India's largest coal handling agency - Mjunction

India's largest coal handling agency - Mjunction

India's largest coal handling agency - Mjunction

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Cover Story<br />

complete longwall mining systems (consisting of powered<br />

roof supports, an armored face conveyor, and a longwall<br />

shearer, continuous haulage systems, battery haulers and roof<br />

bolters.<br />

Additionally, Joy also maintains an extensive network of<br />

service and replacement parts distribution centres to rebuild<br />

and service equipment and to sell replacement parts and<br />

consumables in support of its installed base. This network<br />

includes five service centres in the US and eight outside the<br />

US, all of which are strategically located in major underground<br />

mining regions. The surface mining equipment unit of the<br />

company P&H Mining Equipment continued to build upon the<br />

successful introduction of AC-drive electric mining shovels in<br />

2009. This is applied to its wide-track P&H 4100BOSS shovels for<br />

oil sand mining and other soft-ground operations in 2008. ACdrive<br />

P&H 4100XPC shovels will be introduced starting in 2010.<br />

P&H Mining Equipment introduced a new remote health<br />

monitoring system during 2009 to help mine operations<br />

optimize productivity and reliability performance on their<br />

P&H shovels. This system features powerful shovel systems<br />

health monitoring, data trending and diagnostics tools that<br />

help mine maintenance personnel obtain faster resolution of<br />

machine performance issues.<br />

Meanwhile, the Continental Crushing & Conveying<br />

completed a new <strong>coal</strong> offloading and storage facility for the<br />

port of Tyne, UK. The fully-integrated system can deliver and<br />

create individual 65,000-ton stockpiles of “separated <strong>coal</strong>.”<br />

It included system monitoring using video cameras and<br />

stockpile height and movement monitoring. This conveyor<br />

system sequencing and pre-start and emergency stop were<br />

installed for safe and efficient transport of material.<br />

BUCYRUS<br />

Although 2009 proved to be a very difficult year for many<br />

US based companies, the situation was not the same for<br />

Bucyrus. It was one of the only few companies which was<br />

able to increase both revenue as well as earning. Considering<br />

that more than 70 percent of the sales are generated outside<br />

US and the relative strength of the international markets, the<br />

geographic diversity has allowed the company to weather<br />

much of the domestic turmoil.<br />

The market uncertainty propelled the company to reevaluate<br />

the overall plan for 2009, and as a result, the company<br />

was able to set up a solid base for financial year 2010. The<br />

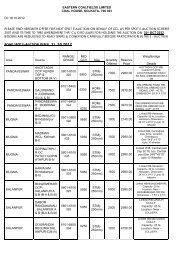

78%<br />

2009 Machine sales by commodity<br />

Coal Copper Iron ore Oil Sands Other<br />

Source: Bucyrus & Insights Research<br />

company decided to proactively manage the $2.5-billion<br />

backlog the company had at the end of 2008, by trying to help<br />

the customers to defer their expenses in the face of softening<br />

demand for their commodities.<br />

The company removed as much of this backlog as possible<br />

in 2010. This levelled the revenue in 2009 and gave the company<br />

substantial backlog support in 2010. In addition to this, strong<br />

aftermarket activity, particular in the spare parts, allowed<br />

Bucyrus to increase the revenue as the year progressed. The<br />

company’s continued parts initiatives in the underground<br />

segment has also proved effective. Thus, the revenues exceed<br />

2008 level by 6 percent and the margins improved.<br />

Apart from the strong market strategy, the company<br />

acquired Terex Mining of Terex Cooperation on February 19,<br />

2010. The acquisition has made Bucyrus the premier supplier of<br />

mining equipment. This has allowed the company to diversify<br />

the product basket across a broader range of commodities and<br />

double the potential market to approximately $30 billion.<br />

This would help the company to benefit from the strong<br />

presence of Terex Mining in the Asia Pacific region. In addition<br />

to this, Terex Mining has a strong presence in China, whereas<br />

Bucyrus has absolutely no market share on a standalone basis.<br />

With this acquisition, the company’s installed base moved up<br />

to $40 billion from $30 billion. The size of the installed base<br />

of surface and underground mining original equipment at<br />

December 31, 2009 was around $20 billion, which increased<br />

to approximately $30 billion with Terex acquisition, and $10<br />

billion respectively.<br />

The company’s product lines include dragline, electric<br />

mining shovels, rotary blasthole drills, longwall systems,<br />

room and pillar machinery and belt systems. The company’s<br />

aftermarket services include replacement parts, maintenance,<br />

technical advice, structural and mechanical engineering,<br />

repairs, rebuilds, refurbishments and upgrades.<br />

1%<br />

3%<br />

10%<br />

8%<br />

2009 Total sales by product<br />

12%<br />

2009 Total sales by Region<br />

7%<br />

4%<br />

38%<br />

51%<br />

49%<br />

18%<br />

Aftermarket<br />

Source: Bucyrus & Insights Research<br />

Machines<br />

North America Europe, Russia, India South America Australia/Asia Pacific China Africa<br />

Source: Bucyrus & Insights Research<br />

21%<br />

COAL INSIGHTS 20 October 2010