Tender Document for Construction of Ghorasal 300-450 MW ... - BPDB

Tender Document for Construction of Ghorasal 300-450 MW ... - BPDB

Tender Document for Construction of Ghorasal 300-450 MW ... - BPDB

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

1. Schedule PageSchedule-A Guarantees ………………………………………………Schedule-B Technical Data Sheet……………………………………Schedule-C Drawings to be furnished with Contract……………..Schedule-D Delivery time………………………………………………Schedule-E Tools and Appliances……………………………………Schedule-F Spare Parts……………………………………………..….Schedule-G Deviation……………………………………………………Schedule-H Civil and Building Works………………………………...Schedule-I List <strong>of</strong> Subcontractor……………………………………..Schedule-J Description <strong>of</strong> Training Programme……………………Schedule-K Mobilisation and demobilisation Schedule <strong>for</strong><strong>Construction</strong> Equipment ………………………………...Schedule-L Method <strong>of</strong> Transportation and Unloading <strong>of</strong>heavy Cargo ………………………………………………..<strong>Ghorasal</strong> <strong>300</strong>-<strong>450</strong> <strong>MW</strong> CCPP Project (Vol-2B <strong>of</strong> 2 ) 2

a) HRSG and Steam Turbine simultaneously with GTG start-up.3. Date <strong>of</strong> completion <strong>of</strong> Initial Commercial OperationThe Initial Commercial Operation <strong>of</strong> the unit shall be completed within the periodfrom Effective date <strong>of</strong> Contract:Gas Turbine unit(s) : ----------------------------------------- daysSteam Turbine unit : ----------------------------------------- days<strong>Ghorasal</strong> <strong>300</strong>-<strong>450</strong> <strong>MW</strong> CCPP Project (Vol-2B <strong>of</strong> 2 ) 5

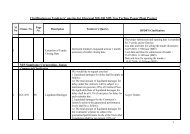

SCHEDULE-BTECHNICAL DATA SHEETB-1 Gas Turbine and Ancillaries1.1 General In<strong>for</strong>mation-Type <strong>of</strong> Gas turbine ---------------Model Number ---------------Manufacturer <strong>of</strong> gas turbine, Country ---------------Min. heat value <strong>of</strong> gas required, KJ/Nm 3 ---------------Normal gas pressure required, bar ---------------Number, type and arrangement <strong>of</strong>combustion chambers, fuel nozzles,flame detectors, etc --------------Number <strong>of</strong> compressor stages --------------Compressor pressure ratio --------------Number <strong>of</strong> power turbine stages --------------Number and type <strong>of</strong> bearings --------------Starting system -------------Type <strong>of</strong> GT control system --------------Description <strong>of</strong> Speed governing systemand fuel control system --------------Description <strong>of</strong> over-speed trip system --------------Compressor cleaning method --------------Gas consumption (Max. Nm 3 /hr) -------------With integration (Totalizer flow meter)-Description <strong>of</strong> cooling system -------------Auxiliary power consumption, KW -------------Moment <strong>of</strong> Inertia, GD 2 <strong>of</strong> Rotor, (kg-m 2 ) ------------1.2 Per<strong>for</strong>mance Data at the Site Condition (35 0 C, 1.013 bar, 98% RH)-Gross output at Site conditionNatural Gas/ HSDBase Load, KW ------------Peak Load, KW ------------- Heat Rate at Site ConditionBase Load, KJ/Kwh -----------<strong>Ghorasal</strong> <strong>300</strong>-<strong>450</strong> <strong>MW</strong> CCPP Project (Vol-2B <strong>of</strong> 2 ) 6

Peak Load, KJ/Kwh ------------Guaranteed rate <strong>of</strong> unit load change iscapable without structural damage, KW/min. ------------Noise at a distance <strong>of</strong> 100 metres (dB) -----------(in each octave band, see section 2, Vol. 2)-Critical speed above and below rated speed ------------Turbine/Compressor Rotor, rpm ------------Generator, rpm ------------FuelNatural GasBasePeak-Gas TurbineInlet Temp. 0 C --------------------------------Exhaust Temp. 0 C ----------------------------------Air flow, Kg/sec. ----------------------------------Turbine Cooling air flow, % ----------------------------------Exhaust gas flow, Kg/sec. ----------------------------------Exhaust Temp. <strong>of</strong> gas burning, 0 C ----------------------------------Max. Exhaust Temp. limit <strong>of</strong> gas burning, 0 C----------------------------------Max. starting time required from ---------------------------------standstill to full speed, min-Max. vibration limit, mm/sec -----------------------------------Min. time required <strong>for</strong> applying fullload to unit,From cold standby, min ----------------------------------From warm shutdown, min -----------------------------------Estimated firing hours at or below Base rating <strong>of</strong>gas burning , between :Minor inspection, hours -----------------------------------Normal inspection, hours -----------------------------------Major overhauls, hours ------------------------------------Estimated firing hours at Peak rating <strong>of</strong>gas burning , between :Minor inspection, hours -----------------------------------Normal inspection, hours -----------------------------------Major overhauls, hours ----------------------------------Estimated shutdown period, hours and<strong>Ghorasal</strong> <strong>300</strong>-<strong>450</strong> <strong>MW</strong> CCPP Project (Vol-2B <strong>of</strong> 2 ) 7

Man-hours <strong>for</strong> :Minor inspectionNormal inspectionMajor overhauls-----hours-----man-hours--------hours-----man-hours--------hours-----man-hours---1.2a Estimated Per<strong>for</strong>mance under different Site conditions :i) Power Rating at Gen. Terminal ( For Natural Gas)a. Ambient Temp. 45 0 C, KW ---------------------------------b. Ambient Temp. 35 0 C, KW ---------------------------------c. Ambient Temp. 25 0 C, KW ---------------------------------d. Ambient Temp. 20 0 C, KW ---------------------------------ii) Heat Rate (LHV) 100% 90% 80% 70% 60% 50% 40%a. Ambient Air Temp.45 0 C, KJ/Kwh ---- ---- ---- ---- ---- ---- ----b. Ambient Air Temp.35 0 C, KJ/Kwh ---- ---- ---- ---- ---- ---- ----c. Ambient Air Temp.25 0 C, KJ/Kwh ---- ---- ---- ---- ---- ---- ----d. Ambient Air Temp.20 0 C, KJ/Kwh ---- ---- ---- ---- ---- ---- ----iii)BasePeakInlet and Exhaust Lossesa. Ambient Air Temp.45 0 CInlet loss, mm Aq ----------------------------------Exhaust loss, mm Aq ----------------------------------b. Ambient Air Temp.35 0 CInlet loss, mm Aq ----------------------------------Exhaust loss, mm Aq ----------------------------------c. Ambient Air Temp.25 0 CInlet loss, mm Aq ----------------------------------Exhaust loss, mm Aq ----------------------------------d. Ambient Air Temp.20 0 CInlet loss, mm Aq ----------------------------------Exhaust loss, mm Aq ----------------------------------iv) Consumption <strong>of</strong> Auxiliary Power :Ambient Temp. 45 0 C, KW ---------------------------------Ambient Temp. 35 0 C, KW ---------------------------------Ambient Temp. 30 0 C, KW ---------------------------------<strong>Ghorasal</strong> <strong>300</strong>-<strong>450</strong> <strong>MW</strong> CCPP Project (Vol-2B <strong>of</strong> 2 ) 8

Ambient Temp. 25 0 C, KW ---------------------------------Ambient Temp. 20 0 C, KW ---------------------------------1.3 Materials :-CompressorMoving blades --------------------------------Fixed blades ---------------------------------Combustion Chamber Liner ---------------------------------Transition piece ---------------------------------TurbineMoving blades ---------------------------------Fixed nozzle ---------------------------------Blades Coating ---------------------------------Blade disc ---------------------------------Shaft ---------------------------------1.4 Turning Gear-Intermittent or continuous rolling ----------------------------------Speed, rpm ----------------------------------Manual-Turning provided or not ----------------------------------Normal Turning period after operationat Base & peak load, hours ------------- ----------------1.5 Lubrication Oil system-Main oil pump capacity, litre/min ----------------------------------Aux. oil pump capacity, litre/min ----------------------------------Emergency oil pump capacity, litre/min ----------------------------------Total quantity <strong>of</strong> oil in system, litre ----------------------------------Type <strong>of</strong> filter ----------------------------------Degree <strong>of</strong> filtration, microns ----------------------------------Manufacturer <strong>of</strong> filter, country ----------------------------------Type <strong>of</strong> lubricant required ---------------------------------1.6 Fuel Systema. Gas Fuel Systemi) Normal operating pressure, bar ----------------------------------Make, country and Type <strong>of</strong> filter ---------------------------------- Degree <strong>of</strong> filtration, microns ----------------------------------Type <strong>of</strong> conditioner ----------------------------------Make and Type <strong>of</strong> Flow meter ---------------------------------<strong>Ghorasal</strong> <strong>300</strong>-<strong>450</strong> <strong>MW</strong> CCPP Project (Vol-2B <strong>of</strong> 2 ) 9

-Dimension <strong>of</strong> unit, mm ----------------------------------Weight, Kg ---------------------------------ii) Cyclone Separator ---------------------------------Model, Make & Country ---------------------------------ii) Gas Booster Compressor (GBC)Model, Make & Country (Either by Man Turbo, Germany/ USA or AtlasCoppco, USA)- Compressor Type ---------------------------------- Make, Country ----------------------------------- Model ---------------------------------- Capacity ----------------------------------- Suction Pressure ----------------------------------- Discharge Pressure ----------------------------------- Discharge Temperature ---------------------------------- Compressor Speed ------------------------------------ Compressor Motor Voltage/ Rating, kV/ KW ----------------------------------- Motor Speed ----------------------------------1.7 Air Intake system-Material <strong>of</strong> louvers ----------------------------------Material <strong>of</strong> intake duct ----------------------------------Intake duct surface treatment ----------------------------------Type <strong>of</strong> air filterPrimary ---------------------------------Secondary ----------------------------------Manufacturer <strong>of</strong> air filter, Country ----------------------------------Material <strong>of</strong> filter medium ----------------------------------Maximum intake velocity, m/s ----------------------------------Maximum pressure loss, mm Aq ----------------------------------Type <strong>of</strong> silencer ----------------------------------Material <strong>of</strong> sound absorber ----------------------------------Manufacturer <strong>of</strong> silencer ----------------------------------Amount <strong>of</strong> air required, m 3 /hr ---------------------------------1.8 Exhaust System-Material <strong>of</strong> stack & Height ----------------------------------Surface treatment <strong>of</strong> stack plate ---------------------------------<strong>Ghorasal</strong> <strong>300</strong>-<strong>450</strong> <strong>MW</strong> CCPP Project (Vol-2B <strong>of</strong> 2 ) 10

-Material <strong>of</strong> expansion joints ----------------------------------Material and thickness <strong>of</strong> liner ----------------------------------Manufacturer <strong>of</strong> expansion joints ----------------------------------Type <strong>of</strong> silencer ----------------------------------Material <strong>of</strong> sound absorber ----------------------------------Manufacturer <strong>of</strong> silencer ----------------------------------Maximum pressure loss, mm Aq ----------------------------------1.9 Deleted1.10 List <strong>of</strong> Turbine Trip Signal -------------------------------------------------------------------------------------------------------------------------------------------------------------------------------1.11 Ventilation Fan <strong>for</strong> Compartment-Design pressure in each -----------------------------------compartment, mm Aq-Number and location <strong>of</strong> ventilation fans ------------------------------------Number and Type <strong>of</strong> air filters -----------------------------------1.12 Fire Protection System-Number, Type and location <strong>of</strong> -----------------------------------fire detectors-Number and location <strong>of</strong> discharge -----------------------------------nozzles-Location <strong>of</strong> CO 2 gas cylinders ------------------------------------Number <strong>of</strong> CO 2 gas cylinders ------------------------------------Capacity <strong>of</strong> each cylinder, N/m 3 ------------------------------------Filling pressure, bar ------------------------------------ Pumps -----------------------------------1.13 Weight and Dimension (L X W X H)-Gas Turbine Package, 1000×Kg ------------------------------------Generator Package, 1000×Kg ------------------------------------Auxiliary Package, 1000×Kg ------------------------------------Control Package, 1000×Kg ------------------------------------Max. Shipping Weight, 1000×Kg ------------------------------------Max. Shipping Dimension (Name)------------------- , mm --------<strong>Ghorasal</strong> <strong>300</strong>-<strong>450</strong> <strong>MW</strong> CCPP Project (Vol-2B <strong>of</strong> 2 ) 11

-Heaviest Piece during erection, 1000×Kg ------------------------------------Heaviest Piece during maintenance, 1000×Kg --------------------------B-2 Generator and Ancillaries2.1 Generator-Manufacturer, Country -----------------------------------Type -----------------------------------KVA rating / power factor 0.8 -----------------------------------Max. leading & lagging KVAR capability at pf -----------------------------------Rated voltage between lines, KV -----------------------------------Connection <strong>of</strong> armature winding -----------------------------------Rated Current, A -----------------------------------Rated frequency, Hz -----------------------------------Efficiencyat pf 0.8, % ----------------------------------at pf 1.0, % -----------------------------------Stator overloading, % -----------------------------------Critical speed, rpm -----------------------------------Max. torque when the stator is short-circuited, Nm -----------------------------------Generator CharacteristicsInstantaneous Max. short-circuit currentat nominal voltage, A peak ----------------------------------sub-transient reactance, Xd” pu ----------------------------------transient reactance, Xd’ pu ----------------------------------synchronous reactance, Xd pu ----------------------------------negative sequence reactance, pu ----------------------------------zero sequence reactance, pu ----------------------------------field time Constant, Td’ 0 sec ----------------------------------Transient time Constant, Td sec ----------------------------------initial time Constant, Td” sec -----------------------------------Moment <strong>of</strong> inertia GD 2 <strong>of</strong> rotor, Kg-m 2 -----------------------------------percent rise on voltage when full load isrejected and operating at pf 0.8 , % ----------------------------------pf 1.0 , % -----------------------------------Telephone influence factorBalanced ----------------------------------Residual ----------------------------------<strong>Ghorasal</strong> <strong>300</strong>-<strong>450</strong> <strong>MW</strong> CCPP Project (Vol-2B <strong>of</strong> 2 ) 12

-Class <strong>of</strong> winding insulationArmature winding ----------------------------------Field winding --------------------------Type <strong>of</strong> cooling-Short circuit ratio, sat-Generator rated excitation requirements <strong>for</strong>operation at rated kVAExcitation voltage -------------------------Excitation current -------------------------- Generator calculated losses at 100% Base ratingTotal generator iron loss, kW -------------------------Generator stator I 2 R loss, kW -------------------------Generator rotor I 2 R loss, kW -------------------------Generator stray load loss, kW -------------------------Generator windage loss, kW -------------------------Total generator loss, kW -------------------------- Generator cooling system --------------------------Generator weightsWeight <strong>of</strong> rotor, kg -------------------------Weight <strong>of</strong> complete stator, kg -------------------------2.2 Exciter (Brushless)- Manufacturer, Country -------------------------- Type -------------------------- Rated output, kW --------------------------Rated load field voltage at0.80 pf/1.00 pf --------------------------Rated exciter current at0.80 pf./l.00 pf -------------------------- Exciter ceiling voltage, V --------------------------Maximum continuous excitercurrent, A --------------------------Excitation system voltageresponse ratio -------------------------2.3 Automatic Voltage Regulator-Manufacturer, Country -------------------------- Type -------------------------- Description <strong>of</strong> AVR, Ref. No. -------------------------2.4 Generator Protection (Manufacturer Cat. No. or Type)-Manufacturer ABB, Switzerland or Sweden/ Alstom, France/ Siemens, Germany-Generator differential relay --------------------------Generator ground over-current relay --------------------------Field / rotor ground detection system --------------------------Reverse power relay --------------------------Loss <strong>of</strong> field relay --------------------------Voltage restraint over-current relays --------------------------Negative phase sequence relay --------------------------Under/Over Frequency relay -------------------------- Sychro-Check relay -------------------------<strong>Ghorasal</strong> <strong>300</strong>-<strong>450</strong> <strong>MW</strong> CCPP Project (Vol-2B <strong>of</strong> 2 ) 13

- Auxiliary relays --------------------------Lockout relays -------------------------2.5 Generator Switchgear-Manufacturer, Country --------------------------Circuit breakerCatalogue No. -------------------------Type -------------------------Interrupting Media SF 6Closing current at 125 volts DC, A -------------------------Time to close, m sec -------------------------Tripping current at 125 volts DC, A -------------------------Time to trip, m sec -------------------------- Rating and capabilitiesCurrent rating, A -------------------------Voltage rating, V -------------------------Nominal 3 phase interrupting capacity, MVA -------------------------Maximum symmetrical interrupting capacity, kA -------------------------3 second short time rating, kA -------------------------Closing and latching capability, kA -------------------------- Operating Mechanism --------------------------Instruments and devices Manufacturer TypeCurrent trans<strong>for</strong>mersSingle ratio -------------------------Multi ratio -------------------------Potential trans<strong>for</strong>mers -------------------------Control and instrument switches -------------------------Indicating lights --------------------------Lightning arresters --------------------------Surge protection devices --------------------------Type <strong>of</strong> bus insulation --------------------------Type <strong>of</strong> bus supports --------------------------Type <strong>of</strong> insulation on connections --------------------------Size <strong>of</strong> completely assembled switchgearLength, mm -------------------------Width, mm -------------------------Height, mm -------------------------- Total weight <strong>of</strong> switchgear, kg -------------------------B-3 Heat Recovery Steam Generator and Ancillary Equipment3.1 General-Type <strong>of</strong> HRSG [Vertical]/ [Horizontal] --------------------------------Model Number --------------------------------Manufacturer <strong>of</strong> HRSG, Country -------------------------------3.2 Per<strong>for</strong>mance<strong>Ghorasal</strong> <strong>300</strong>-<strong>450</strong> <strong>MW</strong> CCPP Project (Vol-2B <strong>of</strong> 2 ) 14

(1) at MCR- Maximum Continuous Rating atHot Gas Input with Gas TurbineGenerator base rating, kg/hr -------------------------------- Superheater exit pressure, bar -------------------------------- Superheater exit temperature, 0 C -------------------------------- Feed Water temperature at Economiser -------------------------------inlet, 0 C- Total Pressure loss through the --------------------------------steam generator, mm Aq.- Pressure loss though the -------------------------------superheater section, mm Aq. --------------------------------- Pressure loss though the -------------------------------Evaporator section, mm Aq. --------------------------------- Pressure loss though the -------------------------------economiser section, mm Aq. ------------------------------Gas leakage through bypass damper ------------------------------ Heat absorbing rateSuperheater section, kg/m 2 /hr ---------------------------------Evaporator section, kg/m 2 /hr ---------------------------------Economiser section, kg/m 2 /hr ---------------------------------- Gas Temperature ---------------------------------Gas Turbine exhaust temp., 0 C ---------------------------------Superheater inlet, 0 C ---------------------------------Evaporator inlet, 0 C ---------------------------------Economiser outlet, 0 C ---------------------------------- Pinch point temperature, 0 C ---------------------------------- Approach Temperature, 0 C ---------------------------------- Gas VelocitiesSuperheater section, m/sec ---------------------------------Evaporator section, m/sec ---------------------------------Economiser section, m/sec ---------------------------------- Exhaust gas temperature ----------------------------------at HRSG outlet, 0 C- Water temperatureEntering economiser, 0 C ----------------------------------Leaving economiser, 0 C ----------------------------------<strong>Ghorasal</strong> <strong>300</strong>-<strong>450</strong> <strong>MW</strong> CCPP Project (Vol-2B <strong>of</strong> 2 ) 15

- Design pressure <strong>for</strong> high ----------------------------------pressure portion, bar- Working pressure at superheater ----------------------------------outlet, bar- Working pressure at HRSG ----------------------------------steam drum, bar- Static head, drum water level to ----------------------------------economiser inlet, bar- Working pressure at economiser, bar ----------------------------------(2) at Partial Load(Gas Turbine output at Site Condition)100% 75% 50% 25%- Exhaust gas flow, kg/hr ------- ------- ------- -------- Exhaust gas temp., 0 C ------- ------- ------- -------- Steam Output, kg/hr ------- ------- ------- -------- Superheater exit pressure, bar ------- ------- ------- -------- Superheater exit temp., 0 C ------- ------- ------- -------- Feed Water temp. at ------- ------- ------- -------economiser inlet, 0 C- Pinch point temp., 0 C ------ ------- ------- -------- Approach temp., 0 C ------- ------- ------- -------Gas TemperatureSuperheater inlet, 0 C ------- ------- ------- -------Evaporator inlet, 0 C ------- ------- ------- -------Economiser outlet, 0 C ------- ------- ------- -------3.3 Operating Limit- Max. gas temperature atsuperheater inlet during start-up, 0 C ----------------------------------- Max. superheater metal temperature atduring start-up, 0 C ----------------------------------- Max. drum metal differentialtemperature during pressure raising, 0 C ----------------------------------- Max. rate <strong>of</strong> decrease insaturation temperature, 0 C ----------------------------------- Max. water temperature be<strong>for</strong>edraining HRSG, 0 C ----------------------------------- Max. superheater steam pressure, bar ---------------------------------<strong>Ghorasal</strong> <strong>300</strong>-<strong>450</strong> <strong>MW</strong> CCPP Project (Vol-2B <strong>of</strong> 2 ) 16

- Max. superheater steam temp., 0 C ----------------------------------- Min. load <strong>for</strong> superheater spray, % ----------------------------------- Max. casing design pressure, mm Aq. ----------------------------------3.4 Evaporator Section- Manufacturer, country ----------------------------------- Heating surface, m 2 ----------------------------------- Heat absorbing rate, kj/m 2 /hr ----------------------------------- Method <strong>of</strong> joining long tubes ----------------------------------- Method <strong>of</strong> fixing tubes to header oror drum ----------------------------------- Tube outside diameter, mm ----------------------------------- Tube thickness, mm ----------------------------------- Tube pitching, mm ----------------------------------- Casing thickness, mm ----------------------------------3.5 Drum- Manufacturer, country ----------------------------------- <strong>Construction</strong> ----------------------------------- Internal diameter, mm ----------------------------------- Thickness, mm ----------------------------------Length, mm ----------------------------------Steam purifier,Manufacturer, countryType- Design pressure, bar ----------------------------------Operating pressure, bar ----------------------------------3.6 Safety Valve- Manufacturer, country ----------------------------------1) <strong>for</strong> Drum- Type ----------------------------------Number ----------------------------------Size <strong>of</strong> valve, mm ----------------------------------Capacity, kg/hr ----------------------------------Design lifting pressure, bar ----------------------------------2) <strong>for</strong> superheater- Type ----------------------------------Number ----------------------------------<strong>Ghorasal</strong> <strong>300</strong>-<strong>450</strong> <strong>MW</strong> CCPP Project (Vol-2B <strong>of</strong> 2 ) 17

Size <strong>of</strong> valve, mm ----------------------------------Capacity, kg/hr ----------------------------------Design lifting pressure, bar -----------------------------------Details <strong>of</strong> assessment <strong>of</strong>safety valve capacity, Ref. No. ----------------------------------3.7 Superheater- Manufacturer, Country ----------------------------------- Type ----------------------------------- Design Pressure, bar ----------------------------------- Heating Surface, m 2 ----------------------------------- Tube outside diameter, mm ----------------------------------- Tube thickness, mm ----------------------------------- Length, mm ----------------------------------- Effective length per element, m ----------------------------------- Method <strong>of</strong> arrangement ----------------------------------- Number <strong>of</strong> elements ----------------------------------- Number <strong>of</strong> steam flow -----------------------------------Tube pitching -----------------------------------Max. design tube temp., 0 C -----------------------------------Tube class and finish -----------------------------------Method <strong>of</strong> fixing tubes to header -----------------------------------Type <strong>of</strong> tube support and material -----------------------------------Method <strong>of</strong> jointing long tube ----------------------------------- Header Inlet Outlet<strong>Construction</strong> ----------------------------------Inside diameter, mm ----------------------------------Thickness, mm ----------------------------------Material ----------------------------------Particular <strong>of</strong> terminal point, Ref. No. ----------------------------------3.8 Superheater Steam Temperature Control Equipment- Description <strong>of</strong> Control equipment ------------------------------------Control range ----------------------------------1) In case <strong>of</strong> surface or condenser type -----------------------------------Heating surface <strong>of</strong> cooling tube, m 2 ------------------------------------Outside diameter <strong>of</strong> cooling tubes, mm ------------------------------------Thickness <strong>of</strong> cooling tubes, mm ------------------------------------<strong>Ghorasal</strong> <strong>300</strong>-<strong>450</strong> <strong>MW</strong> CCPP Project (Vol-2B <strong>of</strong> 2 ) 18

Diameter <strong>of</strong> shell inside, mm ------------------------------------Thickness <strong>of</strong> shell, mm ------------------------------------Type <strong>of</strong> joint ------------------------------------Temperature <strong>of</strong> cooling water, 0 C ------------------------------------2) In case <strong>of</strong> spray type- Nozzle diameter, mm ------------------------------------Diameter <strong>of</strong> sleeve, mm ------------------------------------Length <strong>of</strong> sleeve, mm ------------------------------------Water pressure <strong>of</strong> inlet, bar ------------------------------------- Water temperature at inlet, 0 C ------------------------------------- Maximum quantity <strong>of</strong> spray water, kg/hr ------------------------------------3.9 Economiser- Manufacturer, Country ----------------------------------- Type ----------------------------------- Design Pressure, bar ----------------------------------- Heating Surface, m 2 ----------------------------------- Tube outside diameter, mm ----------------------------------- Tube thickness, mm ----------------------------------- Tube Length, m -----------------------------------Tube arrangement -----------------------------------Tube pitching, mm ----------------------------------- Tube class and finish ----------------------------------Method <strong>of</strong> fixing tubes to header ----------------------------------Type <strong>of</strong> tube support and material ----------------------------------HeaderOutside diameter, mm ----------------------------------Thickness, mm ----------------------------------3.10 Auxiliary Pumps(1) Circulating pump (Evaporator), if any- Manufacturer, Country ----------------------------------- Type ----------------------------------- Discharge flow, kg/sec ----------------------------------- Speed, rpm --------------------------------- Power required, KW --------------------------------- Material <strong>of</strong>Casing ----------------------------------Impeller ----------------------------------<strong>Ghorasal</strong> <strong>300</strong>-<strong>450</strong> <strong>MW</strong> CCPP Project (Vol-2B <strong>of</strong> 2 ) 19

Shaft ----------------------------------- Type <strong>of</strong> motor ----------------------------------(2) Circulating pump (Economiser)- Manufacturer, Country ----------------------------------- Type ----------------------------------- Discharge flow, kg/sec ----------------------------------- Speed, rpm ----------------------------------- Power required, KW ----------------------------------- Material <strong>of</strong>Casing ----------------------------------Impeller ----------------------------------Shaft ----------------------------------- Type <strong>of</strong> motor ----------------------------------(3) Others (if any), <strong>Tender</strong>ers should use additional sheet3.11 Weights- Total steam generator (dry), kg ------------------------------------ Total steam generator (operational), kg ------------------------------------- Evaporator section, (dry), kg ------------------------------------Superheater section (dry), kg ------------------------------------Economiser section (dry), kg ------------------------------------Casing, kg ------------------------------------Supporting steel works, kg ------------------------------------Flues and ducts, kg ------------------------------------Soot blower, kg ------------------------------------Instrument and control, kg ------------------------------------Galleries and ladders, kg ------------------------------------Insulation and lagging, kg ------------------------------------Drum, kg ------------------------------------3.12 Materials- Drum ------------------------------------- Drum plates, shell ------------------------------------- Evaporator tube ----------------------------------- Evaporator header ----------------------------------- Superheater tube ----------------------------------<strong>Ghorasal</strong> <strong>300</strong>-<strong>450</strong> <strong>MW</strong> CCPP Project (Vol-2B <strong>of</strong> 2 ) 20

- Economiser tube ----------------------------------- Soot blower supply piping ----------------------------------- Insulation and lagging ----------------------------------3.13 Other in<strong>for</strong>mation- Statement <strong>of</strong> min. load and duration, Ref. No. ----------------------------------- Statement <strong>of</strong> min. time <strong>for</strong> start-up, Ref. No. ----------------------------------- After 8 hours shut down ----------------------------------- After 48 hours shut down ----------------------------------- From cold condition ----------------------------------(Note: In<strong>for</strong>mation shall be furnished in graphic <strong>for</strong>m showing gasentering temperature, steam temperature and steam pressure vs. time)- Statement <strong>of</strong> drum metal temperature andmetal differential temperature duringstart-up and shut-down. Ref. No. ------------------------------ Statement <strong>of</strong> permissible <strong>for</strong>ced coolingrates and any limitations Ref. No. ------------------------------ Per<strong>for</strong>mance curves showing superheatertemperature from min. load up to MCR Ref. No. -----------------------------B-4 Steam Turbine and Ancillary Equipment4.1 Steam Turbine-Type <strong>of</strong> steam turbine --------------------------------Model Number --------------------------------Manufacturer <strong>of</strong> steam turbine, Country -------------------------------- Rating at generator terminal, <strong>MW</strong> -------------------------------- Minimum safe continuous load, <strong>MW</strong> -------------------------------- Overload rating -------------------------------- Maximum load at 48 Hz <strong>for</strong> up to30 min. duration -------------------------------- Speed, rpm -------------------------------- Steam Condition -------------------------------Temp. at turbine stop valve, 0 C -------------------------------Pressure at turbine stop valve, bar -------------------------------Design temp. at exhaust, 0 C -------------------------------Design vacuum press. at exhaust, mmHg -------------------------------- Number <strong>of</strong> bleed points -------------------------------<strong>Ghorasal</strong> <strong>300</strong>-<strong>450</strong> <strong>MW</strong> CCPP Project (Vol-2B <strong>of</strong> 2 ) 21

- Number <strong>of</strong> exhaust -------------------------------- Guaranteed heat rate at rated output, kj/kwh --------------------------- Expected heat rate at max. expectedcapability, kj/kwh ------------------------------ Expected heat rate under turbineoverload condition, kj/kwh ----------------------------- Type <strong>of</strong> governing, throttle or -------------------------------nozzle control system- Size (mm) and number <strong>of</strong> main steaminlet connections ------------------------------- Size (mm) and number <strong>of</strong> exhaustconnections ------------------------------- Critical speed above <strong>300</strong>0 rpm ------------------------------- Critical speed below <strong>300</strong>0 rpm ------------------------------- Distance between bearing centres, mm ------------------------------- Max. steam pressure in wheel case at MCR, bar ----------------------------- Velocity compounded stageMean diameter <strong>of</strong> moving blades, mm ------------------------------Clear height <strong>of</strong> 1 st moving blades, mm ------------------------------- Impulse stagesNumber <strong>of</strong> stages ------------------------------Mean diameter <strong>of</strong> 1 st moving blades, mm ------------------------------Clear height <strong>of</strong> 1 st moving blades, mm ------------------------------Mean diameter <strong>of</strong> last moving blades, mm ------------------------------Clear height <strong>of</strong> last moving blades, mm -------------------------------- Reaction stagesNumber <strong>of</strong> flows ------------------------------Number <strong>of</strong> stages per flows ------------------------------Mean diameter <strong>of</strong> 1 st moving blades, mm ------------------------------Clear height <strong>of</strong> 1 st moving blades, mm ------------------------------Mean diameter <strong>of</strong> last moving blades, mm ------------------------------Clear height <strong>of</strong> last moving blades, mm -------------------------------- Total actual annulus area last stage blades, m 2 ------------------------------- Minimum running clearance <strong>of</strong> bladesor shroudingRadial clearance, mm ------------------------------Axial clearance, mm ------------------------------<strong>Ghorasal</strong> <strong>300</strong>-<strong>450</strong> <strong>MW</strong> CCPP Project (Vol-2B <strong>of</strong> 2 ) 22

- Casing bursting diaphragm press, bar ------------------------------- Number <strong>of</strong> built-up diaphragm, ------------------------------- Speed at which turning gear rotates rotor, rpm ------------------------------- Number <strong>of</strong> branches required on auxiliarysteam manifold and <strong>for</strong> what purpose ------------------------------- Description <strong>of</strong> blade protection from erosion Ref. No.----------------------- Description <strong>of</strong> method <strong>of</strong> testing <strong>of</strong> bladeharmonics, Ref. No. ------------------------------- Description <strong>of</strong> turbine pre-warmingand start-up cycle, Ref. No. ------------------------------- Description <strong>of</strong> method <strong>of</strong> bolting casinghalves, supporting individual casing,provision to accommodate expansion andmeans <strong>of</strong> equalising differential expansion, Ref. No. ----------------------------- Description <strong>of</strong> thermal treatment <strong>for</strong> turbinecasings, Ref. No. ------------------------------- Description <strong>of</strong> thermocouples inturbine casing, Ref. No. ------------------------------- Maximum allowable loads on turbine casingAt steam inlet, kg ------------------------------kg-m ------------------------------At extraction points, kg ------------------------------kg-m ------------------------------At exhaust, kg ------------------------------kg-m -------------------------------Moment <strong>of</strong> Inertia, GD 2 <strong>of</strong> Rotor, (kg-m 2 ) -------------------------------- Type <strong>of</strong> thrust block ------------------------------- Description <strong>of</strong> on load testing <strong>of</strong> steamvalve, Ref. No. ------------------------------- Description <strong>of</strong> start-up following on outage<strong>of</strong> few minutes, 8 hours and 48 hours, Ref. No. ------------------------------ Description <strong>of</strong> gland sealingarrangement, Ref. No. ------------------------------- Description <strong>of</strong> vacuum unloadingand trip gear, Ref. No. ------------------------------- Description <strong>of</strong> low pressure unloadingand trip gear, Ref. No. ------------------------------<strong>Ghorasal</strong> <strong>300</strong>-<strong>450</strong> <strong>MW</strong> CCPP Project (Vol-2B <strong>of</strong> 2 ) 23

- Scheme <strong>for</strong> turbine drainage andautomatic traps, Ref. No. ------------------------------- Material <strong>of</strong> construction <strong>for</strong> majorcomponents, Ref. No. ------------------------------4.2 Speed Governing System- Type --------------------------------- Model Number --------------------------------- Manufacture, country --------------------------------- Steady state speed regulation, % --------------------------------- Max. dead band at rated speed, % --------------------------------- Speed changer synchronising, % --------------------------------- Speed changer governing range, % --------------------------------- Range <strong>of</strong> speed droop, % --------------------------------- Permanent speed after full loadhas been rejected, rpm --------------------------------- Max. momentary speed after fullload has been rejected, rpm --------------------------------- Turbine speed at which emergencygovernor operates, rpm (%) --------------------------------- Acceleration time, sec --------------------------------- Description <strong>of</strong> automatic turbinestart-up system, Ref. No. --------------------------------4.3 Lubricating Oil system(1) Main oil pump- Type --------------------------------- Manufacturer, Country --------------------------------- Driven by --------------------------------- Capacity <strong>of</strong> pump, lit/min --------------------------------- Lube oil pressure, bar --------------------------------(2) Auxiliary oil pump (full duty)- Type --------------------------------- Model No. --------------------------------- Manufacturer, Country --------------------------------- Speed <strong>of</strong> pump --------------------------------- Capacity <strong>of</strong> pump, lit/min --------------------------------- Pressure at which pump cuts in, bar --------------------------------- Brake horsepower, kw ---------------------------------<strong>Ghorasal</strong> <strong>300</strong>-<strong>450</strong> <strong>MW</strong> CCPP Project (Vol-2B <strong>of</strong> 2 ) 24

- Material <strong>of</strong> construction <strong>for</strong> majorcomponents, Ref. No. ---------------------------------- Complete description <strong>of</strong> operation ---------------------------------including per<strong>for</strong>mance curves <strong>of</strong>capacity vs suction pressure, Ref. No.(3) Ac motor driven flushing oil pump- Type --------------------------------- Model No. --------------------------------- Manufacturer, Country --------------------------------- Speed <strong>of</strong> pump --------------------------------- Capacity <strong>of</strong> pump, lit/min --------------------------------- Pressure at which pump cuts in, bar --------------------------------- Brake horsepower, kw ---------------------------------- Material <strong>of</strong> construction <strong>for</strong> major ---------------------------------components, Ref. No.- Complete description <strong>of</strong> operation ---------------------------------including per<strong>for</strong>mance curves <strong>of</strong>capacity vs suction pressure, Ref. No.(4) DC motor driven flushing oil pump- Type --------------------------------- Model No. --------------------------------- Manufacturer, Country --------------------------------- Speed <strong>of</strong> pump --------------------------------- Capacity <strong>of</strong> pump, lit/min --------------------------------- Pressure at which pump cuts in, bar --------------------------------- Brake horsepower, kw ---------------------------------- Material <strong>of</strong> construction <strong>for</strong> major ---------------------------------components, Ref. No.- Complete description <strong>of</strong> operation ---------------------------------including per<strong>for</strong>mance curves <strong>of</strong>capacity vs suction pressure, Ref. No.(5) AC & DC (back-up) motor driven jacking oil pump- Type --------------------------------- Model No. --------------------------------- Manufacturer, Country --------------------------------- Speed <strong>of</strong> pump --------------------------------<strong>Ghorasal</strong> <strong>300</strong>-<strong>450</strong> <strong>MW</strong> CCPP Project (Vol-2B <strong>of</strong> 2 ) 25

oil tank interior, pedestals oil wells, etc., Ref. No. --------------------------------(9) Complete description <strong>of</strong> oilpurifier, Ref. No. --------------------------------4.4 Condenser and Auxiliaries(1) Condenser- Erected weight- Empty, kg ----------------------------------Operating, kg ---------------------------------- Steam & water spaces flooded, kg ---------------------------------- Max. depth <strong>of</strong> hot-well, high water ---------------------------------level to top <strong>of</strong> condensate outlet, mm- Condenser duty, kj/hr ---------------------------------- Total effective surface, m 2 ---------------------------------- Circulating water required ---------------------------------- Circulating water velocity through tubesat design inlet temp. and flow, m/sec ---------------------------------- Max. permissible water pressure, bar ---------------------------------- Tube cleaning factor, % ---------------------------------- Heat transfer rate, kj/m 2 /hr ---------------------------------- Design circulating water temp., 0 C ---------------------------------- Condensate temperature leavinghot-well ( normal cir. water flow) , 0 C ---------------------------------- Max. free oxygen in condensate leavinghot-well, cc/lit. ---------------------------------- Terminal temp. difference, 0 C ---------------------------------- Hot-well capacity, litre ---------------------------------- Hot-well storage, ---------------------------------- Temperature <strong>of</strong> gas vapour mixtureleaving condenser, 0 C ---------------------------------- Condenser vacuum100% 75% 50% 25% dutyand 30 0 C inlet water, mm Hg ---------------------------------100% 75% 50% 25% dutyand 35 0 C inlet water, mm Hg ---------------------------------100% 75% 50% 25% dutyand 40 0 C inlet water, mm Hg ---------------------------------<strong>Ghorasal</strong> <strong>300</strong>-<strong>450</strong> <strong>MW</strong> CCPP Project (Vol-2B <strong>of</strong> 2 ) 27

- Absolute pressure at turbineexhaust, mm Hg ---------------------------------- Circulating water friction loss betweeninlet and outlet flangesTubes, m ---------------------------------Water boxes, m ---------------------------------Total, m ---------------------------------- Circulating water friction loss atinlet , m ---------------------------------- Circulating water friction loss atoutlet , m ---------------------------------- Total number <strong>of</strong> tubes ---------------------------------- Effective tube length, m ---------------------------------- Tube materials- Tube O D and thickness, mm ---------------------------------- Tube sheet materials ---------------------------------- Tube sheet thickness, mm ---------------------------------- Shell material ---------------------------------- Shell thickness, mm ---------------------------------- Hot-well material ---------------------------------- Hot-well thickness, mm ---------------------------------- Water box material ---------------------------------- Water box thickness, mm ---------------------------------- Number <strong>of</strong> tube support plates ---------------------------------- Tube support plate material ---------------------------------- Tube support plate thickness, mm ---------------------------------- Internal bolts, nuts and studs ---------------------------------- Circulating water inlet and outlet connectionsSize, mm ---------------------------------Flange rating ---------------------------------- Describe method <strong>of</strong> compensating <strong>for</strong>differential thermal expansion betweentubes and shells, Ref. No. ---------------------------------- Describe steam inlet hood expansion jointand state allowable axial and lateraldisplacement, Ref. No. ---------------------------------- Describe manholes on water boxes, Ref. No. ---------------------------------<strong>Ghorasal</strong> <strong>300</strong>-<strong>450</strong> <strong>MW</strong> CCPP Project (Vol-2B <strong>of</strong> 2 ) 28

- Size <strong>of</strong> steam hood equalising line, mm ---------------------------------Describe cathodic protection provided, Ref. No. -------------------------------Itemised list <strong>of</strong> all special wrenches and toolsrequired <strong>for</strong> maintaining and servicingthe proposed equipment, Ref. No. ----------------------------------- Description <strong>of</strong> condensate controlsystem and method <strong>of</strong> operation, Ref. No. ----------------------------------- Description <strong>of</strong> automatic sequentialcondenser back washing facility, Ref. No. ----------------------------------- Description <strong>of</strong> on -load condenser tubecleaning system and method <strong>of</strong> operation, Ref. No. ----------------------------(2) Condensate pumps- Manufacturer, country ---------------------------------- Type ---------------------------------- Model No. ---------------------------------- Total 'dry' weight <strong>of</strong> an assembledunit (pump coupling & drive) on thefoundation, kg ---------------------------------- Total weight 'full <strong>of</strong> water' <strong>of</strong> an assembledunit on the foundation, kg ---------------------------------Total pump weight ( less driver andcoupling), kg ---------------------------------- Required hoisting clearance (hoistinghook to pump mounting flange) to removepump and motor, m -------------------------------- Number <strong>of</strong> stages -------------------------------- Design capacity, lit./hr -------------------------------- Design total dynamic head, m -------------------------------- Pump shut-<strong>of</strong>f head, m -------------------------------- Rated speed, rpm -------------------------------- Specific speed, rpm -------------------------------- Efficiency at design conditions, % -------------------------------- Rated power at design conditions, kw -------------------------------- Discharge velocity at design flow, m/sec -------------------------------- Design suction temperature, 0 C -------------------------------- Max. permissible increase in pump designhead and/or capacity from specified<strong>Ghorasal</strong> <strong>300</strong>-<strong>450</strong> <strong>MW</strong> CCPP Project (Vol-2B <strong>of</strong> 2 ) 29

values without change in priceHead, m -------------------------------Capacity, lit./hr -------------------------------- Min. required flow when operating at ratedspeed, lit./hr -------------------------------- Sealing water requiredFlow, lit./hr -------------------------------Pressure, bar -------------------------------- Pump materialMounting flange -------------------------------Motor support -------------------------------Coupling -------------------------------Casing -------------------------------Impeller -------------------------------Impeller wear rings -------------------------------Casing wear rings -------------------------------Impeller shaft bearings -------------------------------Shaft guide bearings -------------------------------Shaft guide bearings retainers -------------------------------Impeller shaft -------------------------------Drive shaft -------------------------------Shaft materials at bearings and stuffing box -------------------------------Shaft sleeves -------------------------------Stuffing box -------------------------------Stuffing box packing --------------------------------- Type, manufacturer & country, description<strong>of</strong> thrust bearing including lubrication, Ref. No. -------------------------------- State Max. thrust and describe at whatoperating condition it occurs, Ref. No. -------------------------------(3) Condenser vacuum pump- Manufacturer, country ---------------------------------- Type ---------------------------------- Model No. ---------------------------------- Pump speed, rpm ---------------------------------- Brake horsepower, kw ---------------------------------- Condenser evacuation time from 760 mmHgto 260 mmHg abs., min. ---------------------------------<strong>Ghorasal</strong> <strong>300</strong>-<strong>450</strong> <strong>MW</strong> CCPP Project (Vol-2B <strong>of</strong> 2 ) 30

to 110 mmHg abs., min. ---------------------------------- Maintaining capacity at 110 mmHg abs.per pump, lit/hr ---------------------------------- Rated capacity, lit/hr ---------------------------------- operating weight, kg ---------------------------------- <strong>Construction</strong> & material <strong>of</strong> construction<strong>for</strong> major components, Ref. No. ---------------------------------- Specification <strong>of</strong> cooling water and sealwater requiredQuantity, lit/hr ---------------------------------Pressure, bar ---------------------------------- Complete description <strong>of</strong> operation includingper<strong>for</strong>mance curves <strong>of</strong> capacity vs suctionpressure, Ref. No. ---------------------------------- Quantity <strong>of</strong> free air handled , lit/hr ---------------------------------- Inlet air and vapour pressure at 0 0 C(mmHg abs.) ---------------------------------- Inlet air and vapour temp. 0 C ---------------------------------- Itemised list <strong>of</strong> all special wrenches and flaringtools required to maintain and service thefurnished the equipment, Ref. No. ---------------------------------(4) Steam jet air ejector- Manufacturer, country --------------------------------- Number <strong>of</strong> stages --------------------------------- Nozzle diameter, mm --------------------------------- Initial steam pressure, bar --------------------------------- Initial steam temperature, 0 C --------------------------------- Steam consumption, kg/hr --------------------------------- Maintaining capacity at 110 mmHg abs. --------------------------------- Complete description <strong>of</strong> operation includingper<strong>for</strong>mance curves <strong>of</strong> capacity vs suctionpressure, Ref. No. --------------------------------- Rated capacity (free air), lit/hr --------------------------------- Quantity <strong>of</strong> free air handled, lit/hr --------------------------------- Inlet air and vapour pressure at 0 C (mmHg abs.) ----------------------------- Inlet air and vapour temperature, 0 C --------------------------------<strong>Ghorasal</strong> <strong>300</strong>-<strong>450</strong> <strong>MW</strong> CCPP Project (Vol-2B <strong>of</strong> 2 ) 31

4.5 Deaerator- Weight <strong>of</strong> deaerator section, empty, kg --------------------------------- Storage tank, empty, kg --------------------------------- operating weight <strong>of</strong> unit completely assembled, kg --------------------------------- Flooded weight <strong>of</strong> unit completely assembled, kg --------------------------------- Shipping weight, kg --------------------------------- Heaviest piece to be handled during erectionweight & name, kg --------------------------------- Heaviest piece to be handled during maintenanceweight & name, kg --------------------------------- Describe internal vent condenser, statingmaterials, path <strong>of</strong> steam, water and noncondensablegases; length, thickness anddiameter <strong>of</strong> distributor; number and size<strong>of</strong> spray valves, Ref. No. ---------------------------------- Proposals <strong>for</strong> minimising dissolved oxygenlevels during start-up, Ref. No. --------------------------------- Describe internal steam distributionpath, Ref. No. ---------------------------------- Describe internal water distribution path, Ref. No. ---------------------------- Tray removal and/or access doorsNumber --------------------------------Size and materials --------------------------------- ManholesNumber --------------------------------Size and materials ---------------------------------- Describe anti-vortex baffling, Ref. No. ---------------------------------- Storage tank active capacity, lit. ------------------------------------- Height <strong>of</strong> stored water level measured fromtank contains above capacity, m ---------------------------------- Deaerator sectionShell thickness, mm ---------------------------------Head thickness, mm ---------------------------------- Storage tank sectionShell thickness, mm ---------------------------------Head thickness, mm ---------------------------------<strong>Ghorasal</strong> <strong>300</strong>-<strong>450</strong> <strong>MW</strong> CCPP Project (Vol-2B <strong>of</strong> 2 ) 32

- Tray, sizeNumber ---------------------------------Thickness, mm ---------------------------------- MaterialsDeaerator shell ---------------------------------Storage shell ---------------------------------Trays ---------------------------------Internal compartments ---------------------------------All other internal parts ---------------------------------Spray valves ---------------------------------Impingement baffles ---------------------------------Antivortex baffles ---------------------------------- Describe number, location, type <strong>of</strong>manhole and access doors, Ref. No. ---------------------------------- List <strong>of</strong> special tools provided, Ref. No. ---------------------------------- Pressure drop from steam inlet nozzle tostorage tank steam space above storedwater at design conditions, bar ---------------------------------- Temperature <strong>of</strong> deaerator effluent atdesign conditions, 0 C ---------------------------------- Static pressure required at inlet to waterdistribution at design conditions, bar ---------------------------------- Max. steam quantity leaving deaeratorvents at design conditions, kg/hr ---------------------------------- Pressure drop across condensate inletvalves at design conditions, bar ---------------------------------B-5 Generator and Ancillaries (<strong>for</strong> Steam Turbine)5.1 Generator-Manufacturer, Country -----------------------------------Type -----------------------------------KVA rating / power factor 0.8 -----------------------------------Max. leading & lagging KVAR capability at pf -----------------------------------Rated voltage between lines, KV -----------------------------------Connection <strong>of</strong> armature winding -----------------------------------Rated Current, A -----------------------------------Rated frequency, Hz ----------------------------------<strong>Ghorasal</strong> <strong>300</strong>-<strong>450</strong> <strong>MW</strong> CCPP Project (Vol-2B <strong>of</strong> 2 ) 33

-Efficiencyat pf 0.8, % ----------------------------------at pf 1.0, % -----------------------------------Stator overloading, % -----------------------------------Critical speed, rpm -----------------------------------Max. torque when the stator is short-circuited, Nm -----------------------------------Generator CharacteristicsInstantaneous Max. short-circuit currentat nominal voltage, A peak ----------------------------------sub-transient reactance, Xd” pu ----------------------------------transient reactance, Xd’ pu ----------------------------------synchronous reactance, Xd pu ----------------------------------negative sequence reactance, pu ----------------------------------zero sequence reactance, pu ----------------------------------field time Constant, Td’ 0 sec ----------------------------------Transient time Constant, Td sec ----------------------------------initial time Constant, Td” sec -----------------------------------Moment <strong>of</strong> inertia GD 2 <strong>of</strong> rotor, Kg-m 2 -----------------------------------percent rise on voltage when full load isrejected and operating at pf 0.8 , % ----------------------------------pf 1.0 , % -----------------------------------Telephone influence factorBalanced ----------------------------Residual -----------------------------Class <strong>of</strong> winding insulationArmature winding ---------------------------Field winding -----------------------------Type <strong>of</strong> cooling-Short circuit ratio, (sat.)-Generator rated excitation requirements <strong>for</strong>operation at rated kVAExcitation voltage, V -------------------------Excitation current, A -------------------------- Generator calculated losses at 100% Base ratingTotal generator iron loss, kW -------------------------Generator stator I 2 R loss, kW -------------------------Generator rotor I 2 R loss, kW -------------------------Generator stray load loss, kW -------------------------Generator windage loss, kW -------------------------Total generator loss, kW -------------------------- Generator cooling system -------------------------- Generator weights<strong>Ghorasal</strong> <strong>300</strong>-<strong>450</strong> <strong>MW</strong> CCPP Project (Vol-2B <strong>of</strong> 2 ) 34

5.2 Exciter (Brushless)Weight <strong>of</strong> rotor, kg -------------------------Weight <strong>of</strong> complete stator, kg -------------------------- Manufacturer, Country -------------------------- Type -------------------------- Rated output, kW --------------------------Rated load field voltage at0.80 pf/1.00 pf --------------------------Rated exciter current at0.80 pf./l.00 pf -------------------------- Exiter ceiling voltage, V --------------------------Maximum continuous excitercurrent, A --------------------------Excitation system voltageresponse ratio -------------------------5.3 Automatic Voltage Regulator-Manufacturer, Country -------------------------- Type -------------------------- Description <strong>of</strong> AVR, Ref. No. -------------------------5.4 Generator Protection (Manufacturer Cat. No. or Type)Relay Manufacturer -------------------------Generator differential relay --------------------------Generator ground over-current relay --------------------------Field / rotor ground detection system --------------------------Reverse power relay --------------------------Loss <strong>of</strong> field relay --------------------------Voltage restraint over-current relays --------------------------Negative phase sequence relay --------------------------Under/Over Frequency relay -------------------------- Synchro-Check Relay -------------------------- Auxiliary relays --------------------------Lockout relays -------------------------5.5 Generator Switchgear-Manufacturer, Country --------------------------Circuit breakerInterrupting Media SF 6Catalogue No. -------------------------Type -------------------------Closing current at 125 volts DC, A ---------------------Time to close, m sec -------------------------Tripping current at 125 volts DC, A -------------------------Time to trip, m sec -------------------------- Rating and capabilitiesCurrent rating, A -------------------------Voltage rating, V -------------------------Nominal 3 phase interrupting capacity, MVA -------------------------Maximum symmetrical interrupting capacity, kA -------------------------3 second short time rating, kA -------------------------<strong>Ghorasal</strong> <strong>300</strong>-<strong>450</strong> <strong>MW</strong> CCPP Project (Vol-2B <strong>of</strong> 2 ) 35

Closing and latching capability, kA -------------------------- Operating Mechanism -------------------------Instruments and devices Manufacturer TypeCurrent trans<strong>for</strong>mersSingle ratio -------------------------Multi ratio -------------------------Potential trans<strong>for</strong>mers -------------------------Control and instrument switches -------------------------Indicating lights --------------------------Lightning arresters --------------------------Surge protection devices --------------------------Type <strong>of</strong> bus insulation --------------------------Type <strong>of</strong> bus supports --------------------------Type <strong>of</strong> insulation on connections --------------------------Size <strong>of</strong> completely assembled switchgearLength, mm -------------------------Width, mm -------------------------Height, mm -------------------------- Total weight <strong>of</strong> switchgear, kg -------------------------B-6 Mechanical Auxiliary Equipment6.1 HRSG Feed Water Pump(1) Feed Pump- Manufacturer, country -------------------------- Type -------------------------- Model Number -------------------------- Number <strong>of</strong> stages -------------------------- Running speed, rpm -------------------------- Critical speed, rpm -------------------------- Pump capacity at design conditions, kg/hr -------------------------- Max. leak-<strong>of</strong>f quantity, lit/hr --------------------------- Pressure at pump discharge, bar --------------------------- Pressure at outlet <strong>of</strong> non-return valve, bar --------------------------- Min. NPSH, m --------------------------- Bore <strong>of</strong> suction branch, mm --------------------------- Bore <strong>of</strong> discharge branch, mm --------------------------Type <strong>of</strong> branches, mm --------------------------Min. diametrical clearance at specified temp., mm --------------------------Type <strong>of</strong> coupling --------------------------Pump automatic cut-in pressure, bar --------------------------Min. load pump can operate, % <strong>of</strong> MCR --------------------------(2) Feed Pump Motor- Manufacturer, country ---------------------------Type ---------------------------Model No. ---------------------------Frame size ---------------------------Speed at rated output, rpm ---------------------------Rated output, KW ---------------------------Nominal supply voltage, KV ---------------------------Frequency, Hz ---------------------------Full load currency, A ---------------------------Power factor at full load ---------------------------Class <strong>of</strong> insulation ---------------------------<strong>Ghorasal</strong> <strong>300</strong>-<strong>450</strong> <strong>MW</strong> CCPP Project (Vol-2B <strong>of</strong> 2 ) 36

Quantity <strong>of</strong> cooling water required, lit/hr ---------------------------Max. temperature rise, 0 C ---------------------------Enclosure ---------------------------Type <strong>of</strong> bearings ---------------------------Full load torque, kg-m ---------------------------Starting torque in percent <strong>of</strong> full load torque, % ---------------------------Max. torque in percent <strong>of</strong> full load torque, % ---------------------------(3) Weight- Weight <strong>of</strong> pump shaft and impellers, kg ---------------------------Weight <strong>of</strong> pump complete, kg ---------------------------Weight <strong>of</strong> motor stator, kg ---------------------------Weight <strong>of</strong> motor rotor, kg ---------------------------- Weight <strong>of</strong> bedplate, kg ---------------------------(4) Materials- Pump casing ---------------------------- Pump shaft ---------------------------- Impellers ---------------------------- Guide vanes ---------------------------- Shaft sleeves ---------------------------- Wearing rings ---------------------------- Balance disc ---------------------------- Balance disc wearing plate ---------------------------- Grand packing ---------------------------6.2 Circulating Water System(1) Circulating water pump- Manufacturer, country ---------------------------- Type ---------------------------- Model Number ---------------------------- Number <strong>of</strong> stages ---------------------------- Running speed, rpm ---------------------------- Critical speed, rpm ---------------------------- Pump capacity at design conditions, kg/hr ---------------------------- Pressure at pump discharge, bar ---------------------------- Bore <strong>of</strong> suction branch, mm ---------------------------- Bore <strong>of</strong> discharge branch, mm ------------------------------Min. diametrical clearance at specified temp., mm ---------------------------Type <strong>of</strong> coupling ---------------------------Type <strong>of</strong> thrust bearing ---------------------------- Distance between centre line <strong>of</strong> impeller andlowest water level, m --------------------------- CW pump suction head loss, m --------------------------(2) CW Pump Motor- Manufacturer, country ---------------------------Type ---------------------------Model No. ---------------------------Frame size ---------------------------Speed at rated output, rpm ---------------------------Rated output, KW ---------------------------Nominal supply voltage, KV ---------------------------Frequency, Hz ---------------------------Full load currency, A ---------------------------<strong>Ghorasal</strong> <strong>300</strong>-<strong>450</strong> <strong>MW</strong> CCPP Project (Vol-2B <strong>of</strong> 2 ) 37

Power factor at full load ---------------------------Class <strong>of</strong> insulation ---------------------------Quantity <strong>of</strong> cooling water required, lit/hr ---------------------------Max. temperature rise, 0 C ---------------------------Enclosure ---------------------------Type <strong>of</strong> bearings ---------------------------Full load torque, kg-m ---------------------------Starting torque in percent <strong>of</strong> full load torque, % ---------------------------Max. torque in percent <strong>of</strong> full load torque, % ---------------------------- Overload capacity, % ---------------------------- Provision <strong>of</strong> anti-condensation heater ---------------------------- Provision <strong>of</strong> winding temperature indicators ---------------------------(3) Discharge Valve-Manufacturer, country ---------------------------- Type ---------------------------- Model No. ---------------------------- Bore, mm ---------------------------- Design pressure, bar --------------------------- Test pressure, bar --------------------------- Max. flow, lit/hr --------------------------- Normal flow, lit/hr --------------------------- Opening time, sec --------------------------- Closing time, sec --------------------------- Valve actuation --------------------------(4) Reversing Valve-Manufacturer, country --------------------------- Type --------------------------- Bore, mm --------------------------- Model No. -------------------------- Design pressure, bar --------------------------- Test pressure, bar --------------------------- Max. flow, lit/hr --------------------------- Normal flow, lit/hr --------------------------- Reversing time, sec --------------------------- Valve actuation --------------------------(5) Cathodic Protection Equipment-Manufacturer, country --------------------------- Type --------------------------- Model No.- Nominal supply voltage, v --------------------------- Nominal supply frequency, Hz --------------------------- Nominal supply phase --------------------------Number <strong>of</strong> anodes --------------------------Material <strong>of</strong> anodes --------------------------- Max. anode current, A --------------------------(6) Pipework- Manufacturer, country ---------------------------Bore, mm ---------------------------Material ---------------------------Design pressure, bar ---------------------------Test pressure, bar ---------------------------Wall thickness, mm ---------------------------<strong>Ghorasal</strong> <strong>300</strong>-<strong>450</strong> <strong>MW</strong> CCPP Project (Vol-2B <strong>of</strong> 2 ) 38

Details <strong>of</strong> lining, Ref. No. ---------------------------(7) Weight- Weight <strong>of</strong> pump & column pipe , kg ---------------------------Weight <strong>of</strong> pump complete, kg ---------------------------Weight <strong>of</strong> motor, kg ---------------------------Max. dynamic load on foundation, kg ---------------------------- Max. load on crane hook, kg ---------------------------(8) Materials- C W pump ---------------------------Suction <strong>of</strong> bellmouth ---------------------------Casing ball ---------------------------Diffuser ---------------------------Impellers ---------------------------Pump shaft ---------------------------Shaft sleeves ---------------------------Delivery bend ---------------------------Foundation ring ---------------------------Stuffing box packing -------------------------- Discharge pipework -------------------------- Venting pipework -------------------------6.3 Cooling Tower- Manufacturer, country -------------------------- Type -------------------------- Capacity, m 3 / hr -------------------------- Cooling surface area, m 2 -------------------------- Depression <strong>of</strong> Temp (at site condition), 0 C ------------------------- Inlet water temp. 0 C ------------------------- Outlet water temp. 0 C ------------------------- Air flow rate, m 3 / sec ------------------------- No. <strong>of</strong> Cell (including 25% additional cell) -------------------------- Cooling Tower Basin Capacity, m 3 -------------------------- Make up water requirement, m 3 / hr -------------------------6.4 Compressed Air Equipment(1) Air Compressor- Manufacturer, country -------------------------- Type -------------------------- Capacity, lit/hr -------------------------- Discharge pressure, bar -------------------------- Speed, rpm -------------------------- Efficiency at rated output, % -------------------------- Power required, kw -------------------------- Description <strong>of</strong> compressor (main components), Ref. No. -------------------------- Weight, kg -------------------------(2) Compressor Motor- Manufacturer, country -------------------------- Type -------------------------- Voltage, KV -------------------------- Speed at rated output, rpm -------------------------- Rating, KW -------------------------<strong>Ghorasal</strong> <strong>300</strong>-<strong>450</strong> <strong>MW</strong> CCPP Project (Vol-2B <strong>of</strong> 2 ) 39

- Max. starting current as percentage <strong>of</strong> full load, % -------------------------- Efficiency, % -------------------------- Class <strong>of</strong> insulation -------------------------- Weight, kg -------------------------(3) Inlet Air Filter- Manufacturer, country -------------------------- Type -------------------------- Size -------------------------- Description, Ref. No. -------------------------(4) Moisture Separator- Manufacturer, country -------------------------- Type --------------------------- Size --------------------------- Capacity --------------------------(5) Automatic Drain Trip- Manufacturer, country -------------------------- Type -------------------------- Size -------------------------- Capacity -------------------------(6) Air Receiver- Manufacturer, country -------------------------- Capacity, lit -------------------------- Dimension, mm -------------------------- Thickness <strong>of</strong> shell plate, mm -------------------------- Type <strong>of</strong> construction -------------------------- Design pressure, bar -------------------------- Weright, kg -------------------------- Safety valve setting pressure, bar -------------------------B-7 230 kV Switchgear, Equipment7.1 230 kV Circuit Breaker- Manufacturer, Country -------------------------- Type designation -------------------------- Number <strong>of</strong> poles -------------------------- Rated voltage, KV -------------------------- Maximum design voltage-Minimum voltage <strong>for</strong> ratedinterrupting capacity, KV -------------------------- Rated continuous current, A -------------------------- Rated frequency, Hz -------------------------- Rated insulation levelImpulse withstand voltage, kV-peak --------------------------Power frequency withstandvoltage (1 mm.), KV --------------------------Rated interrupting capacity, MVA -------------------------- Maximum interrupting current, kA -------------------------- Rated momentary current -------------------------- Rated duration <strong>of</strong> short-Circuit, sec -------------------------- Rated making current, kA-peak --------------------------Operating duty -------------------------<strong>Ghorasal</strong> <strong>300</strong>-<strong>450</strong> <strong>MW</strong> CCPP Project (Vol-2B <strong>of</strong> 2 ) 40

- Operating time, m sec. --------------------------Rated interrupting time, m sec -------------------------.-Closing time, m sec --------------------------Opening time, m sec. --------------------------Minimum dead time, m sec. --------------------------Reclosing time, m sec. --------------------------First-pole-to clear factorAt 100% breaking capacity -------------------------At 10% breaking capacity --------------------------Out <strong>of</strong> phase breaking currentAt 2.0 times rated voltage, KA -------------------------At 2.5 times rated voltage, KA --------------------------Creepage distance <strong>of</strong> the insulator, mm --------------------------Weight <strong>of</strong> complete circuit breaker, Kg --------------------------Type <strong>of</strong> operating mechanism --------------------------Outline drawings, No --------------------------Standard specifications to which thecircuit breaker shall con<strong>for</strong>m --------------------------Attached type test report, No -------------------------7.2 230 kV Current Trans<strong>for</strong>mer- Manufacturer , Country -------------------------- Type designation -------------------------- Rated voltage, KV -------------------------- Maximum design voltage, KV- Rated Primary Current, A -------------------------- Rated Secondary current, A -------------------------- Rated frequency, Hz -------------------------- Rated insulation levelImpulse withstand voltage, kV-peak -------------------------- Power frequency withstandvoltage (1 mm.), KV -------------------------- Number <strong>of</strong> cores -------------------------For metering service -------------------------For relaying service -------------------------- Accuracy Class -------------------------For metering service -------------------------For relaying service -------------------------- Rated Burden -------------------------For metering service, VA -------------------------.For relaying service, VA -------------------------- Rated continuous thermal current, %- Short-time current rating,(1 sec), KA -------------------------- Creepage distance <strong>of</strong> insulator, mm -------------------------- Weight <strong>of</strong> single phase unit, Kg-Out line drawing, No --------------------------Standard specification to which the CTshall con<strong>for</strong>m --------------------------Attached type test report, No -------------------------7.3 230 KV Voltage Trans<strong>for</strong>mer- Manufacturer, Country -------------------------- Type designation -------------------------- Rated voltage, KV -------------------------<strong>Ghorasal</strong> <strong>300</strong>-<strong>450</strong> <strong>MW</strong> CCPP Project (Vol-2B <strong>of</strong> 2 ) 41