Technical Manual for Ribbed Belt Drives

Technical Manual for Ribbed Belt Drives

Technical Manual for Ribbed Belt Drives

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

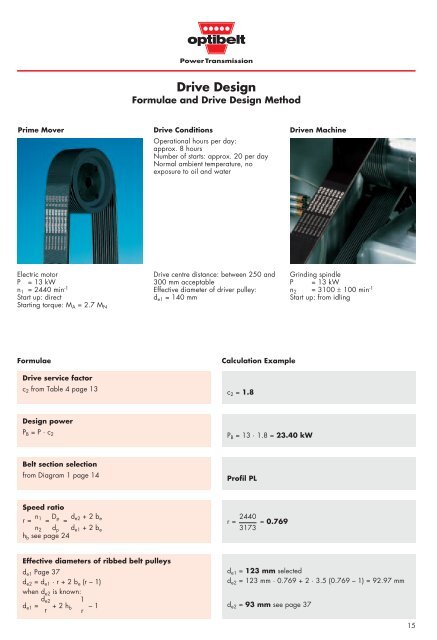

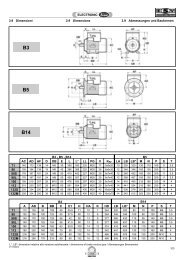

Drive DesignFormulae and Drive Design MethodPrime MoverDrive ConditionsOperational hours per day:approx. 8 hoursNumber of starts: approx. 20 per dayNormal ambient temperature, noexposure to oil and waterDriven MachineElectric motorP = 13 kWn 1 = 2440 min -1Start up: directStarting torque: M A = 2.7 M NDrive centre distance: between 250 and300 mm acceptableEffective diameter of driver pulley:d e1 = 140 mmGrinding spindleP = 13 kWn 2 = 3100 ± 100 min -1Start up: from idlingFormulaeDrive service factorc 2 from Table 4 page 13Calculation Examplec 2 = 1.8Design powerP B = P · c 2P B = 13 · 1.8 = 23.40 kW<strong>Belt</strong> section selectionfrom Diagram 1 page 14Profil PLSpeed ratior =n 1 D= p=d e2 + 2 b en 2 d p d e1 + 2 b eh b see page 242440r = = 0.7693173Effective diameters of ribbed belt pulleysd e1 Page 37d e2 = d e1 · r + 2 b e (r – 1)when d e2 is known:d e2 1d e1 = + 2 h b – 1rr( )d e1 = 123 mm selectedd e2 = 123 mm · 0.769 + 2 · 3.5 (0.769 – 1) = 92.97 mmd e2 = 93 mm see page 3715