T E M / T E L - Master-Bilt

T E M / T E L - Master-Bilt

T E M / T E L - Master-Bilt

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

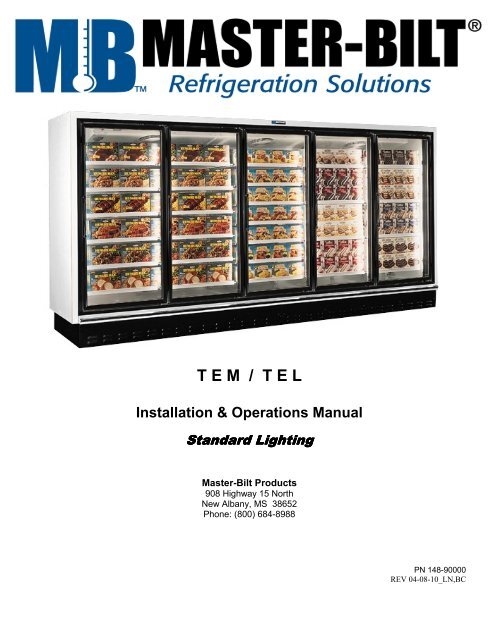

T E M / T E LInstallation & Operations ManualStandard Lighting<strong>Master</strong>-<strong>Bilt</strong> Products908 Highway 15 NorthNew Albany, MS 38652Phone: (800) 684-8988PN 148-90000REV 04-08-10_LN,BC

INTRODUCTIONThank you for purchasing a <strong>Master</strong>-<strong>Bilt</strong> cabinet. This manual contains important instructions for installing, using andservicing a <strong>Master</strong>-<strong>Bilt</strong> TEL/TEM Top Coil Endless Case. A parts list is included in with this manual. Read all thesedocuments carefully before installing or servicing your equipment.NOTICERead this manual before installing your cabinet. Keep the manual and refer to it before doing any service on theequipment. Failure to do so could result in personal injury or damage to the cabinet.DANGERImproper or faulty hook-up of electrical components of the refrigeration units can result in severe injury ordeath.All electrical wiring hook-ups must be done in accordance with all applicable local, regional or nationalstandards.NOTICEInstallation and service of the refrigeration and electrical components of the cabinet must be performed by arefrigeration mechanic and/or a licensed electrician.The portions of this manual covering refrigeration and electrical components contain technical instructions intended onlyfor persons qualified to perform refrigeration and electrical work.This manual cannot cover every installation, use or service situation. If you need additional information, call or write us:Customer Service Department<strong>Master</strong>-<strong>Bilt</strong> ProductsHighway 15 NorthNew Albany, MS 38652Phone (800) 684-8988Fax (800) 684-89884

WARNING LABELS AND SAFETY INSTRUCTIONSThis symbol is the safety-alert symbol. When you see this symbol on your cabinet or in thismanual, be alert to the potential for personal injury or damage to your equipment.Be sure you understand all safety messages and always follow recommended precautionsand safe operating practices.NOTICE TO EMPLOYERSYou must make sure that everyone who installs, uses or services your cabinet is thoroughly familiar with allsafety information and procedures.Important safety information is presented in this section and throughout this section and throughout the manual. Thefollowing signal words are used in the warnings and safety messages:DANGER:Severe injury or death will occur if you ignore the message.WARNING: Severe injury or death can occur if you ignore the message.CAUTION: Minor injury or damage to your cabinet can occur if you ignore the message.NOTICE: This is important installation, operation or service information. If you ignore the message,you may damage your cabinet.The warning and safety labels shown throughout this manual are placed on your <strong>Master</strong>-<strong>Bilt</strong> Products cabinet atthe factory. Follow all warning label instructions. If any warning or safety labels become lost or damaged, callyour customer service department at (601) 534-9061 for replacements.This label is located on top of the electrical controlpanel and on the wiring channel.5

STORE CONDITIONSThe <strong>Master</strong>-<strong>Bilt</strong> TEL/TEM cases are designed to operate in the controlled environment of an air conditioned store. Thestore temperature should be at or below 75°F and a relative humidity of 55% or less. At higher temperature or humidityconditions, the performance of these cases may be affected and the capacity diminished. It is not uncommon in a newlyconstructed store for the temperature and humidity to be above design conditions. These excessive conditions mayproduce sweating in the case until the store is operational and the ambient environment is more desirable.LOCATIONThe <strong>Master</strong>-<strong>Bilt</strong> TEL/TEM should not be positioned where it is directlyexposed to rays of the sun or near a direct source of radiant heat or airflow.Cabinet should not be built into an enclosed area. If this case is to belocated against a wall there should be at least a 4” space between thewall and the back of the case, with 4” open space at top and one or bothends. This space will allow for the circulation of air behind the casewhich will prevent condensation on the exterior surfaces.Make sure that the floor that will support this equipment is of adequatestrength to prohibit sagging. After confirming the dimensions of case withthe blueprint measure off and mark on the floor the exact location of thecases for the entire lineup. Snap chalk lines where the base skids of thecase are to be located as shown in Figure 1.Figure 17

LEVELINGIt is very important that this equipment be perfectly level. This will allow for proper and complete drainage of theevaporator coil and for proper case alignment. A perfectly level area is generally not available where the equipment is tobe installed. Mark the location of all case joining points front and back. Use a transit to locate the highest point on thechalk lines. This point will be a reference point for determining shim-pack heights. Using the reference point, mark thedifference directly on the floor to each joining point front and back. Shim each joining point to equal the reference pointas required. Tape all shims in place. If the installation is an entire lineup install the case that will be positioned at thehighest point first. Check that the equipment in the lineup is level as the installation proceeds.JOINING SECTIONS, TEL/TEMRemove the case from its shipping skid. Set the first caseinto its desired position with required shims in preparationfor joining it with its adjacent case.The joining gasket for cases in a lineup is factory installedand is shown in balck in Figure 2. This gasket is onlyrequired on one end of cases in a lineup as only onegasket is needed between two cases. Inspect the gasketinsure that it is properly located and is not damaged.Remove the protective covering on the outside face of theadjoining tape. The cases are now ready to be joinedtogether. Remove the second case from its shipping skid,remove the “X” braces from the open end of the sections,and move it into position against the end of the first case.Properly level the second case with the appropriate shimstoBolt the cases together through the eight holes that areprovided in the aluminum triangular gussets as shown inFigure 4. Tighten the bolts until all seams are fully closed.Do not over tighten.Figure 4GASKETSUPPORT POSTDOOR FRAMETo join the door frames, drill through the support posts with 9/64”drill, using countersunk holes as a guide. Use the long screws (inthe bag tied to the door handle) to draw the frames together. SeeFigure 5.Figure 510

REFRIGERATION SYSTEM EVACUATING AND CHARGING1. Blow out all refrigerant lines with dry nitrogen or carbon dioxide to eliminate the possibility ofdirt, scale, etc. remaining inside.2. Connect all lines and leak test all connections.3. Connect a good high vacuum pump to both the low and high side evacuation valves.4. Operate the pump until a vacuum of 1500 microns (0.06 inches of mercury) absolute pressure is obtained. At thispoint, the vacuum should be broken by the introduction of refrigerant into the system, through a drier, until thepressure is brought up to zero pounds gauge. Repeat this procedure two more times. During the final evacuation, avacuum of 500 microns (0.02 inches of mercury) absolute pressure should be obtained. After this vacuum isreached, the system can be fully charged with refrigerant.DEFROST TERMINATION/ TEMPERATURE CONTROLSFor a TEL/TEM, the controls are located at the top of the cabinet on the right hand side. Nothing will have to be removedto access the controls.The temperature control is adjusted by simply turning the knob clockwise for a colder case and counter-clockwise for awarmer case. The defrost termination control sensor ismounted directly on the end plate of the coil. This control determines how long the defrost cycle will last. By adjusting thedefrost termination control clockwise the defrost cycle will be shortened. By adjusting the defrost termination controlcounter-clockwise the defrost cycle will become longer.CONTROL SETTINGSTEL (Low Temp)TEM (Med Temp)Temperature Control -25 - +22°F 32 - 51°FCondensing Unit Time Clock4 times/day (6hours);N/A40 minutes fail safe*Condensing Unit Low Pressure Control Cut in 20 lbs: Diff. 18 lbs. Cut in 35 lbs: Diff. 25 lbs.Condensing Unit High Pressure Control 400 lbs 380 lbsDefrost Termination 40 - 75°F N/A*This is a standard setting; climates with extreme humidity may require more defrost times or longer fail safesettings.STARTING PROCEDURE1. Check the temperature holding range against the control setting.2. Check the defrost control system to see that all ice is removed from the coil during each defrost cycle.3. Check pressures.4. Check EPR Valve for proper pressure when applicable.13

FINAL CHECK LISTA. Check high-low pressure control settings.B. Check setting of defrost timer:1. Four defrost/24 hours, with 30 minute fail safe.C. Check operating pressure.D. Check electrical requirements of unit to supply voltage.E. Set temperature control for desired temperature range.F. Check setting of thermostatic expansion valve for proper operation. Approx. 10°F superheat.G. Check sight glass for proper refrigerant charge.H. Check system for proper defrost settings and operation.I. Check condensing unit for vibrating or rubbing tubing. Dampen and clamp as required.J. All valves should be completeley open counter-clockwise.K. Check packing nuts on all service valves.L. Replace all service valve caps and latch unit covers.M. Check refrigeration line for proper P-traps and proper locations.N. Check drain for proper P-traps and proper locations.DOOR PLASTIC (GASKET RETAINER) REPLACEMENTStarting in corner, gently pull the rubber gasket away from the door plastic. With gasket removed, insert a flat-headscrewdriver under the outside edge of the plastic, and gently pry up. At either end of the plastic run the screwdriver thecomplete length and width of the door rail. With the outside edge of the plastic released, push the plastic towards theglass to remove. To replace, insert the edge of the plastic into the inside door rail groove. Snap the outside edge of theplastic cover over the outside edge of the door rail.DOOR GASKET REPLACEMENTRemove the old gasket by starting in the corner, gently pulling gasket away from the plastic. To replace the gasket,remove the top and bottom door plastic, and slide the gasket up the two verticals. Slide the top and bottom plastic ontothe gasket, and replace the top and bottom plastic on the door rail. Tuck in the corners of the gasket with a flat-headscrewdriver.BALLAST REPLACEMENT, TEL/TEMFor a TEL/TEM, the magnetic ballasts are located in the raceway at the bottom of the cabinet. The kickplate will have tobe removed to access the ballasts. Consult the wiring diagrams for the TEL/TEM on pages 31 thru 34 of this manual.DOOR HEATER REPLACEMENTRemove door gasket and plastic. Remove the center side access plate located on the side of the door. The wiring forthe door is done in the center side of the hinge rail. To remove the heater, unplug the solid lead wires: Black or Red,White, and Green/Yellow (ground). If the glass is heated, unplug the Black and White solid wires from the glass. Heaterwire lies in track on the back outside edge of door. Pull the heater out. Reverse instructions to replace the door heater.Plug in Black or Red lead wire from hinge pin to Black or Red lead wire from heater, White lead wire from hinge pin toWhite heater lead, and Green/Yellow lead from hinge pin to ground.Note: If glass is heater, plug in Black and White lead wires coming off heater loom to Black and White lead wires fromglass. Replace side access plate. Replace the door plastic and gasket.14

SERVICE INSTRUCTIONS (Trouble Shooting Guide)1. High head pressure and high back pressure:A. Condenser coil clogged or restricted.B. Condenser fan motor defective.2. Low back pressure and low head pressure:A. Restriction in system.B. Refrigerant undercharged.C. Leak in system.3. Pressures normal – cabinet warm:A. Coil blocked with frost or ice (see #4).B. Refrigerant undercharged.C. Control set too warm.D. Air screen disturbance.4. Coil blocked with frost or ice:A. Defective temperature control. E. P-trap in drain not installed.B. Time clock not operating properly. F. Doors aren’t sealing when closed.C. Improper time clock setting. G. Air screen disturbance.D. Ambient conditions above 75°F/55% RH. H. Evaporator fan motor defective.E. Defrost heater not operating. I. Low voltage.5. Compressor starts and runs – but cycles on overload:A. Low voltage.B. Dropped phase (3 phase).C. Overload protector defective.D. High head pressure (see#1).6. Compressor will not start – hums, but cycles on overload:A. Low voltage.B. Relay defective.C. Overload defective.D. High head pressure (see #1).7. Special service situations:If moisture or liquid is observed around or under a <strong>Master</strong>-<strong>Bilt</strong> cabinet, an immediate investigation should bemade by qualified personnel to determine the source of moisture or liquid. The investigation made shoulddetermine if the cabinet is malfunctioning or if there is a simple housekeeping problem.Moisture or liquid around or under a cabinet is a potential slip/fall hazard for persons walking by or working in thegeneral area of the cabinet.Any cabinet malfunction or housekeeping problem that creates a slip/fall hazard around or under a cabinet shouldbe corrected immediately.15

MASTER-BILT PART NUMBERSThe table below gives <strong>Master</strong>-<strong>Bilt</strong> part numbers. Use this chart when ordering replacement parts for your TEL/TEMcases.Description TEL (Low Temp) TEM (Med Temp)Evaporator CoilConsult FactoryExpansion Valve09-0963409-09631Sporlan SBFSE-A-ZPSporlan SBFVE-A-CDefrost Heater Consult Factory N/ADrain Line Heater17-09063N/A230V / 6 ½ WattsHeater Safety19-01307Texas Instruments #500971N/ADefrost Termination/Fan Delay19-00890Ranco #F-25-118-0N/ATemperature Control19-1360719-00884Eaton 9540Ranco A30-1762Evaporator Fan Motor13-0068313-00685208-230V / 1550 RPM120 V / 1550 RPMEvaporator Fan Blade 15-01184 15-01184Evaporator Fan Guard 25-00205 25-00205Drum Thermometer 19-13586 19-13586Standard ShelfWire Cantilever33-01385 33-01385Door FrameConsult FactoryStandard Door (Black)Anthony Model 10131-02207 (30”)31-02225 (24”)31-02212 (30”)31-02230 (24”)Ballast23-01458 (1 Lamp)23-00360 (1 Lamp)23-01480 (2 Lamp)Ballast DriverAnthony LED CONVERTOR23-01730 23-01730LED Mullion light barAnthony Low powe 4100K23-01727Anthony23-01727AnthonyLamp Left Side light barAnthony Low power 4100K23-01728Anthony23-01728AnthonyLamp Right Side light barAnthony Low power 4100K23-01729Anthony23-01729AnthonyLight SwitchAnthony ELS/Connexxion19-13685Anthony F-1248619-13685Anthony F-12486Door GasketAnthony37-01273 (30”)37-01280 (24”)37-01273 (30”)37-01280(24”)Torque-<strong>Master</strong> (Black)Anthony35-01464Anthony F-122R-B35-01464Anthony F-122R-B35-0145635-01456Torque RodAnthony D-64203Anthony D-64203Top Hinge PinAnthony35-01484Anthony D-6423835-01484Anthony D-64238Lamp HolderAnthony ELS23-01615Anthony AE-1102823-01615Anthony AE-11028Lamp HolderAnthony Connexxion Top23-01616Anthony AE-1279723-01616Anthony AE-12797Lamp HolderAnthony Connexxion Bottom23-01617Anthony AE-1279623-01617Anthony AE-1279623-0161823-01618Connector w/wireAnthony XX-13246Anthony XX-13246Lens BridgeAnthony ELS/Connexxion23-01619Anthony AE-7266123-01619Anthony AE-72661Prismatic LensAnthony ELS/Connexxion23-01620Anthony AE-7241923-01620Anthony AE-72419Flourescent LampAnthony ELS/Connexxion23-01585Anthony AE-7213923-01585Anthony AE-72139Single Station Socket 23-01494 23-01494Double Station Socket 23-01493 23-01493Door Frame Heater, MullionDoor Frame Heater, TopConsult FactoryDoor Frame Heater, Bottom16

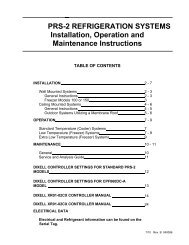

REQUIRED CONDENSING UNITS FOR TEM/TEL SERIES35°F AVERAGE PRODUCT TEMP.+20°F SUCTION75°F AIR CONDITIONED STORE55% RELATIVE HUMIDITY-3°F AVERAGE PRODUCT TEMP.-11°F SUCTION75°F AIR CONDITIONED STORE55% RELATIVE HUMIDITY-12°F AVERAGE PRODUCT TEMP.-18°F SUCTION75°F AIR CONDITIONED STORE55% RELATIVE HUMIDITYCOND. UNIT REQUIRED FORAIR TEMP. ENTERING CONDENSER*COND. UNIT REQUIRED FORAIR TEMP. ENTERING CONDENSER*COND. UNIT REQUIRED FORAIR TEMP. ENTERING CONDENSER*NO. OFDOORS90°F 100°F 110°F 90°F 100°F 110°F 90°F 100°F 110°F2 MHHZ0071B MHHZ0071B MHHZ0071B MHLZ0071 MHLZ0071 MHLZ0071 MHLZ0091 MHLZ0091 MHLZ00913 MHHZ0071B MHHZ0071B MHHZ0071B MHLZ0071 MHLZ0091 MHLZ0091 MHLZ0091 MHLZ0121 MHLZ01214 MHHZ0071B MHHX0081B MHHX0081B MHLZ0091 MHLZ0091 MHLZ0121 MHLZ0121 MHLZ0121 MHLZ01215 MHHZ0081B MHHZ0081B MHHZ0111 MHLZ0091 MHLZ0121 MHLZ0121 MHLZ0121 MSLZ0151 MSLZ01816 MHHZ0111 MHHZ0111 MHHZ0111 MHLZ0121 MHLZ0121 MSLZ0151 MSLZ0151 MSLZ0181 MSLZ02217 MHHZ0111 MHHZ0111 MHHZ0171 MHLZ0121 MSLZ0151 MSLZ0181 MSLZ0181 MSLZ0221 MSLZ02218 MHHZ0171 MHHZ0171 MHHZ0171 MSLZ0151 MSLZ0181 MSLZ0181 MSLZ0221 MSLZ0221 MSLZ02219 MHHZ0171 MHHZ0171 MHHZ0191 MSLZ0181 MSLZ0181 MSLZ0221 MSLZ0221 MSLZ0221 BSLZ075010 MHHZ0171 MHHZ0191 MHHZ0191 MSLZ0181 MSLZ0221 MSLZ0221 MSLZ0221 BSLZ0750 BSLZ075011 MHHZ0191 MHHZ0191 MHHZ0221 MSLZ0221 MSLZ0221 MSLZ0221 BSLZ0750 BSLZ0750 BSLZ075012 MHHZ0191 MHHZ0221 MHHZ0221 MSLZ0221 MSLZ0221 BSLZ0750 BSLZ0750 BSLZ0750 BSLZ100013 MHHZ0191 MHHZ0221 MHHZ0251 MSLZ0221 BSLZ0750 BSLZ0750 BSLZ0750 BSLZ1000 BCLZ075014 MHHZ0221 MHHZ0251 MHHZ0251 BSLZ0750 BSLZ0750 BSLZ0750 BSLZ1000 BSLZ1000 BSLZ150015 MHHZ0251 MHHZ0251 MHHZ0301 BSLZ0750 BSLZ0750 BSLZ1000 BSLZ1000 BSLZ1000 BSLZ150016 MHHZ0251 MHHZ0251 MHHZ0301 BSLZ0750 BSLZ1000 BSLZ1000 BSLZ1000 BSLZ1500 BSLZ150017 MHHZ0251 MHHZ0301 MHHZ0331 BSLZ0750 BSLZ1000 BSLZ1000 BSLZ1500 BSLZ1500 BSLZ150018 MHHZ0301 MHHZ0301 MHHZ0331 BSLZ1000 BSLZ1000 BSLZ1500 BSLZ1500 BSLZ1500 BSLZ150019 MHHZ0301 MHHZ0331 MHHZ0331 BSLZ1000 BSLZ1000 BSLZ1500 BSLZ1500 BSLZ1500 BSLZ150020 MHHZ0301 MHHZ0331 MHHZ0431 BSLZ1000 BSLZ1500 BSLZ1500 BSLZ1500 BSLZ1500 BCLZ150021 MHHZ0331 MHHZ0331 MHHZ0431 BSLZ1000 BSLZ1500 BSLZ1500 BSLZ1500 BSLZ1500 BCLZ150022 MHHZ0331 MHHZ0431 MHHZ0431 BSLZ1500 BSLZ1500 BSLZ1500 BSLZ1500 BCLZ1500 BCLZ150023 MHHZ0331 MHHZ0431 MHHZ0431 BSLZ1500 BSLZ1500 BSLZ1500 BSLZ1500 BCLZ1500 BCLZ150024 MHHZ0431 MHHZ0431 MHHZ0431 BSLZ1500 BSLZ1500 BSLZ1500 BCLZ1500 BCLZ1500 BCLZ150025 MHHZ0431 MHHX0441 MHHZ0501 BSLZ1500 BSLZ1500 BSLZ1500 BCLZ1500 BCLZ1500 BCLZ1500