluggable hollow chamber sealing<br />

<strong>·</strong> Overhead door closer<br />

<strong>·</strong> Wearless, self-regulating heating<br />

<strong>system</strong> for freezing rooms<br />

Closure types for wall qualities<br />

Revolving door:<br />

With one-sided insulation<br />

Sliding door:<br />

With one-sided insulation<br />

Revolving door:<br />

With double-sided insulation<br />

Sliding door:<br />

With double-sided insulation<br />

Revolving door:<br />

In panel walls<br />

Sliding door:<br />

Panel walls<br />

Application parameters<br />

Dimensions:<br />

Red = technical<br />

feasibility,<br />

White = according to<br />

the approval<br />

and vice versa<br />

500<br />

LH =<br />

2000 - 3500<br />

3500<br />

LB =<br />

≥ LB + 300 1000 - 3000 188<br />

3000<br />

Page 12<br />

Sliding door:<br />

<strong>·</strong> Stainless steel travelling gear with plastic<br />

roller<br />

<strong>·</strong> Element design<br />

<strong>·</strong> Ball bearing ground guiding roller<br />

<strong>·</strong> Pluggable hollow chamber sealing<br />

<strong>·</strong> Opening cable<br />

<strong>·</strong> Surface in stainless steel/RAL/galvanized<br />

Legend<br />

Sliding door: Dimension of the<br />

wall = clear dimension<br />

LH =<br />

1700 - 2100<br />

2100<br />

≥188 LB = 500 - 1200 188<br />

1200<br />

You will find the approval at www.stoebich.de

Special Constructions<br />

Sleeves<br />

Page 13<br />

System advantages<br />

<strong>·</strong> Very large opening, e.g. 15 x 1 m<br />

<strong>·</strong> Several conveyor <strong>system</strong>s can run through one opening<br />

<strong>·</strong> Fixed deep <strong>closures</strong> with intumescent components<br />

<strong>·</strong> Crane way closure (slide door and butterfly valve)<br />

Design<br />

<strong>·</strong> Combination of the different designs of conveyor <strong>system</strong> <strong>closures</strong><br />

<strong>·</strong> Combination of different closing directions, e.g. from below horizontally<br />

pushing and from above tilting<br />

<strong>·</strong> Various constructions based on more than 100 fire tests<br />

<strong>·</strong> Re-opening is made manually, electric motor driven or pneumatically<br />

System advantages<br />

Design<br />

Craneway Tilt tray sorter<br />

<strong>·</strong> no movable sealing element<br />

<strong>·</strong> Clearing of the closing area for non combustible conveyed<br />

material is not necessary<br />

<strong>·</strong> Little demand for space at the wall (small demand for<br />

overlapping)<br />

<strong>·</strong> Protected steel frame construction in terms of fire protection<br />

<strong>·</strong> Intumescend sealing blocks (being attached to fire these blocks<br />

start to foam) in several sealing levels<br />

<strong>·</strong> Cross section of the sealing is adjusted to the conveyed material<br />

You will find the approval at www.stoebich.de

Retaining and clearing<br />

Problem-oriented clearing of the closing area.<br />

For stopped<br />

conveyor <strong>system</strong>s<br />

Gravity roller conveyor<br />

Stop M<br />

Pulling out of<br />

general cargo<br />

Pulling out of<br />

bulk goods<br />

Blowing out of<br />

the conveyed<br />

material<br />

Clearing<br />

Crushing of the<br />

conveyed goods<br />

Protective<br />

screen<br />

When roller conveyor<br />

<strong>system</strong>s run through<br />

the closure with an<br />

inclination, the delay of<br />

the closing process is<br />

adequate. Precondition<br />

is that it may not lead<br />

to a back draught<br />

of the goods to the<br />

closure level.<br />

For conveyed goods,<br />

which can be crushed<br />

or displaced by kinetic<br />

energy because of their<br />

properties, the clearing<br />

<strong>system</strong> “A-Y1 type”<br />

offers an economic<br />

possibility.<br />

General cargo, which<br />

move on the conveyor<br />

<strong>system</strong> with gaps<br />

between one to the<br />

other, can be pulled<br />

out of the closing area<br />

via swivelling return<br />

motion lever with<br />

stored pneumatic<br />

energy.<br />

A rake, driven by stored<br />

energy, swivels into the<br />

conveyor process and<br />

pulls out the conveyed<br />

material.<br />

Light conveyed goods<br />

can be blown out<br />

of the closing range<br />

by means of stored<br />

compressed air.<br />

Page 14<br />

For conveyor <strong>system</strong>s<br />

which continue conveying<br />

an emergency power<br />

<strong>system</strong> is necessary<br />

Light barrier control<br />

Logistics<br />

Stop M M<br />

Closing area<br />

surveillance<br />

Initiator occupied<br />

Retaining<br />

of bulk material<br />

Clearing<br />

Initiator<br />

free<br />

I II III<br />

Passage safeguard<br />

Scan of the<br />

hanger position<br />

Security area<br />

Parking space<br />

One or more<br />

transversally arranged<br />

light barriers control<br />

the closing level. In<br />

case of a detected gap<br />

the conveyor <strong>system</strong><br />

stops.<br />

Bulk goods can be<br />

retained by means<br />

of a slider . The<br />

arrangement of<br />

the slider can be<br />

rectangular, diagonal<br />

or according to the<br />

snowplough principle.<br />

Only after the clearing<br />

the conveyor <strong>system</strong> is<br />

stopped.<br />

When several<br />

separated conveyor<br />

<strong>system</strong>s are used for<br />

the conveyor process,<br />

the closing range<br />

can be cleared by<br />

switching-off of the<br />

incoming conveyor<br />

route and continued<br />

running of the<br />

outgoing conveyor<br />

route.<br />

The closing area<br />

surveillance is defined<br />

for the distance that is<br />

necessary to guarantee<br />

the closing range to be<br />

free of conveyed goods.<br />

Usually in front of and<br />

behind this closing<br />

area surveillance,<br />

proximity switches<br />

(initiators) are placed.<br />

With this <strong>system</strong> it has<br />

to be guaranteed that<br />

all openings are free<br />

simultaneously during<br />

the closing period.<br />

In dependence on<br />

the uniformity of the<br />

hanger distances as<br />

well as of the hangers<br />

itself, control elements<br />

have to be installed.<br />

Die Zulassung finden Sie unter www.stoebich.de

S type<br />

System advantages<br />

<strong>·</strong> No flexible rail parts, thus minimum wear and low-noise<br />

<strong>·</strong> Secure function, few movable parts Installation to wall and ceiling, all closing directions,<br />

as well hanging drive position<br />

<strong>·</strong> Limited closing power and controlled closing velocity<br />

<strong>·</strong> Cable sealings integrable<br />

<strong>·</strong> Rail joints only max. 4 mm<br />

Design<br />

<strong>·</strong> Bearing, corrosion protected steel construction<br />

<strong>·</strong> Frame and shutter planked on both sides with 20 mm Promatect H,<br />

<strong>·</strong> Shutter additionally with 2 mm galvanized steel plate<br />

<strong>·</strong> Incoming-/outgoing- as well as inter-rail fixed<br />

<strong>·</strong> Closing power via interior hydraulic door closer<br />

<strong>·</strong> Re-opening is made manually or electric motor driven by direct-current<br />

motor and electromagnetic coupling<br />

Closure types for the conveyor technique<br />

S 1 type - upright drive<br />

Application<br />

parameters<br />

and vice versa<br />

≥LB + 420 LB = 200 - 800 ≥130<br />

S 1 type - hanging drive<br />

Dimensions: White = according to the approval<br />

≥115 LH = 400-900 ≥125<br />

and vice versa<br />

≥190 LB=200-800 ≥345<br />

page 15<br />

≥115 LH = LH + 210<br />

400 - 900<br />

Brickwork<br />

according to DIN 1053-1,<br />

wall thickness d ≥ 115 mm<br />

Concrete/reinforced concrete<br />

according to DIN 1045,<br />

wall thickness d ≥ 100 mm<br />

Gas concrete<br />

according to DIN 4165,<br />

wall thickness d ≥ 115 mm<br />

Metal single-plank walls<br />

Wall qualities<br />

<strong>Universal</strong> T (Trommel)<br />

<strong>Universal</strong> KL (Klappe)<br />

Die Zulassung finden Sie unter www.stoebich.de

Addresses<br />

<strong>Stöbich</strong> - Fire Protection<br />

<strong>Stöbich</strong> <strong>Brandschutz</strong> gained the position of the world wide<br />

market leader for conveyor <strong>system</strong> <strong>closures</strong> since 1980 and also<br />

became international trendsetter in the field of flexible smoke<br />

and fire protection <strong>system</strong>s which are made of fabrics.<br />

The know-how which grew by the immense number of<br />

completed projects and fire tests as well as the proven<br />

constructive competence take company <strong>Stöbich</strong> to be a fire<br />

protection specialist with a wide range of products and a broad<br />

range of services.<br />

Eight world novelties and four awards express the innovative and<br />

customer orientated design of the <strong>Stöbich</strong> products as well as<br />

the efficient control of all processes.<br />

Four affiliates and numerous national and international<br />

representations allow for a direct presence and proximity to the<br />

customer during all stages of a project.<br />

Headquarter<br />

<strong>Stöbich</strong> <strong>Brandschutz</strong><br />

GmbH<br />

Pracherstieg 6<br />

38644 Goslar, Germany<br />

Phone +49-(0)5321-5708-0<br />

Fax +49-(0)5321-5708-71<br />

Affiliate South<br />

<strong>Stöbich</strong> <strong>Brandschutz</strong><br />

GmbH<br />

Gewerbehof 8<br />

73441 Bopfingen, Germany<br />

Phone +49-(0)7362-9614-0<br />

Fax +49-(0)7362-9614-50<br />

Affiliate East<br />

<strong>Stöbich</strong> <strong>Brandschutz</strong><br />

GmbH<br />

Geltestraße 12<br />

06188 Landsberg OT Queis, Germany<br />

Phone +49-(0)34602-552-0<br />

Fax +49-(0)34602-552-50<br />

Affiliate West<br />

<strong>Stöbich</strong> <strong>Brandschutz</strong><br />

GmbH<br />

Max-Planck-Straße 13<br />

59423 Unna, Germany<br />

Phone +49-(0)2307-98689-0<br />

Fax +49-(0)2307-98689-50<br />

International Representatives<br />

<strong>·</strong> Australia<br />

<strong>·</strong> Austria<br />

<strong>·</strong> Belarus<br />

<strong>·</strong> Belgium<br />

<strong>·</strong> Bosnia and<br />

Herzegovina<br />

<strong>·</strong> Bulgaria<br />

<strong>·</strong> Croatia<br />

<strong>·</strong> Cyprus<br />

<strong>·</strong> Czechia<br />

<strong>·</strong> Denmark<br />

<strong>·</strong> Estonia<br />

<strong>·</strong> Finland<br />

<strong>·</strong> France<br />

<strong>·</strong> Greece<br />

<strong>·</strong> Great Britain<br />

<strong>·</strong> Hong Kong<br />

<strong>·</strong> Hungary<br />

<strong>·</strong> Ireland<br />

<strong>·</strong> Italy<br />

<strong>·</strong> Latvia<br />

<strong>·</strong> Liechtenstein<br />

Affiliate South • Gewerbehof 8 • 73441 Bopfingen <strong>·</strong> Germany<br />

Affiliate East • Geltestraße 12 • 06188 Landsberg OT Queis <strong>·</strong> Germany<br />

Affiliate West • Max-Planck-Straße 13 <strong>·</strong> 59423 Unna <strong>·</strong> Germany<br />

<strong>·</strong> Lithuania<br />

<strong>·</strong> Luxembourg<br />

<strong>·</strong> Macedonia<br />

<strong>·</strong> Netherlands<br />

<strong>·</strong> New Zealand<br />

<strong>·</strong> Norway<br />

<strong>·</strong> Poland<br />

<strong>·</strong> Portugal<br />

<strong>·</strong> Romania<br />

<strong>·</strong> Russia<br />

<strong>·</strong> Sweden<br />

<strong>·</strong> Switzerland<br />

<strong>·</strong> Serbia and<br />

Montenegro<br />

<strong>·</strong> Slovakia<br />

<strong>·</strong> Slovenia<br />

<strong>·</strong> Spain<br />

<strong>·</strong> Turkey<br />

<strong>·</strong> Ukraine<br />

<strong>·</strong> UAE<br />

<strong>·</strong> USA<br />

Further information<br />

(Please see Video,<br />

CD or Internet)<br />

06/2009-E