Technical Manual for Ribbed Belt Drives

Technical Manual for Ribbed Belt Drives

Technical Manual for Ribbed Belt Drives

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

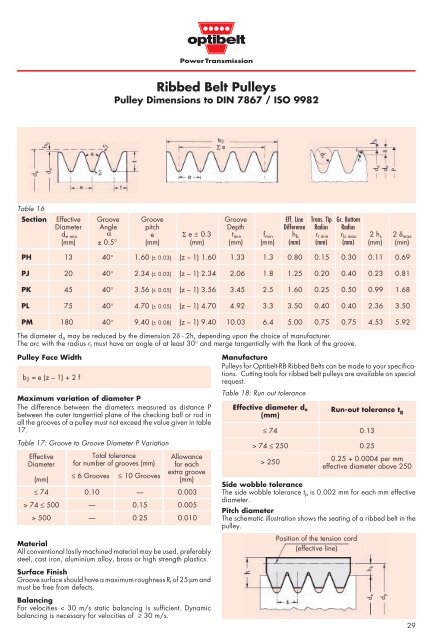

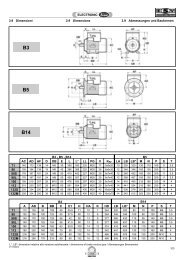

<strong>Ribbed</strong> <strong>Belt</strong> PulleysPulley Dimensions to DIN 7867 / ISO 9982d ph bd ed ePTable 16SectionEffectiveGroove GrooveGrooveEff. Line Trans. Tip Gr. BottomDiameter Angle pitchDepthDifference Radius Radiusd e minα e Σ e ± 0.3 t min f min h b r t min r b max 2 h s 2 δ max(mm) ± 0.5° ( mm) (mm)( mm) (mm)(mm) (mm) ( mm) ( mm)(mm)PH 13 40° 1.60 (± 0.03) (z – 1) 1.60 1.33 1.3 0.80 0.15 0.30 0.11 0.69PJ 20 40° 2.34 (± 0.03) (z – 1) 2.34 2.06 1.8 1.25 0.20 0.40 0.23 0.81PK 45 40° 3.56 (± 0.05) (z – 1) 3.56 3.45 2.5 1.60 0.25 0.50 0.99 1.68PL 75 40° 4.70 (± 0.05) (z – 1) 4.70 4.92 3.3 3.50 0.40 0.40 2.36 3.50PM 180 40° 9.40 (± 0.08) (z – 1) 9.40 10.03 6.4 5.00 0.75 0.75 4.53 5.92The diameter d a may be reduced by the dimension 2δ - 2h s depending upon the choice of manufacturer.The arc with the radius r t must have an angle of at least 30° and merge tangentially with the flank of the groove.Pulley Face Widthb 2 = e (z – 1) + 2 fMaximum variation of diameter PThe difference between the diameters measured as distance Pbetween the outer tangential plane of the checking ball or rod inall the grooves of a pulley must not exceed the value given in table17.Table 17: Groove to Groove Diameter P VariationEffectiveTotal toleranceAllowanceDiameter <strong>for</strong> number of grooves (mm) <strong>for</strong> eachextra groove≤ 6 Grooves ≤ 10 Grooves(mm)(mm)≤ 74 0.10 — 0.003> 74 ≤ 500 — 0.15 0.005> 500 — 0.25 0.010MaterialAll conventional lasily machined material may be used, preferablysteel, cast iron, aluminium alloy, brass or high strength plastics.Surface FinishGroove surface should have a maximum roughness R t of 25 µm andmust be free from defects.BalancingFor velocities < 30 m/s static balancing is sufficient. Dynamicbalancing is necessary <strong>for</strong> velocities of ≥ 30 m/s.ManufacturePulleys <strong>for</strong> Optibelt-RB <strong>Ribbed</strong> <strong>Belt</strong>s can be made to your specifications.Cutting tools <strong>for</strong> ribbed belt pulleys are available on specialrequest.Table 18: Run out toleranceEffective diameter d e(mm)Run-out tolerance t R≤ 74 0.13> 74 ≤ 250 0.25> 2500.25 + 0.0004 per mmeffective diameter above 250Side wobble toleranceThe side wobble tolerance t p is 0.002 mm <strong>for</strong> each mm effectivediameter.Pitch diameterThe schematic illustration shows the seating of a ribbed belt in thepulley.Position of the tension cord(effective line)h bd ed p29