Health and Safety in Shearing (PDF 917kb) - WorkSafe Victoria

Health and Safety in Shearing (PDF 917kb) - WorkSafe Victoria

Health and Safety in Shearing (PDF 917kb) - WorkSafe Victoria

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

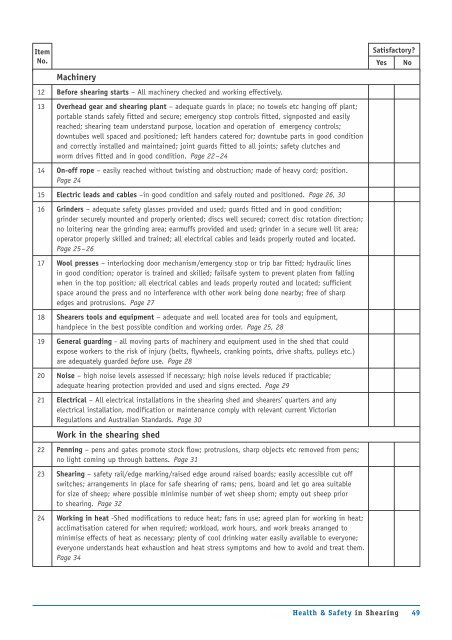

ItemNo.Mach<strong>in</strong>ery12 Before shear<strong>in</strong>g starts – All mach<strong>in</strong>ery checked <strong>and</strong> work<strong>in</strong>g effectively.13 Overhead gear <strong>and</strong> shear<strong>in</strong>g plant – adequate guards <strong>in</strong> place; no towels etc hang<strong>in</strong>g off plant;portable st<strong>and</strong>s safely fitted <strong>and</strong> secure; emergency stop controls fitted, signposted <strong>and</strong> easilyreached; shear<strong>in</strong>g team underst<strong>and</strong> purpose, location <strong>and</strong> operation of emergency controls;downtubes well spaced <strong>and</strong> positioned; left h<strong>and</strong>ers catered for; downtube parts <strong>in</strong> good condition<strong>and</strong> correctly <strong>in</strong>stalled <strong>and</strong> ma<strong>in</strong>ta<strong>in</strong>ed; jo<strong>in</strong>t guards fitted to all jo<strong>in</strong>ts; safety clutches <strong>and</strong>worm drives fitted <strong>and</strong> <strong>in</strong> good condition. Page 22–2414 On-off rope – easily reached without twist<strong>in</strong>g <strong>and</strong> obstruction; made of heavy cord; position.Page 2415 Electric leads <strong>and</strong> cables –<strong>in</strong> good condition <strong>and</strong> safely routed <strong>and</strong> positioned. Page 26, 3016 Gr<strong>in</strong>ders – adequate safety glasses provided <strong>and</strong> used; guards fitted <strong>and</strong> <strong>in</strong> good condition;gr<strong>in</strong>der securely mounted <strong>and</strong> properly oriented; discs well secured; correct disc rotation direction;no loiter<strong>in</strong>g near the gr<strong>in</strong>d<strong>in</strong>g area; earmuffs provided <strong>and</strong> used; gr<strong>in</strong>der <strong>in</strong> a secure well lit area;operator properly skilled <strong>and</strong> tra<strong>in</strong>ed; all electrical cables <strong>and</strong> leads properly routed <strong>and</strong> located.Page 25–2617 Wool presses – <strong>in</strong>terlock<strong>in</strong>g door mechanism/emergency stop or trip bar fitted; hydraulic l<strong>in</strong>es<strong>in</strong> good condition; operator is tra<strong>in</strong>ed <strong>and</strong> skilled; failsafe system to prevent platen from fall<strong>in</strong>gwhen <strong>in</strong> the top position; all electrical cables <strong>and</strong> leads properly routed <strong>and</strong> located; sufficientspace around the press <strong>and</strong> no <strong>in</strong>terference with other work be<strong>in</strong>g done nearby; free of sharpedges <strong>and</strong> protrusions. Page 2718 Shearers tools <strong>and</strong> equipment – adequate <strong>and</strong> well located area for tools <strong>and</strong> equipment,h<strong>and</strong>piece <strong>in</strong> the best possible condition <strong>and</strong> work<strong>in</strong>g order. Page 25, 2819 General guard<strong>in</strong>g - all mov<strong>in</strong>g parts of mach<strong>in</strong>ery <strong>and</strong> equipment used <strong>in</strong> the shed that couldexpose workers to the risk of <strong>in</strong>jury (belts, flywheels, crank<strong>in</strong>g po<strong>in</strong>ts, drive shafts, pulleys etc.)are adequately guarded before use. Page 2820 Noise – high noise levels assessed if necessary; high noise levels reduced if practicable;adequate hear<strong>in</strong>g protection provided <strong>and</strong> used <strong>and</strong> signs erected. Page 2921 Electrical – All electrical <strong>in</strong>stallations <strong>in</strong> the shear<strong>in</strong>g shed <strong>and</strong> shearers’ quarters <strong>and</strong> anyelectrical <strong>in</strong>stallation, modification or ma<strong>in</strong>tenance comply with relevant current <strong>Victoria</strong>nRegulations <strong>and</strong> Australian St<strong>and</strong>ards. Page 30Work <strong>in</strong> the shear<strong>in</strong>g shed22 Penn<strong>in</strong>g – pens <strong>and</strong> gates promote stock flow; protrusions, sharp objects etc removed from pens;no light com<strong>in</strong>g up through battens. Page 3123 Shear<strong>in</strong>g – safety rail/edge mark<strong>in</strong>g/raised edge around raised boards; easily accessible cut offswitches; arrangements <strong>in</strong> place for safe shear<strong>in</strong>g of rams; pens, board <strong>and</strong> let go area suitablefor size of sheep; where possible m<strong>in</strong>imise number of wet sheep shorn; empty out sheep priorto shear<strong>in</strong>g. Page 3224 Work<strong>in</strong>g <strong>in</strong> heat -Shed modifications to reduce heat; fans <strong>in</strong> use; agreed plan for work<strong>in</strong>g <strong>in</strong> heat;acclimatisation catered for when required; workload, work hours, <strong>and</strong> work breaks arranged tom<strong>in</strong>imise effects of heat as necessary; plenty of cool dr<strong>in</strong>k<strong>in</strong>g water easily available to everyone;everyone underst<strong>and</strong>s heat exhaustion <strong>and</strong> heat stress symptoms <strong>and</strong> how to avoid <strong>and</strong> treat them.Page 34Satisfactory?Yes No<strong>Health</strong> & <strong>Safety</strong> <strong>in</strong> Shear<strong>in</strong>g 49