Latent Print Development - National Criminal Justice Reference ...

Latent Print Development - National Criminal Justice Reference ...

Latent Print Development - National Criminal Justice Reference ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

C H A P T E R 7 <strong>Latent</strong> <strong>Print</strong> <strong>Development</strong><br />

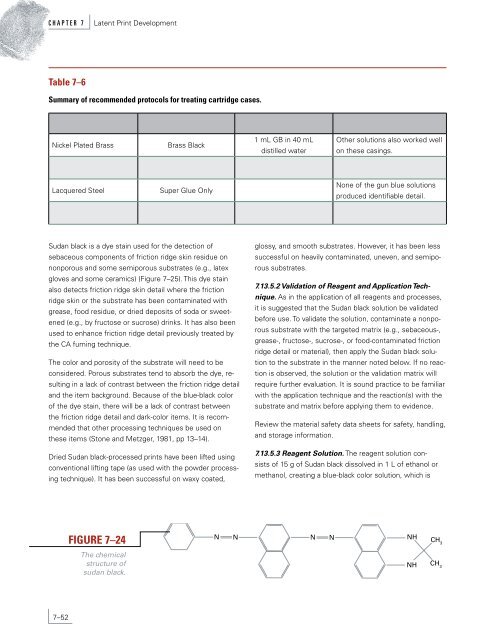

Table 7–6<br />

Summary of recommended protocols for treating cartridge cases.<br />

Cartridge Type<br />

Sudan black is a dye stain used for the detection of<br />

sebaceous components of friction ridge skin residue on<br />

nonporous and some semiporous substrates (e.g., latex<br />

gloves and some ceramics) (Figure 7–25). This dye stain<br />

also detects friction ridge skin detail where the friction<br />

ridge skin or the substrate has been contaminated with<br />

grease, food residue, or dried deposits of soda or sweetened<br />

(e.g., by fructose or sucrose) drinks. It has also been<br />

used to enhance friction ridge detail previously treated by<br />

the CA fuming technique.<br />

The color and porosity of the substrate will need to be<br />

considered. Porous substrates tend to absorb the dye, resulting<br />

in a lack of contrast between the friction ridge detail<br />

and the item background. Because of the blue-black color<br />

of the dye stain, there will be a lack of contrast between<br />

the friction ridge detail and dark-color items. It is recommended<br />

that other processing techniques be used on<br />

these items (Stone and Metzger, 1981, pp 13–14).<br />

Dried Sudan black-processed prints have been lifted using<br />

conventional lifting tape (as used with the powder processing<br />

technique). It has been successful on waxy coated,<br />

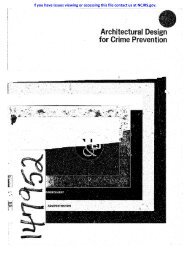

FIGURE 7–24<br />

The chemical<br />

structure of<br />

sudan black.<br />

Suggested Treatment<br />

After Superglue<br />

Nickel Plated Brass Brass Black<br />

Brass<br />

Formula 44/40 Instant<br />

Gun Blue<br />

Lacquered Steel Super Glue Only<br />

Aluminum Aluminum Black<br />

7–52<br />

Gun Blue (GB) Dilution Comments<br />

1 mL GB in 40 mL<br />

distilled water<br />

0.5 mL GB in 40 mL<br />

distilled water<br />

0.5 mL GB in 40 mL<br />

distilled water<br />

Other solutions also worked well<br />

on these casings.<br />

Other solutions also worked well<br />

on these casings.<br />

None of the gun blue solutions<br />

produced identifiable detail.<br />

This is the only solution that<br />

worked on this metal.<br />

glossy, and smooth substrates. However, it has been less<br />

successful on heavily contaminated, uneven, and semiporous<br />

substrates.<br />

7.13.5.2 Validation of Reagent and Application Technique.<br />

As in the application of all reagents and processes,<br />

it is suggested that the Sudan black solution be validated<br />

before use. To validate the solution, contaminate a nonporous<br />

substrate with the targeted matrix (e.g., sebaceous-,<br />

grease-, fructose-, sucrose-, or food-contaminated friction<br />

ridge detail or material), then apply the Sudan black solution<br />

to the substrate in the manner noted below. If no reaction<br />

is observed, the solution or the validation matrix will<br />

require further evaluation. It is sound practice to be familiar<br />

with the application technique and the reaction(s) with the<br />

substrate and matrix before applying them to evidence.<br />

Review the material safety data sheets for safety, handling,<br />

and storage information.<br />

7.13.5.3 Reagent Solution. The reagent solution consists<br />

of 15 g of Sudan black dissolved in 1 L of ethanol or<br />

methanol, creating a blue-black color solution, which is<br />

N N N N NH<br />

NH<br />

CH 3<br />

CH 3