India's largest coal handling agency - Mjunction

India's largest coal handling agency - Mjunction

India's largest coal handling agency - Mjunction

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

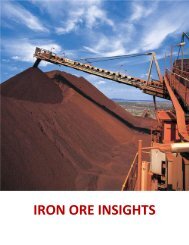

Cover StoryConveyor belts: An essential logistics deviceCoal Insights BureauAconveyor belt is a mechanical apparatus consistingof a continuous moving belt that transportsmaterials from one place to another. The device,which has become essential equipment for the globalmining industry, was first conceived in the 19th century.In 1901, Sandvik invented and started production ofsteel conveyor belts. Four years later, Richard Sutcliffeproduced the first conveyor belts for use in <strong>coal</strong> mines.Over the years, rapid technological advancement hasresulted in extensive specialisation and customisation ofthis important logistics device.The belt forms a continuous loop which is supportedeither on rollers (for heavy loads) or on a metal slider pan(if loads are light enough to prevent frictional drag onthe belt). Motors operating through constant or variablespeedreduction gears usually provide the power. Aconveyor belt consists of two or more pulleys, with acontinuous loop of material that rotates about them. Thisloop is actually the conveyor belt. Belt conveyors can beof various sorts namely fabric, rubber, plastic, leather ormetal, and are driven by a power-operated roll mountedunderneath or at one end of the conveyor.As per the varied industrial requirements, there arebroadly three different types of conveyor belts:♦ ♦ Basic belt♦ ♦ Snake sandwich belt♦ ♦ Long beltA basic belt conveyor consists of two or more pulleyswhich hold onecontinuous lengthof material. Thesetypes of belts can bemotorised or requiremanual effort. As thebelt moves forward,all the items on the beltare carried forward.This type of device iscommonly used in packaging or parcel delivery services,which require quick relocation of materials from one placeto another with minimal human intervention. The belt istypically installed at waist height to improve the ergonomicsfor the staff that are interacting with the materials.The structure generally consists of a metal frame withrollers installed at various intervals along the length of thebelt. The belt is typically a smooth, rubber material thatcovers the rollers. As the belt moves over the rollers, theitems placed on the belt are transferred with low frictiondue to the use of multiple rollers.The snake sandwich conveyor consists of twoseparate conveyor belts,set up parallel to eachother holding the productin place while movingalong the belt. This typeof belt is used for movingitems up steep inclines, upto 90 degrees. It was firstintroduced in 1979 andwas mainly designed formoving rocks and othermaterials out of a mine.The system was designedto make use of widelyavailable hardware and used simple principles to ensurethat it was easy to repair. The system is able to move a highvolume of materials at a consistent rate. Smooth surfacedbelts allow the conveyor belts to be cleaned automaticallywith the use of belt scrapers and plows. The design isflexible enough to allow the materials redirected off theconveyor belt at any point through simple redirection.The last andfinal one, the longbelt conveyor isa system of threedrive units usedto move materialsover a longdistance. The mostimportant featureof this system is the ability of the rollers to handle bothhorizontal and vertical curves. The long belt conveyorsystem can reach up to 13.8 km (8.57 miles) in length. Thistype of conveyor belt is often used in mining operations totransport materials to remote construction or building sitelocations, such as the bottom of a mining pit.a leading manufacturer, has launched a strong conveyormaintenance product programme along with offering a widearray of products. The company, a top official said, aims toprovide a “one stop shop” for rubber related mining products.According to industry sources, this trend could become moreprominent in the coming years due to increased competitionfrom domestic as well as overseas vendors, especially fromChina.Another significant change this industry is undergoing is thechange in customer focus to cost competitiveness. AccordingCOAL INSIGHTS 8 November 2010