Latent Print Development - National Criminal Justice Reference ...

Latent Print Development - National Criminal Justice Reference ...

Latent Print Development - National Criminal Justice Reference ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

then added to 500 mL of distilled water and stirred until<br />

completely mixed. The shelf life of the solution is indefinite.<br />

7.13.5.4 Sequential Methodology and Processing<br />

Technique. Before processing with sudan black, view the<br />

item with a forensic light source to detect any inherent<br />

fluorescence of the friction ridge residue or the substrate.<br />

Photograph any visible detail.<br />

• Place the Sudan black solution in a clean glass or metal<br />

dish, pouring in a sufficient amount to submerge the<br />

item being processed. The solution can also be applied<br />

by spraying. It is recommended that the immersion<br />

technique be used to prevent inhalation of airborne<br />

particulate spray.<br />

• Allow item to be immersed in the solution for approximately<br />

2 minutes. If the item has been previously processed<br />

using the CA fuming technique, the item may<br />

require longer immersion time in the solution.<br />

• Rinse item under cool or cold, slow-running tap water,<br />

or place item in a clean dish containing cool or cold<br />

water until excess dye is removed from the background.<br />

• Allow item to dry at room temperature.<br />

• View the developed blue-black image; faint images have<br />

been improved by a second treatment with the Sudan<br />

black solution (follow the previous application steps). It<br />

is suggested that the item be viewed with a forensic<br />

light source after Sudan black processing because the<br />

background may fluoresce, creating enhanced contrast.<br />

• Any developed images will need to be photographed for<br />

comparison, documentation, and archival purposes.<br />

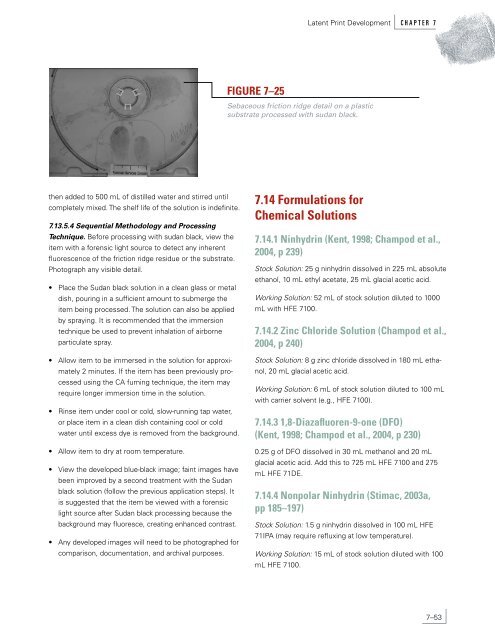

FIGURE 7–25<br />

<strong>Latent</strong> <strong>Print</strong> <strong>Development</strong> C H A P T E R 7<br />

Sebaceous friction ridge detail on a plastic<br />

substrate processed with sudan black.<br />

7.14 Formulations for<br />

Chemical Solutions<br />

7.14.1 Ninhydrin (Kent, 1998; Champod et al.,<br />

2004, p 239)<br />

Stock Solution: 25 g ninhydrin dissolved in 225 mL absolute<br />

ethanol, 10 mL ethyl acetate, 25 mL glacial acetic acid.<br />

Working Solution: 52 mL of stock solution diluted to 1000<br />

mL with HFE 7100.<br />

7.14.2 Zinc Chloride Solution (Champod et al.,<br />

2004, p 240)<br />

Stock Solution: 8 g zinc chloride dissolved in 180 mL ethanol,<br />

20 mL glacial acetic acid.<br />

Working Solution: 6 mL of stock solution diluted to 100 mL<br />

with carrier solvent (e.g., HFE 7100).<br />

7.14.3 1,8-Diazafluoren-9-one (DFO)<br />

(Kent, 1998; Champod et al., 2004, p 230)<br />

0.25 g of DFO dissolved in 30 mL methanol and 20 mL<br />

glacial acetic acid. Add this to 725 mL HFE 7100 and 275<br />

mL HFE 71DE.<br />

7.14.4 Nonpolar Ninhydrin (Stimac, 2003a,<br />

pp 185–197)<br />

Stock Solution: 1.5 g ninhydrin dissolved in 100 mL HFE<br />

71IPA (may require refluxing at low temperature).<br />

Working Solution: 15 mL of stock solution diluted with 100<br />

mL HFE 7100.<br />

7–53