Rexroth MTA 200 Rexroth BTV 20.4A - Nuova Elva

Rexroth MTA 200 Rexroth BTV 20.4A - Nuova Elva

Rexroth MTA 200 Rexroth BTV 20.4A - Nuova Elva

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Industrial<br />

Hydraulics<br />

Electric Drives<br />

and Controls<br />

exroth IndraControl VCP 20<br />

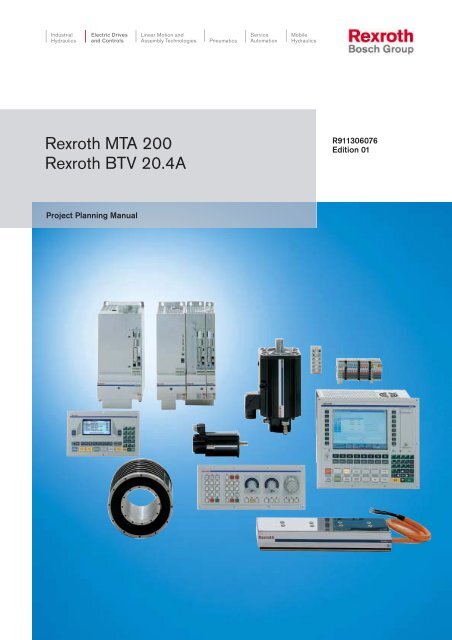

<strong>Rexroth</strong> <strong>MTA</strong> <strong>200</strong><br />

<strong>Rexroth</strong> <strong>BTV</strong> <strong>20.4A</strong><br />

Project Planning Manual<br />

Linear Motion and<br />

Assembly Technologies Pneumatics<br />

Service<br />

Automation<br />

Mobile<br />

Hydraulics<br />

R911306076<br />

Edition 01

About this Documentation <strong>Rexroth</strong> <strong>BTV</strong> <strong>20.4A</strong><br />

Title<br />

Type of Documentation<br />

Document Typecode<br />

Internal File Reference<br />

Purpose of Documentation<br />

Record of Revisions<br />

Copyright<br />

Validity<br />

Published by<br />

Note<br />

<strong>Rexroth</strong> <strong>MTA</strong> <strong>200</strong><br />

<strong>Rexroth</strong> <strong>BTV</strong> <strong>20.4A</strong><br />

Project Planning Manual<br />

DOK-<strong>MTA</strong><strong>200</strong>-<strong>BTV</strong><strong>20.4A</strong>***-PR01-EN-P<br />

Document Number 120-1720-B317-01/EN<br />

This documentation describes the hardware components of the <strong>Rexroth</strong><br />

<strong>MTA</strong> <strong>200</strong> control system which are included in the operating PC<br />

<strong>BTV</strong> <strong>20.4A</strong>.<br />

Description Release<br />

Date<br />

Notes<br />

120-1720-B317-01/EN 06.<strong>200</strong>4 First issue<br />

© <strong>200</strong>4 Bosch <strong>Rexroth</strong> AG<br />

Copying this document, giving it to others and the use or communication<br />

of the contents thereof without express authority, are forbidden. Offenders<br />

are liable for the payment of damages. All rights are reserved in the event<br />

of the grant of a patent or the registration of a utility model or design<br />

(DIN 34-1).<br />

The specified data is for product description purposes only and may not<br />

be deemed to be guaranteed unless expressly confirmed in the contract.<br />

All rights are reserved with respect to the content of this documentation<br />

and the availability of the product.<br />

Bosch <strong>Rexroth</strong> AG<br />

Bgm.-Dr.-Nebel-Str. 2 • D-97816 Lohr a. Main<br />

Telephone +49 (0)93 52/40-0 • Tx 68 94 21 • Fax +49 (0)93 52/40-48 85<br />

http://www.boschrexroth.com/<br />

Dept. BRC/ESM5 (OI)<br />

Dept. BRC/ESM6 (DiHa)<br />

This document has been printed on chlorine-free bleached paper.<br />

DOK-<strong>MTA</strong><strong>200</strong>-<strong>BTV</strong><strong>20.4A</strong>***-PR01-EN-P

<strong>Rexroth</strong> <strong>BTV</strong> <strong>20.4A</strong> Contents I<br />

Contents<br />

1 Overview 1-1<br />

1.1 System Concept ........................................................................................................................... 1-1<br />

1.2 Regarding this Documentation ..................................................................................................... 1-1<br />

1.3 Additional Documentation............................................................................................................. 1-2<br />

1.4 Important Directions for Use......................................................................................................... 1-4<br />

Appropriate Use....................................................................................................................... 1-4<br />

Inappropriate Use .................................................................................................................... 1-5<br />

Notes for Electro Static Discharge........................................................................................... 1-5<br />

1.5 Safety Instructions for Electric Drives and Controls ..................................................................... 1-6<br />

Introduction .............................................................................................................................. 1-6<br />

Explanations ............................................................................................................................ 1-6<br />

Hazards by Improper Use........................................................................................................ 1-7<br />

General Information................................................................................................................. 1-8<br />

Protection Against Contact with Electrical Parts ..................................................................... 1-9<br />

Protection Against Electric Shock by Protective Low Voltage (PELV) .................................. 1-11<br />

Protection Against Dangerous Movements ........................................................................... 1-11<br />

Protection Against Magnetic and Electromagnetic Fields During Operation and<br />

Mounting ................................................................................................................................ 1-14<br />

Protection Against Contact with Hot Parts ............................................................................ 1-15<br />

Protection During Handling and Mounting............................................................................. 1-15<br />

Battery Safety ........................................................................................................................ 1-15<br />

Protection Against Pressurized Systems .............................................................................. 1-16<br />

2 Machine Operator Terminal <strong>BTV</strong> <strong>20.4A</strong> 2-1<br />

2.1 Brief Description ........................................................................................................................... 2-1<br />

Standard Configuration of the <strong>BTV</strong> 20.4 ................................................................................. 2-2<br />

Additional <strong>BTV</strong> <strong>20.4A</strong> Modules................................................................................................ 2-2<br />

Firmware and Software Configurations ................................................................................... 2-3<br />

2.2 Front Plate, Keyboard................................................................................................................... 2-4<br />

Floppy Disk Flap, Reset Button............................................................................................... 2-4<br />

Operating Display .................................................................................................................... 2-5<br />

Overview of Keys..................................................................................................................... 2-5<br />

Machine and PLC Function Keys ............................................................................................ 2-7<br />

Addressing via PLC ................................................................................................................. 2-8<br />

Replacing the Slide-in Strips ................................................................................................... 2-9<br />

2.3 Keyboard Layout......................................................................................................................... 2-11<br />

2.4 Technical Data............................................................................................................................ 2-15<br />

General Technical Data......................................................................................................... 2-15<br />

Ambient Conditions ............................................................................................................... 2-15<br />

DOK-<strong>MTA</strong><strong>200</strong>-<strong>BTV</strong><strong>20.4A</strong>***-PR01-EN-P

II Contents <strong>Rexroth</strong> <strong>BTV</strong> <strong>20.4A</strong><br />

Wear Parts............................................................................................................................. 2-16<br />

2.5 Measurements ............................................................................................................................ 2-17<br />

Housing Dimensions.............................................................................................................. 2-17<br />

2.6 Installation Dimensions............................................................................................................... 2-21<br />

2.7 Connections................................................................................................................................ 2-22<br />

General Connections............................................................................................................. 2-22<br />

Interfaces of NC CPU Card - Computer Configuration 45..................................................... 2-24<br />

LPT1 Printer Interface and SIS.............................................................................................. 2-26<br />

Internal Wiring........................................................................................................................ 2-28<br />

Sample Applications .............................................................................................................. 2-29<br />

2.8 Ordering Information................................................................................................................... 2-34<br />

Type Key................................................................................................................................ 2-34<br />

Configuration Type Key ......................................................................................................... 2-35<br />

Accessories ........................................................................................................................... 2-36<br />

2.9 Supplied Accessories (Scope of Delivery).................................................................................. 2-39<br />

3 PC CPU Configuration 45 3-1<br />

3.1 Brief Description ........................................................................................................................... 3-1<br />

3.2 Technical Data.............................................................................................................................. 3-1<br />

Electrical Specifications........................................................................................................... 3-1<br />

CPU and Memory Specifications............................................................................................. 3-1<br />

3.3 PhoenixBIOS Setup...................................................................................................................... 3-2<br />

Main PhoenixBIOS Setup Menu.............................................................................................. 3-3<br />

PhoenixBIOS Settings for the <strong>BTV</strong> 20.4.................................................................................. 3-4<br />

3.4 Installation of SO-DIMM Memory Modules................................................................................... 3-9<br />

3.5 Temporary Connection of Additional IDE Devices ..................................................................... 3-10<br />

Connection for Power Supply Cable...................................................................................... 3-10<br />

IDE Port ................................................................................................................................. 3-11<br />

4 PC CPU Configuration 44 4-1<br />

4.1 Brief Description ........................................................................................................................... 4-1<br />

4.2 Technical Data.............................................................................................................................. 4-2<br />

Electrical Specifications........................................................................................................... 4-2<br />

CPU and Memory Specifications............................................................................................. 4-2<br />

4.3 PhoenixBIOS Setup...................................................................................................................... 4-2<br />

PhoenixBIOS Settings of the NC CPU .................................................................................... 4-3<br />

5 NC Multifunction Card NCM02 5-1<br />

5.1 Brief Description ........................................................................................................................... 5-1<br />

5.2 Features........................................................................................................................................ 5-1<br />

5.3 Available Versions ........................................................................................................................ 5-2<br />

5.4 Interfaces ...................................................................................................................................... 5-3<br />

5.5 Coding and Component Diagrams ............................................................................................... 5-4<br />

+NCM0201 .............................................................................................................................. 5-4<br />

+NCM0202 .............................................................................................................................. 5-5<br />

+NCM0204 .............................................................................................................................. 5-6<br />

DOK-<strong>MTA</strong><strong>200</strong>-<strong>BTV</strong><strong>20.4A</strong>***-PR01-EN-P

<strong>Rexroth</strong> <strong>BTV</strong> <strong>20.4A</strong> Contents III<br />

5.6 Slot Brackets................................................................................................................................. 5-7<br />

CNC Fault (X21) ...................................................................................................................... 5-7<br />

Fast I/Os (X23) ........................................................................................................................ 5-8<br />

Status Indicators...................................................................................................................... 5-8<br />

5.7 Additional SERCOS Rings............................................................................................................ 5-9<br />

+NCMZ003 .............................................................................................................................. 5-9<br />

+NCMZ004 .............................................................................................................................. 5-9<br />

X24.* Transmitter................................................................................................................... 5-10<br />

X25.* Receiver....................................................................................................................... 5-10<br />

Status Indicators.................................................................................................................... 5-10<br />

Connections........................................................................................................................... 5-10<br />

NCM in the <strong>BTV</strong><strong>20.4A</strong> ........................................................................................................... 5-11<br />

5.8 Connection Cable ....................................................................................................................... 5-11<br />

Cable Specifications .............................................................................................................. 5-12<br />

5.9 NCIO Card .................................................................................................................................. 5-12<br />

General Information............................................................................................................... 5-12<br />

Slot Bracket ........................................................................................................................... 5-13<br />

X22 I/O Interface ................................................................................................................... 5-13<br />

Installation.............................................................................................................................. 5-15<br />

5.10 Phoenix Block I/O Module ILB IB 24 DI16 DO16 ....................................................................... 5-15<br />

Connection............................................................................................................................. 5-16<br />

Signal Assignment................................................................................................................. 5-16<br />

6 PLC Modules MTS-P01.2 and MTS-P02.2 6-1<br />

6.1 Brief Description ........................................................................................................................... 6-1<br />

6.2 Technical Data.............................................................................................................................. 6-3<br />

General Information................................................................................................................. 6-3<br />

Power Supply........................................................................................................................... 6-3<br />

EMC......................................................................................................................................... 6-3<br />

Interfaces ................................................................................................................................. 6-4<br />

6.3 Communication............................................................................................................................. 6-4<br />

PLC Inputs for the Machine Function Keys (X8) ..................................................................... 6-4<br />

Connection of <strong>BTV</strong> 20 PLC Function Keys (X12).................................................................... 6-4<br />

PLC Ready (X5)....................................................................................................................... 6-5<br />

COM Interface (X16) ............................................................................................................... 6-5<br />

BT Bus (X15) ........................................................................................................................... 6-5<br />

6.4 Commissioning ............................................................................................................................. 6-8<br />

Assembly ................................................................................................................................. 6-8<br />

Setting of Addresses ............................................................................................................... 6-8<br />

Battery ..................................................................................................................................... 6-9<br />

Status Information and Error Diagnosis .................................................................................. 6-9<br />

6.5 INTERBUS Master Connection .................................................................................................. 6-12<br />

Brief Description .................................................................................................................... 6-12<br />

Setting the I/O Address ......................................................................................................... 6-13<br />

Technical Data....................................................................................................................... 6-13<br />

Interface Assignment............................................................................................................. 6-14<br />

DOK-<strong>MTA</strong><strong>200</strong>-<strong>BTV</strong><strong>20.4A</strong>***-PR01-EN-P

IV Contents <strong>Rexroth</strong> <strong>BTV</strong> <strong>20.4A</strong><br />

6.6 PROFIBUS DP Connection ........................................................................................................ 6-15<br />

Brief Description of Master and Slave Connection................................................................ 6-15<br />

Setting I/O Addresses............................................................................................................ 6-16<br />

Status and Diagnosis Information.......................................................................................... 6-17<br />

Technical Data....................................................................................................................... 6-17<br />

Interface Assignment............................................................................................................. 6-18<br />

6.7 Connecting the Manual Operator Panel BTC 06........................................................................ 6-19<br />

6.8 Configurations............................................................................................................................. 6-21<br />

MTS-P0*.2-D2-B1-NN-NN-NN-FW ....................................................................................... 6-21<br />

MTS-P0*.2-D2-P1-NN-NN-NN-FW ....................................................................................... 6-22<br />

7 Tips and Tricks 7-1<br />

7.1 <strong>BTV</strong> Replacement......................................................................................................................... 7-1<br />

Hard Disk Image...................................................................................................................... 7-1<br />

Control Parameters (NCM Replacement) ............................................................................... 7-1<br />

CMOS Variables...................................................................................................................... 7-2<br />

PLC Retain Data (PLC Replacement)..................................................................................... 7-2<br />

8 Index 8-1<br />

9 Service & Support 9-1<br />

9.1 Helpdesk....................................................................................................................................... 9-1<br />

9.2 Service-Hotline ............................................................................................................................. 9-1<br />

9.3 Internet.......................................................................................................................................... 9-1<br />

9.4 Vor der Kontaktaufnahme... - Before contacting us... .................................................................. 9-1<br />

9.5 Kundenbetreuungsstellen - Sales & Service Facilities ................................................................. 9-2<br />

DOK-<strong>MTA</strong><strong>200</strong>-<strong>BTV</strong><strong>20.4A</strong>***-PR01-EN-P

<strong>Rexroth</strong> <strong>BTV</strong> <strong>20.4A</strong> Overview 1-1<br />

1 Overview<br />

1.1 System Concept<br />

1.2 Regarding this Documentation<br />

DOK-<strong>MTA</strong><strong>200</strong>-<strong>BTV</strong><strong>20.4A</strong>***-PR01-EN-P<br />

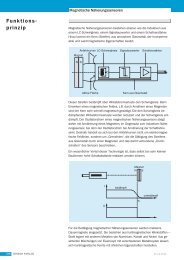

The consistent implementation of PC technology and the use of<br />

international industry standards has made it possible to fully integrate the<br />

control hardware in the operator PC while still ensuring simple and clear<br />

connections to drives and I/O peripherals.<br />

This integral solution guarantees that only defined and tested device<br />

configurations will be provided and supplied.<br />

The defined combination of various hardware components forms the<br />

basis of the <strong>MTA</strong> <strong>200</strong> control system. The operator PC itself as well as<br />

the components that are already installed in the operator PC on delivery<br />

are described in detail in this documentation.<br />

Fig. 1-1: Control architecture<br />

<strong>MTA</strong> Steuerungsarchitektur.jpg

1-2 Overview <strong>Rexroth</strong> <strong>BTV</strong> <strong>20.4A</strong><br />

1.3 Additional Documentation<br />

This includes the following components:<br />

Type Description Chapter<br />

<strong>BTV</strong> <strong>20.4A</strong> Operator PC with integrated control hardware 2<br />

ETXP3-700 PC-CPU 3<br />

ETXP3-400 NC-CPU 4<br />

NCM02 NC module with SERCOS interface 5<br />

NCIO I/O module for fast I/Os 5<br />

MTS-P Integrated PLC 6<br />

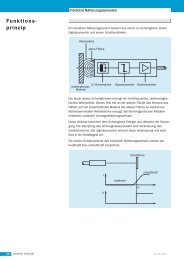

The openness of the control system allows the machine manufacturer to<br />

independently carry out application-specific hardware settings in the PC<br />

part, such as measured values recording, network connections, etc. In<br />

this case, the machine manufacturer must provide supplements to the<br />

hardware documentation.<br />

Fig. 1-2: System architecture<br />

Systemübersicht <strong>MTA</strong>.jpg<br />

DOK-<strong>MTA</strong><strong>200</strong>-<strong>BTV</strong><strong>20.4A</strong>***-PR01-EN-P

<strong>Rexroth</strong> <strong>BTV</strong> <strong>20.4A</strong> Overview 1-3<br />

DOK-<strong>MTA</strong><strong>200</strong>-<strong>BTV</strong><strong>20.4A</strong>***-PR01-EN-P<br />

The <strong>MTA</strong> <strong>200</strong> control system includes additional hardware components<br />

that are described in separate documents:<br />

Type Description Documentation<br />

BTA 20.4 Machine operator<br />

control panel<br />

DOK-SUPPL*-BTA20.4****-PR01-EN-P<br />

BTM 15 Machine user panel DOK-MTC<strong>200</strong>-BTM15******-PR02-EN-P<br />

BTM 16 Machine user panel DOK-MTC<strong>200</strong>-BTM16.1****-FKB1-EN-P<br />

PCK03 Drawer keyboard DOK-SUPPL*-PCK03.3****-PR01-DE-P<br />

BTC 06 Hand-held terminal DOK-SUPPL*-BTC06******-PR03-EN-P<br />

<strong>BTV</strong> 06 Mini control panel DOC-SUPPL*-<strong>BTV</strong>06.1****-PR02-EN-P<br />

RECO12 Switch cabinet I/Os for<br />

Interbus<br />

RMG12 Gateway module for I/O<br />

coupling<br />

DOK-CONTRL-RECO12.2***-PRJ2-EN-P<br />

DOK-CONTRL-RMG12.2****-PR02-EN-P<br />

RMC RECO analog module DOK-CONTRL-RMC12.2****-ANW1-EN-P<br />

SMx Protection type<br />

modules for Interbus<br />

RECO<br />

Inline<br />

RECO<br />

Fieldline<br />

Brief overview<br />

Interbus S system<br />

Profibus DP system<br />

Bus terminal, Interbus<br />

Bus terminal, Profibus<br />

Digital I/O modules<br />

Analog I/O modules<br />

Counter module<br />

Interbus devices<br />

Profibus devices<br />

DOK-CONTRL-SM*12.1****-PRJ2-EN-P<br />

DOK-CONTRL-R-IL*INLINE-KB02-EN-P<br />

DOK-CONTRL-R-IL*IBSSYS-AW02-EN-P<br />

DOK-CONTRL-R-IL*PBSSYS-AW02-EN-P<br />

DOK-CONTRL-R-IL*IBS-BK-FK04-DE-P<br />

DOK-CONTRL-R-IL*PB*-BK-FK02-EN-P<br />

DOK-CONTRL-R-IL*DIO***-FK05-EN-P<br />

DOK-CONTRL-R-IL*AIO***-FK02-EN-P<br />

DOK-CONTRL-R-IL*CNT***-AW02-EN-P<br />

DOK-CONTRL-RF-FLS-IB**-PR01-EN-P<br />

DOK-CONTRL-RF-FLS-PB**-PR01-EN-P<br />

The <strong>MTA</strong> <strong>200</strong> control system is supplemented by the intelligent digital<br />

drives of the Diax 04 and IndraDrive series.

1-4 Overview <strong>Rexroth</strong> <strong>BTV</strong> <strong>20.4A</strong><br />

1.4 Important Directions for Use<br />

Appropriate Use<br />

Introduction<br />

Bosch <strong>Rexroth</strong> products represent state-of-the-art developments and<br />

manufacturing. They are tested prior to delivery to ensure operating safety<br />

and reliability.<br />

The products may only be used in the manner that is defined as<br />

appropriate. If they are used in an inappropriate manner, then situations<br />

can develop that may lead to property damage or injury to personnel.<br />

Note: Bosch <strong>Rexroth</strong>, as manufacturer, is not liable for any damages<br />

resulting from inappropriate use. In such cases, the guarantee<br />

and the right to payment of damages resulting from<br />

inappropriate use are forfeited. The user alone carries all<br />

responsibility of the risks.<br />

Before using Bosch <strong>Rexroth</strong> products, make sure that all the prerequisites<br />

for appropriate use of the products are satisfied:<br />

• Personnel that in any way, shape or form uses our products must first<br />

read and understand the relevant safety instructions and be familiar<br />

with appropriate use.<br />

• If the product takes the form of hardware, then they must remain in<br />

their original state, in other words, no structural changes are permitted.<br />

It is not permitted to decompile software products or alter source<br />

codes.<br />

• Do not mount damaged or faulty products or use them in operation.<br />

• Make sure that the products have been installed in the manner<br />

described in the relevant documentation.<br />

Areas of use and application<br />

For <strong>BTV</strong> <strong>20.4A</strong> Bosch <strong>Rexroth</strong> defines appropriate use for installation into<br />

control panel, into the wall or door of a switch cabinet or directly into<br />

enclosure of machine tool.<br />

It may only be operated under the mounting and installation conditions<br />

specified in this documentation, in the position of use described, and<br />

under the ambient conditions specified (temperature, protection category,<br />

humidity, EMC, and the like).<br />

Note: <strong>BTV</strong> <strong>20.4A</strong> may only be used with the accessories and parts<br />

specified in this document. If a component has not been<br />

specifically named, then it may not be either mounted or<br />

connected. The same applies to cables and lines.<br />

Operation is only permitted in the specified configurations and<br />

combinations of components using the software and firmware<br />

as specified in the relevant function descriptions.<br />

Every <strong>MTA</strong> <strong>200</strong> control system has to be parameterized and programmed<br />

before start-up from qualified application staff.<br />

DOK-<strong>MTA</strong><strong>200</strong>-<strong>BTV</strong><strong>20.4A</strong>***-PR01-EN-P

<strong>Rexroth</strong> <strong>BTV</strong> <strong>20.4A</strong> Overview 1-5<br />

Inappropriate Use<br />

Notes for Electro Static Discharge<br />

DOK-<strong>MTA</strong><strong>200</strong>-<strong>BTV</strong><strong>20.4A</strong>***-PR01-EN-P<br />

Typical applications of <strong>MTA</strong> <strong>200</strong> control system are machine tools for<br />

following processing technologies:<br />

• Milling and grinding crankshafts<br />

• Grinding camshafts<br />

• Cogwheel processing<br />

Using the <strong>BTV</strong> <strong>20.4A</strong> outside of the above-referenced areas of application<br />

or under operating conditions other than described in the document and<br />

the technical data specified is defined as “inappropriate use".<br />

<strong>BTV</strong> <strong>20.4A</strong> may not be used if<br />

• they are subject to operating conditions that do not meet the above<br />

specified ambient conditions. This includes, for example, operation<br />

under water, in the case of extreme temperature fluctuations or<br />

extremely high maximum temperatures or if<br />

• Bosch <strong>Rexroth</strong> has not specifically released them for that intended<br />

purpose. Please note the specifications outlined in the general Safety<br />

Guidelines!<br />

In case of discharging via the controller or printed circuit boards, these<br />

components can be damaged by electrostatic charging of persons and/or<br />

tools. Therefore, please observe the following notes:<br />

CAUTION<br />

Risk of damage to the electronic components<br />

and deterioration of their operating safety by<br />

electrostatic charging!<br />

⇒ Bodies coming into contact with components and<br />

printed circuit boards must be discharged by<br />

grounding. Otherwise, errors in the controller can<br />

occur.<br />

Example for such bodies:<br />

• when soldering, the soldering gun<br />

• your own body (grounding by contact with a conductive, grounded<br />

object)<br />

• parts and tools (when deposited on a conductive surface)<br />

Components exposed to this risk may only be stored in conductive<br />

packaging.

1-6 Overview <strong>Rexroth</strong> <strong>BTV</strong> <strong>20.4A</strong><br />

1.5 Safety Instructions for Electric Drives and Controls<br />

Introduction<br />

Explanations<br />

Read these instructions before the initial startup of the equipment in order<br />

to eliminate the risk of bodily harm or material damage. Follow these<br />

safety instructions at all times.<br />

Do not attempt to install or start up this equipment without first reading all<br />

documentation provided with the product. Read and understand these<br />

safety instructions and all user documentation of the equipment prior to<br />

working with the equipment at any time. If you do not have the user<br />

documentation for your equipment, contact your local Bosch <strong>Rexroth</strong><br />

representative to send this documentation immediately to the person or<br />

persons responsible for the safe operation of this equipment.<br />

If the equipment is resold, rented or transferred or passed on to others,<br />

then these safety instructions must be delivered with the equipment.<br />

WARNING<br />

Improper use of this equipment, failure to follow<br />

the safety instructions in this document or<br />

tampering with the product, including disabling<br />

of safety devices, may result in material<br />

damage, bodily harm, electric shock or even<br />

death!<br />

The safety instructions describe the following degrees of hazard<br />

seriousness in compliance with ANSI Z535. The degree of hazard<br />

seriousness informs about the consequences resulting from noncompliance<br />

with the safety instructions.<br />

Warning symbol with signal<br />

word<br />

DANGER<br />

WARNING<br />

CAUTION<br />

Degree of hazard seriousness according<br />

to ANSI<br />

Death or severe bodily harm will occur.<br />

Death or severe bodily harm may occur.<br />

Bodily harm or material damage may occur.<br />

Fig. 1-3: Hazard classification (according to ANSI Z535)<br />

DOK-<strong>MTA</strong><strong>200</strong>-<strong>BTV</strong><strong>20.4A</strong>***-PR01-EN-P

<strong>Rexroth</strong> <strong>BTV</strong> <strong>20.4A</strong> Overview 1-7<br />

Hazards by Improper Use<br />

DOK-<strong>MTA</strong><strong>200</strong>-<strong>BTV</strong><strong>20.4A</strong>***-PR01-EN-P<br />

DANGER<br />

DANGER<br />

WARNING<br />

WARNING<br />

CAUTION<br />

CAUTION<br />

CAUTION<br />

High voltage and high discharge current!<br />

Danger to life or severe bodily harm by electric<br />

shock!<br />

Dangerous movements! Danger to life, severe<br />

bodily harm or material damage by<br />

unintentional motor movements!<br />

High electrical voltage due to wrong<br />

connections! Danger to life or bodily harm by<br />

electric shock!<br />

Health hazard for persons with heart<br />

pacemakers, metal implants and hearing aids in<br />

proximity to electrical equipment!<br />

Surface of machine housing could be extremely<br />

hot! Danger of injury! Danger of burns!<br />

Risk of injury due to improper handling! Bodily<br />

harm caused by crushing, shearing, cutting and<br />

mechanical shock or incorrect handling of<br />

pressurized systems!<br />

Risk of injury due to incorrect handling of<br />

batteries!

1-8 Overview <strong>Rexroth</strong> <strong>BTV</strong> <strong>20.4A</strong><br />

General Information<br />

• Bosch <strong>Rexroth</strong> AG is not liable for damages resulting from failure to<br />

observe the warnings provided in this documentation.<br />

• Read the operating, maintenance and safety instructions in your<br />

language before starting up the machine. If you find that you cannot<br />

completely understand the documentation for your product, please ask<br />

your supplier to clarify.<br />

• Proper and correct transport, storage, assembly and installation as<br />

well as care in operation and maintenance are prerequisites for<br />

optimal and safe operation of this equipment.<br />

• Only persons who are trained and qualified for the use and operation<br />

of the equipment may work on this equipment or within its proximity.<br />

• The persons are qualified if they have sufficient knowledge of the<br />

assembly, installation and operation of the equipment as well as an<br />

understanding of all warnings and precautionary measures noted in<br />

these instructions.<br />

• Furthermore, they must be trained, instructed and qualified to switch<br />

electrical circuits and equipment on and off in accordance with<br />

technical safety regulations, to ground them and to mark them<br />

according to the requirements of safe work practices. They must have<br />

adequate safety equipment and be trained in first aid.<br />

• Only use spare parts and accessories approved by the manufacturer.<br />

• Follow all safety regulations and requirements for the specific<br />

application as practiced in the country of use.<br />

• The equipment is designed for installation in industrial machinery.<br />

• The ambient conditions given in the product documentation must be<br />

observed.<br />

• Use only safety features and applications that are clearly and explicitly<br />

approved in the Project Planning Manual.<br />

For example, the following areas of use are not permitted: construction<br />

cranes, elevators used for people or freight, devices and vehicles to<br />

transport people, medical applications, refinery plants, transport of<br />

hazardous goods, nuclear applications, applications sensitive to high<br />

frequency, mining, food processing, control of protection equipment<br />

(also in a machine).<br />

• The information given in the documentation of the product with regard<br />

to the use of the delivered components contains only examples of<br />

applications and suggestions.<br />

The machine and installation manufacturer must<br />

• make sure that the delivered components are suited for his<br />

individual application and check the information given in this<br />

documentation with regard to the use of the components,<br />

• make sure that his application complies with the applicable safety<br />

regulations and standards and carry out the required measures,<br />

modifications and complements.<br />

• Startup of the delivered components is only permitted once it is sure<br />

that the machine or installation in which they are installed complies<br />

with the national regulations, safety specifications and standards of the<br />

application.<br />

DOK-<strong>MTA</strong><strong>200</strong>-<strong>BTV</strong><strong>20.4A</strong>***-PR01-EN-P

<strong>Rexroth</strong> <strong>BTV</strong> <strong>20.4A</strong> Overview 1-9<br />

DOK-<strong>MTA</strong><strong>200</strong>-<strong>BTV</strong><strong>20.4A</strong>***-PR01-EN-P<br />

• Operation is only permitted if the national EMC regulations for the<br />

application are met.<br />

The instructions for installation in accordance with EMC requirements<br />

can be found in the documentation "EMC in Drive and Control<br />

Systems".<br />

The machine or installation manufacturer is responsible for<br />

compliance with the limiting values as prescribed in the national<br />

regulations.<br />

• Technical data, connections and operational conditions are specified in<br />

the product documentation and must be followed at all times.<br />

Protection Against Contact with Electrical Parts<br />

Note: This section refers to equipment and drive components with<br />

voltages above 50 Volts.<br />

Touching live parts with voltages of 50 Volts and more with bare hands or<br />

conductive tools or touching ungrounded housings can be dangerous and<br />

cause electric shock. In order to operate electrical equipment, certain<br />

parts must unavoidably have dangerous voltages applied to them.

1-10 Overview <strong>Rexroth</strong> <strong>BTV</strong> <strong>20.4A</strong><br />

DANGER<br />

High electrical voltage! Danger to life, severe<br />

bodily harm by electric shock!<br />

⇒ Only those trained and qualified to work with or on<br />

electrical equipment are permitted to operate, maintain<br />

or repair this equipment.<br />

⇒ Follow general construction and safety regulations<br />

when working on high voltage installations.<br />

⇒ Before switching on power the ground wire must be<br />

permanently connected to all electrical units according<br />

to the connection diagram.<br />

⇒ Do not operate electrical equipment at any time, even<br />

for brief measurements or tests, if the ground wire is<br />

not permanently connected to the points of the<br />

components provided for this purpose.<br />

⇒ Before working with electrical parts with voltage higher<br />

than 50 V, the equipment must be disconnected from<br />

the mains voltage or power supply. Make sure the<br />

equipment cannot be switched on again unintended.<br />

⇒ The following should be observed with electrical drive<br />

and filter components:<br />

⇒ Wait five (5) minutes after switching off power to allow<br />

capacitors to discharge before beginning to work.<br />

Measure the voltage on the capacitors before<br />

beginning to work to make sure that the equipment is<br />

safe to touch.<br />

⇒ Never touch the electrical connection points of a<br />

component while power is turned on.<br />

⇒ Install the covers and guards provided with the<br />

equipment properly before switching the equipment on.<br />

Prevent contact with live parts at any time.<br />

⇒ A residual-current-operated protective device (RCD)<br />

must not be used on electric drives! Indirect contact<br />

must be prevented by other means, for example, by an<br />

overcurrent protective device.<br />

⇒ Electrical components with exposed live parts and<br />

uncovered high voltage terminals must be installed in a<br />

protective housing, for example, in a control cabinet.<br />

DOK-<strong>MTA</strong><strong>200</strong>-<strong>BTV</strong><strong>20.4A</strong>***-PR01-EN-P

<strong>Rexroth</strong> <strong>BTV</strong> <strong>20.4A</strong> Overview 1-11<br />

DOK-<strong>MTA</strong><strong>200</strong>-<strong>BTV</strong><strong>20.4A</strong>***-PR01-EN-P<br />

To be observed with electrical drive and filter components:<br />

DANGER<br />

High electrical voltage on the housing!<br />

High leakage current! Danger to life, danger of<br />

injury by electric shock!<br />

⇒ Connect the electrical equipment, the housings of all<br />

electrical units and motors permanently with the<br />

safety conductor at the ground points before power is<br />

switched on. Look at the connection diagram. This is<br />

even necessary for brief tests.<br />

⇒ Connect the safety conductor of the electrical<br />

equipment always permanently and firmly to the<br />

supply mains. Leakage current exceeds 3.5 mA in<br />

normal operation.<br />

⇒ Use a copper conductor with at least 10 mm² cross<br />

section over its entire course for this safety conductor<br />

connection!<br />

⇒ Prior to startups, even for brief tests, always connect<br />

the protective conductor or connect with ground wire.<br />

Otherwise, high voltages can occur on the housing<br />

that lead to electric shock.<br />

Protection Against Electric Shock by Protective Low Voltage (PELV)<br />

All connections and terminals with voltages between 0 and 50 Volts on<br />

<strong>Rexroth</strong> products are protective low voltages designed in accordance with<br />

international standards on electrical safety.<br />

WARNING<br />

Protection Against Dangerous Movements<br />

High electrical voltage due to wrong<br />

connections! Danger to life, bodily harm by<br />

electric shock!<br />

⇒ Only connect equipment, electrical components and<br />

cables of the protective low voltage type (PELV =<br />

Protective Extra Low Voltage) to all terminals and<br />

clamps with voltages of 0 to 50 Volts.<br />

⇒ Only electrical circuits may be connected which are<br />

safely isolated against high voltage circuits. Safe<br />

isolation is achieved, for example, with an isolating<br />

transformer, an opto-electronic coupler or when<br />

battery-operated.<br />

Dangerous movements can be caused by faulty control of the connected<br />

motors. Some common examples are:<br />

• improper or wrong wiring of cable connections<br />

• incorrect operation of the equipment components<br />

• wrong input of parameters before operation<br />

• malfunction of sensors, encoders and monitoring devices<br />

• defective components<br />

• software or firmware errors

1-12 Overview <strong>Rexroth</strong> <strong>BTV</strong> <strong>20.4A</strong><br />

Dangerous movements can occur immediately after equipment is<br />

switched on or even after an unspecified time of trouble-free operation.<br />

The monitoring in the drive components will normally be sufficient to avoid<br />

faulty operation in the connected drives. Regarding personal safety,<br />

especially the danger of bodily injury and material damage, this alone<br />

cannot be relied upon to ensure complete safety. Until the integrated<br />

monitoring functions become effective, it must be assumed in any case<br />

that faulty drive movements will occur. The extent of faulty drive<br />

movements depends upon the type of control and the state of operation.<br />

DOK-<strong>MTA</strong><strong>200</strong>-<strong>BTV</strong><strong>20.4A</strong>***-PR01-EN-P

<strong>Rexroth</strong> <strong>BTV</strong> <strong>20.4A</strong> Overview 1-13<br />

DOK-<strong>MTA</strong><strong>200</strong>-<strong>BTV</strong><strong>20.4A</strong>***-PR01-EN-P<br />

DANGER<br />

Dangerous movements! Danger to life, risk of<br />

injury, severe bodily harm or material damage!<br />

⇒ Ensure personal safety by means of qualified and<br />

tested higher-level monitoring devices or measures<br />

integrated in the installation. Unintended machine<br />

motion is possible if monitoring devices are disabled,<br />

bypassed or not activated.<br />

⇒ Pay attention to unintended machine motion or other<br />

malfunction in any mode of operation.<br />

⇒ Keep free and clear of the machine’s range of motion<br />

and moving parts. Possible measures to prevent<br />

people from accidentally entering the machine’s<br />

range of motion:<br />

- use safety fences<br />

- use safety guards<br />

- use protective coverings<br />

- install light curtains or light barriers<br />

⇒ Fences and coverings must be strong enough to<br />

resist maximum possible momentum, especially if<br />

there is a possibility of loose parts flying off.<br />

⇒ Mount the emergency stop switch in the immediate<br />

reach of the operator. Verify that the emergency stop<br />

works before startup. Don’t operate the machine if<br />

the emergency stop is not working.<br />

⇒ Isolate the drive power connection by means of an<br />

emergency stop circuit or use a starting lockout to<br />

prevent unintentional start.<br />

⇒ Make sure that the drives are brought to a safe<br />

standstill before accessing or entering the danger<br />

zone. Safe standstill can be achieved by switching off<br />

the power supply contactor or by safe mechanical<br />

locking of moving parts.<br />

⇒ Secure vertical axes against falling or dropping after<br />

switching off the motor power by, for example:<br />

- mechanically securing the vertical axes<br />

- adding an external braking/ arrester/ clamping<br />

mechanism<br />

- ensuring sufficient equilibration of the vertical axes<br />

The standard equipment motor brake or an external<br />

brake controlled directly by the drive controller are<br />

not sufficient to guarantee personal safety!

1-14 Overview <strong>Rexroth</strong> <strong>BTV</strong> <strong>20.4A</strong><br />

⇒ Disconnect electrical power to the equipment using a<br />

master switch and secure the switch against<br />

reconnection for:<br />

- maintenance and repair work<br />

- cleaning of equipment<br />

- long periods of discontinued equipment use<br />

⇒ Prevent the operation of high-frequency, remote<br />

control and radio equipment near electronics circuits<br />

and supply leads. If the use of such equipment<br />

cannot be avoided, verify the system and the<br />

installation for possible malfunctions in all possible<br />

positions of normal use before initial startup. If<br />

necessary, perform a special electromagnetic<br />

compatibility (EMC) test on the installation.<br />

Protection Against Magnetic and Electromagnetic Fields During<br />

Operation and Mounting<br />

Magnetic and electromagnetic fields generated near current-carrying<br />

conductors and permanent magnets in motors represent a serious health<br />

hazard to persons with heart pacemakers, metal implants and hearing<br />

aids.<br />

WARNING<br />

Health hazard for persons with heart<br />

pacemakers, metal implants and hearing aids in<br />

proximity to electrical equipment!<br />

⇒ Persons with heart pacemakers, hearing aids and<br />

metal implants are not permitted to enter the<br />

following areas:<br />

- Areas in which electrical equipment and parts are<br />

mounted, being operated or started up.<br />

- Areas in which parts of motors with permanent<br />

magnets are being stored, operated, repaired or<br />

mounted.<br />

⇒ If it is necessary for a person with a heart pacemaker<br />

to enter such an area, then a doctor must be<br />

consulted prior to doing so. Heart pacemakers that<br />

are already implanted or will be implanted in the<br />

future, have a considerable variation in their electrical<br />

noise immunity. Therefore there are no rules with<br />

general validity.<br />

⇒ Persons with hearing aids, metal implants or metal<br />

pieces must consult a doctor before they enter the<br />

areas described above. Otherwise, health hazards<br />

will occur.<br />

DOK-<strong>MTA</strong><strong>200</strong>-<strong>BTV</strong><strong>20.4A</strong>***-PR01-EN-P

<strong>Rexroth</strong> <strong>BTV</strong> <strong>20.4A</strong> Overview 1-15<br />

Protection Against Contact with Hot Parts<br />

DOK-<strong>MTA</strong><strong>200</strong>-<strong>BTV</strong><strong>20.4A</strong>***-PR01-EN-P<br />

CAUTION<br />

Protection During Handling and Mounting<br />

Battery Safety<br />

Housing surfaces could be extremely hot!<br />

Danger of injury! Danger of burns!<br />

⇒ Do not touch housing surfaces near sources of heat!<br />

Danger of burns!<br />

⇒ After switching the equipment off, wait at least ten<br />

(10) minutes to allow it to cool down before touching<br />

it.<br />

⇒ Do not touch hot parts of the equipment, such as<br />

housings with integrated heat sinks and resistors.<br />

Danger of burns!<br />

Under certain conditions, incorrect handling and mounting of parts and<br />

components may cause injuries.<br />

CAUTION<br />

Risk of injury by incorrect handling! Bodily<br />

harm caused by crushing, shearing, cutting and<br />

mechanical shock!<br />

⇒ Observe general installation and safety instructions<br />

with regard to handling and mounting.<br />

⇒ Use appropriate mounting and transport equipment.<br />

⇒ Take precautions to avoid pinching and crushing.<br />

⇒ Use only appropriate tools. If specified by the product<br />

documentation, special tools must be used.<br />

⇒ Use lifting devices and tools correctly and safely.<br />

⇒ For safe protection wear appropriate protective<br />

clothing, e.g. safety glasses, safety shoes and safety<br />

gloves.<br />

⇒ Never stand under suspended loads.<br />

⇒ Clean up liquids from the floor immediately to prevent<br />

slipping.<br />

Batteries contain reactive chemicals in a solid housing. Inappropriate<br />

handling may result in injuries or material damage.<br />

CAUTION<br />

Risk of injury by incorrect handling!<br />

⇒ Do not attempt to reactivate discharged batteries by<br />

heating or other methods (danger of explosion and<br />

cauterization).<br />

⇒ Never charge non-chargeable batteries (danger of<br />

leakage and explosion).<br />

⇒ Never throw batteries into a fire.<br />

⇒ Do not dismantle batteries.<br />

⇒ Do not damage electrical components installed in the<br />

equipment.

1-16 Overview <strong>Rexroth</strong> <strong>BTV</strong> <strong>20.4A</strong><br />

Protection Against Pressurized Systems<br />

Note: Be aware of environmental protection and disposal! The<br />

batteries contained in the product should be considered as<br />

hazardous material for land, air and sea transport in the sense<br />

of the legal requirements (danger of explosion). Dispose<br />

batteries separately from other waste. Observe the legal<br />

requirements in the country of installation.<br />

Certain motors and drive controllers, corresponding to the information in<br />

the respective Project Planning Manual, must be provided with<br />

pressurized media, such as compressed air, hydraulic oil, cooling fluid<br />

and cooling lubricant supplied by external systems. Incorrect handling of<br />

the supply and connections of pressurized systems can lead to injuries or<br />

accidents. In these cases, improper handling of external supply systems,<br />

supply lines or connections can cause injuries or material damage.<br />

CAUTION<br />

Danger of injury by incorrect handling of<br />

pressurized systems !<br />

⇒ Do not attempt to disassemble, to open or to cut a<br />

pressurized system (danger of explosion).<br />

⇒ Observe the operation instructions of the respective<br />

manufacturer.<br />

⇒ Before disassembling pressurized systems, release<br />

pressure and drain off the fluid or gas.<br />

⇒ Use suitable protective clothing (for example safety<br />

glasses, safety shoes and safety gloves)<br />

⇒ Remove any fluid that has leaked out onto the floor<br />

immediately.<br />

Note: Environmental protection and disposal! The media used in the<br />

operation of the pressurized system equipment may not be<br />

environmentally compatible. Media that are damaging the<br />

environment must be disposed separately from normal waste.<br />

Observe the legal requirements in the country of installation.<br />

DOK-<strong>MTA</strong><strong>200</strong>-<strong>BTV</strong><strong>20.4A</strong>***-PR01-EN-P

<strong>Rexroth</strong> <strong>BTV</strong> <strong>20.4A</strong> Machine Operator Terminal <strong>BTV</strong> <strong>20.4A</strong> 2-1<br />

2 Machine Operator Terminal <strong>BTV</strong> <strong>20.4A</strong><br />

2.1 Brief Description<br />

L 1-8 machine<br />

function keys<br />

Line in strips<br />

for Key lable<br />

HALT<br />

NACH<br />

TAKTENDE<br />

OPERATOR PROG<br />

MASCHINE<br />

STOP<br />

EINHEIT<br />

STOP<br />

DOK-<strong>MTA</strong><strong>200</strong>-<strong>BTV</strong><strong>20.4A</strong>***-PR01-EN-P<br />

L1<br />

L2<br />

L3<br />

L4<br />

L5<br />

L6<br />

L7<br />

L8<br />

EINHEIT<br />

STOP<br />

The <strong>BTV</strong> <strong>20.4A</strong> is a PC-based machine operator terminal that also<br />

contains all the hardware of the <strong>MTA</strong> <strong>200</strong> control system. Depending on<br />

the configuration, slots are available for customer-specific extensions in<br />

the PC bus.<br />

Note: This chapter describes the <strong>BTV</strong> <strong>20.4A</strong> in its version for the<br />

<strong>MTA</strong> <strong>200</strong> control system. The <strong>BTV</strong> 20 can also be procured as<br />

a pure industrial PC, as a PC with integrated PLC, or as a PC<br />

with integrated MTC<strong>200</strong> control system. These versions are<br />

described in the general <strong>BTV</strong> 20 documentation<br />

DOK-MTC<strong>200</strong>-<strong>BTV</strong>20.3****-PR03-EN-P.<br />

The figure below shows the structure of the <strong>BTV</strong> 20.4 front plate:<br />

F2 F3<br />

OP2<br />

ZUM<br />

WERKZEUG-<br />

WECHSEL<br />

F4 F5 F6 F7 F8 F9<br />

OP3 OP4 OP5 OP6 OP7 OP8 OP9<br />

SONDER-<br />

FUKTIONEN<br />

FEHLER<br />

LÖSCHEN<br />

SYSTEM<strong>200</strong><br />

Fig. 2-1: <strong>BTV</strong> 20.4 front plate<br />

R1<br />

R2<br />

R3<br />

R4<br />

R5<br />

R6<br />

R7<br />

R8<br />

TEMP HD POWER<br />

7 8 9 N + -<br />

< F1 F1 F10 F10< > - +<br />

4 5<br />

6<br />

. .<br />

.<br />

PROG<br />

SFT<br />

PROG<br />

- SHIFT<br />

,<br />

1<br />

2<br />

3<br />

,<br />

,<br />

NEXT INFO TAB INS DEL<br />

NEXT INFO TAB INS DEL<br />

0<br />

CTRL ALT<br />

SP SP<br />

CTRL ALT<br />

ESC<br />

OK<br />

Machine<br />

control keys<br />

R 1-8 machine<br />

function keys<br />

3.5-in floppy disk<br />

drive / Smart card<br />

Connector for<br />

ext. keyboard + mouse<br />

Status indicators<br />

POWER<br />

HD<br />

TEMP<br />

=Power supply:<br />

ON<br />

= Hard disk access<br />

= Overtemperature<br />

indicator<br />

Front.FH7<br />

The front plate consists of a 4 mm-thick aluminum plate with beveled<br />

edges. It is coated with a chemically resistant polyester film with an<br />

imprint that covers the entire front plate. The integrated 10.4" TFT color<br />

display provides for excellent visualization of the data. A 3.5" disk drive, a<br />

reset button and a connection for an external keyboard or mouse are<br />

located behind the flap for floppy disks. Three LEDs indicate the operating<br />

status of the <strong>BTV</strong> 20.4. A key-operated switch locks safety functions.

2-2 Machine Operator Terminal <strong>BTV</strong> <strong>20.4A</strong> <strong>Rexroth</strong> <strong>BTV</strong> <strong>20.4A</strong><br />

Standard Configuration of the <strong>BTV</strong> 20.4<br />

Additional <strong>BTV</strong> <strong>20.4A</strong> Modules<br />

Furthermore, the <strong>BTV</strong> 20.4 is equipped with an extensive applicationoriented<br />

function keyboard with the following keys:<br />

• Machine function keys<br />

• Function and operation keys<br />

• PLC function keys with intermediate stages<br />

• Keypad<br />

For further information regarding the functioning and assignment of the<br />

individual keys as well as the front plate elements discussed above, see<br />

the description of the front plate in chapter 4.<br />

• Pentium SLOT CPU, min. 700 MHz, with integrated graphics<br />

controller, 4 MB screen memory and Ethernet connection<br />

• Either 128 or 256 MB RAM<br />

• At least 3 GB hard disk<br />

• 3.5" floppy disk drive<br />

• 10.4" TFT color display<br />

• 115 - 230 V AC power pack<br />

In the model functioning as an <strong>MTA</strong> <strong>200</strong> control system, the <strong>BTV</strong> <strong>20.4A</strong> is<br />

equipped with the following additional modules:<br />

• NC CPU Pentium Slot CPU with 400 MHz<br />

• NCM NC module with one SERCOS interface<br />

• NCZ module with one or two additional SERCOS interfaces<br />

• PLC module with INTERBUS-S or Profibus master connection<br />

• NIO module for parallel connection of fast I/Os<br />

All currently existing configurations can be found in the configuration type<br />

key (see page 2-35).<br />

All the listed modules are described in detail in the following chapters.<br />

DOK-<strong>MTA</strong><strong>200</strong>-<strong>BTV</strong><strong>20.4A</strong>***-PR01-EN-P

<strong>Rexroth</strong> <strong>BTV</strong> <strong>20.4A</strong> Machine Operator Terminal <strong>BTV</strong> <strong>20.4A</strong> 2-3<br />

Firmware and Software Configurations<br />

DOK-<strong>MTA</strong><strong>200</strong>-<strong>BTV</strong><strong>20.4A</strong>***-PR01-EN-P<br />

Operating System<br />

Due to licensing reasons, the <strong>BTV</strong> 20.4 is delivered only with a<br />

preinstalled operating system.<br />

The following firmware configurations are available for the <strong>BTV</strong> <strong>20.4A</strong>:<br />

Firmware type Description<br />

FWA-<strong>BTV</strong>*44-WNT-04VRS-DE-OEM WindowsNT 4.0 German<br />

FWA-<strong>BTV</strong>*44-WNT-04VRS-EN-OEM WindowsNT 4.0 English<br />

FWA-<strong>BTV</strong>*44-WNT-05VRS-DE-OEM Windows<strong>200</strong>0 German<br />

FWA-<strong>BTV</strong>*44-WNT-05VRS-EN-OEM Windows<strong>200</strong>0 English<br />

Fig. 2-2: Firmware configurations for <strong>MTA</strong> <strong>200</strong><br />

The SWA, SWL, SWS and/or SWP ordered together with the <strong>BTV</strong> <strong>20.4A</strong><br />

are installed on the <strong>BTV</strong> prior to delivery.<br />

Bosch <strong>Rexroth</strong> does not pre-install any software requiring export<br />

authorization; the final customer has to install this type of software<br />

subsequently when commissioning the <strong>BTV</strong> 20.

2-4 Machine Operator Terminal <strong>BTV</strong> <strong>20.4A</strong> <strong>Rexroth</strong> <strong>BTV</strong> <strong>20.4A</strong><br />

2.2 Front Plate, Keyboard<br />

Floppy Disk Flap, Reset Button<br />

Under the floppy disk flap, there is a reset button, which can be reached<br />

using a thin object (pen, etc.), as well as the connection for an external<br />

keyboard. This connection can be used as a service interface if the<br />

PCK03 drawer keyboard is not available.<br />

Note: When the reset button is pressed, all open applications are<br />

terminated without saving and the computer is rebooted.<br />

CAUTION<br />

In the <strong>MTA</strong> <strong>200</strong>, the reset button affects only the PC part<br />

of the control. The NC part is initially unaffected and<br />

continues to run. When booting the PC part, however,<br />

the communication task to the NC will get stuck - now the<br />

<strong>BTV</strong> must be restarted.<br />

⇒ For that reason, it is recommended that the reset<br />

button not be used with the <strong>MTA</strong>.<br />

STEM<strong>200</strong><br />

Fig. 2-3: Position of the reset button<br />

R1<br />

R2<br />

R3<br />

R4<br />

R5<br />

R6<br />

R7<br />

R8<br />

TEMP HD POWER<br />

Reset button<br />

Floppyklappe.FH7<br />

Note: When you use the disk drive, keep the floppy disk flap open.<br />

When the flap is closed, the diskette may be ejected, leading<br />

to write and read errors.<br />

DOK-<strong>MTA</strong><strong>200</strong>-<strong>BTV</strong><strong>20.4A</strong>***-PR01-EN-P

<strong>Rexroth</strong> <strong>BTV</strong> <strong>20.4A</strong> Machine Operator Terminal <strong>BTV</strong> <strong>20.4A</strong> 2-5<br />

Operating Display<br />

Overview of Keys<br />

L1<br />

M9<br />

L2<br />

M10<br />

L3<br />

M11<br />

L4<br />

M12<br />

L5<br />

M13<br />

L6<br />

M14<br />

L7<br />

M15<br />

L8<br />

M16<br />

OPERATOR PROG<br />

F2 F3<br />

OP2<br />

Indramat<br />

F2 F3<br />

OP2<br />

DOK-<strong>MTA</strong><strong>200</strong>-<strong>BTV</strong><strong>20.4A</strong>***-PR01-EN-P<br />

Under the floppy disk flap, there are 3 LEDs with the following<br />

explanations:<br />

Temp Temperature monitoring<br />

Power Lights up when the <strong>BTV</strong> 20 is supplied with voltage and is<br />

switched on<br />

HDD Lights up during disk access<br />

R8<br />

7<br />

<<br />

Fig. 2-4: Operating displays<br />

F4 F5 F6 F7 F8 F9<br />

OP3 OP4 OP5 OP6 OP7 OP8 OP9<br />

R1<br />

M1<br />

R2<br />

M2<br />

R3<br />

M3<br />

R4<br />

M4<br />

R5<br />

M5<br />

R6<br />

M6<br />

R7<br />

M7<br />

R8<br />

M8<br />

TEMP<br />

TEMP HD POWER<br />

8<br />

F1<br />

TEMP HD POWER<br />

9<br />

F10<br />

SYSTEM<strong>200</strong> <strong>BTV</strong>20<br />

7 8 9 N +<br />

7<br />

<<br />

8 9 N +<br />

<<br />

F1 F10 -<br />

F1 F10 > -<br />

4 5 6 .<br />

4 5 6 .<br />

SFT<br />

PROG<br />

-<br />

,<br />

1 2 3 ,<br />

DEL<br />

NEXT INFO TAB INS INS<br />

0<br />

SP SP<br />

HD POWER<br />

CTRL ALT<br />

ESC<br />

OK<br />

F4 F5 F6 F7 F8 F9<br />

OP3 OP4 OP5 OP6 OP7 OP8 OP9<br />

Fig. 2-5: Position of OP and F keys<br />

N<br />

<<br />

<<br />

+ -<br />

ESC<br />

Key pad<br />

7 8 9 N +<br />

< F1 F10 -<br />

4<br />

PROG<br />

1<br />

NEXT<br />

5<br />

2<br />

INFO<br />

0<br />

SP<br />

6<br />

3<br />

TAB<br />

.<br />

,<br />

-<br />

INS<br />

<<br />

CTRL ALT<br />

OK<br />

Betriebsanz.FH7<br />

SFT<br />

DEL<br />

Function keys<br />

Operation keys<br />

OP_Tast1.FH7<br />

The second function of keys with dual assignments can be triggered by<br />

pressing the Shift key at the same time.

2-6 Machine Operator Terminal <strong>BTV</strong> <strong>20.4A</strong> <strong>Rexroth</strong> <strong>BTV</strong> <strong>20.4A</strong><br />

Note: The OP key row can also be individually labeled with a slide-in<br />

strip (see page 2-9).<br />

Explanation and Replication of Keys<br />

The <strong>BTV</strong> 20 keys can be replicated on a PC keyboard using the following<br />

key combinations:<br />

Key on <strong>BTV</strong> 20.3 Corresponding key on standard<br />

keyboard<br />

OP2<br />

through<br />

OP9<br />

PROG<br />

NEXT<br />

INFO<br />

Maximize in cursor center<br />

Menu<br />

Change windows<br />

Grasp window<br />

CTRL + SHIFT + ALT + F2<br />

CTRL + SHIFT + ALT + F9<br />

CTRL + SHIFT + ALT + Q<br />

CTRL + SHIFT + ALT + N<br />

ALT<br />

Fig. 2-6: Key combinations for <strong>BTV</strong> 20 keys<br />

CTRL + SHIFT + ALT + I<br />

CTRL + SHIFT + ALT + M<br />

CTRL + F6<br />

CTRL + F7<br />

DOK-<strong>MTA</strong><strong>200</strong>-<strong>BTV</strong><strong>20.4A</strong>***-PR01-EN-P

<strong>Rexroth</strong> <strong>BTV</strong> <strong>20.4A</strong> Machine Operator Terminal <strong>BTV</strong> <strong>20.4A</strong> 2-7<br />

Machine and PLC Function Keys<br />

Machine function keys<br />

on the left<br />

L1<br />

L2<br />

L3<br />

L4<br />

L5<br />

L6<br />

L7<br />

L8<br />

OPERATOR PROG<br />

%Q*.1.6<br />

%I*.1.6<br />

%Q*.1.7<br />

%I*.1.7<br />

DOK-<strong>MTA</strong><strong>200</strong>-<strong>BTV</strong><strong>20.4A</strong>***-PR01-EN-P<br />

L1<br />

M9<br />

L2<br />

M10<br />

L3<br />

M11<br />

L4<br />

M12<br />

L5<br />

M13<br />

L6<br />

M14<br />

L7<br />

M15<br />

L8<br />

M16<br />

OPERATOR PROG<br />

Indramat<br />

%I*.0.0<br />

%Q*.0.0<br />

%I*.0.7<br />

%Q*.0.7<br />

F2 F3<br />

OP2<br />

F4 F5 F6 F7 F8 F9<br />

OP3 OP4 OP5 OP6 OP7 OP8 OP9<br />

%I*.0.1<br />

%Q*.0.1<br />

%I*.1.0<br />

%Q*.1.0<br />

SYSTEM<strong>200</strong> <strong>BTV</strong>20<br />

R1<br />

M1<br />

R2<br />

M2<br />

R3<br />

M3<br />

R4<br />

M4<br />

R5<br />

M5<br />

R6<br />

M6<br />

R7<br />

M7<br />

R8<br />

M8<br />

TEMP<br />

TEMP HD POWER<br />

7 8 9 N +<br />

7<br />

<<br />

8 9 N +<br />

<<br />

F1 F10 -<br />

F1 F10 > -<br />

4 5 6 .<br />

4 5 6 .<br />

SFT SFT<br />

PROG<br />

-<br />

,<br />

1 2<br />

3 ,<br />

DEL<br />

NEXT INFO TAB INS INS<br />

0<br />

SP SP<br />

HD POWER<br />

CTRL ALT<br />

ESC<br />

OK<br />

PLC function keys<br />

(Addressing)<br />

%I*.0.2<br />

%Q*.0.2<br />

%I*.1.1<br />

%Q*.1.1<br />

%I*.0.3<br />

%Q*.0.3<br />

%I*.1.2<br />

%Q*.1.2<br />

%I*.0.4<br />

%Q*.0.4<br />

%I*.1.3<br />

%Q*.1.3<br />

<<br />

Machine function keys<br />

on the right<br />

%I*.0.5<br />

%Q*.0.5<br />

%I*.1.4<br />

%Q*.1.4<br />

Fig. 2-7: Position of machine and PLC function keys<br />

Machine Function Keys<br />

R1<br />

R2<br />

R3<br />

R4<br />

R5<br />

R6<br />

R7<br />

R8<br />

%I*.0.6<br />

%Q*.0.6<br />

%I*.1.5<br />

%Q*.1.5<br />

S1-7<br />

S8-14<br />

M_plc_tasten.FH7<br />

The machine function keys are implemented in the PLC as direct, hardwired<br />

inputs which are triggered with an absolute address. These keys<br />

are used to start projected PLC or CNC movements.<br />

PLC Function Keys<br />

Furthermore, the <strong>BTV</strong> 20 has LEDs that can be labeled using slide-in<br />

strips. Together with the key-operated switch, these keys are connected<br />

to the PLC; they replace the standard switching elements for fixed PLC<br />

functions such as ‘Basic setting’ or ‘Stop after end of cycle’, etc.

2-8 Machine Operator Terminal <strong>BTV</strong> <strong>20.4A</strong> <strong>Rexroth</strong> <strong>BTV</strong> <strong>20.4A</strong><br />

Addressing via PLC<br />

Alternatives with address<br />

constants<br />

Machine Function Keys<br />

In <strong>BTV</strong>s with an integrated PLC, the machine function keys are connected<br />

directly to the PLC; as a result, they can be addressed directly via the<br />

PLC program.<br />

Machine function keys Address<br />

L1 %I0.1480.0<br />

L2 %I0.1480.1<br />

L3 %I0.1480.2<br />

L4 %I0.1480.3<br />

L5 %I0.1480.4<br />

L6 %I0.1480.5<br />

L7 %I0.1480.6<br />

L8 %I0.1480.7<br />

R1 %I0.1481.0<br />

R2 %I0.1481.1<br />

R3 %I0.1481.2<br />

R4 %I0.1481.3<br />

R5 %I0.1481.4<br />

R6 %I0.1481.5<br />

R7 %I0.1481.6<br />

R8 %I0.1481.7<br />

Fig. 2-8: Addressing of machine function keys<br />

Address constants can be used instead of direct addressing for Bosch<br />

<strong>Rexroth</strong> firmware data types.<br />

Machine function keys, left/right<br />

PLC program identifier Address constants Data type<br />

MFT_L A#iMFK_L MFK_L<br />

MFT_R A#iMFK_R MFK_R<br />

Fig. 2-9: Addressing with address constants<br />

Data type MFK_L contains the elements L1, L2,..., L8 of type BOOL.<br />

Data type MFK_R contains the elements R1, R2,..., R8 of type BOOL.<br />

PLC program example: MFT_L.L1<br />

DOK-<strong>MTA</strong><strong>200</strong>-<strong>BTV</strong><strong>20.4A</strong>***-PR01-EN-P

<strong>Rexroth</strong> <strong>BTV</strong> <strong>20.4A</strong> Machine Operator Terminal <strong>BTV</strong> <strong>20.4A</strong> 2-9<br />

Replacing the Slide-in Strips<br />

DOK-<strong>MTA</strong><strong>200</strong>-<strong>BTV</strong><strong>20.4A</strong>***-PR01-EN-P<br />

PLC Function Keys<br />

PLC function key Address key Address LED<br />

S1 (see illustration) %I*.0.0 %Q*.0.0<br />

S2 %I*.0.1 %Q*.0.1<br />

S3 %I*.0.2 %Q*.0.2<br />

S4 %I*.0.3 %Q*.0.3<br />

S5 %I*.0.4 %Q*.0.4<br />

S6 %I*.0.5 %Q*.0.5<br />

S7 %I*.0.6 %Q*.0.6<br />

S8 %I*.0.7 %Q*.0.7<br />

S9 %I*.1.0 %Q*.1.0<br />

S10 %I*.1.1 %Q*.1.1<br />

S11 %I*.1.2 %Q*.1.2<br />

S12 %I*.1.3 %Q*.1.3<br />

S13 %I*.1.4 %Q*.1.4<br />

S14 %I*.1.5 %Q*.1.5<br />

Key-operated switch,<br />

left (Operator)<br />

Key-operated switch,<br />

right (Prog)<br />

Fig. 2-10: Addressing PLC function keys<br />

%I*.1.6 %Q*.1.6<br />

%I*.1.7 %Q*.1.7<br />

Two free logical addresses within the PLC configuration are to be<br />

assigned for inputs and outputs.<br />

The 14 PLC function keys on the front of the <strong>BTV</strong> 20 can be labeled using<br />

slide-in strips. The row of keys above the PLC function keys (OP2 - OP9)<br />

are also freely configurable using slide-in strips.<br />