India's largest coal handling agency - Mjunction

India's largest coal handling agency - Mjunction

India's largest coal handling agency - Mjunction

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Snap Shot<br />

The concern areas<br />

The miners were trapped at approximately 5 kilometres (3.1<br />

miles) from the mine entrance. What was more worrying was<br />

that the mine had a history of roof instability that had led to<br />

previous roof collapse accidents, including one death. In fact,<br />

a government report warned in July 2010 that the mine owners<br />

had failed "to reinforce the roof". The lack of reinforcement<br />

"had led to [an earlier] collapse of the roof." Till the present<br />

collapse, there had been persistent controversy as to why the<br />

mine was not closed down.<br />

Now, with the discovery of 33 men found alive after 17<br />

days trapped in the mine, the biggest challenge now was the<br />

preservation of their mental health in the months that it could<br />

take to bore a shaft large enough for them to get out.<br />

The rescue plan<br />

With the discovery of the miners being alive, the authorities<br />

put into action the next big plan – that of rescuing the trapped<br />

miners. The President of Chile swung into action and appointed<br />

the man who ran the world's most productive underground<br />

mine, El Teniente, for Chile’s state owned CODELCO copper<br />

company, Andre Sougarret, as the person in charge of the<br />

rescue operation.<br />

The rescue team mobilised three powerful drills, soon to<br />

be known as Plan A, Plan B and Plan C, each with different<br />

methods of pounding through the rock. Plan A was to<br />

drill through the large diameter hole up to the workshop<br />

underground. Plan B was to drill a large diameter hole up<br />

to the refuge chamber, while Plan C focused on drilling a<br />

large diameter hole in between the workshop and the refuse<br />

chamber. The rescuers made it a point to talk to the trapped<br />

miners every day, at first using a phone dropped down the<br />

hole, and eventually by video conference calls.<br />

With three drills advancing towards the men, it was only<br />

a matter of time, before they would have been brought back<br />

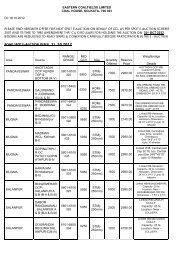

Miner coming out of the capsule<br />

to safety. Sougarret calculated the potential speed of each drill<br />

and zeroed in on three dates - December 1 for Plan A to reach<br />

the refuge, October 10 for Plan B to reach the workshop and<br />

October 30 for the shaft in-between for Plan C. In recent weeks,<br />

the miners began to help with the drilling process, taking<br />

shifts to clear away debris that fell into the tunnel of the mine.<br />

Finally, at 8.05 am on October 9, Plan B broke through. The<br />

widened borehole which was 28 inches in diametre was drilled<br />

by the “Schramm T130XD” category drill employed in the<br />

plan and was completed on Saturday, October 9, even though<br />

it was stopped for approximately 10 hours due to a drill-bit<br />

(Tri-cone roller bit used) change. Incidentally, the Schramm<br />

T130XD is a heavy duty, heavy hoist, carrier mounted drill<br />

rig. The T130XD utilises the latest concepts in mast design and<br />

technology. As on October 8, the others namely the Strata 950<br />

had reached 598 metres deep which was equal to 85 percent.<br />

The RIG-422, the only machine which drills a shaft wide<br />

enough immediately, reached 372 metres or 62 percent.<br />

The drilling was done by U.S.-Chilean drilling company<br />

Geotec. A team from Center Rock Inc. of Berlin had built<br />

and managed the piston-driven hammers that pounded the<br />

hole through quartz and silica, some of the hardest and most<br />

abrasive rock in the world.<br />

Health of trapped miners<br />

One of the main concerns was to prevent nausea among the<br />

miners as the rescue capsule was expected to rotate 350 degrees<br />

some 10 to 12 times through curves in the 28-inch-diametre<br />

escape hole on its way up. Physiologists set up obligatory<br />

exercise schedules to keep the men fit for their trying passage<br />

up the escape shaft, when they may have to hold the same<br />

posture for as much as an hour.<br />

A small video camera in the escape capsule was provided,<br />

to be trained on each miner's face so that the person can be<br />

watched as he ascends. The capsule had oxygen cylinders and<br />

masks and also had a two-way voice communication system.<br />

A day after drillers broke through to where the miners had<br />

been huddled together, officials began detailed monitoring<br />

of their health and working out every detail of the half-mile<br />

ascent that was expected to last about 20 minutes for each man.<br />

Special equipment was sent down to measure their heart<br />

rate, their respiration rate and skin temperature.<br />

During the week before the breakthrough, all the miners<br />

underwent underground stress tests to assess their health.<br />

The Chilean authorities called in Dr. J.D. Polk from NASA,<br />

whose expertise lay in treating astronauts in confined spaces.<br />

He instructed the miners to do leg squats, take salt tablets and<br />

protein fluids. Later, doctors transitioned the men to a solid<br />

diet including meat and rice, with a strict 2200-calorie diet to<br />

keep them slim enough to fit in the evacuation shaft just two<br />

feet (66 cm) in diameter.<br />

Officials were concerned about acute hypertension in some<br />

of the miners as well as the opposite, namely sudden drops<br />

in blood pressure in others, due to the speed at which they<br />

would be ascending nearly half a mile to the surface.<br />

COAL INSIGHTS 78 October 2010