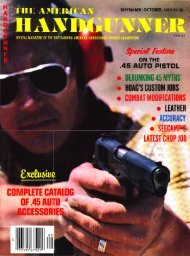

ARDFACTSaboutARDFINISHESThe "blue steel" revolver and auto pistolare slowly giving way to new nickel andchrome finishes that are durablePhoro by John KleinmanBy Michael BaneHard chrome, electroless nickel, Teflon,Nitex, Metaloy-the number of"new" surfaces for handguns seems togrow daily. Just a few years ago the onlyacceptable finish for a handgun was blued,with maybe a few nickeled guns of questionableancestry on the side.But the boom in the handgun shootingsports, such as silhouette and combatshooting, has triggered a search by handgunnersfor the "perfect" handgun finish.This perfect finish will never require cleaning,be indestructible in the face of grimyfingerprints, salt water, and just plain neglect,never wear, and improve the performanceof the gun.Bob Cogan has heard it all before, andhe just laughs."No plated finish is the panacea peoplethink it's going to be;' he says. "No finish isimpregnable, and no finish can stand up toeverything people can think up to do to it."Cogan should know. As the owner ofAccurate Plating and Weaponry in Clearwater,Florida, Cogan has become one ofthe foremost gun platers in the country.His specialty is hard chrome with abrushed finish that uncannily resembles46stainless steel, so much so that at the recentS.H.OT. show in New Orleans an executiveof a major handgun company wasfooled by Cogan's .45 automatic frames."You're sure they're not stainless?" heasked Cogan.Mossberg's Abilene single action revolversand custom pistolsmith Jim Clark'ssuper .45s are both hard chromed by Accurate,as are guns belonging to Alaskanguides and servicemen in Guam. So whenwe decided to try to make heads or tails ofthe glut ofgun finishes, it's only naturalthat we turned to Cogan."There are two kinds of people whoshould have their guns plated," Cogansays. "People who use their guns a lot, and.people who don't use them at all."Almost any finish, he says, will be moredurable than bluing, and any finish will ultimatelywear out. How often you have toclean the gun and how much attention youhave to pay to its maintenance is more afunction of where you live than of thegun's finish."If you live in Arizona and have yourgun hard chromed or electroless nickeled,then maybe you won't ever have to cleanit;' he says. "Try that here in Florida andno matter what kind offinish is on the gun,it's going to rust;'In terms of the straight-out resistance torusting and corrosion, Cogan says the winner,hands-down, is the Teflon" finish.Rather than a plated finish, Teflon' is abaked on chemical finish, and it is fiercelyrust and corrosion resistant."Unfortunately, it is also fairly soft aI\.

won't guarantee nickel plating on a magnumgun."Many factory nickel plating jobs are theresult of a two-stage project-first the gunis copper plated, then the nickel is put onover the copper. "It's stronger, but I stilldon't think it's strong enough," Cogansays.Electroless nickel, he says, is a whole differentanimal. "Electroless, like Nitexwhodoes Colt',s .work-has the samebonding characteristics as chrome," Cogansays, "and it's more resistant to salt thanchrome."Ifit has any drawbacks, he says, they aretwo-fold. Electroless nickel is a softer surfacethan chrome, with a Rockwell HardnessRating in the high 30s as opposed tochrome's Rockwell 60."Electroless also plates everywhere, andthat includes the inside of the barrel andthe inside of the cylinders," Cogan says."That means that you've added usuallyabout .002" ofnickel to the bore and cylinders.To me, if the gun manufacturer hadwanted that bore to be .002 smaller, hewould have made it that size:'Obviously, Cogan's favorite finish is47