India's largest coal handling agency - Mjunction

India's largest coal handling agency - Mjunction

India's largest coal handling agency - Mjunction

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Chief Editor<br />

Rakesh Dubey, Tel: +91 91633 48159, Email: rakesh.dubey@mjunction.in<br />

Editorial Board<br />

Alok Srivastava, General Manager, MMTC Ltd<br />

Amitabh Panda, Group Director (Shipping & Logistics Operations), Tata Steel<br />

Group<br />

Anirudha Gupta, Director, P&H JoyMining Equipment India Ltd<br />

Ashok Jain, Managing Director, Saumya Mining Ltd<br />

Deepak Bhattacharyya, Head – <strong>coal</strong>junction, mjunction services ltd<br />

Ganesan Natarajan, WT Director, President & CEO, Ennore Coke Ltd<br />

Lawrence Metzroth, Vice President – Analysis & Strategy, Arch Coal Inc<br />

M K Palanivel, President – All India Bulk, Samsara Group<br />

S N Choubey, Asst. Vice President – CPC, UltraTech Cement Ltd<br />

Sandeep Kumar, Managing Director, S & T Mining Co Pvt Ltd<br />

Shyam Sundar Beriwala, Chairman, Shyam Steel Industries Ltd<br />

Suresh Thawani, Managing Director, Tata Sponge Iron Ltd<br />

Advertising<br />

Soumitra Bose, Tel: +91 92310 00232, Email: soumitra.bose@mjunction.in<br />

Arvind Saigal, Tel: +91 91633 48078, Email: arvind.saigal@mjunction.in<br />

Sumit Jalan, Tel: +91 92310 65739, Email: sumit.jalan@mjunction.in<br />

Subscription<br />

Anustup Lahiri, Tel: +91 91633 48013, Email: anustup.lahiri@mjunction.in<br />

Design<br />

Debal Ray, Ishawer Kumar Sriwastva, Sobhan Jas<br />

For suggestions, feedback and queries, please write to<br />

<strong>coal</strong>insights@mjunction.in<br />

Registered Office<br />

mjunction services limited, Tata Centre, 43 J L Nehru Rd, Kolkata 700 071<br />

Website: www.mjunction.in<br />

Corporate Head Quarters: Godrej Waterside, 3rd Floor, Tower 1, Plot V, Block DP, Sector V, Salt<br />

Lake, Kolkata 700091, Tel: +91 33 6610 6100, Fax: +91 33 6610 6187 Bokaro: Room 19, Old<br />

Admin Bldg., Bokaro Steel Plant, Bokaro 827001, Tel/Fax: +91 654 2226132 Jamshedpur:<br />

Armoury Rd, Bistupur, Jamshedpur 831001, Tel: +91 6576519985/86/90/91, Tele/Fax:<br />

+91 657 2424432 Durgapur: Room 618, Ispat Bhavan, Durgapur Steel Plant, Durgapur<br />

713203, Tel: +91 343 6510185, Tele/Fax: +91 343 2586946 Rourkela: Administrative<br />

Bldg., Room 624, 6th Floor, Rourkela Steel Plant, Rourkela 769011, Tel: +91 661 6514142,<br />

Fax: +91 661 2513072 Mumbai: Jolly Bhavan II, 403, 4th Floor, 7 New Marine Lines, opp.<br />

Nirmala Niketan Home Science College, Mumbai 400002, Tel: +91 22 66510662 Delhi:<br />

C127, 2nd Floor, Rex House, Naraina Industrial Area, Phase I, New Delhi 110028, Tel: +91<br />

11 25896900/25897000/65661774, Tele/Fax: +91 11 25896100 Bhilai: Room 321, 3rd Floor,<br />

Ispat Bhavan, Bhilai Steel Plant, Bhilai 490001, Tel: +91 788 6451066, Tele/Fax: +91 7882227<br />

136 Chennai: 2nd Floor, Begum Ishpani Complex, Old 44 (New 91) Armenian St, Chennai 600<br />

001, Tel: +91 44 42167417, Tele/Fax: +91 44 42051417<br />

mjunction believes that all junctionites, customers, suppliers, partners,<br />

etc should practice the highest ethical standards in their daily operations.<br />

Report a concern to ethics@mjunction.in<br />

Copyright: All rights reserved. No part of Coal Insights can be reproduced or copied in any<br />

form or by any means without the prior permission of mjunction services limited. Please<br />

inform us if any copyright has been inadvertently infringed.<br />

Disclaimer: This document is for information purpose only. Certain information herein has<br />

been acquired from various external sources believed to be reliable. While we have taken<br />

reasonable care to compile this report, we in no way assume any responsibility for any error<br />

or discrepancy in regards to information contained herein. Readers are requested to make<br />

appropriate judgment without any prejudice or compulsion.<br />

EDITORIAL<br />

Dear Readers,<br />

Technology, other than information technology, has not yet<br />

become a strong point for Indian industry, and much less so for<br />

the mining sector. Despite remarkable improvement in the last<br />

two decades, the country still lags in comparison to the developed<br />

world and some developing nations, particularly China. No<br />

doubt, the Indian mining equipment industry has come a long<br />

way since the setting up of the first unit of Bharat Earthmovers (a<br />

defence PSU) in 1964, but it still has a long way to go.<br />

It is indeed a strange phenomenon that India – the third<br />

<strong>largest</strong> producer of <strong>coal</strong> and lignite, <strong>largest</strong> producer of mica<br />

and fourth <strong>largest</strong> producer of iron ore – still has to source<br />

sophisticated mining equipment, particularly for underground<br />

mining, from overseas. In the words of <strong>coal</strong> minister Sriprakash<br />

Jaiswal, “Equipment supplies are adversely affecting the growth<br />

in production. Performance of equipment being supplied by the<br />

manufacturers is an area of concern and the <strong>coal</strong> industry needs<br />

amicable solutions to the issue.”<br />

The issue of expanding indigenous <strong>coal</strong> production, which<br />

accounts for 80 percent of all mining activity in India, is the<br />

need of the hour. The country needs to grow its <strong>coal</strong> supplies<br />

at 10 percent compared to current 7 percent to match up to the<br />

demand. Fuelling the economy will be crucial for this and the<br />

mining equipment sector is an integral part of this refuelling.<br />

Opencast mining, contributing 90 percent of <strong>coal</strong><br />

production, is nearing saturation and the <strong>coal</strong> producers,<br />

mainly Coal India Ltd, is looking at underground mining<br />

for which they will need sophisticated and highly technical<br />

equipment. Not only CIL, but new entrants into <strong>coal</strong> mining<br />

sector too will need equipment in huge quantity as they start<br />

production from captive blocks.<br />

Also, the consumption of steel is pretty low compared to<br />

international standards and is slated to rise at a furious pace.<br />

This generates a huge demand for iron ore mining and the<br />

equipment needed for that. This could be an area of concern,<br />

as expressed by the minister, and yet a sea of opportunity.<br />

According to some estimates, the overall market size of<br />

Indian mining industry may grow by nearly 20 to 25 times<br />

from the current level of around `15,000 crore by 2015. Also,<br />

the sector is expected to witness huge investment estimated<br />

at around `2,00,000 crore in the next five years. These are<br />

ambitious projections, but given the dramatic pace of growth<br />

in Indian mining production, it could be achievable.<br />

Considering the importance of the mining equipment<br />

industry, the editorial team of Coal Insights has attempted to<br />

highlight various developments in this sector in India as well<br />

as abroad in order to place before its esteemed readers a clear<br />

picture on what is happening and what needs to be done to<br />

improve the situation.<br />

Hope the issues raised and information provided on<br />

mining equipment industry in the current issue of the<br />

magazine besides other regular features would help our<br />

esteemed readers to plan their strategies.<br />

Wishing you a happy and prosperous Diwali.<br />

Warm Regards<br />

Rakesh Dubey<br />

Chief Editor

Contents<br />

COVER STORY<br />

6 Mining equipment makers need to<br />

step up R&D<br />

12 India, China lead global resurgence<br />

14 HEC targets `1000 cr sales by<br />

2011-12<br />

16 BEML plans to double turnover<br />

18 Global cos bank on emerging<br />

economies<br />

COAL MARKET FUNDAMENTALS<br />

22 Steady demand pushes up thermal<br />

<strong>coal</strong><br />

23 Coking <strong>coal</strong> contract price drops for<br />

Q3<br />

FEATURE<br />

25 Competitive bidding: Will it improve<br />

the situation<br />

29 Coal ministry puts illegal mining<br />

onus on state govts<br />

31 Coke shortage may hamper steel<br />

growth<br />

34 India’s m-o-m cement production<br />

falls in Aug<br />

36 Coal ministry faces huge backlog of<br />

linkage applications<br />

38 NELP-IX: bidding to close on March<br />

18<br />

39 Forestry clearance delays may<br />

derail growth prospects<br />

43 India misses Sept power generation<br />

target<br />

GOVERNMENT<br />

47 Coal ministry firm on profit sharing,<br />

doesn’t rule out price rise<br />

INTERNATIONAL<br />

49 Forum seeks Canada-India mining<br />

ties<br />

50 RBCT August <strong>coal</strong> exports go down<br />

51 Australia okays $30-bn <strong>coal</strong> gas<br />

projects<br />

52 New Indonesian norm on low quality<br />

<strong>coal</strong> sales<br />

53 EIA raises 2010 US <strong>coal</strong><br />

consumption and production outlook<br />

EXPERT SPEAK<br />

55 Heat recovery Chinese coke ovens:<br />

Problems & Solutions<br />

58 The menace of over-reporting in<br />

<strong>coal</strong> companies<br />

CORPORATE<br />

60 Abhijeet Group focuses on core<br />

sectors<br />

61 Indonesian cos evince interest in<br />

Nalco JV<br />

62 Sandvik installs its first primary<br />

gyratory crusher<br />

63 CIL in top league after IPO success<br />

64 NTPC’s first nuclear power plant<br />

likely by 2013-14<br />

65 Banks not tapped for captive block<br />

funds<br />

LOGISTICS<br />

66 Freight rates improve strongly in<br />

end-Oct<br />

67 Railways traffic improves in Sept<br />

POWER SECTOR UPDATE<br />

68 All India energy generation<br />

programme and PLF<br />

SNAP SHOT<br />

76 Chile mine rescue – a marvel of<br />

teamwork and determination<br />

E-AUCTION DATA<br />

82 CIL’s August <strong>coal</strong> sales through<br />

e-auction down<br />

ALL INDIA COAL DATA<br />

86 India’s <strong>coal</strong> production rises in<br />

August<br />

PORT DATA<br />

90 Coal import data<br />

COAL INSIGHTS 4 October 2010

India’s <strong>largest</strong> <strong>coal</strong> <strong>handling</strong> <strong>agency</strong><br />

• Handling approximately 60 million tons of <strong>coal</strong> per annum<br />

• More than 60 years of experience<br />

• Over 50 locations across India<br />

• Dealing with all major public & private sector consumers nation-wide<br />

• Providing solutions to all your <strong>coal</strong>-related logistic requirements, including financing<br />

www.kct<strong>coal</strong>sales.com • info@kct<strong>coal</strong>sales.com<br />

COAL INSIGHTS 5 October 2010<br />

Registered Office: Thapar House | 25 Brabourne Road | Kolkata | WB | 700001 • Tel: +91 33 4005 7000 • Fax: +91 33 2242 8684

Cover Story<br />

Mining equipment makers need<br />

to step up R&D<br />

Arusha Das<br />

As India stands on the threshold of a massive<br />

industrial resurgence, the mining sector and<br />

consequently the equipment manufacturers, are<br />

benefiting directly as a consequence.<br />

No wonder then, that domestic and foreign<br />

mining equipment companies are looking<br />

forward to a period of stable growth in<br />

India during the next two to three<br />

years. This optimism is on the back<br />

of resurgence in demand for highend<br />

and cost-effective mining<br />

equipment.<br />

Just about a year ago, the<br />

mining sector was not spared the<br />

effects of the recession, though<br />

it took a milder hit compared to<br />

several other sectors. However,<br />

the recovery has been fast.<br />

“The mining sector has been expanding at 3 to 4<br />

percent yearly, and this growth is expected to continue in<br />

many of the key mining regions of the world with India<br />

and China providing the momentum. Coal production<br />

in the country has moved up by 3-4 percent while<br />

iron ore production has surged by around<br />

4-5 percent,” managing director of<br />

the German engineering federation<br />

VDMA, Rajesh Nath, informed Coal<br />

Insights.<br />

Demand supply curve<br />

The industrial sector registered<br />

a growth of 7.6 percent during<br />

April-November in 2009-<br />

10, against 4.1 percent in the<br />

corresponding period of last year.<br />

The mining sector posted a growth<br />

COAL INSIGHTS 6 October 2010

Cover Story<br />

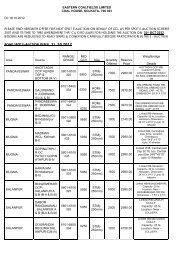

INDUSTRIAL GROWTH INDICATORS - Sectoral<br />

Growth Rates based on IIP<br />

(Growth Rate in percent)<br />

Item<br />

Weight<br />

(%)<br />

2007-08 2008-09<br />

Apr-Nov<br />

08-09<br />

Apr-Nov<br />

09-10<br />

Overall 100 8.5 2.8 4.1 7.6<br />

Mining and Quarrying 10.5 5.1 2.6 3.4 8.3<br />

Manufacturing 79.4 9 2.8 4.2 7.7<br />

Electricity 10.2 6.4 2.8 2.8 6.1<br />

Source: Ministry of Heavy Industries and Public Enterprises &<br />

Insights Research<br />

Sales of equipments in India in units sold<br />

Year International players in India Indian Players<br />

2008-09 4200 500<br />

2009-10 5500 600<br />

2010-11 (Upto Sept) 2700 200<br />

Source: Komatsu & Insights Research<br />

of 8.3 percent during the same period compared to 3.4 percent<br />

registered in the corresponding period of last year. Keeping<br />

this in mind, Coal Insights took a close look at the equipment<br />

manufacturing sector, which is poised to play a crucial role in<br />

the mining growth that is just waiting to happen.<br />

“The equipment industry is in good shape and there is<br />

huge demand for mining equipment. Moreover with massive<br />

expansion plans mapped by SAIL and CIL, mining activities<br />

would considerably rise, the demand for mechanisation and<br />

highly productive, safe, efficient and cost effective machinery<br />

will increase, and thus the growth in demand is inevitable,”<br />

said an industry expert.<br />

The new mining policy of the government of India is also<br />

expected to give a further boost to the mining sector. As per<br />

industry experts, the mining sector now accounts for 2.8<br />

percent of the GDP, and the figure is slated to go up.<br />

“Currently, the market size of mining equipment in the<br />

country is estimated to be over Euro 1 billion. Being a highly<br />

competitive industry, it comprises public as well as private<br />

sector companies including joint ventures and closely held<br />

companies,” said Nath.<br />

However, the Indian local equipment market is still at a<br />

nascent stage, except for some companies like who supply to<br />

the Indian requirements, rest is imported or purchased from<br />

the foreign companies with units in India,” said an official of<br />

Komatsu, an international equipment manufacturer.<br />

Due to the present demand-supply gap, a lot of the current<br />

demand is met by imports. “Around 70 to 80 percent of the<br />

domestic requirement is catered by the domestic production<br />

which is inclusive of the international players who have set<br />

up units in India, while the rest is imported,” a market expert<br />

said. India imports largely from Russia, Germany, China<br />

and also North America. In addition to this, there are many<br />

international companies in the Indian market who import on<br />

behalf of the miners. Some of these companies do not have<br />

manufacturing base but have technology. Thus the designing<br />

is done by them as per market conditions and then it is<br />

manufactured in their base units which is then imported to<br />

India.<br />

“India imports around Euro 600 to 650 million of mining<br />

equipment,” noted Nath. The rationale behind increasing<br />

imports is the perceptible shift in trend towards using larger<br />

size, cost effective and technologically upgraded equipment to<br />

meet the exponentially growing demand for minerals.<br />

“With increasing activity, Indian miners are now looking<br />

for more efficient and technologically sound machines for good<br />

production. Thus, despite the fact that the machineries made<br />

by the foreign companies are expensive, they are gradually<br />

getting accepted in the Indian market. The advantage is that<br />

although there is a high initial investment, the long term<br />

maintenance cost is much lower. Thus, after some resistance<br />

amidst the Indian buyers, it is slowly picking up now,” the<br />

official of Komatsu informed.<br />

In addition to this, most of these products are not<br />

manufactured in India or Indian companies and thus<br />

have to be imported, Coal Insights gathered. Around 80 to<br />

85 percent of the equipment for underground mining are<br />

imported while around 20 to 25 percent are imported for<br />

opencast mining.<br />

“Basically the earlier methods were not efficient, and<br />

machines used to break down. Now with increasing<br />

production, more reliable equipment is required, which will<br />

help in better production,” said an industry expert.<br />

Vis-à-vis the global market, India fares well in terms of price<br />

and quality. However, Indian equipment manufacturers lag<br />

behind their international counterparts in terms of technology,<br />

market experts feel. “Indian equipment is cheaper but there<br />

are limitations in capacity. High capacity equipment is not<br />

yet available in India,” pointed out Nath. “Indian products<br />

are competitive in terms of prices and also in terms of quality<br />

but technological upgradation is required,” said an official of<br />

HEC, one of the leading domestic equipment supplier and<br />

manufacturer.<br />

Thus, the Indian equipment manufacturers are upgrading<br />

themselves both in terms of quality as well as capacity in<br />

order to make themselves globally competitive. “India is<br />

campaigning abroad to take up international mining projects,”<br />

said an official of BEML, the public sector equipment<br />

manufacturing biggie.<br />

Indian equipment has found markets in the Middle East<br />

and Africa, where cost-competitiveness is a bigger factor than<br />

technology. It is also supplying some spares to Europe and<br />

the US.<br />

The sourcing<br />

Indian mine owners generally acquire the equipment by two<br />

routes. They either purchase it or take it on rent or lease. It will<br />

COAL INSIGHTS 8 October 2010

Cover Story<br />

be interesting to note that during recession, the major mine<br />

owners opted for more and more of outsourcing, and thus<br />

direct purchases by mine owners saw a drop.<br />

However, as the markets recovered, the sales have also<br />

increased. “In the <strong>coal</strong> segment 70 percent of the production<br />

is done by CIL and its subsidiaries. They purchase equipment<br />

along with long term service contract. This happens mainly<br />

for large contracts.<br />

The miners look for life warranty period for new machines<br />

which is decided by the manufacturing companies depending<br />

upon the conditions. Thus companies like BEML set up service<br />

centres at the respective areas to provide the best services,”<br />

said an official of BEML.<br />

“The Indian mining industry generally buys 90 percent of<br />

their mining requirement but during buying the maintenance<br />

contract is also included. This is made as a part of the deal and<br />

is done by OEM for the new equipment. The concept of leasing<br />

has just started and some companies are slowly entering in<br />

this route,” the HEC official informed.<br />

Companies like NMDC and SAIL sometimes purchase<br />

the machinery. However, players like Essar go for the<br />

subcontracting route for the major part of their mining<br />

operations. CIL also purchases equipment by either global<br />

tendering or domestic bidding. Most steel companies<br />

outsource just a part of their mining operations, and for certain<br />

activities like overburden removal and wagon loading, they<br />

take the equipment on rental lease.<br />

Mining companies like CIL and NMDC purchase<br />

equipment along with maintenance and repair contract<br />

(MARC). Here the equipment manufacturer has to take the<br />

responsibility of maintenance and repair of the equipment<br />

during its life span.<br />

Pain points<br />

Although the market outlook is optimistic at present, but<br />

very lately the industry has been plagued by the slowdown<br />

in mining activities. “The pace of the projects is not the same<br />

as expected due to land clearance and environmental issues.<br />

The projects are not moving as expected and this scenario<br />

has been continuing for the last six months. The Ministry of<br />

Environment and Forests has modified certain issues. The<br />

effect has been more on <strong>coal</strong> mining than the iron ore mining<br />

therefore the sales of the equipments have gone down,” the<br />

official of Komatsu informed.<br />

But this is a temporary phase, and the demand is likely<br />

to pick up soon as the Prime Minister’s Office has intervened<br />

into the issue and thus it is likely to be resolved soon, as per<br />

industry experts.<br />

“In India demand for <strong>coal</strong> is increasing, but the projects<br />

are affected due to environmental issues. The companies are<br />

busy in land development which indirectly affected the Indian<br />

equipment industry and sales are hit,” said Nath.<br />

Another pain point of the industry is the volatility in steel<br />

prices. As steel is the main raw material for manufacturing<br />

machineries, volatility in steel prices has affected the<br />

machinery prices. Nath noted that this has resulted in the<br />

price of equipment rising across the globe.<br />

The way forward<br />

The mining equipment sector can just grow from this point.<br />

The economy is poised to grow at 8 to 9 percent in the next<br />

decade coupled with huge plans made in all industries,<br />

especially steel, and the demand for raw materials is soaring.<br />

In fact, raw material security is one of the major concerns of<br />

the industrial sector.<br />

The mining industry has targeted to achieve<br />

`4,16,500 crore by 2015. Coal and iron ore mining<br />

is expected to grow as the government has<br />

promised ‘power for all’ in the next couple of<br />

years and the construction of infrastructure is<br />

expected to boom.<br />

As per industry reports, with more and more<br />

international players entering the sector and local<br />

companies ramping up production capacities,<br />

the Indian mining equipment industry is also<br />

expected to see an investment of `22,395 crore in<br />

the next five years.<br />

Clearly the increasing demand would speed<br />

up the high capacity mining and increasing<br />

automation. Thus, the requirement for large<br />

equipment is also expected to shoot up.<br />

The mining sector is now looking at<br />

highly sophisticated, efficient and customised<br />

equipment. Thus, it is imperative for the mining<br />

equipment companies to technologically revamp<br />

itself and increase investment in R&D.<br />

COAL INSIGHTS 10 October 2010

Cover Story<br />

India, China lead global resurgence<br />

Arusha Das<br />

As opposed to the Indian mining sector which was<br />

largely unaffected by the global meltdown, the global<br />

mining sector was hit quite badly.<br />

However, there is a gradual, albeit slow, improvement in<br />

the global scenario. The global demand for mining machinery<br />

and equipment began to plummet in 2008 due to the downturn.<br />

The decline in demand continued through 2009 but some<br />

growth although very slow has been seen in 2010.<br />

In terms of unit sales, China represents the <strong>largest</strong> market<br />

for mining machinery worldwide, as per industry experts.<br />

“The mining in the European countries is still slow. But there<br />

is growth in both India and China and these markets will be<br />

expanding further in future.<br />

During recession and in 2009 the global mining sector<br />

was hit, which hit the equipment manufacturers as well. This<br />

resulted in a drop of 15 to 20 percent in the sales turnover of<br />

the equipment manufacturers. But in 2010 the situation is<br />

somewhat better,” said an industry expert.<br />

Referring to the German mining equipment industry,<br />

managing director of German engineering federation VDMA,<br />

Rajesh Nath, told Coal Insights that the industry has overcome<br />

the crisis well. In 2009, the industry turnover was Euro 3.5<br />

billion and in 2008 it was almost at the same level.<br />

“The mining equipment industry in Germany posted better<br />

results than any other engineering industry in the region as<br />

a lot of supplies catered to the massive Chinese requirement<br />

along with some backlog orders,” Nath informed.<br />

Speaking about the current scenario, an official of HEC<br />

said that: “In the international market, the Chinese market is<br />

robust. In Australia, mining is growing. In addition to this,<br />

in Brazil the steel industry is surging. Thus, there is huge<br />

opportunity mainly from BRIC nations.”<br />

The mining sector<br />

However, very lately, the international commodity markets<br />

were being influenced by near term slowing from China<br />

and from declining momentum of industrial production in<br />

the US.and other developed countries. Both China’s and US<br />

steel output is down in the second half of 2010. This slowing<br />

growth in steel production is impacting near term demand for<br />

met <strong>coal</strong> and iron ore. Thus, demand for these raw materials is<br />

levelling off along with softening of prices.<br />

Meanwhile, copper imports into China also have been<br />

impacted by significant reductions in Shanghai exchange<br />

stocks. China’s slowing down is being offset by increased<br />

demand in the rest of the world, and this is providing support<br />

to pricing.<br />

As a result, copper expansion projects are happening in<br />

North and South America and Australia, along with future<br />

greenfield projects in Central Africa and Mongolia.<br />

In the seaborne thermal <strong>coal</strong> markets, it continued to be<br />

robust through the first half of 2010, led by China and India.<br />

Imports are expected to moderate in the second half. In<br />

addition, India’s major new power plants are being sited in<br />

coastal regions to enable access to seaborne markets.<br />

Thus, future demand will continue to be driven by new<br />

<strong>coal</strong>-fired power generating capacity scheduled to come on<br />

line in Asia Pacific during 2010. These additions will increase<br />

regional <strong>coal</strong> consumption.<br />

In the interim, the US.<strong>coal</strong> market continued to improve.<br />

Although the macroeconomic factors could impact near term<br />

demand, but if the longer term fundamentals continue to<br />

improve, it would trigger a positive outlook for commodity<br />

markets. Emerging markets will continue to industrialise their<br />

economies and the developed countries will continue to recover.<br />

Thus, the demand for mined commodities continues to be<br />

dominated by strong imports from the emerging markets, and<br />

from China and India in particular, with improving but still<br />

weak fundamentals from the industrialised countries. “India<br />

has been growing fast in terms of mining and in China also<br />

there is massive growth,” said an official of BEML.<br />

Thus, India is gradually witnessing growing interest from<br />

the international players. Nath pointed out that there has been<br />

a number of investments made last year. “ThyssenKrupp<br />

Materials Handling Pty Ltd. (TKMH), a subsidiary of German<br />

based global corporation, ThyssenKrupp AG has set up a<br />

manufacturing unit in India.<br />

Carlisle Companies Inc, a US based manufacturer<br />

announced the opening of its first India office in Chennai.<br />

The company has several diversified divisions including<br />

construction materials. Carlisle Trading and Manufacturing<br />

India Pvt Ltd, a wholly owned subsidiary of Carlisle<br />

Companies Inc will initially focus on India’s growing mining,<br />

construction and power sectors.<br />

Another mining equipment maker, Hectronic GmbH,<br />

has launched its India operations through a wholly owned<br />

subsidiary. The company offers “Intelligent Fuel Management<br />

Solutions” that help cut down unaccountable fuel costs. The<br />

solution uses globally proven robust technology of hardware<br />

and software which provides great tool for tracking and<br />

control on critical refuelling operation. By implementing<br />

Intelligent Fuel Management Solution, one can achieve total<br />

transparency in refuelling operation and can take more<br />

responsible decisions.<br />

Wirtgen GmbH, a member company of the Wirtgen<br />

Group, an internationally active group of companies in the<br />

COAL INSIGHTS 12 October 2010

Cover Story<br />

construction equipment industry, is setting up a unit in Pune.<br />

The unit is likely to be completed in another year.<br />

In addition to this, German companies are also tying up<br />

with Indian producers. For instance, HAZEMAG & EPR<br />

GmbH is a company belonging to the renowned EPR group,<br />

which has ventured into the mineral processing sector by<br />

tying up with Hari Machineries. The company is now going<br />

for licence agreement with Hari Machineries.<br />

Thus, Hari Machineries would be manufacturing for<br />

the company. The German companies are looking forward<br />

for JV or tie up with Indian companies and much of such<br />

activities would be seen soon as Germany looks at India as an<br />

opportunity region,” Nath explained.<br />

Market outlook<br />

Global demand for seven major products of mining equipment<br />

expanded by a year-on-year average rate of about 15 percent<br />

from the fiscal year ended March 31, 2004 through the fiscal<br />

year ended March 31, 2008. It was driven by growth of demand<br />

centering on emerging economies.<br />

With such positive outlook, the global mining equipment<br />

demand is likely to grow significantly over the years. Presently,<br />

China is a major market for mining equipment worldwide,<br />

backed by the country’s expanding mining industry. In<br />

addition to China, Australia and India are the other major<br />

markets in the Asia-Pacific region, where demand related to<br />

mining equipment is high.<br />

HEC targets `1000 cr sales by 2011-12<br />

Arusha Das<br />

India is home to myriad metals and minerals with<br />

significant reserves and the mining sector has an<br />

optimistic outlook.<br />

The Heavy Engineering Corporation Ltd (HEC),<br />

manufacturer of equipment and machinery for the iron<br />

and steel industry and mining, is all set to almost double<br />

its sales to `1000 crore by financial year 2011-12 from the<br />

existing `512 crore.<br />

“We are targeting sales of around `750 crore by the end<br />

of the current financial year and further take it forward<br />

to `1000 crore in 2011-12,” a company official told Coal<br />

Insights.<br />

In order to achieve the target, the company has mapped<br />

a multi pronged strategy. On one hand, it is trying to<br />

diversify itself in various segments, and on the other, it is<br />

trying to enter the export market.<br />

“We are optimistic that with these strategies in line, we<br />

will be able to post a profit of `35 crore by the end of the<br />

current financial year and take it to `100 crore by the end<br />

of next financial year, from the current profit of `27 crore,”<br />

he added.<br />

The PSU was also in talks with the Nuclear Power<br />

Corporation for opportunities for products used in nuclear<br />

reactors. The company will try to bring a foreign company<br />

as technical and financial collaborator for making finished<br />

products for nuclear power plants. The nuclear business<br />

project expenditure may be around `1000 crore.<br />

In addition to this, the company is also planning to<br />

expand its product basket and incorporate the complete<br />

range of large crushers in the existing product line. The<br />

company is also in talks with international players for new<br />

products but nothing has been finalised as of now.<br />

“We are open to tie-ups with international partners as<br />

the industry is now looking for technologically advanced<br />

machines, in view of the growing demand of <strong>coal</strong> and iron<br />

ore in the country,” the official hinted. The company is<br />

optimistic that all this will translate into consistent year on<br />

year growth of 20 percent.<br />

Meanwhile, the Ranchi-based engineering PSU is<br />

planning to list its shares on the bourses and a proposal<br />

will be sent to the government in the next financial year.<br />

The company can supply 25 excavators and two to three<br />

crushers per year, in the mining segment. The company has<br />

recently acquired an order from North eastern Coalfield,<br />

for a key dragline after 15 years.<br />

“We have recently got an order for one key dragline<br />

from North Eastern Coalfield, a subsidiary of Coal India<br />

Limited, after 15 years. This machine has a weight of 2000<br />

tons and requires 14-15 months for manufacturing. We<br />

are also expecting two similar orders in this segment,” the<br />

official said.<br />

The official informed that though the company is<br />

working on having its footprint in the international<br />

markets, it is not getting too many enquiries as the<br />

international mining segment is still slow. The company<br />

has three manufacturing units namely – Heavy Machine<br />

Building Plant<br />

(HMBP), Heavy Machine Tools Plant (HMTP) and<br />

Foundry Forge Plant (FFP). The company manufactures a<br />

wide range of equipment for steel plants, material <strong>handling</strong><br />

equipment like wagon tipplers and EOT cranes, heavy<br />

machine tools including CNC Machine tools and special<br />

purpose machine tools and various types of castings,<br />

forgings and rolls etc.<br />

COAL INSIGHTS 14 October 2010

Cover Story<br />

Beml plans to double turnover<br />

Arusha Das<br />

With the country’s industrial sector poised for a<br />

quantum leap, the outlook for India’s mining sector<br />

is bright, triggered by strong domestic demand.<br />

BEML Limited, one of the leading names that come to mind<br />

in the Indian mining equipment industry, is all set to tap<br />

the long-term prospects of the industry. The company plans<br />

to penetrate further into the market both in the domestic as<br />

well as in the global segments. For that, it intends to increase<br />

production on one hand and on the other, tap newer markets.<br />

The leading manufacturer of heavy earth moving<br />

equipment has a capex plan of `180 crore this fiscal and a<br />

similar amount next year. “We plan to double the current<br />

turnover to `7000 crore. The fastest-growing segment will be<br />

mining and construction and there will be some growth in<br />

defence too,” a company official told Coal Insights.<br />

The company has recently formed a joint venture with<br />

Mineral Exploration Corporation (MECL). Referring to this,<br />

the official noted that there are over 200 to 300 <strong>coal</strong> and non<strong>coal</strong><br />

mines allotted to the private sector which need someone<br />

to offer consultancy, mine planning and exploration services<br />

to them. It was to tap these huge opportunities in the domestic<br />

market that the JV was formed. In addition to this, the company<br />

will also be providing drilling equipment through this JV.<br />

BEML, along with Coal India (CIL) and Damodar Valley<br />

Corporation (DVC), has also acquired the plant and machinery<br />

of Mining and Allied Machinery Corporation (MAMC) in<br />

Durgapur in August 2010. BEML will have a 48 percent stake<br />

and 50 percent voting rights in the new joint venture. The<br />

company will leverage the assets, technology and expertise of<br />

MAMC in the new business. MAMC, which was 100 percent<br />

owned by the Ministry of Heavy Industries, has now been<br />

renamed MAMC Industries. The plant had been shut for eight<br />

years. The West Bengal government has agreed to give BEML<br />

BEML product basket<br />

BD475 BD355 BD355X BD155<br />

Crawler Dozers BD155X BD230 BD80 BD65X<br />

BD65-1 BD65 BD50 BD31<br />

Wheel Dozers BD46W BD30W-1 BD14W<br />

BE1600 BE1000-1 BE1000E BE700<br />

Excavators BE300LC BE220 BE220LC BE220X<br />

BE200<br />

BE71<br />

BH100 BH90 BH85-1 BH70 BH60<br />

Dump Trucks<br />

BH50M BH40 BH35-2 BH35<br />

MT4400AC MT4400 MT3700AC MT3700B MT3600B<br />

MT3300AC MT3300 MT3000<br />

Loaders BL200-1 BL656-1 BL636-1<br />

Backhoe Loaders BL9H(4X4) BL9H<br />

Source: BEML & Insights Research<br />

land on lease for the plant, which will make equipment for the<br />

steel and power sectors and underground mining equipment.<br />

“We plan to restart the plant soon,” noted the official.<br />

Meanwhile, with the intention to diversify and foray into<br />

new segments, the company has recently opened a new plant<br />

in Palakkad, Kerala, to manufacture components for railway<br />

coaches. It is spread over 375 acres of land and has a builtup<br />

area of 2 lakh sq ft. The investment on the new plant was<br />

about `150 crore, and the project was completed in 10 months<br />

from the day the land was handed over to the company. In<br />

phase II, BEML will spend `140 crore, and it is now waiting<br />

for the Kerala government to give them 600 acres before<br />

they start work. In addition, BEML is also expanding two<br />

facilities in Mysore and Kolar gold fields, where the company<br />

manufactures heavy vehicles used by the army in deserts<br />

and hilly terrain, at a cost of `180 crore. The company will<br />

commission them in the next fiscal.<br />

In addition to this, the company has just come out with<br />

an 80-ton aluminium wagon for freight corridors, for which<br />

Nalco supplies the material. BEML is also in the process of<br />

building a 100-ton stainless steel wagon with SAIL. The<br />

company is also looking at high-speed and medium speed<br />

trains. The company now has four units, including the new<br />

Palakkad one. Of these, the KGF complex and Mysore unit are<br />

involved in producing mining equipment which account for<br />

60 percent of the total equipment produced by the company.<br />

The company’s earth moving division (EMD) at Kolar Gold<br />

Fields (KGF) is located about 100 km from Bangalore. It is the<br />

biggest manufacturing plant of BEML catering to design and<br />

development, manufacturing, testing and after-sales service of<br />

earth moving equipment and its aggregates.<br />

The company is also secured in terms of raw material.<br />

BEML’s subsidiary company, Vigyan Industries Limited,<br />

produces casting which caters to the in house requirements,<br />

while the remaining is sold in the open market.<br />

The company has posted a growth of 18 percent in the<br />

sales to `3557.67 crore in 2009-10 compared to `3013.47 crore<br />

in the corresponding period in the previous year. The value<br />

of production also posted a growth of 12.5 percent, reaching<br />

`3708.66 crore in the financial year 2009-10 compared to<br />

`3294.19 crore in the corresponding period in the previous year.<br />

Despite the notable increase in sales volume, the profit<br />

took a hit owing to low metro car sales, lesser quantum of<br />

sales of spares and lesser turnover of exports coupled with<br />

severe competition that had pressure on the margins. There<br />

was drop in exports on the account of global recession and<br />

also many orders could not be converted into LC owing to<br />

fund constraints with the customers. However, the company<br />

has increased its international presence from 55 countries to 56<br />

countries and added Brazil to the list. It has also initiated steps<br />

to maximise the profits.<br />

COAL INSIGHTS 16 October 2010

Cover Story<br />

Global cos bank on emerging economies<br />

Arusha Das<br />

There was a very strong commodities market correction in<br />

2009. The collapse of US market in Q4 of 2008 has directly<br />

impacted the demand for commodities and thus the<br />

mining equipment market. However, the situation is improving<br />

and the growth is driven by the emerging economies. Thus<br />

the global mining equipment majors are now looking towards<br />

these strategic markets which are being fuelled by the growth of<br />

infrastructure development projects resulting from advancing<br />

urbanization as well as the expansion of demand for commodities<br />

and energy sources resulting from an increasing population.<br />

KOMATSU<br />

As the market showed signs of recovery, some economies<br />

generated signs of recovery, reflecting positive effects of the<br />

economic stimulus packages of their respective governments.<br />

The positive effects of the Chinese economic growth are<br />

reaching the surrounding Asian countries and those with<br />

natural resources, helping their economic recovery. However,<br />

the pace of economic recovery was dull in Japan, North<br />

America and Europe.<br />

Thus, Komatsu was engaged in production adjustment<br />

around the world and achieved an appropriate level of<br />

inventories in the first half. The company also reorganised<br />

production of businesses of both the construction, mining and<br />

utility equipment and the industrial machinery and others,<br />

while realigning sales of construction equipment and forklift<br />

trucks in Japan.<br />

In addition to this, to ensure sales and profits, Komatsu<br />

reinforced ICT-deployed businesses, such as the KOMTRAX<br />

(Komatsu Machine Tracking System), strengthened operations<br />

in China and mining equipment, in which business was<br />

expanding, and worked to strengthen the parts and service<br />

business. Affected by global demand the market did not come<br />

back to the level of the pre-financial meltdown. Thus, both<br />

sales and profits declined from the previous fiscal year.<br />

The company is anticipating that economic growth in these<br />

emerging countries will drive global demand. The company has<br />

positioned Asia, Oceania, Latin America, Africa and some other<br />

emerging economies as “strategic markets,” and is working<br />

to drive growth. The company’s strengths are its global sales,<br />

service and production networks. As of June 30, 2010, Komatsu<br />

has 205 distributors in 148 countries, covering 99 percent of<br />

global demand in units. Forty-five production facilities of its<br />

construction, mining and utility equipment business are in<br />

operation in Japan, China, the Americas, Europe and CIS.<br />

India operations<br />

The company’s manufacturing facilities are located in Chennai<br />

and Bangalore. The Chennai facility concentrates on more of<br />

larger size equipment, while the Bangalore facility is a joint<br />

Percentage Share of Sales by Region for 2010<br />

(To Outside Customers)<br />

7%<br />

7%<br />

13%<br />

22%<br />

Source: Komatsu & Insights Research<br />

3%<br />

venture with Larsen & Toubro. Komatsu is targeting to run on<br />

100 percent capacity even in the current fiscal, said a company<br />

official. Relying on the upcoming growth in the mining sector<br />

of India, Komatsu is planning to enhance their market position<br />

by measures like product launchings before competitors,<br />

expansion of local production and further reinforcement of<br />

sales and product support operations.<br />

Specifically, the company intends to make a decisive<br />

difference from competitors with no downtime of customers’<br />

machines by not only providing products with superior QCDS,<br />

that is, quality, cost, delivery and safety but also ensuring<br />

prompt spare parts delivery and service. The company is also<br />

strengthening manufacturing cost reduction activities in China.<br />

JOY GLOBAL<br />

Joy Global Inc., a leading manufacturer and servicer of high<br />

productivity mining equipment for the extraction of <strong>coal</strong> and<br />

other minerals and ores, also chalked out a strategy to beat<br />

recession. Joy opened its first Smart Services Center in South<br />

Africa. Through the use of wireless technology, Joy engineers<br />

can gather relevant information on machines working<br />

underground. This provided preemptive and predictive<br />

feedback which in turn provided better machine performance<br />

and lower costs while maintaining focus on worker safety.<br />

The company also delivered and commissioned the <strong>largest</strong><br />

capacity powered roof supports in the world. The mine in<br />

Australia started production with a full Joy system (shearer,<br />

armored face conveyor, powered roof supports and control<br />

platforms), including state of the art powered roof supports.<br />

This has set a new benchmark in lifecycle design and test, with<br />

successful 90,000 cycle testing and a rated capacity of 1900 tons.<br />

Joy has also delivered Top Coal Caving capability for its<br />

armored face conveyor product in China. The company has a<br />

significant presence in Australia, South Africa, the UK, China<br />

and the US as well as sales offices and service facilities in India,<br />

Poland and Russia. The company’s product basket includes<br />

continuous miners, shuttle cars, flexible conveyor trains,<br />

18%<br />

11%<br />

19%<br />

Japan<br />

China<br />

North America<br />

Asia & Oceania<br />

Europe<br />

Middle East & Africa<br />

Latin America<br />

CIS<br />

COAL INSIGHTS 18 October 2010

Cover Story<br />

complete longwall mining systems (consisting of powered<br />

roof supports, an armored face conveyor, and a longwall<br />

shearer, continuous haulage systems, battery haulers and roof<br />

bolters.<br />

Additionally, Joy also maintains an extensive network of<br />

service and replacement parts distribution centres to rebuild<br />

and service equipment and to sell replacement parts and<br />

consumables in support of its installed base. This network<br />

includes five service centres in the US and eight outside the<br />

US, all of which are strategically located in major underground<br />

mining regions. The surface mining equipment unit of the<br />

company P&H Mining Equipment continued to build upon the<br />

successful introduction of AC-drive electric mining shovels in<br />

2009. This is applied to its wide-track P&H 4100BOSS shovels for<br />

oil sand mining and other soft-ground operations in 2008. ACdrive<br />

P&H 4100XPC shovels will be introduced starting in 2010.<br />

P&H Mining Equipment introduced a new remote health<br />

monitoring system during 2009 to help mine operations<br />

optimize productivity and reliability performance on their<br />

P&H shovels. This system features powerful shovel systems<br />

health monitoring, data trending and diagnostics tools that<br />

help mine maintenance personnel obtain faster resolution of<br />

machine performance issues.<br />

Meanwhile, the Continental Crushing & Conveying<br />

completed a new <strong>coal</strong> offloading and storage facility for the<br />

port of Tyne, UK. The fully-integrated system can deliver and<br />

create individual 65,000-ton stockpiles of “separated <strong>coal</strong>.”<br />

It included system monitoring using video cameras and<br />

stockpile height and movement monitoring. This conveyor<br />

system sequencing and pre-start and emergency stop were<br />

installed for safe and efficient transport of material.<br />

BUCYRUS<br />

Although 2009 proved to be a very difficult year for many<br />

US based companies, the situation was not the same for<br />

Bucyrus. It was one of the only few companies which was<br />

able to increase both revenue as well as earning. Considering<br />

that more than 70 percent of the sales are generated outside<br />

US and the relative strength of the international markets, the<br />

geographic diversity has allowed the company to weather<br />

much of the domestic turmoil.<br />

The market uncertainty propelled the company to reevaluate<br />

the overall plan for 2009, and as a result, the company<br />

was able to set up a solid base for financial year 2010. The<br />

78%<br />

2009 Machine sales by commodity<br />

Coal Copper Iron ore Oil Sands Other<br />

Source: Bucyrus & Insights Research<br />

company decided to proactively manage the $2.5-billion<br />

backlog the company had at the end of 2008, by trying to help<br />

the customers to defer their expenses in the face of softening<br />

demand for their commodities.<br />

The company removed as much of this backlog as possible<br />

in 2010. This levelled the revenue in 2009 and gave the company<br />

substantial backlog support in 2010. In addition to this, strong<br />

aftermarket activity, particular in the spare parts, allowed<br />

Bucyrus to increase the revenue as the year progressed. The<br />

company’s continued parts initiatives in the underground<br />

segment has also proved effective. Thus, the revenues exceed<br />

2008 level by 6 percent and the margins improved.<br />

Apart from the strong market strategy, the company<br />

acquired Terex Mining of Terex Cooperation on February 19,<br />

2010. The acquisition has made Bucyrus the premier supplier of<br />

mining equipment. This has allowed the company to diversify<br />

the product basket across a broader range of commodities and<br />

double the potential market to approximately $30 billion.<br />

This would help the company to benefit from the strong<br />

presence of Terex Mining in the Asia Pacific region. In addition<br />

to this, Terex Mining has a strong presence in China, whereas<br />

Bucyrus has absolutely no market share on a standalone basis.<br />

With this acquisition, the company’s installed base moved up<br />

to $40 billion from $30 billion. The size of the installed base<br />

of surface and underground mining original equipment at<br />

December 31, 2009 was around $20 billion, which increased<br />

to approximately $30 billion with Terex acquisition, and $10<br />

billion respectively.<br />

The company’s product lines include dragline, electric<br />

mining shovels, rotary blasthole drills, longwall systems,<br />

room and pillar machinery and belt systems. The company’s<br />

aftermarket services include replacement parts, maintenance,<br />

technical advice, structural and mechanical engineering,<br />

repairs, rebuilds, refurbishments and upgrades.<br />

1%<br />

3%<br />

10%<br />

8%<br />

2009 Total sales by product<br />

12%<br />

2009 Total sales by Region<br />

7%<br />

4%<br />

38%<br />

51%<br />

49%<br />

18%<br />

Aftermarket<br />

Source: Bucyrus & Insights Research<br />

Machines<br />

North America Europe, Russia, India South America Australia/Asia Pacific China Africa<br />

Source: Bucyrus & Insights Research<br />

21%<br />

COAL INSIGHTS 20 October 2010

<strong>coal</strong> market fundamentals<br />

Steady demand pushes up thermal <strong>coal</strong><br />

Arnab Mallick<br />

The global thermal <strong>coal</strong> market is back on fire once again<br />

with benchmark price showing significant rise over<br />

last few weeks, primarily on back of robust demand.<br />

Coal shipments from Australia’s Newcastle port has been<br />

witnessing steady w-o-w growth over the last few weeks.<br />

There has been continuing steady demand from China and<br />

India. At the same time, demand has picked up significantly<br />

in other Asian markets as well, including Japan. It has been<br />

learnt that Japan’s power generation by its 10 main utilities<br />

have gone up significantly, as heat wave continues thereby<br />

supporting air conditioning demand. Although most of the<br />

power generation is fuelled by crude oil, it has also resulted in<br />

significant rise in thermal <strong>coal</strong> consumption as well.<br />

Much of the improvement seen over the past few weeks<br />

can be attributed to the growing demand for thermal <strong>coal</strong> from<br />

both India and China. Besides, buying interest from China for<br />

the fourth-quarter was also increasing, ahead of the winter<br />

months. But though the utilities are planning to increase stocks<br />

for winter, they are in no hurry as current stocks are still high.<br />

According to the globalCOAL NEWC index, the benchmark<br />

price index for the Asian market, thermal <strong>coal</strong> prices improved<br />

to $99.03 per ton for the week ended October 22 as compared<br />

to $94.89 per ton for the week ended September 24.<br />

The price appreciation has been even sharper in the South<br />

African market, thanks to fundamental improvement in<br />

market sentiment. According to globalCOAL RB index for<br />

South African <strong>coal</strong>, price of thermal <strong>coal</strong> improved to $93.96<br />

per ton for the week ended October 22, as compared to $84.14<br />

per ton for the week ended September 24.<br />

The rising demand sentiment has been quite evident from<br />

the steady export figures from the Nescastle port. As per latest<br />

data, <strong>coal</strong> exports at Australia's Newcastle port, the world's<br />

<strong>largest</strong> <strong>coal</strong> export terminal, rose 27 percent in the week ended<br />

October 18 as compared to its previous week. According to<br />

data available with port authority, total exports from the port,<br />

which ships mostly thermal <strong>coal</strong> used in power plants, were<br />

2.4 million tons (mt) in the week to October 18, climbing from<br />

1.9 mt the previous week.<br />

110<br />

105<br />

100<br />

95<br />

90<br />

globalCOAL NEWC Index<br />

85<br />

15- 29- 12- 26- 12- 26- 9- 23- 7- 21- 4- 18- 2- 16- 30- 13- 27- 10- 24- 8- 22-<br />

Jan Jan Feb Feb Mar Mar Apr Apr May May Jun Jun Jul Jul Jul Aug Aug Sep Sep Oct Oct<br />

globalCOAL RB Index<br />

98<br />

96<br />

94<br />

92<br />

90<br />

88<br />

86<br />

84<br />

82<br />

80<br />

15- 29- 12- 26- 12- 26- 9- 23- 7- 21- 4- 18- 2- 16- 30- 13- 27- 10- 24- 8- 22-<br />

Jan Jan Feb Feb Mar Mar Apr Apr May May Jun Jun Jul Jul Jul Aug Aug Sep Sep Oct Oct<br />

Week ended<br />

Meanwhile, the vessel queue at the port fell slightly to 12<br />

ships from 13, but the average waiting time for vessels at the<br />

port increased slightly to 13.92 days from previous week’s<br />

comparable level of 13.78 days. It is worth noting at this juncture<br />

that a similar price trend has also been observed in Indonesia, the<br />

latest exporter of thermal <strong>coal</strong> after Australia. As per available<br />

information, the reference price for <strong>coal</strong> sales in Indonesia has<br />

also climbed in October for the first time since June.<br />

As per market sources, the price of <strong>coal</strong> with a gross energy<br />

value of 6322 kilocalories a kg gained 3 percent to $92.68 per<br />

ton this month compared with September when reference price<br />

was $90.05 per ton. Sources said that the Directorate General<br />

of Coal, Minerals and Geothermal at the energy ministry has<br />

made a similar statement. Brands including Gunung Bayan<br />

1 has been commanding highest price of around $99.79 per<br />

ton as compared to previous month’s level of $96.94 per ton<br />

followed by Prima Coal and Pinang 6150 at $97.55 per ton and<br />

$87.92 per ton respectively.<br />

In the meantime, it has also been learnt that prices are being<br />

settled for contracts between Australian shippers and Japanese<br />

utilities for the year from October. Prices are being set at $97 to $98<br />

per ton, the same as the larger volume contracts which took effect<br />

from April 2010. Media reports quoting a Citibank report noted<br />

that domestic prices in China are more stable, however, were at<br />

around $112 per ton for 6000 kilocalorie fob Qinhuangdao and<br />

the arbitrage has closed as a consequence at the end of September.<br />

China's imports for August were a robust 13.3 mt.<br />

Citi Group said that: “Our already positive view on the<br />

thermal <strong>coal</strong> market was reaffirmed by our recent work on<br />

the true competitive position of Australian exports vs China’s<br />

production. We expect the price to average $100 per ton<br />

in 2011, and our long term price is $90 per ton.” However,<br />

demand for thermal <strong>coal</strong> from India is likely to rise further<br />

in the coming days as the country would have to meet its<br />

own commercial and industrial demand. The country’s <strong>coal</strong><br />

imports have been growing rapidly over the past few years<br />

and if its power production targets are to be met, then it would<br />

have to continue to do so even this year.<br />

COAL INSIGHTS 22 October 2010

<strong>coal</strong> market fundamentals<br />

Coking <strong>coal</strong> contract price drops for Q3<br />

Arnab Mallick<br />

Contract negotiations for various categories of coking<br />

<strong>coal</strong> were finally completed among leading miners and<br />

steel makers. It was felt during the end of September<br />

that negotiations for the third quarter had been partially<br />

settled with BF steel producers. As per available information,<br />

a number of BF steel producers fixed the semi-soft coking <strong>coal</strong><br />

prices loaded at Newcastle with several Australian suppliers<br />

at $138 per ton fob to $140 per ton fob for the third quarter.<br />

Since the price in the second quarter was set at $172 per ton<br />

fob, the prices for the third quarter have been reduced by $32<br />

to $34 (18.6 to 19.8 percent) from the previous quarter.<br />

At this stage, however, negotiations with the two <strong>largest</strong><br />

suppliers of semi-soft coking <strong>coal</strong> loaded at Newcastle,<br />

Xstrata and Rio Tinto had not yet been settled. In contrast, the<br />

negotiations with the two <strong>largest</strong> suppliers of semi-soft coking<br />

<strong>coal</strong>, Xstrata and Rio Tinto, took longer and the agreement on<br />

semi-soft coking <strong>coal</strong> exported by these suppliers could not be<br />

reached within September. That was because both suppliers<br />

strongly opposed the large price reduction.<br />

However, it finally got settled in the middle of October. Rio<br />

Tinto Coal has settled semi-soft coking <strong>coal</strong> prices for October-<br />

December at $143 per ton fob with its Japanese customers, a<br />

drop of almost 17 percent from the $172 per ton achieved in<br />

the third quarter, said informed sources. The price won by<br />

Rio betters the $138-140 per ton fob Newcastle port that was<br />

achieved by smaller semi-soft coking <strong>coal</strong> producers in NSW’s<br />

Hunter Valley at the end of September.<br />

On October 1, Wesfarmers Ltd of Australia announced<br />

that its contract prices of metallurgical <strong>coal</strong>s (hard coking <strong>coal</strong>,<br />

semi-hard coking <strong>coal</strong> and PCI <strong>coal</strong>) produced at Curragh<br />

<strong>coal</strong> mine under its own operation fell by an average 11<br />

percent for the contract period between October-December<br />

2010 as compared with those for the previous quarter (July-<br />

September). Out of that the contract price of Curragh hard<br />

coking <strong>coal</strong> during October-December remained $205 per ton<br />

fob, down $20 (8.9 percent) from the previous quarter.<br />

It is to be noted here that hard coking <strong>coal</strong> negotiations<br />

between the BF steel producers and BHP Billiton Mitsubishi<br />

Alliance (BMA) ended in agreement on August 30. The prices<br />

of main brands of hard coking <strong>coal</strong> exported by BMA in the<br />

third quarter became $209 per ton fob each for Peak Downs<br />

and Saraji <strong>coal</strong>, $205 per ton fob each for Goonyella <strong>coal</strong> and<br />

Riverside <strong>coal</strong>, $195 per ton fob for Norwich Park <strong>coal</strong> and $190<br />

per ton fob for Gregory <strong>coal</strong> with price reduction of $16 to $20<br />

COAL INSIGHTS 23 October 2010

<strong>coal</strong> market fundamentals<br />

for every brand from the second quarter (July-September). At<br />

the same time at the end of August, low volatile (LV) PCI <strong>coal</strong><br />

of Russian origin was set at $130 per ton fob with the reduction<br />

of $40 (22.5 percent) from the previous quarter. Furthermore<br />

from end August through early September, the prices of LV<br />

PCI <strong>coal</strong> produced in Queensland Australia have been settled<br />

one after another. LV PCI <strong>coal</strong> for the third quarter became<br />

$147 per ton to $150 per ton fob, down $30 to $33 (16.7 percent<br />

to 18.3 percent) from the previous quarter.<br />

The price negotiations with the blast furnace steel<br />

producers on Hongay anthracite of Vietnamese origin for the<br />

third quarter of the fiscal year 2010 (October-December) was<br />

also heard to have been completed. The contract price for the<br />

third quarter of Hongay No.6 <strong>coal</strong> for PCI operation was set at<br />

$150 or so, while that of the Hongay No.8 <strong>coal</strong> for sintering at<br />

$143 per ton fob or so with price reductions of $30 plus (about<br />

17 percent) for No.6 <strong>coal</strong> and $27 plus (about 16 percent) from<br />

the first half of the fiscal year 2010 (April-September).<br />

Meanwhile, as the quarterly contract prices are getting<br />

settled, weakness is seen in certain crucial markets including<br />

China. Market sources revealed that domestic coking <strong>coal</strong><br />

prices in China’s Shanxi province have become depressed<br />

due to weak demand. Many feel that relatively high priced<br />

coking <strong>coal</strong> price have impacted demand from coke makers.<br />

Coke market lukewarm<br />

The global coke market, which is clearly dominated by<br />

China, has remained rather uneventful. As per available<br />

information, domestic coke prices in China’s Shanxi<br />

province have remained more-or-less stable over the past<br />

month, despite weak demand from steel mills. Market<br />

sources informed that first grade coke in Shanxi province<br />

was selling for RMB 1800 to 1850 per ton ($270-277 per<br />

ton) on October 11 including 17 percent VAT, the same<br />

price as on September 17.<br />

Prices of second grade coke from the province were<br />

around RMB 1700 per ton ($255 per ton) including 17<br />

percent VAT, up slightly by RMB 20-50 per ton ($3-8 per<br />

ton) compared with 1,650-1,680 per ton on September 17.<br />

Overall, the market has been impacted by the relatively<br />

weak demand situation.<br />

Things were no different back home during the first<br />

half of October. During the first week of the month, coke<br />

price hovered between $370 and $390 per ton depending<br />

on requirement, which is almost the same or slightly on<br />

the lower side compared to the rates prevailing around<br />

a fortnight ago. At that time, Chinese coke was available<br />

in India at around $400 per ton fob. Vietnamese coke was<br />

also available at around the same rate ($400 per ton).<br />

However, things have been improving of late. During<br />

early second half of the month, coke (with ash content<br />

12.5 percent) was selling at a minimum price of `20,500<br />

per ton.<br />

Sources informed that around October 19, prevailing price<br />

of hard coking <strong>coal</strong> in northern China’s Shanxi province was<br />

around RMB 1450 to 1500 per ton ($218-226 per ton) including<br />

17 percent VAT, down by RMB 50 per ton ($8 per ton) from<br />

RMB 1500 per ton on September 20.<br />

As far as supply is concerned, it has been learnt that<br />

Xstrata Coal saw its production of coking <strong>coal</strong> decline 5<br />

percent in the third quarter 2010 from the same period a year<br />

ago to 1.9 million tons (mt). Production of semi-soft coking<br />

<strong>coal</strong> (Australia) was also lower in Q3 2010 to 1.5 mt from 1.7<br />

mt in Q3 2009. Average received prices for coking <strong>coal</strong> were<br />

however much higher than the previous year at $230.40 per<br />

ton in Q3 2010 compared to $150.90 per ton in Q3 2009. Semisoft<br />

prices were also much higher in Q3 2010 at $149 per ton<br />

from $83.30 per ton in Q3 2009.<br />

Russian raw materials producer Evraz also saw its<br />

production drop. Evraz’s coking <strong>coal</strong> production fell 20.8<br />

percent to 1524 mt in Q3 2010 from 1923 mt in Q3 2009. This<br />

lower figure was the result of an explosion at the Raspadskaya<br />

mine on May 9.<br />

However, things may get tougher in the spot market on<br />

back of supply problem from Queensland. Heavy rains in<br />

central Queensland have caused coking <strong>coal</strong> spot prices<br />

to jump $10 per ton and major producers to declare force<br />

majeure on <strong>coal</strong> exports during middle of October. As a result,<br />

Wesfarmers has reduced its 2010-11 coking <strong>coal</strong> production<br />

guidance by around 3,00,000 tons to 6.2 to 6.7 mt because of<br />

bad weather. Anglo American Metallurgical Coal said it was<br />

unable to confirm that it issued a force majeure notice because<br />

of disruptions to its Cap<strong>coal</strong> German Creek and Foxleigh<br />

mines in Queensland. Although the impact on supply is yet to<br />

be fully understood, it is hoped that supply would get normal<br />

shortly. Heavy rains have also affected coking <strong>coal</strong> production<br />

in Indonesia.<br />

However, long term expectation remains intact. Many<br />

analysts feel that the coking <strong>coal</strong> market is for continued<br />

supply tightness until 2013. The proportion of coking <strong>coal</strong> that<br />

China imports is likely to grow until 2013 as it will be unable<br />

to meet its own additional demand for coking <strong>coal</strong> over the<br />

period, even based on a “relatively pessimistic” forecast of<br />

slowing steel production over the next few years.<br />

Speaking at a recently held Dry Bulk Shipping Market<br />

Outlook Conference, director of commodities research at<br />

Deutsche Bank, Daniel Brebner, said that China’s attempts to<br />

increase its domestic coking <strong>coal</strong> production, as well as imports<br />

from neighbouring Mongolia, will suffer from infrastructure<br />

constraints. The construction of an additional railroad to carry<br />

coking <strong>coal</strong> and thermal <strong>coal</strong> from Inner Mongolia and Shanxi<br />

to the northern port of Qinhuangdao will increase capacity<br />

when it is completed in 2012, Brebner notes. However, he<br />

believes that bottlenecks will not be eliminated.<br />

Demand from Brazil and India, which are nearly wholly<br />

dependent on imports of coking <strong>coal</strong>, will continue to rise over<br />

the period, placing upward pressure on prices. On the supply<br />

side, the major coking <strong>coal</strong> producers are unlikely to in1crease<br />

production significantly over the next two years.<br />

COAL INSIGHTS 24 October 2010

Feature<br />

Competitive bidding:<br />

Will it improve the situation<br />

Coal Insights Bureau<br />

The ministry of <strong>coal</strong> recently cleared all hurdles in the<br />

way of introduction of the system of allocation of captive<br />

<strong>coal</strong> blocks through competitive bidding route. The<br />

main argument behind the introduction of this new system<br />

is to speed up the process of development of such blocks by<br />

selecting serious players or consumers.<br />

The new system is likely to be introduced within next six<br />

months and the notification seeking application for allotment<br />

of <strong>coal</strong> blocks through this new system of competitive<br />

bidding route, is likely to come sometime towards end of<br />

current financial year 2010-11 and the first allotment might<br />

be made anytime around first or second quarter of next<br />

financial year.<br />

However, certain doubts are being raised on whether this<br />

new system will at all help the government realise its goal of<br />

increasing the country’s <strong>coal</strong> production through captive <strong>coal</strong><br />

block route.<br />

Till now, the allocation of <strong>coal</strong> blocks to private parties is<br />

being done through the mechanism of an Inter-Ministerial and<br />

Inter-Governmental body called the Screening Committee. The<br />

Screening Committee is chaired by the Secretary (Coal) and<br />

comprises representatives from the Ministry of Steel, Ministry<br />

of Power, Ministry of Industry and Commerce, Ministry of<br />

Environment and Forests, Ministry of Railways, Coal India<br />

Ltd (CIL), Central Mine Planning and Design Institute Ltd<br />

(CMPDIL) and the concerned state governments.<br />

This committee evaluates the applications received from<br />

various entities and then allots a single block to a single entity<br />

or multiple entities depending upon their requirement as well<br />

as various other parameters.<br />

As per the Coal Ministry’s Annual Report of 2009-10, a<br />

total of 229 <strong>coal</strong> blocks (148 existing and 81 newly identified)<br />

had been identified for allocation to specified end users and<br />

government companies. There are 25 remaining <strong>coal</strong> blocks<br />

with geological reserves of about 7262.66 million tons (mt)<br />

from the old list that is yet to be allotted.<br />

COAL INSIGHTS 25 October 2010

Feature<br />

Allocattees pulled up for<br />

inordinate delay<br />

Peeved at the dismal progress, the <strong>coal</strong> ministry has<br />

pulled up existing <strong>coal</strong> block allocattees, both public<br />

and private, for delay in the development of captive<br />

blocks. Only last month, the ministry declared it has<br />

identified as many as 93 <strong>coal</strong> blocks where almost all the<br />

requisite milestones are pending. Of these, 45 belong<br />

to government sector companies and the rest 48 to the<br />

private sector.<br />

The list of these ‘laggards’ include large companies<br />

including NTPC, ArcelorMittal, Bhushan Steel, Monnet<br />

Ispat, Hindalco, Usha Martin and GVK Power, among<br />

others. Since September to date, the ministry has issued<br />

show cause notices to at least 31 block allocattees. Four<br />

blocks were even deallocated during the April to June<br />

period.<br />

“We want to enhance <strong>coal</strong> production of the country.<br />

For this, we can snatch the <strong>coal</strong> blocks back,” <strong>coal</strong><br />

minister, Sriprakash Jaiswal, has said.<br />

Recently, the <strong>coal</strong> ministry asked all captive block<br />

allocatees and joint venture companies (JVCs) to submit<br />

information about the status of captive blocks and<br />

associated end-use projects, to the Office of the Coal<br />

Controller and the ministry by October 15. This was part<br />

of the quarterly review exercise conducted by the ministry<br />

to examine the progress made in the development of<br />

such blocks.<br />