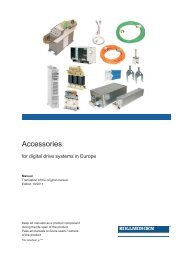

Accessories for Kollmorgen digital servo systems - Portal ...

Accessories for Kollmorgen digital servo systems - Portal ...

Accessories for Kollmorgen digital servo systems - Portal ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

05/2013 <strong>Kollmorgen</strong>This page has been deliberately left blank.6 <strong>Accessories</strong> Manual Europe

<strong>Kollmorgen</strong> 05/2013 General1 General1.1 About this manualThis manual describes accessories <strong>for</strong> <strong>Kollmorgen</strong> <strong>digital</strong> <strong>servo</strong> amplifiers. It contains essentialtechnical data. The manual is only valid in conjunction with the instructions manual <strong>for</strong> the <strong>servo</strong>amplifier and <strong>servo</strong> motor you are using in your application.You will find copies of the instructions manual <strong>for</strong> <strong>Kollmorgen</strong> <strong>servo</strong> amplifiers and <strong>servo</strong> motors onthe CD ROM included in the scope of supply and on our Internet site. The documents are availablein Acrobat Reader <strong>for</strong>mat in multiple languages (system requirements: WINDOWS, Internetbrowser, Acrobat Reader).Servo amplifier product family names appear in abbreviated <strong>for</strong>mat:Servo amplifier Abbreviation Servo amplifier AbbreviationSERVOSTAR 300 S300 S701...724 S701...724SERVOSTAR 400 S400 S748/772 S748/772SERVOSTAR 601...620 S601...620 AKD-xzzzy AKDMore detail in<strong>for</strong>mation can be found in the "Technical WIKI" available at www.wiki-kollmorgen.eu.1.2 Hints <strong>for</strong> the online edition (PDF <strong>for</strong>mat)Bookmark:Table of contents and index are active bookmarks.Table of contents and index in the text:The lines are active cross references. Click on the desired line and the appropriate page is indicated.Page/chapter numbers in the text:Page/chapter numbers with cross references are active. Click at the page/chapter number to reachthe indicated target.1.3 Safety Notes1.3.1 SymbolsThis section helps you to recognize and avoid dangers to people and objects.SymbolIndicationIndicates a hazardous situation which, if not avoided, will result in death orserious injury.Indicates a hazardous situation which, if not avoided, could result in deathor serious injury.Indicates a hazardous situation which, if not avoided, could result in minoror moderate injury.This is not a safety symbol. This symbol indicates situations which, if notavoided, could result in property damage.This is not a safety symbol. This symbol indicates important notes.<strong>Accessories</strong> Manual Europe 7

General 05/2013 <strong>Kollmorgen</strong>1.3.2 You should pay attention to thisRead the documentation!Read the available documentation be<strong>for</strong>e installation and commissioning. Improper handling of thedevices can cause harm to people or damage to property. The operator must there<strong>for</strong>e ensure thatall persons entrusted to work on the devices have read and understood the manual and that thesafety notices in this manual are observed.Always observe the whole drive system built with <strong>servo</strong>amplifier, cables, motor, accessories (filters,chokes, etc.). This means, that all documentation which exist <strong>for</strong> the components, must be available,must be read and must be understood.Pay attention to the technical data!Adhere to the technical data and the specifications on connection conditions (rating plate and documentation).If permissible voltage values or current values are exceeded, the devices can be damaged,e.g. through overheating.Specialist staff required!Only properly qualified personnel are permitted to per<strong>for</strong>m such tasks as transport, assembly, setupand maintenance. Qualified specialist staff are persons who are familiar with the transport, installation,assembly, commissioning and operation of power electronics and who bring their relevant minimumqualifications to bear on their duties:Transport : only by personnel with knowledge of handling electrostaticallysensitive components.Mech. Installation : only by mechanically qualified personnel.Electr. Installation : only by electrically qualified personnel.Setup : only by qualified personnel with extensive knowledge of electricalengineering and drive technologyThe qualified personnel must know and observe IEC 60364 / IEC 60664 and national accident preventionregulations..Additional requirements on specialist staff may also result from the risk assessment.Hot surface!Some devices can reach temperatures of up to 80°C during operation. Touching them can result inminor burns. Observe the permissible mounting position and ensure that a sufficient distance ismaintained from neighboring assembliesEarthing!It is vital that you ensure that the device housing is safely earthed to the PE (protective earth) busbarin the switch cabinet. Without low-resistance earthing no personal protection can be guaranteedand there is a risk of death from electric shock.High voltages!Keep the switching cabinet closed when the equipment is in operation. Not having optical displaysdoes not guarantee an absence of voltage. Power connections may carry voltage even if the motoris not turning.Do not unplug any connectors during operation. There is a risk of death or severe injury from touchingexposed contacts. Power connections may be live even when the motor is not rotating. Thiscan cause flashovers with resulting injuries to persons and damage to the contacts.DC Bus link connections can carry dangerous voltage levels over an hour after the line voltage hasbeen switched off (self-discharge time). Danger of death from electric shock.Be<strong>for</strong>e commencing work on the modules’ power terminals, check the voltage at the connection terminalsis de-energized to ground and to each other.8 <strong>Accessories</strong> Manual Europe

Digital Drive Systems 05/2013 <strong>Kollmorgen</strong>2.2 Drive System with S400Control / PLCI/O p.53Brake Resistor(optional) p.30PC p.4024V-PSU p.Motor-Feedback p.79Motor-PowerMotor Brake p.63Cables drawn bold are shielded. Electrical ground isdrawn with dash-dotted lines. Optional devices are connectedwith dashed lines to the <strong>servo</strong> amplifier.10 <strong>Accessories</strong> Manual Europe

<strong>Kollmorgen</strong> 05/2013 Digital Drive Systems2.3 Drive System with S601...620PC p.40Motor-Feedback p.79Control / PLCI/O p.5324V-PSU p.Brake Resistor(optional) p.30Motor choke (optional) p.35Motor-PowerMotor Brake p.63Cables drawn bold are shielded. Electrical ground isdrawn with dash-dotted lines. Optional devices are connectedwith dashed lines to the <strong>servo</strong> amplifier.<strong>Accessories</strong> Manual Europe 11

Digital Drive Systems 05/2013 <strong>Kollmorgen</strong>2.4 Drive System with S701...724PC p.40Control / PLCI/O p.53Motor-Feedback p.7924V-PSU p.Motor-PowerMotor Brake p.63Brake Resistoroptional p.30Motor choke(optional) p.35Cables drawn bold are shielded. Electrical ground isdrawn with dash-dotted lines. Optional devices are connectedwith dashed lines to the <strong>servo</strong> amplifier.12 <strong>Accessories</strong> Manual Europe

<strong>Kollmorgen</strong> 05/2013 Digital Drive Systems2.5 Drive System with S748/772PC p.40EtherNetMotor-Feedback p.79SPSI/O p.53Brake Resistor p.30Motor-PowerMotor Brake p.6324V-PSU p.Cables drawn bold are shielded.<strong>Accessories</strong> Manual Europe 13

Digital Drive Systems 05/2013 <strong>Kollmorgen</strong>2.6 Drive System with AKD-x00306...0240624V-PSU p.PC p.40PLCI/O p.53Brake Resistor(optional) p.30Mains Filter p.24Motor Choke(optional) p.35Motor-Feedback p.79Motor-Power p.63Cables drawn bold are shielded. Electrical ground isdrawn with dash-dotted lines. Optional devices are connectedwith dashed lines to the <strong>servo</strong> amplifier.14 <strong>Accessories</strong> Manual Europe

<strong>Kollmorgen</strong> 05/2013 Digital Drive Systems2.7 Drive System with AKD-x00307...0240724V-PSU p.PC p.40PLCI/O p.53Brake Resistor(optional) p.30Motor Choke(optional) p.35Motor-Feedback p.79Motor-Power p.63Cables drawn bold are shielded. Electrical ground isdrawn with dash-dotted lines. Optional devices are connectedwith dashed lines to the <strong>servo</strong> amplifier.<strong>Accessories</strong> Manual Europe 15

Digital Drive Systems 05/2013 <strong>Kollmorgen</strong>This page has been deliberately left blank.16 <strong>Accessories</strong> Manual Europe

<strong>Kollmorgen</strong> 05/2013 Mechanical Tools3 Mechanical Tools3.1 Suspension Unit <strong>for</strong> motorsSuspended load. Risk of death if load falls. Never step under the load,while the motor is raised!You must read the instructions manual <strong>for</strong> the suspension unit ZPMZ 120/292. Observe the "safetyinstructions" and "use as directed" hints be<strong>for</strong>e starting transportation work.The Suspension Unit ZPMZ 120/292 is designed <strong>for</strong> suspended handling exclusively of motors (i.e.,without attached units such as gearboxes, clutches, etc.) with a maximum weight of 120 kg andBeamDouble chainsuspenderMotorSuspenderZPMZ 120/292Motor suspension methodsmaximum nominal span of the extreme suspension hooks of 292 mm.The suspended unit consists of a Beam, suspended off the crane hook and two double-run chainsuspenders. The motor may be borne on two or four runs of the chain suspender.The suspenders (number depends on the motor type) are delivered with the motor.Technical DataLifting capacity120 kgNominal span292 mmLug width44,7 mmLug height51 mmWeight0,83 kgNumber of cycles a year 20.000Average load 60 %Order codeFA00092<strong>Accessories</strong> Manual Europe 17

Mechanical Tools 05/2013 <strong>Kollmorgen</strong>3.2 Fan Kit <strong>for</strong> AKM7 motorsObserve the mounting instructions delivered with the fan kit. The fan housing can be mounted eitherwith both the supplied brackets and spacers or with the brackets only. The choice of mountingmethod depends on the application. If strong vibrations are expected, you should use both bracketsand spacers. Motors with integrated brakes require the longs spacers.Mounting the fan kit enlarges the motor by approximately 65 mm. The detailled final dimensions ofAKM7 motors with mounted fan kit can be found in the instructions manual of the AKM motorseries.Ventilation of AKM7 motors allow increased current of the motors. This higher current usually requireslarger wiring cross section compared to not ventilated motors. The necessary data <strong>for</strong> currentand wiring cross section can be found in the technical data section of the AKM instructions manual.Technical DataSupply voltage 24 VDCSupply current 270 mAElectrical power 6,5 WSurfaceCoated with polyester powder coating in matt black, not resistant against solventsProtection class IP 20Connection Cable gland 10mm, cable diameter 4 mm to 6 mmTerminals0,33 mm² to 4 mm²Weight2,52 kgOrder code AKM7-FANMounting bracketStandoff boltCable glandMounting bracketTerminal stripConnection cableCover sheetFan housing18 <strong>Accessories</strong> Manual Europe

Mains chokes 05/2013 <strong>Kollmorgen</strong>5.5 Mains choke 3LA number of <strong>servo</strong> amplifiers can be connected to one and the same mains choke; the rated currentof the mains choke must be greater than or at least equal to the total current of the connected <strong>servo</strong>amplifiers.Photo: 3L 0,2-160-4, all models aresimilarTechnical DataTypeNominalCurrent[A]uk[%]A[mm]B[mm]C[mm]D[mm]E[mm]F[mm]Inductivity[mH]Terminals[mm²]Weight [kg]3L 0,5-63-4 0.47 63 4 185 170 77 122 215 8x12 16 9.653L 0,4-80-4 0.37 80 4 210 175 85 125 240 8x12 16 12.53L 0,2-160-4 0.19 160 4 291 273 116.5 148.5 310 10x18 95 273L 0,24-50-2 0.24 50 2 152.5 114.3 88.9 114.3 163 6.5 10 5.93L 0,2-75-2 0.20 75 2 185 170 77 122 220 8x12 35 9.922 <strong>Accessories</strong> Manual Europe

<strong>Kollmorgen</strong> 05/2013 Mains filters2 Mains filters2.1 GeneralAKD-x00306...02406 <strong>servo</strong> amplifiers require an external mains filter. All other <strong>servo</strong> amplifiers featurebuilt-in mains filters (see the relevant instructions manual).The filtering effect of the mains filters can only be assured if the permissible throughput rating of themains filters is not exceeded even on peak loading of the <strong>servo</strong> amplifiers with Ipeak.The max. available throughput rating of the mains filter Pmax F 3 UNINFmust be higher than themax. power consumption of the <strong>servo</strong> amplifiers P g 3 U I and higher than themax V N peakViini3max. power consumption of the motors Pmax M gkEi IpeakVi1000 2The rated current I NF of the mains filter in a system with i axes must be higher than IMore in<strong>for</strong>mation can be found on the WIKI page "Mains Filter".iNFPmaxM3 UN.2.2 Important noterPower terminals are capable of conducting hazardous voltage up to 10minutes after the mains voltage has been disconnected. Risk of electricshock. Be<strong>for</strong>e starting work on power terminals, check that thephase-to-earth and phase-to-phase voltages have de-energised.Due to the high earth leakage currents induced by the system, you should observe the requirementsof EN 61800-5-1 (e.g. fixed installation, 10 mm² or double protective earth) when carryingout mounting and installation work. You must read the instructions manual <strong>for</strong> the <strong>servo</strong> amplifier/<strong>servo</strong>motor you are using in your application and observe the safety instructions they containbe<strong>for</strong>e commencing mounting/installation work.A connection diagram appears in the <strong>servo</strong> amplifier instructions manual.2.3 Type assignmentServo amplifierMains filterS300, S400, S601...620, S700, AKD-x00307...02407 (240 to 480V) not requiredAKD-x00306...02406 (120 to 240V)1NF, 3NF2.4 Order codesArticle Order code RemarksMains filter 1NF-10 (230 VAC, 10A) DE-201565 single phase, 230V AC, CE*, ULMains filter 1NF-12 (230 VAC, 12A) DE-201566 single phase, 230V AC, CE*, ULMains filter 1NF-20B (125V/230 VAC, 20A) DE-201865 single phase, IEC 230V AC, UL 125 V AC, CE*Mains filter 1NF-25 (230 VAC, 25A) DE-201568 single phase, 230V AC, CE*, ULMains filter 3NF-07 (480 VAC, 07A) DE-201569 three phases, 480V AC, CE*, ULMains filter 3NF-16 (480 VAC, 16A) DE-201570 three phases, 480V AC, CE*, ULMains filter 3NF-30 (480 VAC, 30A) DE-201571 three phases, 480V AC, CE*, UL* No EC directive matchs mains filters actually. Don't hesitate to use the filters in Europe, because they aremanufactured according to harmonized standards concerning creeping and voltage distances.<strong>Accessories</strong> Manual Europe 23

Mains filters 05/2013 <strong>Kollmorgen</strong>2.5 Mains filters 1NF-10...12Observe the safety instructions in chapter 2.2.For single-phase operation only.Technical DataNominalType Current[A]*NominalVoltage[V]A[mm]B[mm]C[mm]D[mm]F[mm]M[mm]N[mm]P[mm]Weight[kg]Connection1NF-10 10 230 85 49 40.3 54 75 5.3 6.3 87 0.29 Fast-on1NF-12 12 230 156 57.5 45.4 130.5 143 5.3 6 156 0.73 Fast-on* at 40°C environment temperature24 <strong>Accessories</strong> Manual Europe

<strong>Kollmorgen</strong> 05/2013 Mains filters2.6 Mains filters 1NF-20B, 1NF-25Observe the safety instructions in chapter 2.2.For single-phase operation only.Technical DataNominal VoltageType Nominal Current [A]* IEC UL/CSA Weight[kg]1NF-20B 20 230V 125V 0.931NF-25 25 230V 230V 0.7* at 50°C environment temperatureConnection PhaseConnection PETerminalsWires up to 4mm²Torque 0.6 to 0.8 Nm Bolt M 6Wires up to 10mm² Torque 3.5 to 4 NmTorque 1.5 to1.8 Nm<strong>Accessories</strong> Manual Europe 25

Mains filters 05/2013 <strong>Kollmorgen</strong>2.7 Mains filters 3NF-07...30Observe the safety instructions in chapter 2.2.For three-phase operation only.Technical DataTypeNom.Current*A[mm]B[mm]C[mm]D[mm]F[mm]G[mm]M[mm]P[mm]Weight[kg]Terminals3NF-07 7 A 190 40 70 160 180 20 4.5 180 0.5 4mm²,3NF-16 16 A 250 45 70 220 235 25 5.4 240 0.8 0.7 to 0.8Nm M5,3NF-30 30 A 270 50 85 240 255 30 5.4 260 1.210mm², 2.2Nm1.9 to 2.2Nm* at 50°C environment temperaturePEBolt26 <strong>Accessories</strong> Manual Europe

<strong>Kollmorgen</strong> 05/2013 Brake resistors7 Brake resistors7.1 GeneralDuring braking with the aid of the motor, energy is fed back into the <strong>servo</strong> amplifier. This regenerativeenergy is dissipated as heat in the brake resistor. The brake resistor is switched on by thebrake circuit. Different resistance values have to be used depending on the <strong>servo</strong> amplifier. Allresistors meet the requirements of CE directives and are UL-registered.Hints <strong>for</strong> calculation of the brake power can be found in our Product WIKI on page "Calculation ofbrake power", more in<strong>for</strong>mation to the resistors are given on WIKI page "Brake Resistors".7.2 Important notesThe brake resistor surface temperature can exceed 250°C. Risk of burns!Measure the temperature and wait until temperature dropped down below40°C, be<strong>for</strong>e touching the resistor housing.Inadequate levels of cooling air or incorrect installation can lead to overheating and destruction ofthe resistor and surrounding components.- May only be installed in switchgear cabinets, comply with the permissible installationtypes and clearances (see dimensional drawing).- Ensure there is unobstructed convection <strong>for</strong> cooling purposes.- Use temperature-resistant materials in the vicinity of the resistor.- The connection terminals must never be located within the flow range of the heatedwaste air.The following requirements must be met to ensure the brake resistors work properly: Compliance with required installation clearancesCompliance with permissible installation typeUnhindered access of cooling airUnhindered diverting of warmed up airRated data with maximum ambient temperature 40°C, in case of ambient temperature higherthan 40°C, power must be reduced by 4% per 10K temperature riseYou must read the instructions manual <strong>for</strong> the <strong>servo</strong> amplifier/<strong>servo</strong> motor you are using in yourapplication and observe the safety instructions they contain be<strong>for</strong>e commencing mounting/installationwork.A connection diagram appears in the <strong>servo</strong> amplifier's instructions manual.<strong>Accessories</strong> Manual Europe 27

Brake resistors 05/2013 <strong>Kollmorgen</strong>7.3 Type assignmentServo amplifier Brake resistor Resistance/ RemarksS300 (S3xx61) BAR(U) 66 optionalS300 (S3xx01) BAR(U) 91 optionalS400 BAR(U) 33 optionalS601...620 BAR(U) 33 optionalS701-712 BAR(U) 33 optionalS724 BAR(U)/BAS(U) 23 optionalS748 BAS(U) 15 usually requiredS772 BAS(U) 10 usually requiredAKD-X00306 BAFP(U)/BAR(U)/BAS(U) 33 usually requiredAKD-X00606 BAFP(U)/BAR(U)/BAS(U) 33 usually requiredAKD-X01206 BAFP(U)/BAR(U)/BAS(U) 33 optionalAKD-X02406 BAR(U)/BAS(U) 15 optionalAKD-X00307 BAR(U)/BAS(U) 33 optionalAKD-X00607 BAR(U)/BAS(U) 33 optionalAKD-X01207 BAR(U)/BAS(U) 33 optionalAKD-X02407 BAR(U)/BAS(U) 23 optional7.4 Order codesArticleAmplifierResistance[]RatedPower[W]Max.Power[W]Order codeBrake resistor BAS(U) 2000-1010 2000 3200 DE-103874Brake resistor BAS(U) 3000-10 S77210 3000 4800 DE-103875Brake resistor BAS(U) 6000-10 10 6000 9600 DE-103876Brake resistor BAR(U) 500-1515 500 800 DE-201439Brake resistor BAR(U) 1000-15 15 1000 1600 DE-201440AKD-X02406,Brake resistor BAS(U) 2000-15 15 2000 3200 DE-103871S748Brake resistor BAS(U) 3000-15 15 3000 4800 DE-103872Brake resistor BAS(U) 6000-15 15 6000 9600 DE-103873Brake resistor BAR(U) 600-2323 600 960 DE-200613Brake resistor BAR(U) 1000-23 23 1000 1600 DE-200614AKD-X02407,Brake resistor BAS(U) 2000-23 23 2000 3200 DE-200615S724Brake resistor BAS(U) 3000-23 23 3000 4800 DE-200616Brake resistor BAS(U) 4000-23 23 4000 6400 DE-200617Brake resistor BAFP(U) 100-3333 100 160 DE-201437Brake resistor BAFP(U) 200-33AKD-X003 to33 200 320 DE-20143812,Brake resistor BAR(U) 250-33 33 250 400 DE-106254S400,Brake resistor BAR(U) 500-33 33 500 800 DE-106255S601...620,Brake resistor BAR(U) 1500-33S701-71233 1500 2400 DE-106258Brake resistor BAS(U) 3000-33 33 3000 4800 DE-201407Brake resistor BAR(U) 300-6666 300 480 DE-107161Brake resistor BAR(U) 600-66 S300 (S3xx61) 66 600 960 DE-107162Brake resistor BAR(U) 1000-66 66 1000 1600 DE-107163Brake resistor BAR(U) 300-9191 300 480 DE-107164Brake resistor BAR(U) 600-91 S300 (S3xx01) 91 600 960 DE-107165Brake resistor BAR(U) 1000-91 91 1000 1600 DE-10716628 <strong>Accessories</strong> Manual Europe

<strong>Kollmorgen</strong> 05/2013 Brake resistors7.5 External brake resistor BAFP(U)Protection class: IP40The surface temperature can exceed 250°C.Risk of burns and fire! Measure the temperaturebe<strong>for</strong>e touching.<strong>Accessories</strong> Manual Europe 29

Brake resistors 05/2013 <strong>Kollmorgen</strong>7.6 External brake resistor BAR(U)Protection class: IP20The surface temperature can exceed 250°C.Risk of burns and fire! Measure the temperaturebe<strong>for</strong>e touching.30 <strong>Accessories</strong> Manual Europe

<strong>Kollmorgen</strong> 05/2013 Brake resistors7.7 External brake resistor BAS(U)Protection class: IP20The surface temperature can exceed 250°C.Risk of burns and fire! Measure the temperaturebe<strong>for</strong>e touching.<strong>Accessories</strong> Manual Europe 31

Brake resistors 05/2013 <strong>Kollmorgen</strong>This page has been deliberately left blank.32 <strong>Accessories</strong> Manual Europe

<strong>Kollmorgen</strong> 05/2013 Capacitor Modules8 Capacitor Modules8.1 GeneralKCM modules (KOLLMORGEN Capacitor Modules) absorb energy generated by the motorwhen it is operating in generator mode. Normally, this energy is dissipated as waste via brake resistors.KCM modules, however, feed the energy they have stored back into the DC Bus link as andwhen it is required.KCM-SKCM-PKCM-ESaves energy: The energy stored in the capacitor module during regenerative braking is availablethe next time acceleration happens. The module’s inception voltage is calculated automaticallyduring the first load cycles.Power in spite of power failure: If the power supply fails, the module provides the <strong>servo</strong> amplifierwith the stored energy that is required to bring the drive to a standstill in a controlled manner (thisonly applies to the power supply voltage; battery-back the 24 V supply separately).Erxpansion module <strong>for</strong> both applications. Expansion modules are available in two capacitanceclasses.8.2 Important notesDC Bus link terminals in <strong>servo</strong> <strong>systems</strong> carry high DC voltage of up to900 V. Touching the terminals while they are carrying voltage is extremelydangerous. Switch off (disconnect) the line voltage. You must only workon the connections when the system is disconnected.It can take over an hour <strong>for</strong> the modules to self-discharge. Check thestate of charge with a measuring device that is suitable <strong>for</strong> a DC voltageof up to 1,000 V. When measuring a voltage of over 40 V between theDC+/DC- terminals or to ground, discharge the modules as described inthe KCM Instructions Manual.You must read the instructions manual <strong>for</strong> the <strong>servo</strong> amplifier/<strong>servo</strong>motor you are using in yourapplication and observe the safety instructions they contain be<strong>for</strong>e commencing mounting/installationwork.Wiring diagram and mor important notes concerning wiring can be found in the KCM instructionsmanual and in the instructions manual of the used <strong>servo</strong> amplifier.8.3 Type assignment8.4 Order codesServo amplifier KCM Module Servo amplifier KCM ModuleS300 all Modules S640 - S670 not allowedS400 all Modules S748 - S772 not allowedS601 - S620 all Modules AKD-x00306...02406 not allowedS701 - S724all ModulesAKD-x00307...02407 all ModulesType/Order CodeKCM-S200-0000KCM-P200-0000KCM-E200-0000KCM-E400-0000RemarksEnergy Saving Module, 1.6 kWsPower Module, 2 kWsExpansion Module 2 kWsExpansion Module 4 kWs<strong>Accessories</strong> Manual Europe 33

Capacitor Modules 05/2013 <strong>Kollmorgen</strong>8.5 KCM ModuleObserve the safety instructions in chapter 8.2 and in the instructionmanual of the <strong>servo</strong> amplifier.Permissible assembly type: Vertical, ground connections at the bottom. Otherassembly positions are not permitted. Observe the required free space to nextdevice. Ensure there is unobstructed convection <strong>for</strong> cooling purposes.Technical DataStorage Rated supply Peak supplyInceptionPower ProtectionWeightType Capacity voltage voltagevoltage[kW] Class[kg][Ws] [V=][V=][V=]KCM-S200 1600calculated 6,9KCM-P200 2000 max 950 VDC470 VDC 6,9max 850 VDC18 IP20KCM-E200 2000 (30s in 6min)- 4,1KCM-E400 4000 - 6,234 <strong>Accessories</strong> Manual Europe

<strong>Kollmorgen</strong> 05/2013 Motor chokes9 Motor chokes9.1 GeneralShielded motor cablesFor reasons of electromagnetic compatibility, the motor must be supplied with power via a shieldedcable. The structure of a cable with 100% shielding and the capacity equivalent circuit diagram (toearth) are shown below.Why use motor chokes?To compensate high capacitive charge/discharge currents typical of shielded motor cables approx.25 m and longer.To reduce current alternation noise in the motor.To reduce current ripple in the motor.The <strong>digital</strong> <strong>servo</strong> amplifiers’ high switching frequencies and steep switching edges give rise to thetransfer of capacitive currents to the shield by the three phases (U, V, W). These currents flow fromthe shield to earth. Depending on the cable length and cable capacity (determined by design), thiscan lead to the generation of shield currents with peak values of up to 20 A.These shield currents place a load on the <strong>servo</strong> amplifiers and motor and, on large <strong>systems</strong>, lead toshifts in potential which can damage other components.This effect is evident in particular on <strong>systems</strong> with multiple amplifiers operating in parallel on thesame mains filter.The motor chokes slow down the rate of rise of the motor current (reduce edge steepness), therebyreducing the current transferred to the shield.Why is the cross-section of the motor cable important?Motor cables longer than 50 m with a small cross-section (e.g. 4 x 1.0 mm²) and there<strong>for</strong>e a higherequivalent resistance are able to reduce the oscillation tendency of the LCR oscillating circuit(amplifier/choke/cable/motor). This cross-section can also be advantageous <strong>for</strong> cable lengths shorterthan 50 m if the cable capacity and motor inductance are very high. However, the current loadingof the cable must always be within the limits specified by EN 60204.<strong>Accessories</strong> Manual Europe 35

Motor chokes 05/2013 <strong>Kollmorgen</strong>9.2 Important notesThe choke can become hot during operation (rising to temperatures inexcess of 80°C). Risk of fire! There<strong>for</strong>e, you should make sure that thechoke is mounted a sufficient distance away from neighbouringcomponents. Provide the requisite conditions <strong>for</strong> unobstructed convectionto cool the choke.You must read the instructions manual <strong>for</strong> the <strong>servo</strong> amplifier/<strong>servo</strong> motor you are using in yourapplication and observe the safety instructions they contain be<strong>for</strong>e commencing mounting/installationwork. This manual is only valid in conjunction with the instructions manual <strong>for</strong> the <strong>servo</strong> amplifierand <strong>servo</strong> motor you are using in your application.Mount the motor choke 3YLN on a conductive earthed assembly plate in the switchgear cabinet.The choke box 3YL-24 can be mounted to DIN rails as well.The motor choke is wired into the cable close to the amplifier. When laying the motor cable, allowabout 400 mm <strong>for</strong> the connection to the choke.Connection diagram see the <strong>servo</strong> amplifier instructions manual.9.3 Type assignmentServo amplifier Motor choke ConditionS300 3YL-24, 3YLN-xx Motor cable 25mS400 3YL-24, 3YLN-xx Motor cable 25mS601...620 3YL-24, 3YLN-xx Motor cable 25mS701...724 3YL-24, 3YLN-xx Motor cable 25mS748/772usually not required, in case of cable length 25mand unusual conditions, ask our customer supportAKD-X003x to AKD-X006x 3YLN-06 Motor cable 25mAKD-X012x 3YLN-14 Motor cable 25mAKD-X024x 3YLN-24 Motor cable 25m9.4 Order codesArticle Nominal Current Approvals Order codeMotor choke box 3YL-24 24 A CE DE-90074Motor choke 3YLN-06 6 A CE, UL DE-107929Motor choke 3YLN-10 10 A CE, UL DE-107930Motor choke 3YLN-14 14 A CE, UL DE-107931Motor choke 3YLN-20 20 A CE, UL DE-107932Motor choke 3YLN-24 24 A CE, UL DE-20144736 <strong>Accessories</strong> Manual Europe

<strong>Kollmorgen</strong> 05/2013 Motor chokes9.5 Motor choke 3YL-24Technical data:Rated data Sym Unit 3 YL-24Rated Current I 0rms A Max.3x24Frequency f max kHz 8.3Inductivity L µH 120Resistance R mOhm 2.6Weight G kg 1.4Cable diameter (Shield clamp) - mm 4 to 13.5Wire cross section U-V-W max. (terminals) - mm² 4Wire cross section BR+/- max. (terminals) - mm² 2.5<strong>Accessories</strong> Manual Europe 37

Motor chokes 05/2013 <strong>Kollmorgen</strong>9.6 Motor choke 3YLN-xxTechnical Data:Rated Data Sym DIM 3YLN-06 3YLN-10 3YLN-14 3YLN-20 3YLN-24Rated current I 0rms A 6 10 14 20 24Rated voltage U nom V 480Rated frequency f nom Hz 0 to 150Max. frequency f max kHz 8Inductivity L µH 900 900 900 450 450Power loss P W 12 14.5 19.4 22.3 23.2Protection class - - IP00Temperature class - - FOperation class - - S1Weight G kg 4.5 5.5 10 10 10Cable diameter(Shield clamp)- mm 4 to 13.5Wiring cross sectionmax. (Terminals)- mm² 10 10 16 16 16Width A mm 155 155 190 190 190Depth B mm 90 105 125 125 125Height C mm 195 195 230 230 230Mounting hole distance D mm 130 130 170 170 170Mounting hole distance E mm 56.5 71.5 78 78 78Mounting screws F - 4xM6 4xM6 4xM6 4xM6 4xM638 <strong>Accessories</strong> Manual Europe

<strong>Kollmorgen</strong> 05/2013 Cables10 Cables<strong>Kollmorgen</strong> assumes no liability <strong>for</strong> errors or damage to equipment caused by cables manufacturedby customers.10.1 Technical data <strong>for</strong> cablesThe table below lists the technical data <strong>for</strong> <strong>Kollmorgen</strong> Europe standard cables. Further in<strong>for</strong>mationon the chemical, mechanical and electrical characteristics of the cables can be found in ourTechnical WIKI (Cables).Insulation materialSheathing PUR (polyurethane, code 11Y)Core insulation PETP (polyesteraphthalate, code 12Y)Capacitance (phase to shield)Motor cableless than 180 pF/m (cross sections >6mm² have larger capacitance)RES/encoder cable less than 120 pF/mTechnical data— The brackets in the core definition indicate the shielding— All cables are suitable <strong>for</strong> use as trailing cables— The technical data refer to use as moveable cables— Operating life : 10 million bending cycles— All cables are UL recognizedCores[mm²]10.2 ToolsOperatingTemperature Range[°C]OutsideDiameter*[mm]min. Bending Radius*static/moved[mm](3x0,5) -30 / +80 6 40/60(4x1) -30 / +80 9 60/90(4x1,5) -30 / +80 10 60/100(4x2,5) -30 / +80 12 80/120(4x4) -30 / +80 13 80/130(4x6) -30 / +80 16 100/160(4x10) -30 / +80 19 120/190(4x16) -30 / +80 24 150/240(4x25) -30 / +80 27 170/270(4x1+(2x1)) -30 / +80 10 60/100(4x1,5+(2x1)) -30 / +80 11 70/110(4x2,5+(2x1)) -30 / +80 14 90/140(4x4+(2x1)) -30 / +80 15 90/150(4x6+(2x1)) -30 / +80 17 110/170(4x10+(2x1,5)) -30 / +80 22 140/220(4x16+(2x1,5)) -30 / +80 26 104/195(4x25+(2x1,5)) -30 / +80 29 117/219(4x1+2x(2x0,75)) -30 / +80 12 48/90(4x1,5+2x(2x0,75)) -30 / +80 13 51/95(2x(2x0,25)) -30 / +80 6 40/60(4x(2x0,25)) -30 / +80 8 50/80(7x(2x0,25)) -30 / +80 9 60/90(8x(2x0,25)) -30 / +80 10 60/100*Tolerance +/- 5%Only work with the special tools that are required <strong>for</strong> the used connectors. You can obtain thesespecial tools from the manufacturer of the connectors or contacts.<strong>Accessories</strong> Manual Europe 39

Cables 05/2013 <strong>Kollmorgen</strong>10.3 PC connection10.3.1 Order codesS300, S400, S600, S700<strong>Kollmorgen</strong> <strong>digital</strong> "Sx" type <strong>servo</strong> amplifiers are equipped with a serial RS232 interface to facilitatecommunication with a standard personal computer (PC). Various types of interface can be used onthe PC. Appropriate cables and in some cases specific accessories will be required to establish theconnection between <strong>servo</strong> amplifier and PC.AKDThe AKD is connected by a standards net cable with RJ45 connectors to the PC or to a Switch/Hub.These cables are described as Ethernet cables on page 57.ArticleOrder CodeCable PC-S300/S400/S600/S700 3m, 9polesDE-90067Setup Kit S300/S400/S600/S700 USBDE-107666Y-Adapter <strong>for</strong> splitting CAN/RS232 and Multilink see p.4410.3.2 PC connection serial USBAn interface converter is required to use the USB interface on a PC. Our "USB" setup kits contain aUSB serial converter and a serial PC cable suitable <strong>for</strong> the amplifier type.Setup Kit S300, S400, S600, S700 USB10.3.3 PC connection serial RS232For the purpose of parameterisation and <strong>for</strong> firmware upgrades, the <strong>servo</strong> amplifiers can be connectedto the serial RS232 interface on a PC. The connecting cable must be shielded. The braidedshield on the RS232 connecting cable is conductively connected to the front panel of the <strong>servo</strong>amplifier via the connector housing on the Sub-D male connector.PC cable <strong>for</strong> S300, S400, S600, S70040 <strong>Accessories</strong> Manual Europe

<strong>Kollmorgen</strong> 05/2013 Cables10.3.4 Preparing serial PC cables <strong>for</strong> S300/S400/S600/S700There are two possible options <strong>for</strong> the interface cables between the <strong>servo</strong> amplifier and your PC. Tofind out which one is correct in your case, you must check the serial interface of the PC that is goingto be connected to the <strong>servo</strong> amplifier. It will be either a 25-pin or a 9-pin SubD connector. Theinterface cable must not be longer than 5m.Material listPart Designation Order codeCable LiYCY 3x0.5mm² DE-91838 (cut to length)SubD socket, 9-pin SubD socket, 9-pin with solder buckets DE-56347Housing, 9-pin Housing <strong>for</strong> 9-pin SubD connector, shielded DE-91904SubD socket, 25-pin SubD socket, 25-pin with solder buckets DE-51870Housing, 25-pin Housing <strong>for</strong> 25-pin SubD connector, shielded DE-82455Screw Fixing screw <strong>for</strong> SubD housing DE-81906The materials listed ensure that the shielding of the cable makes an electrical connection with thehousing of the SubD connectors. If you use materials that do not provide this connection, then youwill have to <strong>for</strong>m the shielding braid into a pigtail, insulate it, and solder it to the body of the SubDconnector.Wiring diagram (example S600)Please note that the view is that seen looking at the back of the sockets (solder side).Using order code DE-90105 you can obtain an adapter plug from us, so that you can plug an interfacecable that is made up <strong>for</strong> the 9-pin RS232 interface into the 25-pin interface. With this adapter,you only need one type of cable <strong>for</strong> different types of PC.<strong>Accessories</strong> Manual Europe 41

Cables 05/2013 <strong>Kollmorgen</strong>Preparing cablesRemove the outer covering of thecable over a length of about 25mm,without damaging the shielding braid.Push the shielding braid back overthe outer covering of the cable, andstrip off the ends of the cores over alength of about 5mm, without damagingthe copper strands.Push a suitable piece of heat-shrinktubing over the outer cover, and heatit up. Leave about 7mm free at theend. Solder the ends of the cores intothe solder buckets of the SubD connector,with a link of insulated wire(see diagram) if required.Use the strain relief to fix the cable tothe bottom half of the housing. Do notovertighten the screws, or the cablewill be crushed. Place the SubD connector,with the wider side below, inthe bottom half of the housing.Check the connections be<strong>for</strong>e closingthe housing, since it cannot be openedagain afterwards withoutdamage. Place the fixing screw inposition in the housing, and thenpress the two halves of the housingfirmly together. Take care that thefixing screw and the SubD connectorinsert are properly located.The 25-pin SubD connector is basically assembled in the same way as the 9-pin version, with thedifference that there are two fixing screws. A separate description is there<strong>for</strong>e not necessary.42 <strong>Accessories</strong> Manual Europe

<strong>Kollmorgen</strong> 05/2013 Cables10.3.5 Y Adapter (Splitter) <strong>for</strong> S300/S600/S700The signals <strong>for</strong> the serial link to the PC and the CAN interface are routed via the same connector onthe <strong>servo</strong> amplifier (X6). Our Y adapters can be used <strong>for</strong> simultaneous access to both interfaces. Inthis case, the interface signals are routed via separate connectors.Order codesArticleY-Programming-Adapter 1 AxisY-Adapter -SR6Y- 4 axes (Multilink cable)Y-Adapter -SR6Y6- 6 axes (Multilink cable)Order CodeDE-108211DE-90060DE-92042Y programming adapter <strong>for</strong> 1 AxisThe multi-axis Y adapters support the simultaneous setup (multi-link) of a number ofS300/S600/S700 in a single setup session.Y adapter <strong>for</strong> 4 axesY adapter <strong>for</strong> 6 axes<strong>Accessories</strong> Manual Europe 43

Cables 05/2013 <strong>Kollmorgen</strong>Preparing a Y-AdapterA Y-Adapter is used to connect several <strong>servo</strong> amplifiers simultaneously to one PC. The communicationbetween the <strong>servo</strong> amplifiers is then carried out according to the CANopen protocol, and theconnection to the PC is made via the RS232 serial interface.Cable dataCharacteristic impedanceCable capacitanceConductor (loop) resistance100-120 max. 60 nF/km159.8 /kmCable length, depending on the transmission rate:Transmission rate / kbps 1000 500 250Max. cable length / m 20 70 115The table refers to the total cable length between the ends of the CANopen bus. The length of cablebetween the PC and the first bus connector must not be more than 5m.Longer transmission distances can be achieved with a lower cable capacitance (max. 30 nF/km)and lower loop resistance (115 /km).For EMC reasons, the SubD connector housings at the amplifier end must fulfil the following conditions:— metal or metallic-coated housing— provision <strong>for</strong> connecting the cable shielding to the housing, large-area connectionMaterial listPart Designation Order CodeCable, PC end LiYCY 3x0.5mm² DE-91838 (to length)Cable, controller end Li2YCY (TP) 2x2x0.25mm² DE-86834 (to length)SubD socket PC end SubD connector 9-pin with solder buckets DE-56347SubD cover PC end Housing <strong>for</strong> 9-pin SubD connector with shielding DE-81905Fixing screw PC end Fixing screw <strong>for</strong> SubD housing DE-81906SubD kit, controller end 9-pin SubD connector (socket) DE-90650Wiring diagram (<strong>for</strong> S300, S600, S700)The wiring diagram shown below is an example <strong>for</strong> the use of a Y-adapter with 4 <strong>servo</strong> amplifiers . Ifyou need more connections, then add them in between Slave 1 and Slave 4. The additional connectorsare wired up exactly as Slave 2/3. If your cable has more connectors than you need, any ofthem can be left free.44 <strong>Accessories</strong> Manual Europe

<strong>Kollmorgen</strong> 05/2013 CablesPreparing cables: PC endRemove the outer covering of thecable over a length of about25mm, without damaging theshielding braid.Push the shielding braid backover the outer covering of thecable, and strip off the ends ofthe cores over a length of about5mm, without damaging the copperstrands.Push a suitable piece ofheat-shrink tubing over the outercover, and heat it up. Leaveabout 7mm free at the end. Solderthe ends of the cores into thesolder buckets of the SubD connector,with a link of insulatedwire (see diagram).Use the strain relief to fix thecable to the bottom half of thehousing. Do not overtighten thescrews, or the cable will be crushed.Place the SubD connectorwith the wider side below, in thebottom half of the housing.Check the connections be<strong>for</strong>eclosing the housing, since it cannotbe opened again afterwardswithout damage. Place the fixingscrew in position in the housing,and then press the two halves ofthe housing firmly together. Takecare that the fixing screw and theSubD connector insert are properlylocated.<strong>Accessories</strong> Manual Europe 45

Cables 05/2013 <strong>Kollmorgen</strong>Preparing cables: amplifier endRemove the outer covering of thecable over a length of about 60mm,without damaging the shielding braid.Push the shielding braid back over theouter covering of the cable, and stripoff the ends of the cores over a lengthof about 7mm, without damaging thecopper strands. The length variesaccording to the type of bootlaceferrule that is used.Push a suitable piece of heat-shrinktubing over the outer cover, and heat itup. Leave about 7mm free at the end.Fit appropriate bootlace ferrules to thecores. Depending on which type ofconnector you are preparing, use diagramA (first bus connector), B (middlebus connector) or C (last bus connector).Use ferrules <strong>for</strong> twin wires if youhave to connect two cores, or one coreand a termination resistor to a singleconnection.Use the strain relief to fix the cable tothe bottom half of the housing. Do notovertighten the screws, or the cablewill be crushed. Wire up the terminalsaccording to the wiring diagram inChapter 10.3.5, and place the connectorp.c.b. with the terminals underneathin the lower half of the housing.Put the two knurled screws in place,and press the two halves of the housingtogether until the four lugs snapinto position.Take care that the connector p.c.b.and the knurled screws are properlylocated.46 <strong>Accessories</strong> Manual Europe

PE<strong>Kollmorgen</strong> 05/2013 Cables10.4 Power Voltage Supply, external brake resistor, DC bus linkThe connectors used (40 A and higher fixed terminals) are included in the scope of supply of the<strong>servo</strong> amplifier. If necessary, the connectors are coded and printed with the corresponding terminaldesignation. The table indicates the type of cable required <strong>for</strong> each intended purpose.We do not deliver configured cables <strong>for</strong> this interface.You must always observe the specifications in respect of cable cross-sections contained in theinstructions manual <strong>for</strong> the <strong>servo</strong> amplifier you are using in your application.Fit suitable wire end ferrules or plug connectors to stripped conductors. A connection diagram appearsin the <strong>servo</strong> amplifier instructions manual.10.4.1 Mating connector (part of delivery)AKD-X02406/0xx07X4Mains supply 1 Mains supply 2 DC-link bus Brake resistorAmplifier # Order Code # Order Code # Order Code # Order CodeS300-230V X0 DE-105856 - - X8 DE-107556 X8 DE-107556S300-400V X0 DE-107557 - - X8 DE-107558 X8 DE-107558S400 X0 DE-102583 - - X0 DE-102583 X0 DE-102583S601...620 X0A DE-92258 X0B DE-92259 X7 DE-90064 X8 DE-90065S701...724 X0 DE-200451 - - X8 DE-200452 X8 DE-200452AKD-X00306/00606 X3CON-CON-CON-- - X3X3AKDX3A-SLAKDX3A-SLAKDX3A-SLAKD-X01206 X3CON-CON-CON-- - X3X3AKDX3B-SLAKDX3B-SLAKDX3B-SLCON-AKDX4-SL10.4.2 Mating connector (optional)- - X3Mains supply DC-link bus / Brake resistorAmplifier # Order Code # Order CodeS701...724 X0Y DE-200851 X8Y DE-200852S701...724 XOF DE-200955 X8F DE-200956AKD-X02406/0xx07 X3Y CON-AKDX3C-SL-YCON-AKDX3C-SLX3CON-AKDX3C-SLWith Y-connectors you can daisy-chain supply voltage or DC-bus link to several amplifiers. Fordetails see instructions manual of the <strong>servo</strong> amplifier. The F-connectors are <strong>for</strong> fast wiring (noscrews).S700AKDX0F X0Y X8F X8Y X3YL1L2L3PEL3L2+RB +RBe+RBi -DC-DC+RBe+RBiPEL3L2L1+RBL110.4.3 Recommended cable typemax.recommended cable @ amplifier rated output currentPurposelengthIn=1.5...10A In=14...24A In=40...70AAC-supply* - H07V-K 1.5 H07V-K 4 H07VVC4-K 3G 2520cm H07V-K 1.5 H07V-K 4 H07V-K 25DC-bus link*2m H07VVC4-K 2X 1.5 H07VVC4-K 2X 4 H07VVC4-K 2X 25Ext. brake resistor* 5m H07VVC4-K 2G 1.5 H07VVC4-K 2G 25* valid only <strong>for</strong> single-axis <strong>systems</strong>. For multi-axis <strong>systems</strong>, please consult our customer support.<strong>Accessories</strong> Manual Europe 47

Cables 05/2013 <strong>Kollmorgen</strong>10.4.4 Preparing cables <strong>for</strong> AKD/S300/S400/S601...620/S700The connections are on the underside or frontside of the <strong>servo</strong> amplifier. Terminal connectors areused, which are included in the delivery package <strong>for</strong> the <strong>servo</strong> amplifier. The connectors are codedand have the appropriate connection designation printed on them. They must never be mixed up.Follow the pin assignment in the instructions manual. When connecting an external brake resistor,please note that the link cable must first be removed.Preparing unshielded cablesIf shielding is not necessary, then we recommend using single cores <strong>for</strong> the wiring inside the switchgearcabinet. Select them from the table above, according to your requirements.Strip off about 10mm of the insulation at the ends of the cores.Take care to avoid damage to the copper strands while doing this.Depending on the cross-section of the core and the type of bootlaceferrule that is used, the length that has to be stripped mayvary by several millimetres.Apply bootlace ferrules to the conductors. As an alternative, youcan also use terminal pins.Connector example S600:Push the ends of the conductors into the connector as far as theywill go. Follow the pin assignment in the connection table above.Tighten the screws of the terminals. Take care that the insulationis not trapped in the terminals.48 <strong>Accessories</strong> Manual Europe

<strong>Kollmorgen</strong> 05/2013 CablesPreparing shielded cablesFirst, remove the outer coveringof the cable and the shieldingbraid over a length of about70mm. Then remove just theouter covering <strong>for</strong> about another50mm, without damaging theshielding braid.Strip off about 10mm of the insulationfrom the ends of the cores.Take care to avoid damage tothe copper strands while doingthis. Depending on the crosssectionof the core and the typeof bootlace ferrule that is used,the length that has to be strippedmay vary by several millimetres.Apply bootlace ferrules to theconductors.As an alternative, you can alsouse terminal pins instead of bootlaceferrules.Connector example S600:Push the ends of the conductorsinto the connector as far as theywill go. Follow the pinassignment in the instructionsmanual. Tighten the screws ofthe terminals. Take care that theinsulation is not trapped in theterminals.<strong>Accessories</strong> Manual Europe 49

Cables 05/2013 <strong>Kollmorgen</strong>10.4.5 Preparing cables <strong>for</strong> S748/772The connections <strong>for</strong> the power supply, the ballast resistor and the DC-link are made through terminalson the bottom of the <strong>servo</strong> amplifier. These terminals can accept core cross-sections from 10to 50mm².The AC supply connection is used as an example <strong>for</strong> preparing a cable.Remove the outer covering of the cableover a length of about 250mm, withoutdamaging the shielding braid.Shorten the shielding to a length of about70mm.Shorten the three cores <strong>for</strong> the supply phasesto 200mm. Strip off all cores <strong>for</strong> a lengthof about 25mm. This length depends on thecore cross-section and the bootlace ferrulesthat are used.Apply bootlace ferrules to the conductors.Connect up the cable according to thewiring diagram in the instructions manual <strong>for</strong>the <strong>servo</strong> amplifier and take care that noinsulation is trapped in the terminals.50 <strong>Accessories</strong> Manual Europe

<strong>Kollmorgen</strong> 05/2013 Cables10.5 24V auxiliary voltage supplyConnectors are used, that are included in the delivery package of the <strong>servo</strong> amplifiers. If necessary,the connectors are coded and printed with the corresponding terminal designation.We do not deliver configured cables <strong>for</strong> this interface.You must always observe the specifications in respect of cable cross-sections contained in theinstructions manual <strong>for</strong> the <strong>servo</strong> amplifier you are using in your application.Fit suitable wire end ferrules or plug connectors to stripped conductors. A connection diagram appearsin the <strong>servo</strong> amplifier instructions manual.10.5.1 Mating connector (part of delivery)Amplifier Connector Order CodeS300 X4 DE-107555S400 X0 DE-102583S601...620 X4 DE-90062S701...724 X4A DE-200449S701...724 X4B DE-200450S748/772 X4 DE-201241S748/772 X9B DE-201193AKD X1 DE-20162810.5.2 Recommended cable typePurpose24V Aux. VoltageObserve voltage drop!recommended cableH07V-K 1.5 oder H07V-K 2.5<strong>Accessories</strong> Manual Europe 51

Cables 05/2013 <strong>Kollmorgen</strong>10.5.3 Preparing cablesThe connection is on the front panel of the <strong>servo</strong> amplifier. A Combicon connector is used, which isincluded in the delivery package of the <strong>servo</strong> amplifiers.Strip off about 10mm of the insulation at the ends of the cores.Take care to avoid damage to the copper strands while doingthis. Depending on the cross- section of the core and the type ofbootlace ferrule that is used, the length that has to be strippedmay vary by a few millimetres.Apply bootlace ferrules to the conductors.As an alternative, you can also use terminal pins instead.Connector example S601...620:Push the ends of the conductors into the connector as far asthey will go. Follow the pin assignment in the instructionsmanual. Tighten the screws of the terminals. Take care that theinsulation is not trapped in the terminals.52 <strong>Accessories</strong> Manual Europe

<strong>Kollmorgen</strong> 05/2013 Cables10.6 Digital/analog Inputs/OutputsThe cables <strong>for</strong> analog signals must be twisted pairs, and shielded. The <strong>digital</strong> signals can be connectedby single wires.We do not deliver configured cables <strong>for</strong> this interface.10.6.1 Mating connector (part of delivery)Digital / analog signalsAS/STOAmplifier # Order Code # Order Code # Order CodeS300 X3 DE-107554 - - X4 DE-107555S400 X3 DE-102585 X1 DE-102584 - -S601...620 X3 DE-90061 - - X10 DE-101696S701...724 X3A DE-200447 X3B DE-200448 X4B DE-200450S748/772 X3A DE-200447 X3B DE-200448 X4 DE-201241AKD X7 DE-201633 X8 DE-201634 X1 DE-20162810.6.2 Recommended cable typePurposeDigital I/OBTBDigital GNDAnalog SetpointAnalog GNDmax.length10m10m10m25m25mrecommended cableH07VK 0,5LiYCY (TP) 4x2x0.25Color codeSignal Color* CableAGNDGYanalog in 1+WHanalog in 1-BNanalog in 2+GNanalog in 2-YELiYCY (TP) 4x2x0.25analog out 1PKanalog out 2BUAGNDRD* according to IEC 60757<strong>Accessories</strong> Manual Europe 53

Cables 05/2013 <strong>Kollmorgen</strong>10.6.3 Preparing cablesFor simplicity, the instructions <strong>for</strong> preparationonly show the section with thecores that have to be shielded and twistedpairs.Remove the outer covering and theshielding braid over a length of about100mm. Remove another section of theouter covering, about 30mm long, withoutdamaging the shielding braid.Secure the cores where they emerge,with a cable tie. Strip off the insulationfrom the cores <strong>for</strong> a length of about5mm, without damaging the copperstrands. This length can vary, accordingto the type of bootlace ferrule that isused.Fit appropriate bootlace ferrules (or terminalpins) to the bared ends of thecores.Wire up the screw terminals of the connectoraccording to the wiring diagram(see also the instructions manual <strong>for</strong> the<strong>servo</strong> amplifier). Tighten the screws andtake care that the insulation is not trappedin the terminals.54 <strong>Accessories</strong> Manual Europe

<strong>Kollmorgen</strong> 05/2013 Cables10.7 ROD/SSI, Stepper motor control, Master-SlaveThis interface can be used <strong>for</strong> several applications (see the amplifiers instructions manual). Thematerial requirements are always the same.We do not deliver configured cables <strong>for</strong> this interface.10.7.1 Mating connector, cable typeArticle Description Order CodeCable 4x2x0.25 (per meter) DE-92186Sub-D connector kit Socket 9-pol., housing and screws DE-81784Connector kit, amplifierend AKD, X9/X1010.7.2 ConnectionX10 male connector 15pin high desity, X9 female connector9pin, 2 housings, screwsAKD-X9+X10-KitThe cable used must be shielded, with twisted pairs to (suggestion acc. to DIN 47100). Since it isimportant which signal pairs are twisted together, the following table shows the colours of the individualcores (to IEC 60757).SubD9S300/S400/S600/S700SubD9, X9AKDCore color @ 5x2x0.25ROD1 3 WH WH2 7 GN n.c.3 8 YE n.c.4 1 GY GN5 2 PK YE6 4 BU GY7 5 RD PK8 n.c. 6 BK BK9 n.c. 9 BN n.c.SSI,Stepper motor control, Master-SlaveThe connector assignment is determined by the use of the interface; see the <strong>servo</strong> amplifier instructionsmanual.10.7.3 Termination resistorsDepending on <strong>servo</strong> amplifier type (see instructions manual <strong>for</strong> the <strong>servo</strong> amplifier) and application,the cable must be terminated by termination resistors at the amplifier end or the control end. Sincethe termination resistors are only installed at the slave end in master-slave operation, the cable isnot end-to end symmetrical, although it is wired 1:1.Take note of the following table (valid <strong>for</strong> S300/S400/S600/S700):Interface function (S300/S400/S600/S700)Pin ROD SSI Stepper motor control Master-SlaveAmplifier Controller Amplifier Controller Amplifier Controller Master Slave1 - - - - - - - -2 -R 150 - - - - - -3 - - - - - - -4 -R 150 R 150 - R 150 - - 5 - - - -R 1506 -R 150 - R 150 R 150 - - 7 - - - -R 1508 - - - - - - - -9 - - - - - - - -The resistance values depend on the characteristic impedance of the cable material<strong>Accessories</strong> Manual Europe 55

Cables 05/2013 <strong>Kollmorgen</strong>10.7.4 Preparing cablesRemove the outer covering of thecable over a length of about25mm, without damaging theshielding braid.Push the shielding braid backover the outer covering of thecable, and strip off the ends of thecores over a length of about 5mm,without damaging the copperstrands.Push a suitable piece of heatshrinktubing over the outer cover,and heat it up. Leave about 7mmfree at the end.Solder the ends of the cores (withthe resistors where required) intothe solder buckets of the SubDconnector. Insulate the connectionsand the resistors so thatthere can be no accidental contactbetween them or with theconnector housing.Use the strain relief to fix thecable to the bottom half of thehousing. Do not overtighten thescrews, or the cable will be crushed.Place the SubD connector,with the wider side below, in thebottom half of the housing.Check the connections be<strong>for</strong>e closingthe housing, since it cannotbe opened again afterwards withoutdamage. Place the fixingscrew in position in the housing,and then press the two halves ofthe housing firmly together. Takecare that the fixing screw and theSubD connector insert are properlylocated.56 <strong>Accessories</strong> Manual Europe

<strong>Kollmorgen</strong> 05/2013 Cables10.8 Ethernet cableConnection to an Ethernet network is possible via two RJ45 connectors in the <strong>servo</strong> amplifiers.These cables can be used <strong>for</strong> all fieldbus connections with standard RJ45 connectors like Ether-CAT, ProfiNET, SynqNet and also <strong>for</strong> the EtherNet TCP/IP Service Port connection of an AKD<strong>servo</strong> amplifier.10.8.1 Order codes Ethernet cable, configuredArticle Length Order codeEthernet cable 0,10m CBN000-002-m10-00Ethernet cable 0,30m CBN000-002-m30-00Ethernet cable 0,50m CBN000-002-m50-00Ethernet cable 1,00m CBN000-002-001-00Ethernet cable 3,00m CBN000-002-003-00Ethernet cable 5,00m CBN000-002-005-00Ethernet cable 10,00m CBN000-002-010-00<strong>Accessories</strong> Manual Europe 57

Cables 05/2013 <strong>Kollmorgen</strong>10.9 CAN bus cableAccording to ISO 11898 you should use a bus cable with a characteristic impedance of 120 . Theusable cable length depends on the transmission rate. The values that we have measured can betaken as a guide, but they should not be interpreted as limits:Cable dataCharacteristic impedanceCable capacitanceConductor (loop) resistance100-120 max. 60 nF/km159.8 /kmCable length, depending on the transmission rate:Transmission rate / kbps 1000 500 250max. cable length / m 20 70 115The table refers to the total cable length between the ends of the bus.Longer transmission distances can be achieved with a lower cable capacitance (max. 30 nF/km)and lower loop resistance (115 /km).10.9.1 CAN bus cable <strong>for</strong> AKDWe deliver configured CAN bus cables <strong>for</strong> AKD.Article Length AKD Order codeCAN Bus cable 0,15m CBP000-002-m15-00CAN Bus cable 0,30m CBP000-002-m30-00CAN Bus cable 1,00m CBP000-002-001-00CAN Bus cable 3,00m CBP000-002-003-00The CAN Termination connector is required <strong>for</strong> bus termination of the last AKD connected to theCAN bus. For connecting an AKD to a CAN device with SubD9 connector the CAN RJ12-SubD9Adapter can be used.ArticleCAN Termination connectorCAN RJ12->SubD9 adapterOrder codeAKD-CAN-TerminationAKD-CAN-RJ12-SubD910.9.2 Can bus cable <strong>for</strong> S300/S400/S600/S700We do not deliver configured cables <strong>for</strong> S300/S400/S600/S700.The materials in the table below ensure that all the requirements are met <strong>for</strong> a CANopen bus cable.Part Designation Order codeCable Li2YCY (TP) 2x2x0.25mm² DE-86894 (cut to length)SubD kit 9-pin SubD connector (socket) DE-90650If your cable has more connectors than you need, any of them can be left free.For EMC reasons, the SubD connector housings must fulfil the following conditions:— metal or metallic-coated housing— provision <strong>for</strong> connecting the cable shielding to the housing, large-area connectionWiring diagram58 <strong>Accessories</strong> Manual Europe

<strong>Kollmorgen</strong> 05/2013 CablesPreparing cablesRemove the outer covering of the cableover a length of about 50mm, withoutdamaging the shielding braid.Push the shielding braid back over theouter covering of the cable, and strip offthe ends of the cores over a length ofabout 7mm, without damaging the copperstrands. The length can vary accordingto the type of bootlaceferrule that is used.Push a suitable piece of heat-shrinktubing over the outer cover, and heat itup. Leave about 7mm free at the end.Fit appropriate bootlace ferrules to thecores. Depending on which type of connectoryou are preparing, use diagramA (inner bus connector), or B (outer busconnector). Use ferrules <strong>for</strong> twin wires ifyou have to connect two cores, or onecore and a termination resistor to asingle connection.Use the strain relief to fix the cable tothe bottom half of the housing. Do notovertighten the screws, or the cable willbe crushed. Wire up the terminalsaccording to the wiring diagram inChapter 10.9.2, and place the connectorp.c.b. with the terminals underneathin the lower half of the housing.Put the two knurled screws in place,and press the two halves of the housingtogether until the four lugs snap intoposition.Take care that the connector p.c.b. andthe knurled screws are properly located.<strong>Accessories</strong> Manual Europe 59

Cables 05/2013 <strong>Kollmorgen</strong>10.10 Hybrid cables10.10.1 Hybrid cable SFD & Motor (i-tec connector)Usable <strong>for</strong> AKM1 (connector option D, feedback C-) and AKD.Without shield plate, with shield clampArticle Usable <strong>for</strong> Order CodeSFD Hybrid cable 1m (4x1+2x(2x0.75)) AKD-X00306 & X00606 CCS1A3-010-001-00SFD Hybrid cable 3m (4x1+2x(2x0.75)) AKD-X00306 & X00606 CCS1A3-010-003-00SFD Hybrid cable 6m (4x1+2x(2x0.75)) AKD-X00306 & X00606 CCS1A3-010-006-00SFD Hybrid cable 12m (4x1+2x(2x0.75)) AKD-X00306 & X00606 CCS1A3-010-012-00SFD Hybrid cable 24m (4x1+2x(2x0.75)) AKD-X00306 & X00606 CCS1A3-010-024-00ConnectionsServo amplifierMotorPair No.AKD AKM FunctionX10/10 1 1 UpX10/11 1 2 0VX10/7 2 3 Data -X10/6 2 4 Data+- - 5 n.c.X2/4 3 A UX2/6 3 B WX2/5 4 C V- 4 E n.c.X2/3 W W PECBDA43160 <strong>Accessories</strong> Manual Europe

<strong>Kollmorgen</strong> 05/2013 Cables10.10.2 Hybrid cable SFD & Motor (IP65 connector)Usable <strong>for</strong> AKM2 to AKM6 (connector option D, feedback C-) and AKD.Without shield plate, with shield clampArticle Usable <strong>for</strong> Order CodeSFD hybrid cable 1m (4x1+2x(2x0.75)) AKD-X00306 & X00606 CCS1A1-010-001-00SFD hybrid cable 3m (4x1+2x(2x0.75)) AKD-X00306 & X00606 CCS1A1-010-003-00SFD hybrid cable 6m (4x1+2x(2x0.75)) AKD-X00306 & X00606 CCS1A1-010-006-00SFD hybrid cable 12m (4x1+2x(2x0.75)) AKD-X00306 & X00606 CCS1A1-010-012-00SFD hybrid cable 24m (4x1+2x(2x0.75)) AKD-X00306 & X00606 CCS1A1-010-024-00With shield plate at amplifier's end, motor connector size 1 (up to 22A)Article Usable <strong>for</strong> Order CodeSFD hybrid cable 1m (4x1.5+2x(2x0.75)) AKD-X01206 & X00307...X01207 CCS2A1-015-001-00SFD hybrid cable 3m (4x1.5+2x(2x0.75)) AKD-X01206 & X00307...X01207 CCS2A1-015-003-00SFD hybrid cable 6m (4x1.5+2x(2x0.75)) AKD-X01206 & X00307...X01207 CCS2A1-015-006-00SFD hybrid cable 12m (4x1.5+2x(2x0.75)) AKD-X01206 & X00307...X01207 CCS2A1-015-012-00SFD hybrid cable 24m (4x1.5+2x(2x0.75)) AKD-X01206 & X00307...X01207 CCS2A1-015-024-00ConnectionsServo amplifierMotorPair No.AKD AKM FunctionX10/6 1 D COM+X10/7 1 C COM-X10/10 2 A UpX10/11 2 B 0VX2/4 3 1 UX2/3 3 PEX2/5 4 3 VX2/6 4 4 WCBDA431<strong>Accessories</strong> Manual Europe 61

Cables 05/2013 <strong>Kollmorgen</strong>10.10.3 Hybrid cable DSL & Motor (IP65 connector)<strong>Kollmorgen</strong> motors with Hiperface DSL feedback are connected to an AKD drive by an eight poleshybrid cable with integrated converter.<strong>Kollmorgen</strong> only guarantees correct functioning of the DSL feedback, if <strong>Kollmorgen</strong> cables areused.Usable <strong>for</strong> AKM2 to AKM6 (connector option D, feedback GE/GF) and AKD.Without shield plate, with shield clampArticle Usable <strong>for</strong> Order CodeDSL Hybrid cable 1m (4x1+2x(2x0.75)) AKD-X00306 & X00606 CCJ1A1-010-001-00DSL Hybrid cable 3m (4x1+2x(2x0.75)) AKD-X00306 & X00606 CCJ1A1-010-003-00DSL Hybrid cable 6m (4x1+2x(2x0.75)) AKD-X00306 & X00606 CCJ1A1-010-006-00DSL Hybrid cable 12m (4x1+2x(2x0.75)) AKD-X00306 & X00606 CCJ1A1-010-012-00DSL Hybrid cable 24m (4x1+2x(2x0.75)) AKD-X00306 & X00606 CCJ1A1-010-024-00With shield plate at amplifier's end, motor connector size 1 (up to 22A)Article Usable <strong>for</strong> Order CodeDSL Hybrid cable 1m (4x1.5+2x(2x0.75)) AKD-X01206 & X00307...X02407 CCJ2A1-015-001-00DSL Hybrid cable 3m (4x1.5+2x(2x0.75)) AKD-X01206 & X00307...X02407 CCJ2A1-015-003-00DSL Hybrid cable 6m (4x1.5+2x(2x0.75)) AKD-X01206 & X00307...X02407 CCJ2A1-015-006-00DSL Hybrid cable 12m (4x1.5+2x(2x0.75)) AKD-X01206 & X00307...X02407 CCJ2A1-015-012-00DSL Hybrid cable 24m (4x1.5+2x(2x0.75)) AKD-X01206 & X00307...X02407 CCJ2A1-015-024-00Article Usable <strong>for</strong> Order CodeDSL Hybrid cable 1m (4x2.5+2x(2x0.75)) AKD-X01206 & X00307...X02407 CCJ2A1-025-001-00DSL Hybrid cable 3m (4x2.5+2x(2x0.75)) AKD-X01206 & X00307...X02407 CCJ2A1-025-003-00DSL Hybrid cable 6m (4x2.5+2x(2x0.75)) AKD-X01206 & X00307...X02407 CCJ2A1-025-006-00DSL Hybrid cable 12m (4x2.5+2x(2x0.75)) AKD-X01206 & X00307...X02407 CCJ2A1-025-012-00DSL Hybrid cable 24m (4x2.5+2x(2x0.75)) AKD-X01206 & X00307...X02407 CCJ2A1-025-024-00Article Usable <strong>for</strong> Order CodeDSL Hybrid cable 1m (4x4+2x(2x1)) AKD-X01206 & X00307...X02407 CCJ2A1-040-001-00DSL Hybrid cable 3m (4x4+2x(2x1)) AKD-X01206 & X00307...X02407 CCJ2A1-040-003-00DSL Hybrid cable 6m (4x4+2x(2x1)) AKD-X01206 & X00307...X02407 CCJ2A1-040-006-00DSL Hybrid cable 12m (4x4+2x(2x1)) AKD-X01206 & X00307...X02407 CCJ2A1-040-012-00DSL Hybrid cable 24m (4x4+2x(2x1)) AKD-X01206 & X00307...X02407 CCJ2A1-040-024-00ConnectionsAmplifierMotorPair #AKD AKM FunctionX10/6 1 D COM+X10/7 1 C COM -X10/10 - - UpX10/11 - - 0VX2/2 2 3 BR+X2/1 2 4 BR-X2/4 3 1 UX2/3 3 2 PEX2/5 4 3 VX2/6 4 4 WCBDA43162 <strong>Accessories</strong> Manual Europe

<strong>Kollmorgen</strong> 05/2013 Cables10.11 Motor cables10.11.1 GeneralStandard versions of <strong>Kollmorgen</strong> motors have either one connector or one terminal box <strong>for</strong> thepower connection. Optional connection types are described in the relevant motor manual.Motor series Power Connection Motor series Power ConnectionAKM1...8 =< 22A Connector size 1 Cartridge DDR =< 22A Connector size 1AKM7...8 > 22A Connector size 1.5 Cartridge DDR > 22A Connector size 1.5DBL1...6 / DBK1...4 Connector size 1 AKM8, DBL7...8 Terminal boxDepending on their power ratings, <strong>Kollmorgen</strong> <strong>servo</strong> amplifiers are equipped with connectors orfixed screw terminals.Technical data of the used cable material can be found on p.39.10.11.2 Motor cables, configuredThe cables differ in respect of how they are connected to the amplifier. There are major differencesin connection method due to the varying requirements in respect of minimum code distances, differentshielding concepts depending on rated voltage and current load. Our pre-assembledready-to-use cables meet the requirements of relevant CE and UL directives.Please note that different conductor cross- sections are required <strong>for</strong> different motors, and that <strong>for</strong>motors with a holding brake the brake signals are also attached through this connector.Connections standard motor connectorsThe view is as seen from the contact side of the mating connector.Standard (size 1), wire max 4mm²Option H (size 1.5), wire max. 10mm²Pin Signal Pin Signal Pin Signal Pin SignalD 3 1 U2 A + Br - + U U2 + + BrC4 V2 B - Br VV V2 - - Br4 W UOptionB3 W2 C n.c. W W2 1J onlyA 1Option (2) PE D n.c. PE 2J onlyMaterial listPart Designation Order CodeCable Overview see p. 39Connector kit (motor end) Size 1.0 EMC Connector 8 poles, size 1.0 DE-92175Washdown connector kit (motor end) Size 1.0 EMC Connector 8 poles, size 1.0, stainless steel DE-201810Connector kit (motor end) Size 1.5 EMC Connector 6 poles, size 1.5 DE-201601<strong>Accessories</strong> Manual Europe 63

Cables 05/2013 <strong>Kollmorgen</strong>10.11.2.1 Order codes motor cables <strong>for</strong> S300230VCBDA431Articlemax. current(EN60204, table 6, Order Codeinstallation type B2)Motor cable (230V) 5m (4x1) 10,1 DE-107485Motor cable (230V) 10m (4x1) 10,1 DE-107486Motor cable (230V) 15m (4x1) 10,1 DE-107487Motor cable (230V) 20m (4x1) 10,1 DE-107488Motor cable (230V) 25m (4x1) 10,1 DE-107489Motor cable (230V) 5m (4x1+(2x0,75)) 10,1 / 8,5 DE-107491Motor cable (230V) 10m (4x1+(2x0,75)) 10,1 / 8,5 DE-107492Motor cable (230V) 15m (4x1+(2x0,75)) 10,1 / 8,5 DE-107493Motor cable (230V) 20m (4x1+(2x0,75)) 10,1 / 8,5 DE-107494Motor cable (230V) 25m (4x1+(2x0,75)) 10,1 / 8,5 DE-107495400V, with shield clampCBDA431Articlemax. current(EN60204, table 6, Order Codeinstallation type B2)Motor cable (400V) 5m (4x1) 10,1 DE-107473Motor cable (400V) 10m (4x1) 10,1 DE-107474Motor cable (400V) 15m (4x1) 10,1 DE-107475Motor cable (400V) 20m (4x1) 10,1 DE-107476Motor cable (400V) 25m (4x1) 10,1 DE-107477Motor cable (400V) 5m (4x1+(2x0,75)) 10,1 / 8,5 DE-107479Motor cable (400V) 10m (4x1+(2x0,75)) 10,1 / 8,5 DE-107480Motor cable (400V) 15m (4x1+(2x0,75)) 10,1 / 8,5 DE-107481Motor cable (400V) 20m (4x1+(2x0,75)) 10,1 / 8,5 DE-107482Motor cable (400V) 25m (4x1+(2x0,75)) 10,1 / 8,5 DE-10748310.11.2.2 Order codes motor cables <strong>for</strong> S400DC4BA31Articlemax. current(EN60204, table 6, Order Codeinstallation type B2)Motor cable 5m (4x1) 10,1 DE-102575Motor cable 10m (4x1) 10,1 DE-102576Motor cable 15m (4x1) 10,1 DE-102806Motor cable 20m (4x1) 10,1 DE-102807Motor cable 25m (4x1) 10,1 DE-102808Motor cable 5m (4x1+(2x0,75)) 10,1 / 8,5 DE-102579Motor cable 10m (4x1+(2x0,75)) 10,1 / 8,5 DE-102580Motor cable 15m (4x1+(2x0,75)) 10,1 / 8,5 DE-102809Motor cable 20m (4x1+(2x0,75)) 10,1 / 8,5 DE-102810Motor cable 25m (4x1+(2x0,75)) 10,1 / 8,5 DE-10281164 <strong>Accessories</strong> Manual Europe

<strong>Kollmorgen</strong> 05/2013 Cables10.11.2.3 Order codes motor cables <strong>for</strong> S601...620DC4BA31Articlemax. current(EN60204, table 6, Order Codeinstallation type B2)Motor cable 5m (4x1) 10,1 DE-90083Motor cable 10m (4x1) 10,1 DE-90084Motor cable 15m (4x1) 10,1 DE-90085Motor cable 20m (4x1) 10,1 DE-90086Motor cable 25m (4x1) 10,1 DE-90087Motor cable 5m (4x1+(2x0,75)) 10,1 / 8,5 DE-90088Motor cable 10m (4x1+(2x0,75)) 10,1 / 8,5 DE-90089Motor cable 15m (4x1+(2x0,75)) 10,1 / 8,5 DE-90090Motor cable 20m (4x1+(2x0,75)) 10,1 / 8,5 DE-90091Motor cable 25m (4x1+(2x0,75)) 10,1 / 8,5 DE-90092Motor cable 5m (4x1,5) 13,1 DE-89918Motor cable 10m (4x1,5) 13,1 DE-89952Motor cable 15m (4x1,5) 13,1 DE-89953Motor cable 20m (4x1,5) 13,1 DE-89954Motor cable 25m (4x1,5) 13,1 DE-89956Motor cable 5m (4x1,5+(2x0,75)) 13,1 / 8,5 DE-89957Motor cable 10m (4x1,5+(2x0,75)) 13,1 / 8,5 DE-89961Motor cable 15m (4x1,5+(2x0,75)) 13,1 / 8,5 DE-89963Motor cable 20m (4x1,5+(2x0,75)) 13,1 / 8,5 DE-89965Motor cable 25m (4x1,5+(2x0,75)) 13,1 / 8,5 DE-89967Motor cable 5m (4x2,5) 17,4 DE-89959Motor cable 10m (4x2,5) 17,4 DE-89960Motor cable 15m (4x2,5) 17,4 DE-89962Motor cable 20m (4x2,5) 17,4 DE-89964Motor cable 25m (4x2,5) 17,4 DE-89966Motor cable 5m (4x2,5+(2x1)) 17,4 / 10,1 DE-89968Motor cable 10m (4x2,5+(2x1)) 17,4 / 10,1 DE-89970Motor cable 15m (4x2,5+(2x1)) 17,4 / 10,1 DE-89971Motor cable 20m (4x2,5+(2x1)) 17,4 / 10,1 DE-89972Motor cable 25m (4x2,5+(2x1)) 17,4 / 10,1 DE-89969<strong>Accessories</strong> Manual Europe 65

Cables 05/2013 <strong>Kollmorgen</strong>10.11.2.4 Order codes motor cables <strong>for</strong> S701-712With shield clamp <strong>for</strong> amplifier's end, motor connector size 1, 6 poles, up to 22ACBDA431Articlemax. current(EN60204, table 6, Order Codeinstallation type B2)Motor cable 5m (4x1) 10,1 DE-107473Motor cable 10m (4x1) 10,1 DE-107474Motor cable 15m (4x1) 10,1 DE-107475Motor cable 20m (4x1) 10,1 DE-107476Motor cable 25m (4x1) 10,1 DE-107477Motor cable 5m (4x1+(2x0,75)) 10,1 / 8,5 DE-107479Motor cable 10m (4x1+(2x0,75)) 10,1 / 8,5 DE-107480Motor cable 15m (4x1+(2x0,75)) 10,1 / 8,5 DE-107481Motor cable 20m (4x1+(2x0,75)) 10,1 / 8,5 DE-107482Motor cable 25m (4x1+(2x0,75)) 10,1 / 8,5 DE-107483With shield plate at amplifier's end, motor connector size 1, 6 poles, up to 22ADC4BA31Articlemax. current(EN60204, table 6, Order Codeinstallation type B2)Motor cable 5m (4x1,5) 13,1 DE-200456Motor cable 10m (4x1,5) 13,1 DE-200457Motor cable 15m (4x1,5) 13,1 DE-200458Motor cable 20m (4x1,5) 13,1 DE-200459Motor cable 25m (4x1,5) 13,1 DE-200460Motor cable 5m (4x1,5+(2x0,75)) 13,1 / 8,5 DE-200462Motor cable 10m (4x1,5+(2x0,75)) 13,1 / 8,5 DE-200463Motor cable 15m (4x1,5+(2x0,75)) 13,1 / 8,5 DE-200464Motor cable 20m (4x1,5+(2x0,75)) 13,1 / 8,5 DE-200465Motor cable 25m (4x1,5+(2x0,75)) 13,1 / 8,5 DE-200466Motor cable 5m (4x2,5) 17,4 DE-200468Motor cable 10m (4x2,5) 17,4 DE-200469Motor cable 15m (4x2,5) 17,4 DE-200470Motor cable 20m (4x2,5) 17,4 DE-200471Motor cable 25m (4x2,5) 17,4 DE-200472Motor cable 5m (4x2,5+(2x1)) 17,4 / 10,1 DE-200474Motor cable 10m (4x2,5+(2x1)) 17,4 / 10,1 DE-200475Motor cable 15m (4x2,5+(2x1)) 17,4 / 10,1 DE-200476Motor cable 20m (4x2,5+(2x1)) 17,4 / 10,1 DE-200477Motor cable 25m (4x2,5+(2x1)) 17,4 / 10,1 DE-200478Motor cable 5m (4x4) 23 DE-200618Motor cable 10m (4x4) 23 DE-200619Motor cable 15m (4x4) 23 DE-200620Motor cable 20m (4x4) 23 DE-200621Motor cable 25m (4x4) 23 DE-200622Motor cable 5m (4x4+(2x1)) 23 / 10,1 DE-200623Motor cable 10m (4x4+(2x1)) 23 / 10,1 DE-200624Motor cable 15m (4x4+(2x1)) 23 / 10,1 DE-200625Motor cable 20m (4x4+(2x1)) 23 / 10,1 DE-200626Motor cable 25m (4x4+(2x1)) 23 / 10,1 DE-20062766 <strong>Accessories</strong> Manual Europe

<strong>Kollmorgen</strong> 05/2013 Cables10.11.2.5 Order codes motor cables <strong>for</strong> S724With shield plate at amplifier's end, motor connector size 1.5, 6 poles-VW+UArticlemax. current(EN60204, table 6, Order Codeinstallation type B2)Motor cable 5m (4x6) 30 DE-201678Motor cable 10m (4x6) 30 DE-201679Motor cable 15m (4x6) 30 DE-201680Motor cable 20m (4x6) 30 DE-201681Motor cable 25m (4x6) 30 DE-201682Motor cable 5m (4x6+(2x1)) 30 / 10,1 DE-201683Motor cable 10m (4x6+(2x1)) 30 / 10,1 DE-201684Motor cable 15m (4x6+(2x1)) 30 / 10,1 DE-201685Motor cable 20m (4x6+(2x1)) 30 / 10,1 DE-201686Motor cable 25m (4x6+(2x1)) 30 / 10,1 DE-201687<strong>Accessories</strong> Manual Europe 67

Cables 05/2013 <strong>Kollmorgen</strong>10.11.2.6 Order codes motor cables <strong>for</strong> S748Wire end ferrules at amplifier's end, motor connector size 1.5, 6 poles-WV+UArticlemax. current(EN60204, table 6, Order Codeinstallation type B2)Motor cable 5m (4x10) 40 DE-201589Motor cable 10m (4x10) 40 DE-201590Motor cable 15m (4x10) 40 DE-201591Motor cable 20m (4x10) 40 DE-201592Motor cable 25m (4x10) 40 DE-201593Motor cable 5m (4x10+(2x1.5)) 40 / 13,1 DE-201594Motor cable 10m (4x10+(2x1.5)) 40 / 13,1 DE-201595Motor cable 15m (4x10+(2x1.5)) 40 / 13,1 DE-201596Motor cable 20m (4x10+(2x1.5)) 40 / 13,1 DE-201597Motor cable 25m (4x10+(2x1.5)) 40 / 13,1 DE-201598Motor cable 5m (4x16) 54 DE-201688Motor cable 10m (4x16) 54 DE-201689Motor cable 15m (4x16) 54 DE-201690Motor cable 20m (4x16) 54 DE-201691Motor cable 25m (4x16) 54 DE-201692Motor cable 5m (4x16+(2x1.5)) 54 / 13,1 DE-201693Motor cable 10m (4x16+(2x1.5)) 54 / 13,1 DE-201694Motor cable 15m (4x16+(2x1.5)) 54 / 13,1 DE-201695Motor cable 20m (4x16+(2x1.5)) 54 / 13,1 DE-201696Motor cable 25m (4x16+(2x1.5)) 54 / 13,1 DE-201697Wire end ferrules on amplifier's end, motor end cut off <strong>for</strong> motors with terminal boxArticlemax. current(EN60204, table 6, Order Codeinstallation type B2)Motor cable 5m (4x10) 40 DE-201698Motor cable 10m (4x10) 40 DE-201699Motor cable 15m (4x10) 40 DE-201700Motor cable 20m (4x10) 40 DE-201701Motor cable 25m (4x10) 40 DE-201702Motor cable 5m (4x10+(2x1.5)) 40 / 13,1 DE-201713Motor cable 10m (4x10+(2x1.5)) 40 / 13,1 DE-201714Motor cable 15m (4x10+(2x1.5)) 40 / 13,1 DE-201715Motor cable 20m (4x10+(2x1.5)) 40 / 13,1 DE-201774Motor cable 25m (4x10+(2x1.5)) 40 / 13,1 DE-201775Motor cable 5m (4x16) 54 DE-201703Motor cable 10m (4x16) 54 DE-201704Motor cable 15m (4x16) 54 DE-201705Motor cable 20m (4x16) 54 DE-201706Motor cable 25m (4x16) 54 DE-201707Motor cable 5m (4x16+(2x1.5)) 54 / 13,1 DE-201776Motor cable 10m (4x16+(2x1.5)) 54 / 13,1 DE-201745Motor cable 15m (4x16+(2x1.5)) 54 / 13,1 DE-201746Motor cable 20m (4x16+(2x1.5)) 54 / 13,1 DE-201747Motor cable 25m (4x16+(2x1.5)) 54 / 13,1 DE-201748Motor cable 5m (4x25) 70 DE-201708Motor cable 10m (4x25) 70 DE-201709Motor cable 15m (4x25) 70 DE-201710Motor cable 20m (4x25) 70 DE-201711Motor cable 25m (4x25) 70 DE-201712Motor cable 5m (4x25+(2x1.5)) 70 / 13,1 DE-201749Motor cable 10m (4x25+(2x1.5)) 70 / 13,1 DE-201750Motor cable 15m (4x25+(2x1.5)) 70 / 13,1 DE-201751Motor cable 20m (4x25+(2x1.5)) 70 / 13,1 DE-201752Motor cable 25m (4x25+(2x1.5)) 70 / 13,1 DE-20175368 <strong>Accessories</strong> Manual Europe

<strong>Kollmorgen</strong> 05/2013 Cables10.11.2.7 Order codes motor cables <strong>for</strong> AKDHybrid cables <strong>for</strong> motors with SFD or DSL feedback see page 60.The cables below are usable <strong>for</strong> AKM1 to AKM7 (connector options 1, 7, B, C, G) and AKD.Without shield plate, with shield clampCBDA431Article Usable <strong>for</strong> Order CodeMotor cable 1m (4x1)CM01A1-010-001-00Motor cable 3m (4x1) CM01A1-010-003-00Motor cable 6m (4x1) CM01A1-010-006-00Motor cable 12m (4x1) CM01A1-010-012-00Motor cable 24m (4x1) CM01A1-010-024-00Motor cable 1m (4x1+(2x1)) CM11A1-010-001-00Motor cable 3m (4x1+(2x1)) CM11A1-010-003-00Motor cable 6m (4x1+(2x1)) AKD-X00306 & X00606 CM11A1-010-006-00Motor cable 12m (4x1+(2x1)) CM11A1-010-012-00Motor cable 24m (4x1+(2x1)) CM11A1-010-024-00With shield plate at amplifier's end, motor connector size 1 (up to 22A)DC4BA31Article Usable <strong>for</strong> Order CodeMotor cable 1m (4x1,5)CM02A1-015-001-00Motor cable 3m (4x1,5) CM02A1-015-003-00AKD-X01206 &Motor cable 6m (4x1,5) CM02A1-015-006-00AKD-X00307...X01207Motor cable 12m (4x1,5) CM02A1-015-012-00Motor cable 24m (4x1,5) CM02A1-015-024-00Motor cable 1m (4x1,5+(2x1))CM12A1-015-001-00Motor cable 3m (4x1,5+(2x1)) AKD-X01206 &CM12A1-015-003-00Motor cable 6m (4x1,5+(2x1)) AKD-X00307...X01207 CM12A1-015-006-00Motor cable 12m (4x1,5+(2x1)) CM12A1-015-012-00Motor cable 24m (4x1,5+(2x1))AKD-X01206 &AKD-X00307...X01207CM12A1-015-024-00Motor cable 1m (4x2,5)CM02A1-025-001-00Motor cable 3m (4x2,5) CM02A1-025-003-00Motor cable 6m (4x2,5) CM02A1-025-006-00Motor cable 12m (4x2,5) CM02A1-025-012-00Motor cable 24m (4x2,5) AKD-X01206 &CM02A1-025-024-00Motor cable 1m (4x2,5+(2x1)) AKD-X00307...X01207 CM12A1-025-001-00Motor cable 3m (4x2,5+(2x1)) CM12A1-025-003-00Motor cable 6m (4x2,5+(2x1)) CM12A1-025-006-00Motor cable 12m (4x2,5+(2x1)) CM12A1-025-012-00Motor cable 24m (4x2,5+(2x1)) CM12A1-025-024-00Motor cable 1m (4x4)CM02A1-040-001-00Motor cable 3m (4x4) CM02A1-040-003-00Motor cable 6m (4x4) CM02A1-040-006-00Motor cable 12m (4x4) CM02A1-040-012-00Motor cable 24m (4x4) AKD-X02406 &CM02A1-040-024-00Motor cable 1m (4x4+(2x1,5)) AKD-X02407CM12A1-040-001-00Motor cable 3m (4x4+(2x1,5)) CM12A1-040-003-00Motor cable 6m (4x4+(2x1,5)) CM12A1-040-006-00Motor cable 12m (4x4+(2x1,5)) CM12A1-040-012-00Motor cable 24m (4x4+(2x1,5)) CM12A1-040-024-00<strong>Accessories</strong> Manual Europe 69